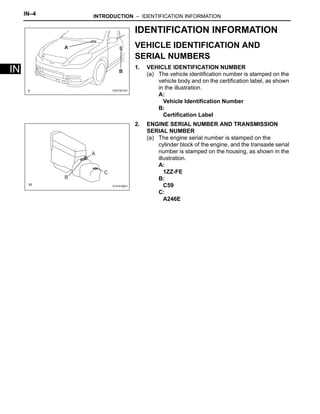

Comprehensive Guide to Repairing the 2009 Matrix

This section provides an extensive overview aimed at enhancing the understanding and upkeep of your vehicle. By delving into various aspects of automotive care, readers will gain valuable insights into ensuring optimal performance and longevity. The focus here is on practical advice and techniques that can empower vehicle owners to tackle common challenges effectively.

Maintenance plays a crucial role in sustaining the functionality and safety of any automobile. From routine checks to more intricate procedures, the knowledge shared in this guide equips enthusiasts and everyday drivers alike with the tools needed for proactive management. Familiarizing oneself with essential components and their functions can lead to informed decisions, ultimately saving time and resources.

In addition to addressing standard upkeep practices, this guide emphasizes the importance of understanding specific systems within the vehicle. Recognizing potential issues before they escalate fosters a more reliable driving experience. With a combination of expert tips and practical examples, this resource aims to cultivate a deeper appreciation for the intricacies of automotive care.

This section aims to provide a comprehensive overview of a specific vehicle model from a particular production year. It encompasses various aspects such as design features, technical specifications, and unique characteristics that distinguish it within its class. By exploring these elements, readers can gain valuable insights into the vehicle’s performance and capabilities.

Key Features and Specifications

The highlighted vehicle is recognized for its blend of functionality and aesthetic appeal. Its engineering incorporates modern technology, ensuring reliability and efficiency. Here are some notable features:

| Attribute | Description |

|---|---|

| Engine Type | Efficient and powerful, designed for optimal performance. |

| Interior Design | Spacious and user-friendly, prioritizing comfort and accessibility. |

| Safety Features | Equipped with advanced safety technologies to ensure passenger security. |

Performance and Handling

The vehicle’s performance metrics showcase its capability on various terrains. Its handling dynamics contribute to a smooth driving experience, making it suitable for both urban and rural environments. Feedback from users often highlights its agility and responsive nature, enhancing overall satisfaction.

Common Issues Encountered

Many users face various challenges when operating their vehicles. Understanding these prevalent problems can aid in timely resolutions and enhance overall performance. Recognizing symptoms early on often leads to more efficient troubleshooting and maintenance strategies.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Engine Misfire | Rough idle, decreased power | Inspect spark plugs, check fuel injectors |

| Brake Warning Light | Light on dashboard, reduced braking efficiency | Check brake fluid level, inspect brake pads |

| Transmission Slipping | Unresponsive gears, unusual noises | Examine transmission fluid, consider professional assessment |

| Overheating | Temperature gauge in the red, steam | Check coolant levels, inspect radiator |

| Battery Issues | Difficulty starting, dim lights | Test battery voltage, replace if necessary |

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of vehicles. Proper tools not only enhance efficiency but also ensure safety while working on various tasks. Below is a list of necessary implements that every enthusiast should consider having on hand for successful upkeep.

Basic Hand Tools

- Wrenches – A variety of sizes for different bolts.

- Screwdrivers – Both flathead and Phillips for various fasteners.

- Pliers – For gripping and twisting wires or components.

- Hammers – Essential for assembly and disassembly tasks.

Specialized Equipment

- Jack and Jack Stands – For safely lifting the vehicle during inspections.

- Diagnostic Scanner – To read error codes and assess system functionality.

- Torque Wrench – Ensures bolts are tightened to specified levels.

- Multimeter – Useful for checking electrical systems.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing common issues effectively and efficiently. By following these detailed steps, you can ensure that problems are diagnosed accurately and resolved with minimal complications. Each procedure is designed to guide you through the necessary tasks while emphasizing safety and precision.

Preparation and Safety Measures

Before starting any maintenance tasks, it is crucial to gather the appropriate tools and materials. Ensure that you have protective gear, such as gloves and goggles, to safeguard against potential hazards. Always disconnect the power source to prevent any electrical accidents. Familiarize yourself with the components involved to streamline the process and enhance your confidence.

Detailed Procedures

Begin with a thorough inspection to identify the specific issue. Document any visible signs of wear or damage. Once the problem is pinpointed, follow the outlined steps to execute the necessary adjustments or replacements. Be meticulous with each phase, and do not hesitate to refer back to this guide for clarification. This methodical approach not only improves the outcome but also extends the lifespan of your equipment.

Understanding Engine Maintenance

Maintaining the heart of a vehicle is essential for ensuring optimal performance and longevity. Regular attention to key components can prevent larger issues down the road. This section explores fundamental practices and considerations for keeping an engine in peak condition.

Engines require a combination of routine inspections, timely fluid changes, and awareness of potential warning signs. Adhering to a maintenance schedule not only enhances efficiency but also minimizes the risk of unexpected breakdowns.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 5,000-7,500 miles | Replace old oil to keep the engine lubricated and functioning smoothly. |

| Air Filter Replacement | Every 15,000-30,000 miles | Ensure clean airflow to the engine for optimal combustion and efficiency. |

| Coolant Check | Every 30,000 miles | Inspect and replace coolant to prevent overheating and maintain engine temperature. |

| Spark Plug Inspection | Every 30,000 miles | Examine and replace spark plugs to ensure proper ignition and fuel efficiency. |

| Belts and Hoses Check | Every 60,000 miles | Inspect for wear and replace as necessary to prevent engine failure. |

Transmission Troubleshooting Techniques

This section delves into effective methods for diagnosing issues related to the power transfer system of a vehicle. Identifying the root cause of transmission problems is crucial for ensuring optimal performance and longevity. By applying systematic approaches, one can pinpoint faults and implement appropriate solutions.

Start with Symptoms: Begin by noting any irregular behaviors, such as unusual noises, slipping gears, or delayed engagement. Understanding these signs helps in narrowing down the potential causes of the issue.

Fluid Inspection: Check the transmission fluid levels and condition. Low fluid can lead to overheating and poor performance, while contaminated fluid may indicate deeper issues within the system.

Diagnostic Tools: Utilizing diagnostic equipment can reveal error codes stored in the vehicle’s computer. These codes provide valuable insights into specific malfunctions that may not be immediately apparent.

Visual Examination: Conduct a thorough visual inspection of the transmission and surrounding components. Look for leaks, damaged hoses, or worn-out parts that could contribute to malfunctioning behavior.

Test Drive: Perform a controlled test drive to replicate the symptoms. This step allows for a more accurate assessment of the issues at hand and helps in determining whether they persist under various driving conditions.

By combining these techniques, one can effectively troubleshoot transmission-related concerns, paving the way for successful repairs and enhanced vehicle reliability.

Electrical System Diagnostics

The assessment of electrical systems is crucial for maintaining optimal performance in vehicles. Proper diagnosis helps identify issues that may disrupt the functionality of various components, ensuring reliability and safety.

When examining the electrical system, several key areas should be considered:

- Battery condition and charge status

- Wiring integrity and connections

- Fuses and relays functionality

- Sensors and actuator operations

- Control module responses

Utilizing appropriate diagnostic tools can greatly enhance the efficiency of troubleshooting. Follow these general steps for effective evaluation:

- Begin with a visual inspection of wiring and connections for any signs of wear or damage.

- Test the battery voltage to ensure it meets specified standards.

- Check the continuity of critical circuits with a multimeter.

- Evaluate the performance of sensors and relays under operational conditions.

- Utilize diagnostic equipment to read error codes from the control modules.

By systematically analyzing each component within the electrical system, technicians can pinpoint faults and implement necessary corrections. This proactive approach not only extends the lifespan of the vehicle’s systems but also enhances overall driving experience.

Brake System Inspection Guide

Ensuring the optimal performance of the braking mechanism is essential for vehicle safety. This section outlines key aspects to examine during the evaluation of the braking system. Regular assessments can help identify potential issues early and maintain reliable operation.

Visual Examination

Begin by inspecting the components for visible wear and damage. Check for fluid leaks, corrosion, or any signs of deterioration. Ensure that the brake pads have adequate thickness and are free of contaminants. Additionally, look for any irregularities in the rotors, such as scoring or uneven surfaces.

Functional Testing

After the visual assessment, perform a functional test of the braking system. Engage the brakes while stationary and observe for any unusual noises or vibrations. Pay attention to the pedal feel; it should be firm without excessive travel. If any abnormalities are detected during these tests, further investigation may be necessary.

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering components are crucial for achieving optimal vehicle performance and safety. These systems play a significant role in providing stability, control, and a smooth driving experience. Making necessary adjustments can enhance handling and reduce tire wear, ensuring a more comfortable ride.

Understanding Suspension Alignment

Suspension alignment involves adjusting the angles of the wheels to the manufacturer’s specifications. This process helps maintain even tire contact with the road, improving traction and handling. Regular checks and adjustments can prevent issues such as uneven tire wear and diminished steering response.

Steering System Calibration

Calibrating the steering system is essential for ensuring that the vehicle responds accurately to driver input. This adjustment involves fine-tuning components to guarantee proper alignment with the front wheels. A well-calibrated steering system enhances maneuverability and provides a safer driving experience.

Cooling System Maintenance Tips

Maintaining the cooling system is essential for optimal engine performance and longevity. A well-functioning cooling system prevents overheating and ensures that the engine operates at the correct temperature. Regular checks and proper care can help you avoid costly repairs and enhance the efficiency of your vehicle.

Regular Inspections

Perform routine inspections of the cooling system components, including hoses, belts, and the radiator. Look for any signs of wear, cracks, or leaks. Addressing small issues early can prevent more significant problems down the road.

Fluid Checks and Changes

Regularly check the coolant level and condition. Ensure that the coolant is clean and free from contaminants. If the fluid appears dirty or has not been changed for an extended period, consider flushing the system and replacing the coolant. This practice helps maintain optimal cooling efficiency and protects engine components.

Bodywork Repairs and Techniques

Maintaining the exterior of a vehicle is essential for both aesthetics and functionality. This section explores various methods and practices aimed at restoring the outer surfaces to their original condition. Whether dealing with minor dents, scratches, or more significant damages, understanding the right techniques can make a substantial difference in the overall appearance and longevity of the vehicle.

Common Techniques for Exterior Restoration

Several methods can be employed to address imperfections in the bodywork. Techniques such as paintless dent removal are effective for minor dings, allowing for quick repairs without compromising the original finish. For deeper scratches or areas with rust, proper sanding and application of touch-up paint are critical to ensure a seamless repair. Each technique requires specific tools and materials, making it crucial to select the appropriate method for the damage at hand.

Preventive Measures and Maintenance

Preventing damage to the exterior is as important as the repair process itself. Regular washing and waxing can protect the paint from environmental factors, while using protective coatings can enhance durability. Additionally, being mindful of parking locations and avoiding debris can significantly reduce the risk of exterior damage.

Cost Estimation for Repairs

Understanding the financial implications of vehicle maintenance is essential for effective budgeting. This section aims to provide insights into estimating expenses associated with necessary fixes and upgrades, helping owners make informed decisions.

Factors Influencing Costs

- Parts Quality: The choice between original equipment and aftermarket components can significantly affect pricing.

- Labor Rates: Mechanic charges can vary based on location and expertise.

- Type of Service: Routine checks often cost less than extensive repairs requiring specialized tools or skills.

Cost Estimation Methods

There are several approaches to estimate the costs effectively:

- Research: Gather information from trusted sources such as auto forums, online marketplaces, and repair shops.

- Quotes: Obtain detailed estimates from multiple service providers to compare prices.

- DIY Assessment: For those with mechanical skills, evaluating the repair process can help gauge potential expenses.

Safety Precautions While Repairing

Engaging in mechanical work requires a mindful approach to ensure personal safety and the integrity of the components involved. Following basic guidelines can significantly reduce the risk of accidents and injuries during the process.

Always wear appropriate protective gear, including gloves, safety goggles, and sturdy footwear. This equipment provides essential barriers against potential hazards, such as sharp objects or harmful substances.

Additionally, it is crucial to maintain a clean and organized workspace. A clutter-free area minimizes the chances of tripping or misplacing tools, which can lead to delays and mistakes. Ensuring proper lighting also helps in identifying potential risks more easily.

Before commencing any task, it is advisable to disconnect power sources or remove batteries. This simple step prevents unexpected electrical shocks or unintended movements that could cause harm.

Lastly, familiarize yourself with the specific procedures and tools required for the task at hand. Understanding the equipment and its functions enhances safety and efficiency, enabling a smoother workflow.