Comprehensive Guide to 2013 MaxxForce 7 Repairs

In this section, we will explore essential information related to the upkeep and troubleshooting of a specific type of vehicle engine. Understanding the inner workings and maintenance procedures is crucial for ensuring optimal performance and longevity.

By delving into various aspects of engine care, including common issues and their resolutions, users will gain valuable insights. This knowledge is not only beneficial for experienced technicians but also empowers vehicle owners to engage in informed discussions regarding their engine’s health.

Equipped with practical advice and detailed instructions, this guide aims to simplify complex procedures and enhance the overall understanding of engine management. Adopting a proactive approach to maintenance can significantly reduce potential complications and enhance the driving experience.

2013 Maxxforce 7 Repair Manual Overview

This section provides a comprehensive overview of the guidelines and procedures necessary for maintaining and servicing the vehicle’s engine. It serves as a valuable resource for technicians and enthusiasts alike, detailing essential practices that ensure optimal performance and longevity.

Understanding the Components is crucial, as this resource outlines various parts and their functions, enabling users to diagnose issues effectively. Knowledge of these elements helps in addressing common problems and performing necessary adjustments.

Maintenance schedules are highlighted throughout, emphasizing the importance of routine checks and part replacements to prevent major failures. Adhering to these recommendations fosters a proactive approach to vehicle care.

Additionally, this guide includes troubleshooting tips that assist users in identifying and resolving operational challenges quickly. With a structured format, it facilitates easy navigation through topics, making it user-friendly for individuals at all skill levels.

Engine Specifications and Features

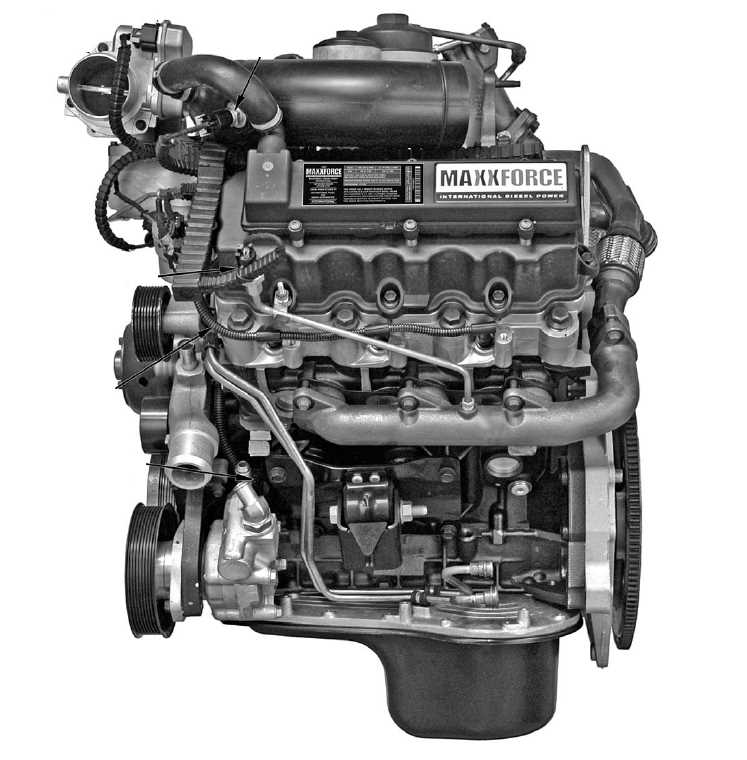

This section provides a comprehensive overview of the engine’s characteristics and capabilities, emphasizing its performance and reliability. Understanding these elements is crucial for maintaining optimal functionality and ensuring long-lasting operation.

Technical Characteristics

The engine boasts a robust design, featuring advanced components that contribute to its efficiency. With a displacement that enhances power delivery and torque, this engine is well-suited for various applications. Key specifications include a multi-valve configuration and a turbocharged system, which collectively improve fuel economy and reduce emissions.

Operational Features

Notable features include an innovative cooling system that maintains optimal temperatures during operation. Additionally, the engine is equipped with a sophisticated electronic control unit (ECU) that optimizes performance parameters, ensuring responsive acceleration and smooth operation. These aspects work together to provide a balanced and reliable driving experience.

Troubleshooting Common Issues

This section addresses frequent challenges encountered with the engine, providing insights into identification and resolution. Understanding these common problems can assist users in maintaining optimal performance and extending the lifespan of their vehicle.

Identifying Engine Problems

Various symptoms may indicate underlying issues with the engine. Recognizing these signs early can prevent more severe damage. Common indicators include:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Loss of Power | Fuel supply issue | Check fuel filter and lines |

| Overheating | Coolant leak | Inspect hoses and radiator |

| Strange Noises | Loose components | Tighten or replace parts |

| Excessive Smoke | Oil leak | Examine seals and gaskets |

Steps for Effective Troubleshooting

To effectively diagnose and resolve issues, follow a systematic approach. Begin with a visual inspection, then perform tests to verify the root cause. Utilizing the right tools and techniques will enhance the troubleshooting process and lead to quicker resolutions.

Maintenance and Service Intervals

Regular upkeep and timely servicing are crucial for ensuring optimal performance and longevity of the engine. Adhering to specified intervals helps in identifying potential issues early, thereby reducing the risk of major repairs and enhancing reliability.

It is recommended to follow the manufacturer’s guidelines for routine inspections, oil changes, and filter replacements. These procedures should be scheduled based on the operational hours or mileage, whichever comes first. Keeping a detailed log of service activities can aid in tracking maintenance history and anticipating future needs.

In addition to standard checks, periodic assessments of the cooling system, fuel delivery components, and electrical systems are essential. By maintaining these elements, users can ensure smooth operation and avoid unexpected breakdowns.

Electrical System Diagnostics

Effective troubleshooting of electrical systems is crucial for ensuring optimal performance and reliability. This process involves a systematic approach to identifying and resolving issues that may arise within the circuitry and components. By understanding the fundamental principles and employing appropriate diagnostic tools, technicians can efficiently pinpoint problems.

Key Components: Begin by familiarizing yourself with the main elements of the electrical system, including the battery, alternator, and wiring harnesses. Each component plays a vital role in the overall functionality.

Diagnostic Procedures: Utilize multimeters and specialized diagnostic equipment to measure voltage, current, and resistance levels. Performing visual inspections of connections and wiring can also help reveal potential faults, such as frayed wires or loose terminals.

Common Issues: Be aware of frequent electrical problems, such as blown fuses, dead batteries, or malfunctioning sensors. Understanding these common faults can streamline the diagnostic process and lead to quicker resolutions.

Conclusion: A thorough approach to electrical system diagnostics not only enhances the longevity of components but also improves the overall safety and efficiency of the vehicle.

Cooling System Repair Procedures

This section provides essential guidelines for addressing issues related to the cooling mechanism of the engine. Proper maintenance of this system is crucial for optimal performance and longevity of the vehicle. The following steps outline the procedures to effectively troubleshoot and resolve cooling system problems.

Identification of Common Issues

- Overheating engine

- Coolant leaks

- Radiator blockages

- Thermostat malfunction

Steps for Addressing Cooling System Problems

- Begin with a visual inspection of the cooling components.

- Check the coolant levels and refill if necessary.

- Examine hoses and connections for any signs of wear or damage.

- Flush the radiator to eliminate any debris or blockages.

- Replace faulty parts such as the thermostat or water pump.

- Conduct a pressure test to ensure there are no leaks.

Fuel System Components and Care

The fuel system plays a crucial role in the overall performance and efficiency of an engine. Proper maintenance and understanding of its components are essential for optimal functionality. This section highlights the main elements of the fuel system and emphasizes the importance of regular care to ensure longevity and reliability.

Key Components

| Component | Description |

|---|---|

| Fuel Tank | Stores the fuel necessary for engine operation. |

| Fuel Pump | Delivers fuel from the tank to the engine at the required pressure. |

| Fuel Filter | Removes impurities and contaminants from the fuel before it reaches the engine. |

| Fuel Injector | Sprays fuel into the engine’s combustion chamber for efficient combustion. |

| Fuel Lines | Transport fuel between the tank, pump, and engine. |

Maintenance Practices

To ensure the fuel system functions efficiently, regular inspection and maintenance are crucial. It is recommended to replace the fuel filter periodically and check for any leaks or damage in the fuel lines. Additionally, keeping the fuel tank clean and using high-quality fuel can prevent build-up and enhance performance.

Transmission and Driveline Insights

The efficiency of power transfer from the engine to the wheels is crucial for optimal vehicle performance. Understanding the various components involved in the transmission and driveline systems is essential for effective maintenance and troubleshooting.

Components Overview: The transmission system comprises several key elements, including gears, clutches, and hydraulic systems. Each part plays a significant role in ensuring smooth gear shifts and proper torque delivery.

Common Issues: Drivers may experience a range of challenges, from slipping gears to unusual noises. Identifying these symptoms early can prevent more extensive damage and costly repairs.

Maintenance Tips: Regular inspections and fluid changes are vital to keep the transmission and driveline in optimal condition. Adhering to recommended service intervals can significantly enhance the longevity of these systems.

Conclusion: A comprehensive understanding of the transmission and driveline mechanics empowers owners to address issues proactively, ensuring reliable performance and safety on the road.

Brake System Inspection Techniques

The evaluation of braking systems is crucial for ensuring optimal performance and safety in vehicles. This process involves a thorough examination of various components to identify potential issues that may compromise functionality. Regular inspections help maintain the integrity of the braking system and enhance overall driving security.

Begin by visually assessing the brake pads and rotors for signs of wear or damage. Check for uneven surfaces, cracks, or excessive thinning, as these conditions can lead to decreased braking efficiency. Additionally, examine the brake fluid level and its condition; contaminated or low fluid can affect the hydraulic system’s performance.

Next, inspect the brake lines and hoses for any signs of leaks or deterioration. Flexible components should be free from cracks or bulges, which can indicate impending failure. Utilizing a brake line inspection tool can aid in detecting hidden issues that may not be immediately visible.

Finally, test the brake pedal feel and response while the vehicle is stationary. A soft or spongy pedal may signal air in the hydraulic system, while a hard pedal could indicate a blockage. Conducting these evaluations regularly ensures the braking system operates at its best, providing safety and reliability on the road.

Suspension and Steering Adjustments

This section focuses on the crucial modifications and calibrations necessary for maintaining optimal performance of the suspension and steering systems. Proper adjustments are essential for enhancing vehicle handling, comfort, and safety. Regular checks and fine-tuning ensure that the components work harmoniously, leading to improved ride quality and stability.

Key Considerations for Adjustments

When performing adjustments, it is vital to consider factors such as load distribution and terrain conditions. Each vehicle may have specific requirements based on its design and intended use. Ensuring that the alignment is accurate will significantly affect tire wear and overall maneuverability. Additionally, attention to shock absorber settings can enhance responsiveness and control during operation.

Steps for Proper Calibration

To achieve accurate settings, begin by inspecting all related components for wear and damage. Check the alignment using a reliable method to ensure it meets the manufacturer’s specifications. Adjust the height of the suspension to maintain an even ride height, which contributes to stability. Finally, verify that the steering components are properly lubricated and adjusted for a smooth steering experience.

Body and Interior Repairs

The exterior and interior components of a vehicle require meticulous attention to ensure both functionality and aesthetics. Maintaining these areas is essential for enhancing overall performance and providing comfort for occupants. Various elements such as panels, upholstery, and accessories can be susceptible to wear and damage over time, necessitating effective methods for restoration and enhancement.

Exterior Panel Restoration

When addressing issues related to the outer panels, it is crucial to assess the extent of damage, whether it be dents, scratches, or rust. Techniques such as dent removal, repainting, and rust treatment can significantly improve the vehicle’s appearance and integrity. Utilizing appropriate materials and tools will ensure a high-quality finish, preserving the structure and aesthetics of the vehicle.

Interior Upholstery Maintenance

Interior surfaces, including seats and dashboards, often encounter wear and tear from regular use. Cleaning, repairing, or replacing upholstery can revitalize the cabin’s look and feel. It is important to choose materials that match the original quality and design while ensuring durability and comfort. Regular upkeep will enhance the driving experience and maintain the value of the vehicle.

Parts Replacement Guidelines

This section provides essential information for the effective substitution of components in machinery. Understanding the proper procedures and recommendations is crucial for maintaining optimal functionality and ensuring longevity.

Before commencing any replacement task, it’s important to follow a systematic approach. This involves identifying the parts that require substitution, assessing the necessary tools, and ensuring you have access to quality replacements. Additionally, always consult the manufacturer’s specifications for precise guidance.

| Step | Description |

|---|---|

| 1 | Identify the defective component that needs to be replaced. |

| 2 | Gather the required tools and new parts for the task. |

| 3 | Disconnect any power sources to ensure safety during the process. |

| 4 | Carefully remove the faulty component, taking note of the installation process. |

| 5 | Install the new part, ensuring it aligns correctly and securely. |

| 6 | Reconnect power and perform tests to verify proper functionality. |

Following these guidelines will enhance the effectiveness of the maintenance procedures and contribute to the overall reliability of the equipment.

Safety Procedures During Repairs

Ensuring safety is paramount when conducting maintenance on machinery. Implementing appropriate measures can prevent accidents and promote a secure working environment. By adhering to essential guidelines, individuals can effectively minimize risks associated with technical tasks.

Prior to commencing any work, it is crucial to equip oneself with the necessary personal protective equipment (PPE). This may include gloves, goggles, and steel-toed boots to safeguard against potential hazards. Additionally, wearing appropriate clothing can further enhance protection.

It is vital to familiarize oneself with the specific characteristics of the equipment being serviced. Understanding its operational features, as well as potential dangers, allows for informed decision-making and improved safety outcomes. Always consult relevant resources for detailed information regarding the machinery.

Maintaining a clean workspace contributes significantly to safety. Keeping tools organized and ensuring that the area is free of clutter can help prevent accidents. Regularly inspecting equipment for wear or damage is also essential in promoting safe operation.

Lastly, communication plays a key role in enhancing safety during maintenance activities. Alerting team members to potential risks and ensuring everyone is aware of their responsibilities can foster a culture of safety and teamwork. Establishing clear protocols can help mitigate risks effectively.