Comprehensive Repair Manual for 2013 VW Tiguan

Ensuring the longevity and optimal performance of your vehicle requires a thorough understanding of its inner workings and regular upkeep. A well-structured resource can be invaluable for enthusiasts and everyday drivers alike, providing essential insights into diagnostics, troubleshooting, and routine care. This knowledge empowers owners to address issues proactively and maintain their automobile in peak condition.

From engine performance to electrical systems, a detailed reference can illuminate the intricacies of automotive mechanics. Each component plays a vital role, and being informed about how to manage them can save time and expenses. Moreover, familiarizing oneself with the specific needs of a vehicle fosters a sense of confidence in tackling various tasks, whether they are minor adjustments or more significant repairs.

Having access to a structured guide not only aids in understanding the vehicle’s features but also enhances safety on the road. By recognizing warning signs and addressing them promptly, drivers can ensure their journeys are smooth and secure. Ultimately, such a resource transforms the often daunting world of vehicle maintenance into a more approachable and manageable endeavor.

Overview of 2013 VW Tiguan

This section provides a comprehensive understanding of a compact SUV that blends functionality with style. Known for its robust performance and versatile features, this vehicle has garnered attention for its balance between comfort and driving dynamics. Enthusiasts appreciate its engaging handling and upscale interior, making it a competitive option in its class.

Performance and Engine Specifications

The vehicle is equipped with a turbocharged engine that delivers a spirited driving experience while maintaining fuel efficiency. Its all-wheel-drive system enhances traction, ensuring stability in various weather conditions. Drivers can expect responsive acceleration and a smooth ride, making it suitable for both urban commutes and adventurous journeys.

Interior Comfort and Technology

Common Issues with the Tiguan

Vehicles from this popular manufacturer often present specific challenges that owners should be aware of. Understanding these potential problems can aid in maintaining optimal performance and longevity.

- Electrical System Failures: Many drivers report issues with the electrical components, which may include:

- Malfunctioning windows

- Faulty dashboard indicators

- Problems with the audio system

- Engine Performance Issues: Some users experience a drop in engine efficiency, which can manifest as:

- Unusual noises during operation

- Decreased fuel economy

- Rough idling or stalling

- Transmission Problems: Transmission-related concerns can lead to:

- Delayed shifting

- Unresponsive gears

- Fluid leaks

- Suspension and Steering Issues: Some vehicles may experience difficulties in handling, which may include:

- Uneven tire wear

- Noises during turns

- Loose steering response

lessCopy code

Awareness of these frequent concerns can empower owners to address issues promptly, ensuring a smoother driving experience.

Essential Tools for Repairs

Having the right equipment is crucial when tackling vehicle maintenance tasks. The appropriate instruments not only enhance efficiency but also ensure safety and accuracy during the process. This section outlines the fundamental tools that every enthusiast or professional should have in their arsenal to perform various automotive services effectively.

Wrenches are indispensable for loosening and tightening nuts and bolts. A set that includes both standard and metric sizes is vital for versatility. Additionally, socket sets provide an efficient way to handle fasteners in tight spaces, making them a must-have for any job.

Jack stands and floor jacks are essential for lifting the vehicle securely. It’s important to ensure that your lifting equipment is rated for the weight of your vehicle to avoid accidents. Another important tool is a screwdriver set, which should include various types, such as Phillips and flathead, to accommodate different screws.

Diagnostic tools, such as an OBD-II scanner, allow for quick identification of issues within the vehicle’s systems. This technology is invaluable for anyone looking to understand and address problems effectively. Furthermore, pliers and cutting tools are beneficial for various tasks, from holding components in place to cutting wires.

Lastly, don’t overlook the importance of safety gear. Gloves, goggles, and other protective equipment are essential to safeguard against potential hazards while working on vehicles. By equipping yourself with these fundamental tools, you’ll be well-prepared for a range of automotive projects.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your vehicle. Regular upkeep is essential not only for reliability but also for enhancing safety and efficiency. By following a systematic routine, you can easily manage various tasks that will keep your automobile in peak condition.

Routine Inspection Tasks

- Check engine oil levels and condition.

- Inspect coolant levels and look for leaks.

- Examine brake fluid and power steering fluid levels.

- Assess tire pressure and tread depth.

- Test the functionality of lights and signals.

Scheduled Maintenance Actions

- Change the engine oil and replace the filter every 5,000 to 7,500 miles.

- Replace air filters every 15,000 to 30,000 miles.

- Inspect and rotate tires every 5,000 to 7,500 miles.

- Flush and replace coolant every 30,000 miles.

- Check and replace brake pads as needed, typically every 20,000 to 50,000 miles.

By adhering to these guidelines, you can help ensure that your vehicle remains in excellent condition, minimizing the likelihood of unexpected breakdowns and costly repairs.

Engine Troubleshooting Tips

When facing issues with the power unit of your vehicle, it’s essential to systematically identify and resolve problems. A methodical approach can save time and resources, ensuring that your automobile operates smoothly and efficiently. Here are some practical guidelines to help you diagnose engine-related concerns effectively.

Common Symptoms and Possible Causes

| Symptom | Possible Cause |

|---|---|

| Engine Won’t Start | Dead battery, faulty starter, or fuel supply issues |

| Rough Idling | Dirty fuel injectors, vacuum leaks, or faulty sensors |

| Overheating | Coolant leaks, faulty thermostat, or blocked radiator |

| Excessive Smoke | Oil leaks, worn piston rings, or coolant intrusion |

Basic Diagnostic Steps

Start by visually inspecting the engine compartment for any obvious signs of wear or damage. Check fluid levels, listen for unusual noises, and monitor warning lights on the dashboard. Utilizing diagnostic tools can provide deeper insights into error codes that may indicate specific malfunctions. By following these steps, you can efficiently narrow down potential issues and implement effective solutions.

Understanding the Electrical System

The electrical system of a vehicle plays a crucial role in its overall functionality, providing power to various components that ensure smooth operation. From the ignition system to the lighting and entertainment features, the effective management of electrical currents is essential for both safety and performance. A comprehensive grasp of this system can aid in troubleshooting issues and performing necessary maintenance.

Key Components

Central to the electrical framework are several vital components, including the battery, alternator, and various wiring harnesses. The battery supplies the necessary energy to start the engine and powers electronic accessories when the engine is off. The alternator, on the other hand, replenishes the battery while the vehicle is running, converting mechanical energy into electrical energy. Properly functioning wiring ensures that electricity flows seamlessly between these components, preventing malfunctions.

Common Issues

Electrical malfunctions can manifest in numerous ways, often leading to frustrating situations for drivers. Common problems include dead batteries, faulty alternators, or damaged wiring. Symptoms may range from dimming lights to complete failure of electronic systems. Regular inspections and understanding the signs of potential issues can help mitigate these problems before they escalate, ensuring reliable operation of the vehicle.

Transmission Maintenance Best Practices

Proper upkeep of your vehicle’s transmission is crucial for ensuring its longevity and optimal performance. Adopting effective maintenance strategies can help prevent costly repairs and enhance driving experience.

Here are some essential practices to follow:

- Regular Fluid Checks: Frequently inspect the transmission fluid level and condition. Low or dirty fluid can lead to poor performance.

- Fluid Changes: Follow the manufacturer’s recommendations for fluid replacement intervals. Fresh fluid maintains lubrication and cooling properties.

- Filter Replacement: Changing the transmission filter is important to keep contaminants at bay. A clogged filter can restrict fluid flow.

- Inspect Seals and Gaskets: Regularly check for leaks around seals and gaskets. Addressing leaks promptly can prevent further damage.

- Monitor Transmission Temperature: Overheating can lead to significant issues. Ensure the cooling system is functioning properly to maintain optimal temperatures.

Incorporating these practices into your maintenance routine can significantly enhance the durability and reliability of your vehicle’s transmission system.

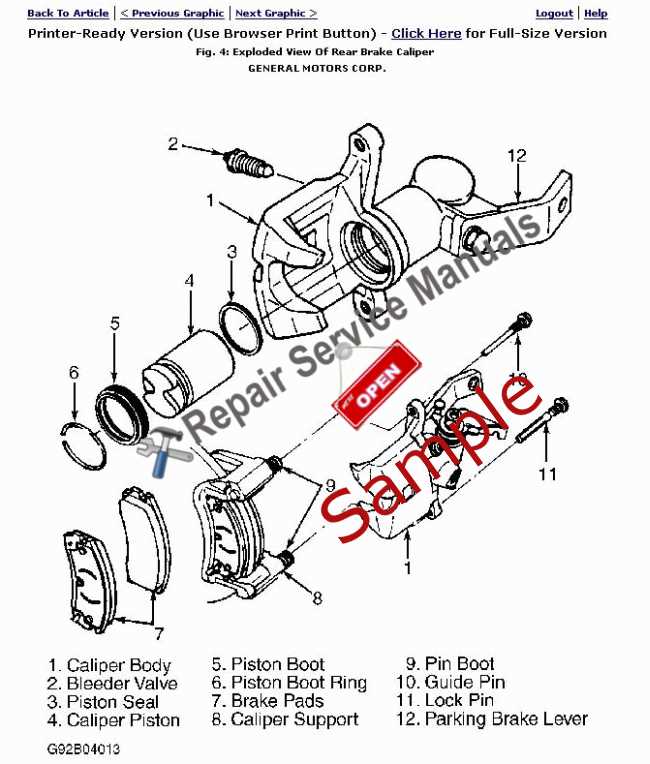

Braking System Inspection Procedures

The braking system is a critical component of vehicle safety, ensuring reliable performance during operation. Regular evaluation of this system is essential to identify any wear or malfunction that could compromise safety. This section outlines the necessary steps to conduct a thorough assessment of the braking components, helping to maintain optimal functionality and enhance driver confidence.

Visual Inspection: Begin with a comprehensive visual examination of the braking system. Check for any signs of fluid leaks, wear on brake pads, and condition of the rotors. Inspect brake lines and hoses for cracks or bulges, and ensure all mounting hardware is secure.

Brake Pad Thickness: Measure the thickness of the brake pads. Pads should generally be replaced when they reach a minimum thickness, typically around 3 mm. Uneven wear may indicate other issues such as caliper malfunction or misalignment.

Rotor Condition: Examine the rotors for signs of scoring, warping, or excessive rust. A smooth, even surface is crucial for effective braking. If any irregularities are detected, resurfacing or replacement may be necessary.

Fluid Level and Quality: Check the brake fluid reservoir for proper fluid levels. Inspect the fluid for contamination; clear fluid indicates good condition, while dark or murky fluid may require replacement to ensure proper system function.

Test Drive: After completing the visual checks, conduct a controlled test drive. Pay attention to any unusual noises, vibrations, or changes in pedal feel. These can indicate underlying issues that need further investigation.

By following these procedures diligently, vehicle owners can ensure their braking system remains in optimal condition, promoting safety and reliability on the road.

Cooling System Repair Techniques

The effectiveness of a vehicle’s cooling apparatus is crucial for maintaining optimal engine performance and longevity. Understanding various methods to address common issues can enhance reliability and efficiency. This section outlines essential approaches to troubleshoot and rectify problems within the cooling system.

1. System Inspection

Begin with a thorough examination of all components, including hoses, radiator, and water pump. Look for signs of wear, leaks, or corrosion. Using a pressure tester can help identify hidden leaks that are not immediately visible.

2. Fluid Replacement

Regularly replacing coolant is vital for preventing overheating and ensuring the system operates smoothly. Follow manufacturer guidelines for the type and mixture of coolant to use. Flush the system periodically to remove contaminants and debris.

3. Thermostat Testing

The thermostat plays a key role in regulating engine temperature. Test its functionality by monitoring the engine’s temperature fluctuations. If it remains closed or stuck, it may need to be replaced to prevent overheating.

4. Radiator Maintenance

Ensure the radiator is free from blockages and dirt. Cleaning the exterior can improve airflow, while flushing the internal passages removes sediment buildup. This maintenance helps maintain efficient cooling performance.

5. Fan Operation Check

The cooling fan is essential for dissipating heat when the vehicle is stationary or moving slowly. Verify that the fan engages at the appropriate temperature. If it fails to operate, inspect the fan motor and associated wiring for faults.

6. Heater Core Inspection

Issues with the heater core can impact both heating and cooling functions. Check for leaks or blockages that might affect coolant flow. A clogged heater core can lead to inadequate cabin heating and decreased overall system efficiency.

Implementing these techniques not only resolves current issues but also helps prevent future complications within the cooling apparatus. Proper care and attention to this system can significantly enhance the vehicle’s performance and durability.

Suspension and Steering Adjustments

Proper alignment and tuning of the suspension and steering systems are crucial for achieving optimal vehicle performance and handling. These adjustments not only enhance ride quality but also contribute to tire longevity and overall safety. Regular maintenance ensures that components function harmoniously, providing a smooth driving experience.

Key Adjustment Areas

Several critical areas require attention when performing adjustments on the suspension and steering systems. Understanding these components can help in diagnosing issues and ensuring proper alignment.

| Component | Description | Adjustment Method |

|---|---|---|

| Camber | Angle of the wheels relative to the vertical axis. | Use adjustment bolts to modify the angle. |

| Toe | Angle of the wheels pointing inwards or outwards. | Adjust tie rods for proper alignment. |

| Caster | Angle of the steering axis in relation to the vertical axis. | Modify strut mounts or control arms. |

Importance of Regular Maintenance

Periodic inspection and adjustment of the suspension and steering systems are essential for maintaining vehicle stability and safety. Neglecting these areas can lead to uneven tire wear, poor handling, and increased risk of accidents. Regular maintenance not only enhances performance but also extends the lifespan of the vehicle’s components.

Bodywork and Interior Repairs

This section focuses on the essential procedures for restoring and maintaining the exterior and interior aspects of your vehicle. Whether addressing minor dents, scratches, or interior wear, understanding these processes can enhance the longevity and aesthetics of your automobile.

For exterior work, common issues include:

- Scratches and paint damage

- Dents from minor collisions

- Corrosion and rust

- Windshield cracks and chips

To effectively manage these problems, follow these steps:

- Assess the damage thoroughly.

- Gather the necessary tools and materials.

- Follow a structured approach for repair, ensuring surface preparation is done correctly.

- Finish with appropriate sealants and coatings to protect against future issues.

When it comes to interior restoration, the focus may involve:

- Upholstery repairs and replacements

- Dashboard and console fixes

- Cleaning and conditioning materials

- Addressing electronic components and controls

Key steps for interior maintenance include:

- Identify areas needing attention.

- Choose the right materials for repair or replacement.

- Ensure a clean and safe working environment.

- Regularly maintain surfaces to prevent further damage.

By adhering to these guidelines, you can successfully restore and enhance both the exterior and interior of your vehicle, ensuring it remains in prime condition for years to come.

Finding OEM Parts for Replacement

When it comes to maintaining vehicle performance and reliability, sourcing original equipment manufacturer components is crucial. These parts are specifically designed to fit your automobile, ensuring compatibility and longevity. Understanding where and how to find these components can save time and enhance the quality of repairs.

Benefits of Using OEM Components

- Perfect Fit: Designed to match the specifications of your vehicle.

- Quality Assurance: Manufactured under strict guidelines to meet industry standards.

- Durability: Often more reliable than aftermarket options.

- Warranty Protection: Many OEM parts come with a warranty, providing peace of mind.

Where to Find OEM Parts

- Authorized Dealerships: The most straightforward option is to visit a certified dealership. They usually carry a comprehensive selection of OEM parts.

- Online Retailers: Numerous websites specialize in OEM components. Look for trusted sellers with good customer reviews.

- Auto Parts Stores: Local stores may offer a range of OEM parts or can order them for you.

- Salvage Yards: A more economical option, salvage yards often have vehicles that are still in good condition, providing OEM parts at a lower cost.

By prioritizing the search for OEM components, you ensure that your vehicle maintains its performance and reliability for years to come.

Resources for DIY Enthusiasts

For those who enjoy tackling vehicle maintenance and enhancements on their own, a wealth of resources is available to aid in the process. From instructional content to essential tools, these materials empower enthusiasts to develop their skills and perform tasks with confidence.

Online Platforms and Communities

Various websites and forums are dedicated to car enthusiasts, offering insights, tutorials, and tips. These platforms create a vibrant community where individuals can share experiences and advice, making them invaluable for anyone looking to improve their automotive knowledge.

Essential Tools and Equipment

Equipping yourself with the right tools is crucial for successful projects. Investing in high-quality equipment not only simplifies tasks but also enhances safety. Below is a table summarizing some must-have items for any DIY workshop:

| Tool | Description |

|---|---|

| Socket Set | Essential for loosening and tightening bolts and nuts. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Jack and Stands | Allows safe lifting of the vehicle for access to undercarriage. |

| Diagnostic Scanner | Helps identify issues by reading error codes from the vehicle’s computer. |

| Toolbox | Organizes all tools efficiently for easy access. |

By leveraging these resources and tools, DIY enthusiasts can tackle a variety of projects with greater ease and assurance, making their automotive experience more rewarding and enjoyable.