Comprehensive Guide to 5.9 Cummins Repair

Maintaining the efficiency and performance of your vehicle’s power unit is crucial for longevity and reliability. This section delves into the essential practices and insights needed to ensure your engine runs smoothly. By following detailed instructions and best practices, you can enhance the durability of your machine.

Understanding the various components and their functions is vital for anyone looking to perform maintenance tasks. Each part plays a significant role in the overall operation, and knowing how to address potential issues can save time and resources. This guide offers a wealth of information designed to equip you with the knowledge needed for effective upkeep.

Moreover, regular inspections and timely interventions can prevent minor concerns from escalating into major problems. By staying proactive, you can not only maintain performance but also improve fuel efficiency and reduce emissions. This resource serves as a valuable tool for both novice and experienced individuals aiming to optimize engine performance.

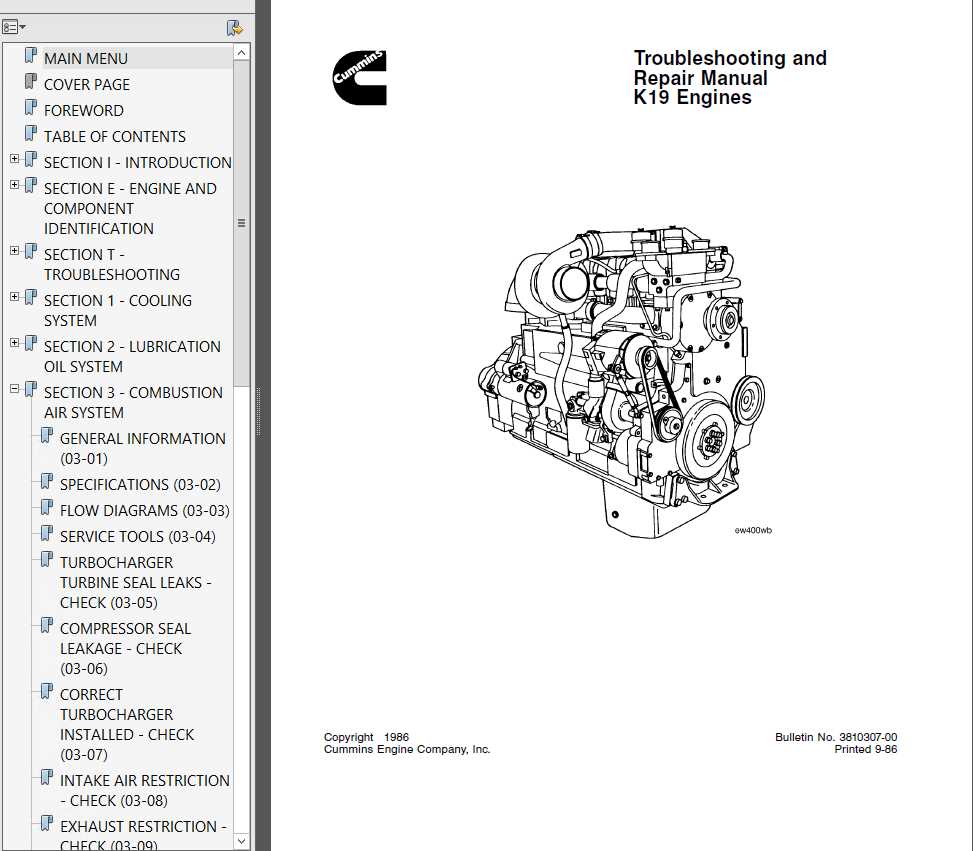

When facing issues with a high-performance engine, systematic diagnosis is essential for effective resolution. Understanding common symptoms and employing a structured approach can lead to successful troubleshooting.

Common Symptoms to Observe

- Unusual noises during operation

- Excessive smoke from the exhaust

- Inconsistent power delivery

- Overheating or temperature fluctuations

Systematic Approach to Diagnosis

- Start with a visual inspection to identify any obvious leaks or damage.

- Check fluid levels and quality to ensure proper operation.

- Use diagnostic tools to read any fault codes from the system.

- Test key components such as fuel injectors and filters for functionality.

- Review maintenance records to determine if any scheduled services are overdue.

Importance of Regular Servicing

Routine maintenance is essential for ensuring the longevity and optimal performance of any machinery. Neglecting this crucial aspect can lead to unexpected breakdowns and costly repairs. By adhering to a consistent service schedule, owners can prevent minor issues from escalating into major problems, ultimately saving time and money.

Benefits of Preventive Care

Engaging in regular upkeep offers numerous advantages. First, it enhances the efficiency of the equipment, allowing it to operate at peak performance. Additionally, it significantly reduces the risk of sudden failures, providing peace of mind to the user. With proper attention, the lifespan of the machinery can be extended, ensuring reliable operation over the years.

Cost-Effectiveness Over Time

Investing in regular maintenance can be more economical in the long run. While some may view servicing as an added expense, the reality is that it often prevents more extensive and expensive repairs down the line. Routine checks and adjustments can identify wear and tear early, allowing for timely interventions and minimizing the likelihood of significant breakdowns.

Upgrading Parts for Enhanced Performance

Improving the capabilities of your vehicle can significantly enhance its overall efficiency and power. By selecting and replacing specific components, enthusiasts can achieve superior functionality and responsiveness. This section explores various enhancements that can be made to boost performance.

Engine Components: Upgrading essential parts such as the turbocharger and intercooler can lead to increased airflow and better thermal efficiency. These modifications allow the engine to operate at higher levels of performance, resulting in improved acceleration and towing capacity.

Fuel System Enhancements: Investing in a high-performance fuel pump and injectors can optimize fuel delivery, ensuring that the engine receives the correct mixture for combustion. This adjustment can lead to more efficient fuel consumption and enhanced power output.

Exhaust System Upgrades: A free-flowing exhaust system can minimize back pressure, allowing exhaust gases to exit more efficiently. This change not only improves performance but can also produce a more aggressive sound that many enthusiasts appreciate.

Tuning Solutions: Finally, utilizing an advanced tuning module can fine-tune the engine’s parameters, maximizing performance gains from any modifications made. Custom tuning can tailor the engine’s response to suit individual driving styles and preferences.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for preventing accidents and injuries. Proper protocols should always be followed to create a secure working environment. This section outlines essential guidelines that should be adhered to while performing maintenance activities.

Personal Protective Equipment

- Always wear appropriate protective gear, including gloves, goggles, and steel-toed boots.

- Utilize ear protection when working in noisy environments to prevent hearing damage.

- Consider wearing a mask to protect against dust and harmful fumes.

Work Area Safety

- Keep the workspace clean and free from clutter to minimize hazards.

- Ensure proper ventilation, especially when working with chemicals or fuel.

- Store tools and equipment securely to prevent tripping or falling.

Essential Fluid Types and Specifications

Understanding the various types of fluids used in engine systems is crucial for maintaining optimal performance and longevity. Each fluid serves a specific purpose, contributing to the overall efficiency and reliability of the engine. Knowledge of their characteristics and specifications is vital for ensuring proper functionality.

Types of Fluids

- Engine Oil: Vital for lubrication, reducing friction between moving parts, and protecting against wear.

- Coolant: Regulates engine temperature, preventing overheating and ensuring efficient thermal management.

- Transmission Fluid: Essential for smooth shifting and protecting transmission components from wear.

- Fuel: Provides energy for combustion, with varying formulations affecting performance and efficiency.

- Brake Fluid: Critical for effective braking performance, ensuring the hydraulic system functions correctly.

Specifications to Consider

- Viscosity: Important for ensuring proper flow and lubrication at varying temperatures.

- Flash Point: Indicates the temperature at which the fluid can ignite, essential for safety.

- Corrosion Resistance: Essential for protecting internal components from deterioration.

- Compatibility: Ensures that the fluid is suitable for use with other materials and fluids present in the system.

- Performance Additives: Enhance specific properties of the fluid, such as detergency or anti-wear characteristics.

Recognizing Engine Symptoms Early

Identifying early signs of engine issues is crucial for maintaining optimal performance and longevity. Timely detection can prevent minor problems from escalating into major repairs, saving both time and resources. Observing unusual behaviors and sounds can provide valuable insights into the condition of your power unit.

Common indicators include strange noises, vibrations, and changes in fuel efficiency. For instance, a sudden drop in power may suggest underlying mechanical issues. Additionally, monitoring dashboard warning lights can offer critical alerts about potential malfunctions.

Paying attention to smoke color is equally important; excessive black, blue, or white smoke can indicate various faults that require immediate attention. Regular maintenance checks and being proactive in assessing your engine’s health can significantly enhance its performance and reliability.

Best Practices for Engine Overhaul

Overhauling an engine is a crucial task that demands careful attention and precision. Following established guidelines can enhance performance and longevity while minimizing the risk of future issues. Proper planning and execution are essential for achieving optimal results.

Preparation and Planning

Before commencing any work, it is vital to gather all necessary tools and components. A detailed checklist can help ensure that no critical parts are overlooked. Additionally, establishing a clean and organized workspace will facilitate a more efficient overhaul process.

Attention to Detail

During the disassembly and reassembly phases, meticulous attention to detail is paramount. Labeling parts and documenting their positions can prevent confusion. Furthermore, using high-quality replacement components will significantly contribute to the reliability and performance of the engine.

Resources for Additional Information

This section aims to provide valuable sources for those seeking further insights and guidance related to maintenance and troubleshooting of specific diesel engines. Accessing reliable information can significantly enhance understanding and improve repair skills.

Online Forums and Communities

Participating in online forums dedicated to automotive repairs can be beneficial. These platforms allow users to share experiences, ask questions, and receive advice from seasoned mechanics and enthusiasts. Engaging with a community can provide practical tips and solutions to common issues.

Technical Publications and Guides

Numerous technical publications offer in-depth knowledge on engine specifications, diagnostics, and maintenance procedures. Utilizing these resources ensures access to accurate and detailed information, which can assist in performing effective repairs and maintenance.

Customer Experiences and Testimonials

This section highlights the diverse experiences and feedback from users who have engaged with maintenance resources for their engines. These insights provide valuable perspectives on performance, reliability, and overall satisfaction.

Many users have shared their stories regarding the efficiency of the guidance available, emphasizing how it has contributed to enhancing the functionality of their vehicles. Here are some common themes from their testimonials:

- Improved Performance: Customers have reported noticeable enhancements in engine responsiveness and fuel efficiency after applying suggested practices.

- Ease of Use: Numerous testimonials highlight the straightforward nature of the information, making it accessible even for those with limited mechanical experience.

- Cost Savings: Many individuals noted significant reductions in maintenance costs, as they were able to perform tasks themselves instead of relying solely on professional services.

- Reliability: Users appreciate the increased reliability of their engines, attributing this to the effective strategies they implemented based on shared experiences.

Overall, the feedback underscores a strong sense of community among users who value shared knowledge and practical advice in optimizing their engine’s performance.