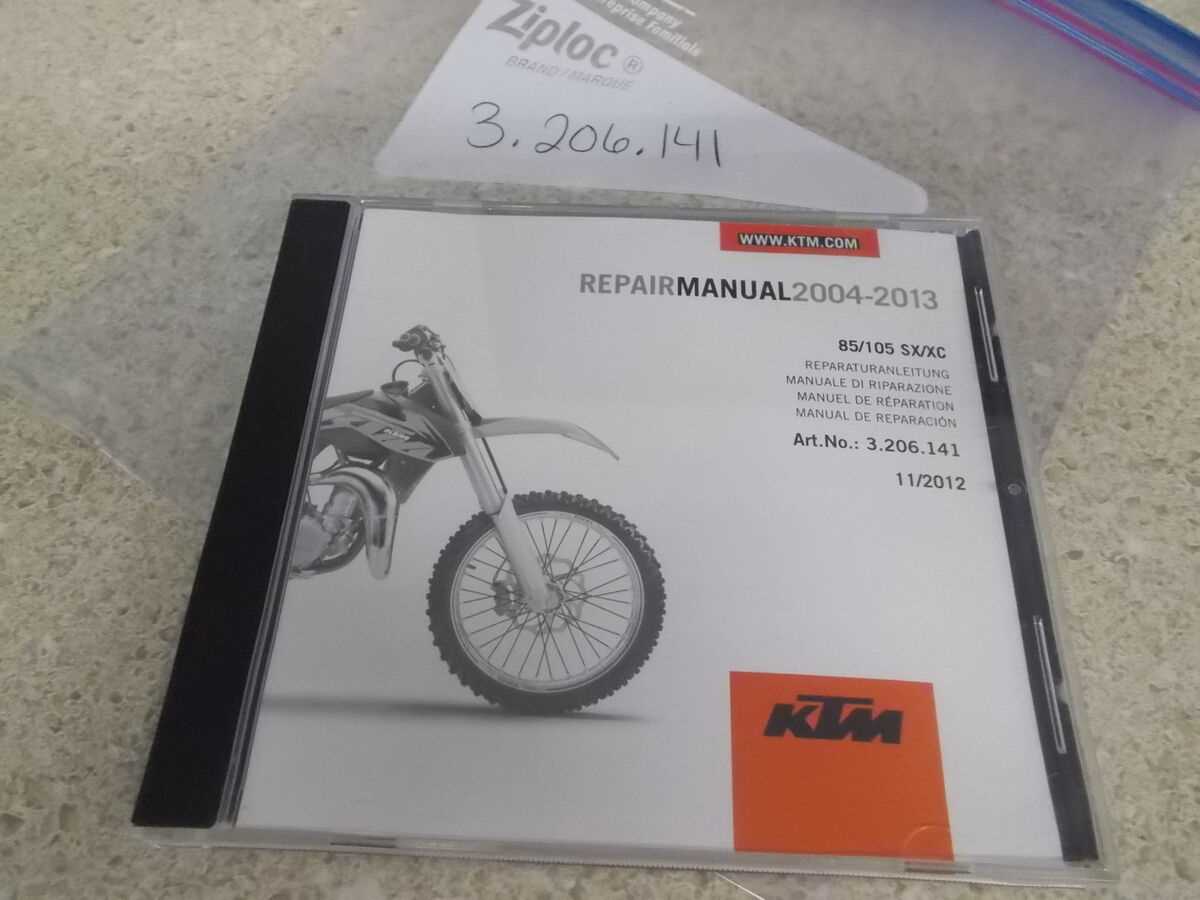

Comprehensive Guide to the 2012 KTM Repair Manual

In the world of high-performance vehicles, having access to comprehensive resources is crucial for ensuring optimal functioning and longevity. This guide serves as a valuable tool for enthusiasts and owners alike, offering insights into the nuances of upkeep and technical support. With a focus on effective problem-solving and routine care, it equips users with the knowledge necessary to maintain their machines in peak condition.

The intricacies of modern engineering demand a thorough understanding of various components and systems. By delving into detailed instructions and expert recommendations, users can navigate the complexities of maintenance with confidence. This resource is designed to empower individuals to take charge of their vehicle’s health, ultimately enhancing the riding experience.

Whether you’re dealing with routine inspections or unexpected challenges, having a structured approach is essential. This compilation not only addresses common issues but also emphasizes preventive measures, ensuring that enthusiasts can enjoy their rides without interruption. Embrace the journey of mastery and elevate your technical prowess with this indispensable guide.

KTM 2012 Overview

This section provides a comprehensive examination of a prominent motorcycle brand’s offerings during a specific year, highlighting their innovations and features. The focus is on the advancements in engineering and design that distinguish these models from their predecessors, aiming to deliver enhanced performance and rider experience.

Performance and Features

The lineup introduced significant improvements in both power and handling. Enhanced suspension systems and refined engine configurations were designed to provide an exhilarating ride. Additionally, features such as lightweight frames and advanced braking systems contributed to superior control and stability on various terrains.

Design and Technology

The aesthetic appeal of these machines was complemented by cutting-edge technology. Streamlined designs not only improved aerodynamics but also reflected the brand’s commitment to innovation. Integration of modern electronics, including advanced telemetry systems, allowed riders to fine-tune their experience, pushing the boundaries of performance and safety.

Importance of Repair Manuals

Having access to comprehensive guides for maintenance and troubleshooting is crucial for ensuring the longevity and optimal performance of any vehicle. These resources serve as valuable references, offering detailed instructions and insights that empower owners to take charge of their machinery.

Benefits of Detailed Guides

One of the primary advantages of such resources is the ability to diagnose issues effectively. With step-by-step instructions, individuals can identify problems quickly, reducing downtime and potentially costly repairs. Furthermore, these guides often include diagrams and illustrations that clarify complex processes, making it easier for users to follow along.

Cost-Effectiveness and Skill Development

Utilizing these instructional materials not only saves money on professional services but also fosters a greater understanding of one’s vehicle. Engaging in maintenance tasks cultivates valuable skills and boosts confidence in handling future issues. By becoming familiar with their machinery, owners can ensure it remains in top condition for years to come.

Common Issues with 2012 KTM Models

When it comes to specific motorcycles from a certain year, enthusiasts often encounter a range of challenges. Understanding these common problems can significantly enhance the ownership experience and maintenance process. Below are frequent issues that riders may face with these machines, along with some tips for addressing them.

Engine Performance Problems

- Overheating: Many owners report issues with the engine temperature rising unexpectedly. Regularly checking the coolant levels and ensuring the radiator is clean can help mitigate this problem.

- Starting Difficulties: A common complaint is the bike not starting promptly. This may be due to battery issues or fuel system clogs. Regular battery maintenance and fuel system cleaning can improve reliability.

Suspension and Handling Concerns

- Fork Seal Leaks: Leaky fork seals can lead to poor handling and safety issues. Inspecting seals regularly and replacing them as needed can prevent further damage.

- Unresponsive Brakes: Riders may experience diminished braking performance. Ensuring brake fluid is at appropriate levels and replacing worn pads can enhance safety.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is essential for achieving optimal results. A well-equipped workspace not only enhances efficiency but also ensures that each task is performed safely and effectively. Familiarizing yourself with the necessary tools can greatly simplify the process, making it more manageable and less daunting.

Essential Instruments

To start, a good set of wrenches and sockets is crucial for loosening and tightening bolts and nuts. A reliable screwdriver set is equally important, as it allows for the manipulation of various screws found throughout the assembly. Additionally, a quality torque wrench ensures that components are secured to the manufacturer’s specifications, preventing damage from over-tightening.

Additional Supplies

Beyond basic tools, consider acquiring pliers for gripping and cutting, and a multimeter for electrical diagnostics. A workbench with adequate lighting can significantly enhance your workspace, making intricate tasks easier to manage. Lastly, keep lubricants and cleaning supplies on hand to maintain optimal performance and longevity of the machinery.

Step-by-Step Maintenance Guide

Proper upkeep of your motorcycle is essential for its longevity and performance. This section provides a comprehensive approach to maintaining your bike, ensuring it runs smoothly and efficiently. Following these steps will help you identify potential issues early and keep your ride in top shape.

Essential Maintenance Tasks

- Check and change the oil regularly to ensure optimal engine performance.

- Inspect the air filter and replace it if it’s dirty or clogged.

- Examine the brakes for wear and replace pads as needed.

- Inspect the chain and sprockets, cleaning and lubricating them periodically.

- Monitor tire pressure and tread depth to enhance safety and handling.

Routine Inspection Steps

- Begin with a visual inspection of the overall condition of the motorcycle.

- Check fluid levels, including coolant, brake fluid, and transmission fluid.

- Test the battery and electrical components to ensure they are functioning correctly.

- Verify that all lights, indicators, and horns are operational.

- Perform a test ride to listen for unusual sounds and assess handling.

Electrical System Troubleshooting

Troubleshooting the electrical system of a vehicle requires a systematic approach to identify and resolve issues effectively. This section outlines essential steps and techniques to diagnose problems within the circuitry and related components.

Initial Inspection: Begin with a thorough visual examination of the wiring harness, connectors, and fuses. Look for any signs of damage, corrosion, or loose connections that could disrupt the flow of electricity.

Power Supply Check: Utilize a multimeter to measure voltage at various points in the system. Ensure that the battery is functioning properly and that power is reaching critical components such as the ignition system and lighting.

Component Testing: Test individual elements, such as switches, relays, and sensors, to verify their operation. If a component is found to be faulty, it should be replaced or repaired as necessary.

Continuity Tests: Perform continuity tests on wiring to ensure there are no breaks in the circuit. This is crucial for identifying hidden issues that may not be immediately apparent during a visual inspection.

Ground Connections: Confirm that all ground points are secure and free of corrosion. Poor grounding can lead to intermittent electrical issues, so addressing this can often resolve multiple problems.

By following these guidelines, you can effectively troubleshoot the electrical system and restore functionality, ensuring a safe and reliable riding experience.

Engine Overhaul Procedures

Undertaking a comprehensive examination and restoration of an engine is essential for ensuring optimal performance and longevity. This process involves a systematic approach to disassembly, inspection, and reassembly, allowing for the identification and rectification of any wear or damage. Properly executed, this procedure can significantly enhance the efficiency and reliability of the power unit.

Preparation Steps

Before commencing the overhaul, it is crucial to gather all necessary tools and parts. The workspace should be clean and organized to facilitate a smooth workflow. The following table outlines the essential items required for this process:

| Item | Description |

|---|---|

| Torque Wrench | Used for precise tightening of bolts to manufacturer specifications. |

| Engine Stand | Provides support and accessibility during disassembly and reassembly. |

| Inspection Tools | Includes micrometers and calipers for measuring components. |

| Replacement Parts | Gaskets, seals, and other components that may need replacement. |

Disassembly and Inspection

The first step in the overhaul is to carefully disassemble the engine, documenting each stage to ensure accurate reassembly. Components should be inspected for signs of wear or damage. Critical areas to examine include the cylinder head, piston, and crankshaft. Each part should be cleaned thoroughly before further evaluation. After inspection, any necessary repairs or replacements should be addressed to restore the engine’s integrity.

Suspension Adjustments and Setup

The proper configuration of your bike’s suspension is crucial for achieving optimal performance and comfort on various terrains. Fine-tuning these components ensures better handling, stability, and rider confidence, allowing you to tackle obstacles more effectively. Each rider’s preferences and riding style are unique, which makes the setup process highly individualistic.

Understanding Suspension Components

Suspension systems typically consist of forks at the front and a shock at the rear. These parts work together to absorb impacts and maintain traction. Adjusting preload, compression, and rebound settings allows you to customize the response of your setup. Preload affects the initial ride height and firmness, while compression and rebound settings control how quickly the suspension reacts to bumps and returns to its original position.

Adjustment Process

Begin by assessing the current setup against your riding style and terrain conditions. Adjust the preload to achieve the desired ride height, ensuring that the bike feels balanced. Next, tweak the compression and rebound settings to find a sweet spot that provides both comfort and control. Testing your adjustments in a safe area helps to refine the settings further, allowing for a personalized and effective suspension experience. Remember, small changes can have a significant impact, so make adjustments gradually and observe the results.

Brake System Maintenance Tips

Ensuring optimal performance and safety of your vehicle’s stopping mechanism is crucial. Regular attention to this component not only enhances safety but also prolongs the lifespan of the entire system. Here are some key practices to maintain and inspect your braking setup effectively.

Regular Inspection

Frequent checks are essential for early detection of potential issues. Pay attention to the following:

- Brake pads: Look for wear indicators or uneven thickness.

- Brake fluid: Check for clarity and proper levels.

- Brake lines: Inspect for leaks or signs of wear.

Fluid Change

Maintaining the quality of your braking fluid is vital for system efficiency. Follow these steps:

- Consult the manufacturer’s recommendations for fluid change intervals.

- Use the specified type of fluid to ensure compatibility.

- Bleed the system to remove air bubbles, ensuring optimal hydraulic performance.

By adhering to these maintenance tips, you can help ensure that your vehicle remains safe and responsive, providing peace of mind on every journey.

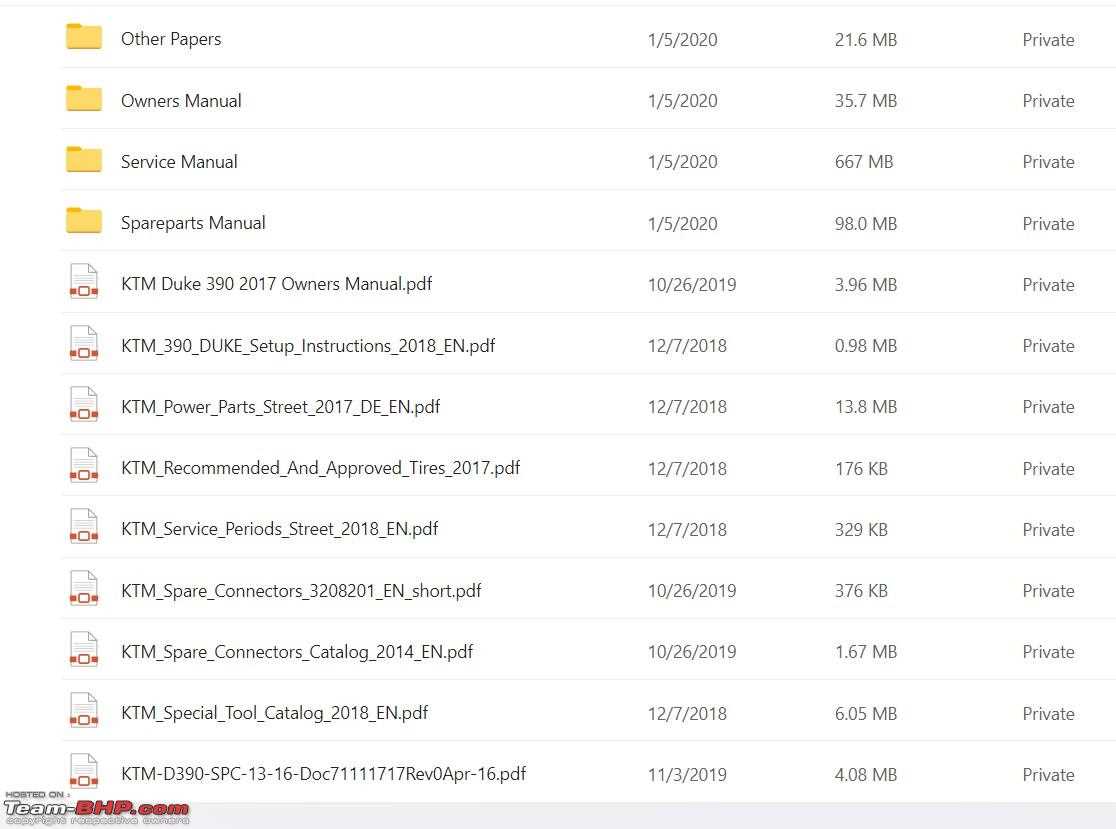

Parts Replacement and Upgrades

Maintaining optimal performance and longevity of your vehicle often involves timely replacement of components and thoughtful upgrades. Understanding which parts to enhance can significantly impact both functionality and riding experience.

When considering changes, it’s essential to evaluate both wear and performance potential. Regular assessments can help identify parts that may require attention.

- Engine Components:

- Oil filters

- Air filters

- Spark plugs

- Suspension Parts:

- Fork seals

- Shock absorbers

- Springs

- Braking System:

- Brake pads

- Rotors

- Brake lines

- Electrical Components:

- Batteries

- Wiring harnesses

- Lights

Upgrading certain parts can enhance performance metrics such as speed, handling, and efficiency. Popular upgrades include:

- Exhaust systems for improved airflow

- Aftermarket suspension kits for better handling

- ECU tuning for optimized engine performance

Always consult with a professional or refer to detailed resources before proceeding with replacements or upgrades to ensure compatibility and safety.

Recommended Oils and Fluids

Choosing the right lubricants and liquids is crucial for optimal performance and longevity of your vehicle. Using the appropriate products ensures smooth operation, reduces wear, and enhances the overall efficiency of the machine. This section outlines the essential types of oils and fluids that are best suited for your needs.

| Fluid Type | Recommended Product | Specifications |

|---|---|---|

| Engine Oil | Full Synthetic Oil | SAE 10W-50 |

| Transmission Fluid | High-Performance Gear Oil | SAE 75W-90 |

| Brake Fluid | DOT 4 Brake Fluid | Meets or exceeds specifications |

| Coolant | Extended Life Antifreeze | 50/50 Mix with Water |

| Chain Lubricant | High-Quality Chain Oil | Specifically designed for motorcycle chains |

Utilizing these recommended products will help maintain peak functionality and prevent potential issues that may arise from improper lubrication or fluid selection. Always refer to your specific model’s requirements for the best results.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is essential for both the individual performing the work and the equipment being serviced. Taking the necessary precautions can prevent accidents and damage, leading to a smoother and more efficient process.

Here are some fundamental safety measures to consider:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to minimize exposure to harmful fumes and ensure a clear workspace.

- Keep your workspace organized and free from clutter to avoid trips and falls.

- Disconnect the battery or power source before beginning any maintenance to prevent accidental starts.

- Use tools that are in good condition and appropriate for the task at hand.

Additionally, be mindful of the following:

- Read any accompanying documentation carefully before starting work.

- Ensure that all fluids are handled properly and disposed of according to local regulations.

- Be cautious when working with sharp or heavy objects.

- If you’re unsure about a procedure, seek guidance or consult a professional to avoid errors.

By adhering to these safety guidelines, individuals can reduce the risk of injury and enhance the effectiveness of their maintenance efforts.