Turbo Diesel 6.5 Repair Guide

This section delves into the essential aspects of maintaining and servicing a specific type of high-performance engine. Understanding its components and functions is crucial for anyone looking to enhance the longevity and efficiency of their vehicle’s powertrain.

Throughout this guide, we will explore various techniques and troubleshooting tips aimed at addressing common issues that may arise. By familiarizing yourself with these processes, you can ensure optimal performance and prevent potential breakdowns.

Whether you are a seasoned mechanic or an enthusiastic DIYer, the knowledge contained here will empower you to tackle maintenance tasks confidently. Let’s embark on this journey to mastering engine care and achieving peak operational efficiency.

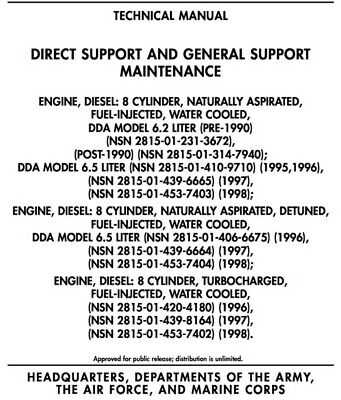

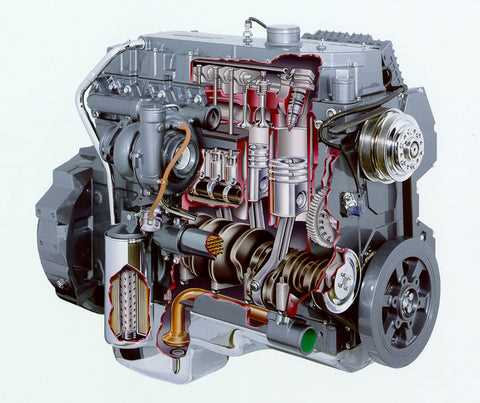

This section aims to provide an overview of specific power units known for their durability and performance. Understanding the intricacies of these engines is essential for effective maintenance and troubleshooting. A comprehensive exploration of their components, functionalities, and common issues will empower users to better manage their systems.

The following table outlines key aspects to consider when delving into the specifics of these power units:

| Aspect | Description |

|---|---|

| Engine Components | Detailed breakdown of essential parts and their roles in operation. |

| Performance Features | Analysis of strengths and capabilities of the units under various conditions. |

| Common Issues | Identification of frequent problems and their potential solutions. |

| Maintenance Tips | Practical advice for ensuring longevity and reliability of the engine. |

Common Issues in Turbo Diesel Systems

Many individuals encounter various challenges when dealing with forced induction engine systems. Understanding these typical problems is crucial for effective maintenance and optimization. This section highlights some prevalent concerns and their implications on performance and reliability.

Boost Pressure Loss

A frequent issue is a reduction in boost pressure, which can lead to decreased engine power. This often results from leaks in the intake system or malfunctions in the pressure control mechanisms. Regular inspections can help identify and rectify these leaks before they impact overall performance.

Excessive Smoke Emission

Another common problem is the presence of excessive smoke from the exhaust. This may indicate incomplete combustion, often due to fuel system issues or air intake restrictions. Addressing these underlying causes is essential to maintain engine efficiency and compliance with emission standards.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan of any engine. By following a few straightforward guidelines, you can significantly enhance performance and reliability, while minimizing potential issues that could arise over time.

Regular Inspections

Conducting routine checks is crucial. Look for signs of wear, leaks, or any unusual noises that may indicate underlying problems. Keeping an eye on fluid levels and overall condition can prevent more severe issues down the line.

Quality Fluids and Filters

Utilizing high-quality lubricants and replacement filters is vital. This practice not only improves engine efficiency but also protects its internal components from premature wear.

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 3,000 – 5,000 miles | Use recommended oil grade |

| Filter Replacement | Every oil change | Choose high-quality filters |

| Fluid Checks | Monthly | Check coolant, brake, and transmission fluids |

| Belt and Hose Inspection | Every 6 months | Replace any worn components |

Tools Required for Effective Repairs

Having the right equipment is essential for performing maintenance tasks efficiently. A well-stocked toolkit ensures that you can address various issues that may arise during the servicing process. Proper tools not only facilitate smoother operations but also help in achieving high-quality outcomes.

Basic hand tools such as wrenches, sockets, and screwdrivers are fundamental for most tasks. Additionally, specialized instruments like torque wrenches and compression gauges can significantly enhance your ability to diagnose and resolve problems accurately. It’s also wise to include safety gear to protect yourself while working.

Investing in high-quality tools will provide reliability and longevity, making your work more enjoyable and effective. Regularly organizing and maintaining your toolkit ensures that everything is easily accessible when needed, allowing for a more productive workflow.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues within the engine system. By following a systematic method, you can identify problems efficiently and implement appropriate solutions.

1. Initial Inspection: Begin with a thorough visual assessment of the engine. Look for any signs of leaks, unusual noises, or irregularities in component connections. This step is crucial to gather initial clues about potential issues.

2. Check Fluid Levels: Ensure that all essential fluids, including oil and coolant, are at the recommended levels. Low fluid levels can lead to performance problems and may indicate underlying issues.

3. Monitor Performance: Start the engine and observe its operation. Pay attention to any strange sounds, vibrations, or warning lights. Document these observations, as they can provide valuable insights into the malfunction.

4. Conduct Diagnostic Tests: Utilize diagnostic tools to run tests on the engine’s electronic systems. Error codes retrieved from the system can help pinpoint specific areas of concern that require further investigation.

5. Examine Key Components: Inspect critical parts such as the fuel system, air intake, and exhaust components. Look for clogs, damage, or wear that could affect performance. Addressing these areas may resolve the issue.

6. Perform a Compression Test: This test assesses the engine’s internal health. Low compression readings can indicate problems such as worn piston rings or valve issues. Ensure the engine is in good condition for optimal performance.

7. Review Repair History: If previous work has been done, review the records to identify any recurring issues or recent repairs. This information can provide context and guide your troubleshooting process.

By following these steps, you can systematically diagnose and address engine issues, ensuring reliable performance and longevity.

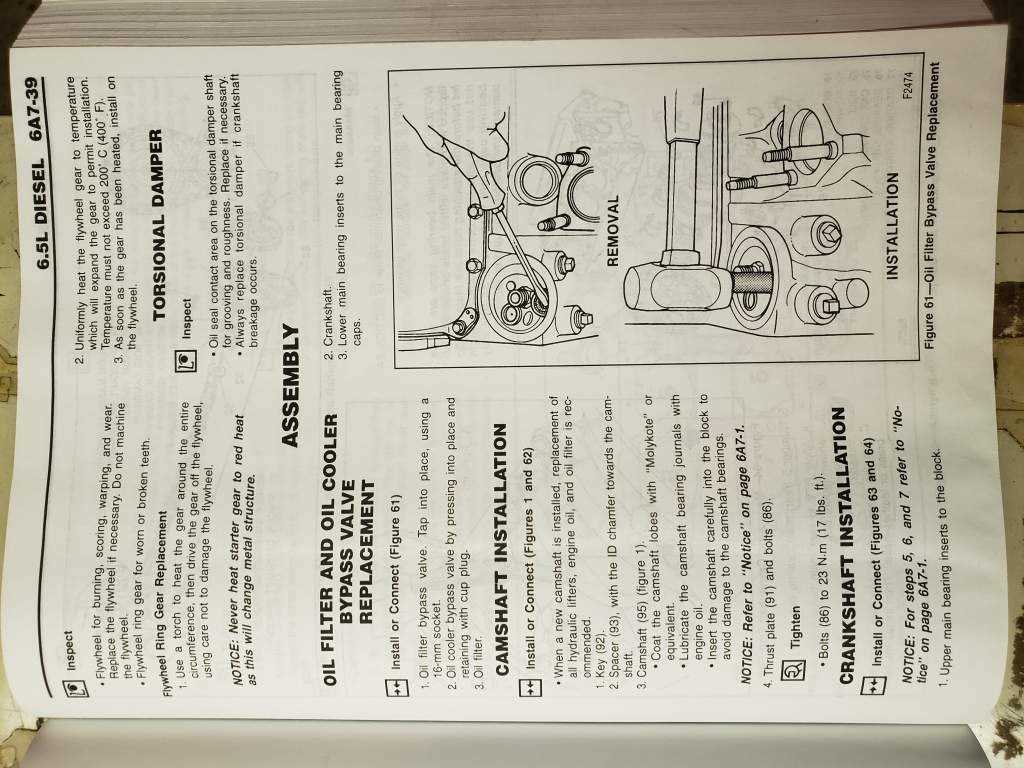

Replacing Key Engine Components

Maintaining optimal performance and longevity of an engine often requires the replacement of essential parts. This process involves careful consideration and precision to ensure each component functions harmoniously within the overall system. Understanding the importance of these elements is crucial for effective management and enhancement of engine efficiency.

When undertaking this task, it is vital to begin with a thorough assessment of the engine’s current condition. Identifying worn or damaged parts allows for informed decision-making regarding necessary replacements. Common components that may require attention include the piston assemblies, valves, and gaskets. Each of these plays a pivotal role in maintaining proper compression and preventing leaks, which can lead to performance issues.

Before proceeding with the replacement, ensure you have the appropriate tools and new components on hand. Follow the manufacturer’s guidelines for disassembly and reassembly, as this will help avoid potential mishaps. Take care to torque bolts to the specified settings and replace seals and gaskets to prevent future leaks.

After the installation of new parts, conducting a comprehensive inspection and test run is essential. This helps verify that the engine is operating smoothly and efficiently. Regular monitoring of these components post-replacement can also aid in early detection of any future issues, ensuring the engine remains in peak condition.

Performance Upgrades for Turbo Diesel

Enhancing the efficiency and power of your engine can significantly improve overall driving experience. Various modifications can be made to achieve higher output and better responsiveness, leading to a more dynamic performance.

- Improved Air Intake Systems: Upgrading to a high-flow air intake can increase the volume of air entering the engine, promoting better combustion and power generation.

- Enhanced Exhaust Systems: A performance exhaust system reduces back pressure, allowing gases to exit more freely and improving engine efficiency.

- ECU Tuning: Reprogramming the engine control unit can optimize fuel delivery and ignition timing, resulting in noticeable performance gains.

- High-Performance Fuel Injectors: Upgrading to injectors that deliver fuel at higher rates can improve power and torque, especially under load.

- Intercooler Upgrades: Installing a larger or more efficient intercooler helps reduce intake air temperatures, enhancing performance and reliability.

These upgrades not only improve the engine’s output but also contribute to better fuel efficiency and overall drivability. When considering modifications, it’s crucial to ensure compatibility with existing components and to follow proper installation procedures.

Fuel System Optimization Techniques

Enhancing the efficiency of a vehicle’s fuel system is crucial for improving overall performance and reducing emissions. Implementing various strategies can lead to better fuel atomization, increased combustion efficiency, and optimal power output.

Key Strategies for Improvement

- Regular Maintenance: Keeping the fuel system clean through routine maintenance ensures optimal performance.

- High-Quality Fuel: Using premium fuel can help maintain the integrity of the fuel injectors and combustion chamber.

- Proper Filtration: Installing quality filters prevents contaminants from entering the system, promoting smoother operation.

Advanced Techniques

- Reprogramming the Engine Control Unit: Adjusting parameters can enhance fuel delivery and timing for improved efficiency.

- Upgrading Fuel Injectors: Switching to high-performance injectors can provide better atomization and response.

- Optimizing Fuel Pressure: Ensuring the correct pressure level maintains efficient fuel flow and combustion.

By adopting these optimization techniques, vehicle owners can significantly improve the performance and longevity of their fuel systems.

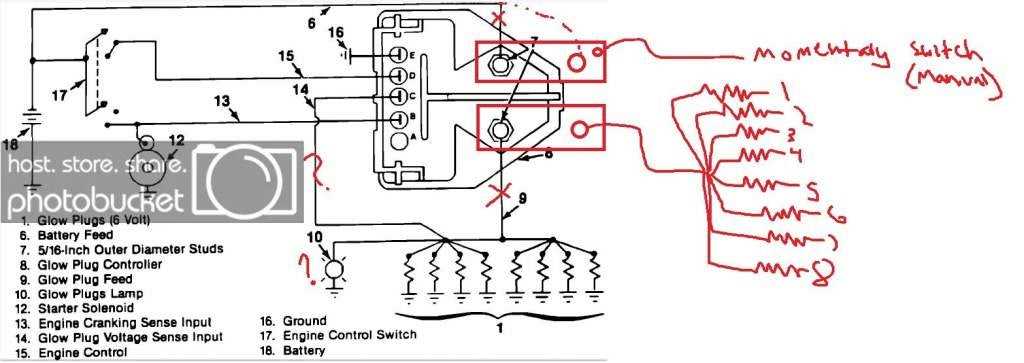

Electrical Systems and Diagnostics

This section delves into the intricacies of electrical components and their functionality within the vehicle’s framework. Understanding these systems is essential for effective troubleshooting and ensuring optimal performance.

Key Components

The electrical system encompasses various elements, each playing a critical role in the overall operation. From the battery that supplies power to the ignition system that initiates engine operation, each component must be functioning correctly to prevent issues.

Diagnostics Procedures

To diagnose electrical problems, a systematic approach is vital. This involves utilizing specialized tools to measure voltage, current, and resistance across different components. Here is a summary of common diagnostic tools:

| Tool | Purpose |

|---|---|

| Multimeter | Measures voltage, current, and resistance. |

| Oscilloscope | Analyzes waveforms in electrical signals. |

| Battery Tester | Evaluates battery health and charge level. |

| Scan Tool | Reads diagnostic trouble codes from the vehicle’s computer. |

Cooling System Maintenance Essentials

Proper upkeep of the cooling mechanism is vital for the longevity and efficiency of any engine. Regular attention ensures optimal performance and helps prevent overheating, which can lead to severe damage. Understanding the key components and best practices for maintenance is crucial for any vehicle owner.

Here are some essential maintenance tips to keep in mind:

- Regular Fluid Checks: Monitor coolant levels frequently to ensure they are within the recommended range. Low levels can lead to inadequate cooling.

- Flush the System: Periodically flushing the cooling system removes contaminants and old fluid, promoting better heat transfer.

- Inspect Hoses and Clamps: Examine all hoses for signs of wear or leaks. Replace any that are cracked or damaged, and ensure clamps are secure.

- Check the Radiator: Ensure the radiator is free of debris and that the fins are not bent. A clean radiator enhances cooling efficiency.

- Monitor Temperature Gauges: Keep an eye on temperature readings while driving. If they rise unexpectedly, investigate potential issues immediately.

By adhering to these maintenance practices, you can help ensure that the cooling system functions effectively, ultimately prolonging the lifespan of your engine.

Best Practices for Oil Changes

Regular maintenance of the lubricant system is crucial for optimal engine performance and longevity. Implementing effective strategies during oil changes can help ensure that your engine remains in peak condition, minimizing wear and tear and enhancing efficiency.

Choosing the Right Lubricant

Selecting the appropriate oil type for your vehicle is fundamental. Refer to the manufacturer’s recommendations for viscosity and specifications to ensure compatibility. Using high-quality products can contribute to better engine protection and performance.

Proper Change Intervals

Adhering to recommended oil change intervals is vital. Factors such as driving conditions, climate, and vehicle usage can influence how often oil should be replaced. Regular checks can help in determining the right timing, preventing issues related to degraded lubricant.