2018 KTM 50 SX Repair Guide

This section provides essential insights into the upkeep and servicing of a popular 50cc off-road bike, ensuring optimal performance and longevity. Understanding the intricacies of maintenance can enhance your riding experience and prevent potential issues.

By delving into the various components and their functions, riders can gain a deeper appreciation for their machine. Regular checks and proper adjustments play a crucial role in maintaining peak efficiency and safety.

Whether you are an experienced rider or a newcomer, familiarizing yourself with essential procedures and troubleshooting tips can empower you to address common challenges. Knowledge is the key to keeping your bike in top shape and ready for any adventure.

This section provides a comprehensive overview of a popular small displacement motorcycle designed for young riders. Known for its lightweight frame and agile handling, this model is an excellent choice for both novice and experienced enthusiasts. The focus here will be on its key features, specifications, and the overall riding experience it offers.

| Feature | Description |

|---|---|

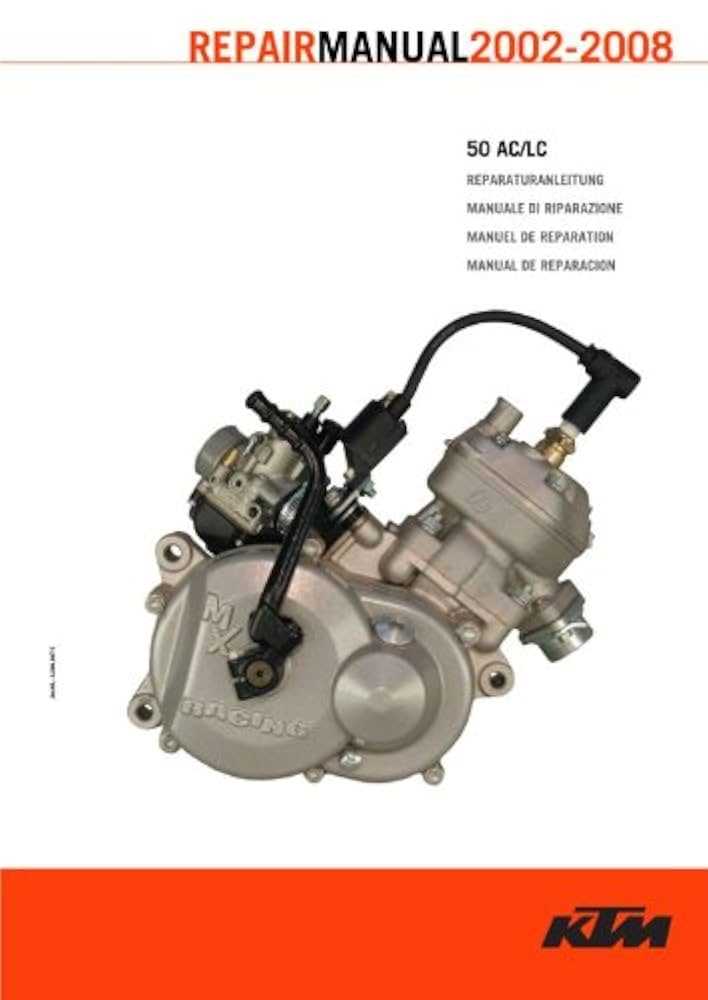

| Engine Type | Single-cylinder, two-stroke engine |

| Displacement | 49cc |

| Weight | Approximately 40 kg (88 lbs) |

| Transmission | Automatic clutch, 2-speed |

| Brakes | Disc brakes front and rear |

Common Issues and Solutions

In any motorized vehicle, certain challenges may arise during operation that can affect performance and longevity. Identifying these common problems and their remedies is essential for maintaining optimal functionality.

Frequent Problems

Many users encounter specific complications that can be resolved with proper knowledge. Below is a table listing some typical issues along with suggested solutions.

| Issue | Solution |

|---|---|

| Engine not starting | Check the fuel supply and ensure the ignition system is functioning properly. |

| Unusual noises | Inspect for loose components and verify lubrication levels are adequate. |

| Poor acceleration | Examine the air filter and fuel lines for blockages. |

| Overheating | Ensure coolant levels are sufficient and check the radiator for obstructions. |

Maintenance Tips

Regular upkeep is crucial to prevent these issues from occurring. Following a routine maintenance schedule can significantly enhance performance and reduce the likelihood of complications.

Tools Required for Maintenance

Proper upkeep of your vehicle involves a variety of essential instruments that ensure its longevity and performance. Having the right equipment on hand allows for efficient service, enhancing the overall functionality and safety of the machine.

To get started, consider acquiring basic hand tools, such as wrenches, pliers, and screwdrivers. These tools are fundamental for addressing minor adjustments and repairs. Additionally, an air compressor can be beneficial for cleaning components and ensuring optimal operation.

For more detailed tasks, specialized equipment like torque wrenches and diagnostic devices may be necessary. These instruments provide precise measurements and facilitate thorough inspections, helping to identify potential issues before they escalate.

Finally, don’t overlook safety gear, including gloves and goggles. Protecting yourself while performing maintenance tasks is crucial for a safe and effective experience.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing common issues encountered during maintenance tasks. Following a structured methodology ensures effective troubleshooting and enhances the longevity of the equipment.

Preparation Phase

Before commencing any task, it is essential to gather all necessary tools and materials. A well-organized workspace contributes significantly to efficiency and safety.

| Tools Required | Description |

|---|---|

| Wrench Set | Various sizes to fit different bolts and nuts. |

| Screwdriver Set | Includes flat and Phillips heads for various screws. |

| Oil and Lubricants | Essential for reducing friction and wear. |

Execution Steps

After preparation, follow these systematic steps to resolve issues:

- Assess the situation to identify the problem area.

- Carefully disassemble components as needed.

- Inspect each part for signs of damage or wear.

- Replace or repair components based on assessment.

- Reassemble everything in reverse order, ensuring all fasteners are secure.

By adhering to this structured process, one can effectively address maintenance needs and enhance performance.

Engine Troubleshooting Tips

Identifying and resolving issues within a power unit can greatly enhance performance and longevity. This section provides valuable insights to help diagnose common problems and implement effective solutions, ensuring optimal operation.

Start by checking for any unusual noises. Knocking or rattling sounds may indicate loose components or insufficient lubrication. If you notice smoke emanating from the exhaust, it could signal a problem with the fuel mixture or internal wear.

Next, monitor the fuel system. Ensure that the fuel is fresh and that the lines are clear of obstructions. If the engine fails to start, examine the spark plug for signs of damage or wear, as this is crucial for ignition. A clean, properly gapped spark plug can make a significant difference in performance.

Additionally, check the cooling system. An overheating engine can lead to severe damage. Verify that the cooling components are functioning correctly and that there are no leaks.

Lastly, keep an eye on performance changes. A sudden drop in power or responsiveness may indicate deeper issues that require immediate attention. Regular maintenance and careful observation can prevent minor problems from escalating into major repairs.

Maintaining the Suspension System

Proper upkeep of the suspension system is crucial for ensuring optimal performance and comfort while riding. Regular attention to this component helps in maintaining stability, enhancing control, and prolonging the lifespan of the vehicle. Understanding the key aspects of suspension care will enable you to keep your ride smooth and responsive.

Inspecting Components

Regular inspections of the suspension components, such as forks and shocks, are essential. Look for signs of wear, leakage, or damage. Identifying issues early can prevent more serious problems down the line. Ensure that all fasteners are tightened to the manufacturer’s specifications, as loose components can lead to performance issues.

Cleaning and Lubrication

Keeping the suspension parts clean is vital. Use appropriate cleaners to remove dirt and debris that can cause wear. After cleaning, apply suitable lubricants to the moving parts to ensure smooth operation. Regular lubrication helps to minimize friction and wear, enhancing the overall performance of the system.

Electrical System Diagnostics

This section focuses on the analysis and troubleshooting of the electrical components within the vehicle. Effective diagnosis is essential to ensure the optimal functioning of various systems that rely on electrical energy, enhancing both performance and safety.

Begin by inspecting the battery and connections for signs of corrosion or damage. A multimeter can be used to check voltage levels, ensuring that the battery provides adequate power. Pay attention to wiring harnesses for any wear or disconnections, which may lead to faults in electrical flow.

Next, assess the performance of essential electrical units such as the ignition system and sensors. Verify that all components are operational and that signals are transmitted correctly. If issues arise, consult circuit diagrams to identify potential problem areas and trace wiring pathways effectively.

Finally, document any anomalies and repairs made during the diagnostic process. This practice not only aids in current troubleshooting but also serves as a valuable reference for future maintenance activities.

Brake System Inspection Guide

This section focuses on ensuring the efficiency and safety of the braking apparatus in your vehicle. Regular evaluation of this system is crucial for maintaining optimal performance and preventing potential hazards during operation.

Visual Examination

Begin with a thorough visual assessment of the components. Check for any signs of wear, damage, or corrosion on the brake pads, rotors, and lines. Identifying issues early can help prevent more significant problems down the line.

Functional Testing

Next, conduct a functional test to gauge the responsiveness of the braking system. Engage the brakes and observe their performance under various conditions. If you notice any irregularities, such as unusual noises or diminished stopping power, it is imperative to address these concerns promptly. Safety should always be the priority.

Preventive Maintenance Practices

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. By implementing a series of proactive measures, you can mitigate potential issues before they escalate, thereby enhancing reliability and safety.

- Check fluid levels frequently to ensure proper operation.

- Inspect tires for wear and proper inflation to maintain traction and stability.

- Examine the braking system regularly for responsiveness and wear.

- Clean air filters to promote efficient engine performance.

- Lubricate moving parts to prevent friction and wear.

Incorporating these practices into your routine will not only extend the life of your vehicle but also improve its overall functionality. Developing a consistent maintenance schedule can help you stay ahead of potential repairs and enhance your riding experience.

Finding Replacement Parts Easily

Locating suitable components for your machine can often feel daunting, but with the right approach, it becomes manageable. Understanding the various sources and methods available can significantly simplify the process of acquiring necessary items.

One effective strategy is to explore reputable online marketplaces, where a wide array of options can be found. These platforms often offer filters to refine searches, making it easier to find exactly what you need. Additionally, connecting with local dealers can provide valuable insights and access to genuine parts tailored for your specific model.

Another avenue to consider is engaging with online communities and forums dedicated to enthusiasts of similar vehicles. These groups can share experiences, recommendations, and even links to trusted suppliers. Utilizing social media platforms to ask for advice can also yield beneficial results.

In summary, by leveraging various resources and connecting with knowledgeable individuals, finding appropriate replacements can become a straightforward task. Always prioritize quality and compatibility to ensure optimal performance of your equipment.