Aisin 30 43le Repair Guide

Understanding the intricacies of automotive transmission systems is essential for ensuring optimal vehicle performance. This section provides a comprehensive overview of common issues and maintenance practices associated with a specific type of transmission commonly found in various vehicles. By gaining insight into the inner workings of this mechanism, owners can better appreciate its role in the overall functionality of their automobiles.

Effective upkeep not only enhances the lifespan of the transmission but also contributes to a smoother driving experience. Various symptoms can indicate potential problems, and being aware of these signs is crucial for timely intervention. Proper knowledge empowers vehicle owners to make informed decisions regarding maintenance, ultimately saving time and costs associated with major repairs.

In this guide, you will discover essential tips and recommendations aimed at preserving the functionality of the transmission system. Whether you are a seasoned enthusiast or a newcomer to automotive care, understanding these fundamentals can lead to a more enjoyable and reliable driving experience.

Aisin 30 43LE Repair Manual

This section provides essential guidance for addressing issues related to a specific transmission model. It is designed to assist users in understanding maintenance, troubleshooting, and overall care for optimal performance.

Key components to focus on include:

- Fluid levels and quality

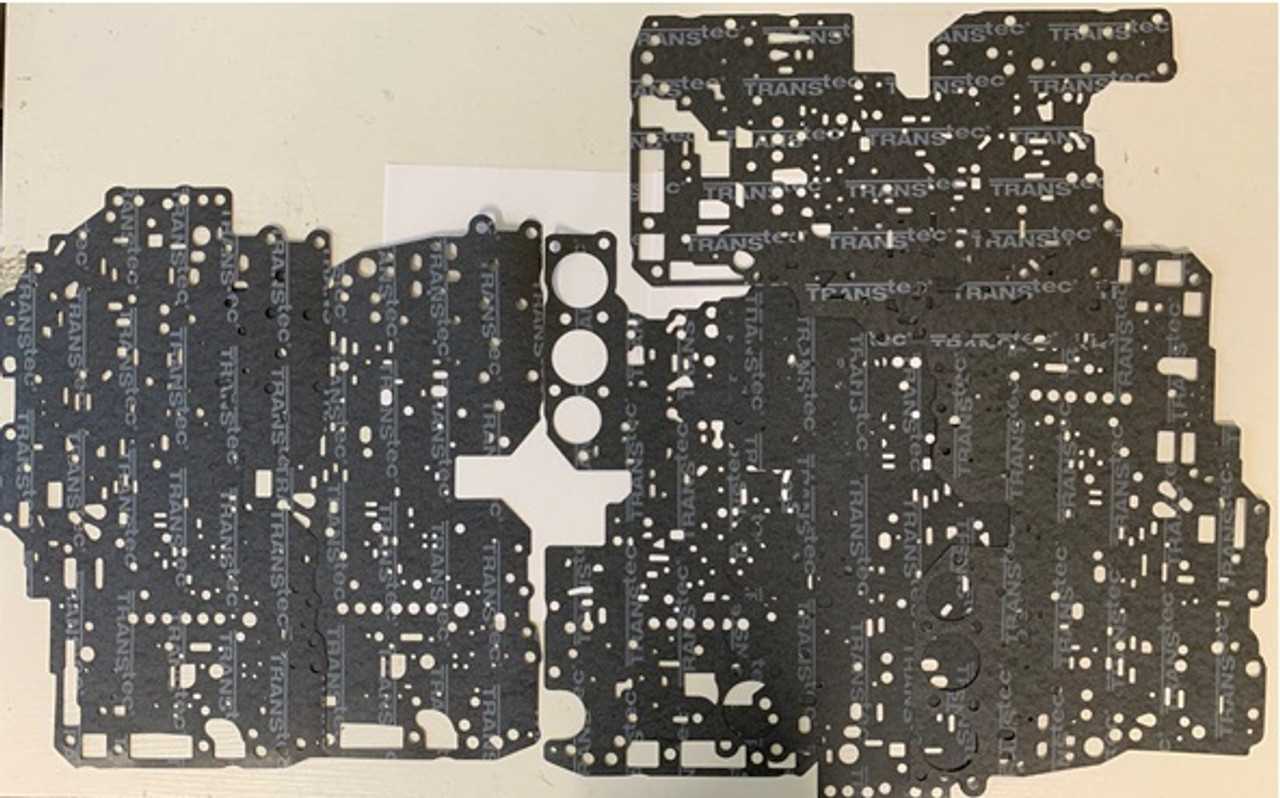

- Seals and gaskets condition

- Transmission mounts

- Electronic control systems

Regular inspections can prevent major complications and extend the lifespan of the unit. It’s crucial to follow recommended practices to ensure functionality and reliability.

For those engaging in more detailed work, the following steps are recommended:

- Check for leaks around seals and connections.

- Monitor the behavior of shifting mechanisms.

- Inspect wiring and electronic components for wear.

- Replace any worn parts promptly to maintain efficiency.

Maintaining this particular type of transmission requires attention to detail and adherence to best practices to achieve lasting results.

Understanding Aisin 30 43LE Transmission

The transmission system is a crucial component of any vehicle, responsible for transferring power from the engine to the wheels. It plays a vital role in ensuring smooth acceleration and optimal performance. This section delves into the intricacies of a specific automatic gearbox, highlighting its design, functionality, and significance in modern vehicles.

This type of transmission is engineered to provide seamless gear shifts, enhancing driving comfort and efficiency. With its advanced features, it adapts to varying driving conditions, contributing to overall vehicle stability. Understanding its operational mechanisms can aid in diagnosing potential issues and ensuring longevity.

Key components of this gearbox include hydraulic systems, control modules, and various sensors that work together to manage shifting processes. These elements are designed to respond to the driver’s inputs and vehicle dynamics, promoting responsive handling. Regular maintenance of these systems is essential to avoid performance degradation and maintain reliability.

Overall, familiarity with the workings of this transmission can empower vehicle owners and technicians alike, facilitating informed decisions regarding upkeep and repair. By grasping its fundamentals, one can appreciate the technological advancements that have shaped contemporary automotive engineering.

Common Issues with Aisin 30 43LE

Various complications may arise with this particular automatic transmission model, often leading to performance concerns. Understanding these common problems can assist owners in diagnosing and addressing issues efficiently.

Fluid Leaks

One prevalent issue involves fluid leaks, which can occur due to worn seals or gaskets. Such leaks not only reduce the effectiveness of the system but may also cause overheating. Regular inspections are essential to identify and rectify these leaks promptly.

Shifting Difficulties

Another common concern is difficulties in shifting gears. This may be attributed to low fluid levels, a malfunctioning solenoid, or other internal components. Addressing these symptoms early can prevent further damage and enhance overall driving experience.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial when tackling any mechanical project. A well-equipped toolkit not only enhances efficiency but also ensures precision in every task. Whether you’re performing a minor adjustment or a significant overhaul, the following items will prove invaluable in your endeavors.

Basic Hand Tools

Start with a set of quality hand tools. Wrenches, screwdrivers, and pliers are fundamental for loosening and tightening various components. A reliable socket set can greatly expedite your work, allowing you to reach tight spaces with ease. Don’t forget to include a torque wrench to ensure proper fastening of bolts.

Diagnostic Equipment

In addition to hand tools, having access to diagnostic gear is essential. A multimeter can help you check electrical systems, while a code reader is indispensable for identifying issues within electronic controls. Investing in these devices will not only save you time but also enhance your understanding of the system you are working on.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to taking apart a specific transmission system. Following a structured method ensures that each component is carefully removed, facilitating effective inspection and reassembly.

1. Preparation

Before starting, gather all necessary tools, including wrenches, screwdrivers, and safety equipment. Ensure the workspace is clean and organized to prevent the loss of small parts.

2. Drain Fluids

Begin by draining all fluids to avoid spills. Use a suitable container to collect the transmission fluid and properly dispose of it afterward.

3. Remove the Exterior Components

Start with the removal of any external elements such as brackets, covers, and electrical connections. Carefully document each step, as this will aid in reassembly.

4. Detach the Housing

Once external parts are removed, unfasten the bolts securing the housing. Gently pry apart the housing, ensuring not to damage any internal components.

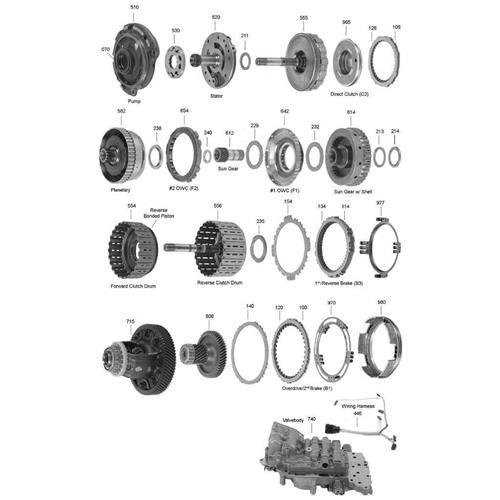

5. Extract Internal Parts

Begin to remove internal elements methodically. Start with the gears and shafts, taking care to note their arrangement. This step is crucial for maintaining the original configuration during reassembly.

6. Inspect and Clean

With all components disassembled, inspect each part for wear or damage. Clean all pieces thoroughly to remove any residue before reassembly.

7. Document Everything

Throughout the disassembly, take notes and photos. This documentation will be invaluable for ensuring accurate reassembly and troubleshooting any issues that may arise.

Inspecting Components for Damage

Thorough examination of vehicle parts is crucial for ensuring optimal functionality and safety. Identifying any wear or degradation early can prevent more significant issues down the line. This section outlines the steps to effectively assess various components, focusing on common signs of damage and how to address them.

Begin by gathering the necessary tools for inspection, such as a flashlight, magnifying glass, and measuring tools. It is also important to have a clean workspace to clearly visualize each part.

| Component | Common Damage Signs | Inspection Method |

|---|---|---|

| Gaskets | Cracks, tears, or deformation | Visual check for integrity |

| Seals | Leaking fluid, hardening, or brittleness | Feel and visual inspection |

| Bearings | Excessive play, noise, or discoloration | Manual rotation and auditory examination |

| Housings | Cracks, corrosion, or distortion | Visual and tactile assessment |

After completing the inspections, document any findings and determine the appropriate next steps, whether that involves replacement, repair, or further monitoring. Regularly scheduled inspections can significantly enhance the longevity and performance of the system.

Replacing Worn-Out Parts

Maintaining the longevity and performance of your vehicle’s transmission requires timely replacement of components that have deteriorated over time. Addressing these worn-out parts not only enhances efficiency but also prevents further damage to the system.

Identifying which elements need to be swapped out is crucial. Regular inspection can reveal signs of wear, such as:

- Unusual noises during operation

- Slipping gears

- Delayed engagement

- Fluid leaks

Once the problematic parts are pinpointed, follow these steps for replacement:

- Gather the necessary tools and replacement components.

- Safely lift and secure the vehicle to access the transmission.

- Carefully remove the worn parts, noting their orientation for reassembly.

- Install the new components, ensuring a snug fit and proper alignment.

- Reassemble any removed parts and lower the vehicle.

- Conduct a thorough test drive to verify functionality.

By proactively replacing worn components, you can significantly extend the life of your vehicle’s transmission and enhance overall performance.

Reassembling the Transmission

The process of putting together a complex mechanical unit requires precision and attention to detail. Each component must be meticulously positioned to ensure optimal functionality. Understanding the sequence and techniques involved is crucial for achieving a successful assembly.

Step-by-Step Assembly Process

Begin by organizing all parts in a clean workspace. Refer to diagrams or notes taken during disassembly to guide the process. Start with the main housing, carefully aligning gears and bearings. Use appropriate lubricants on moving parts to minimize wear and enhance performance. Ensure that all seals are in place to prevent leaks.

Final Checks and Testing

After assembly, double-check all connections and fasteners to confirm they are secure. Conduct a visual inspection for any misplaced components or potential issues. Once verified, proceed with a bench test to assess the operation before installation. This preliminary testing can save time and resources by identifying any problems early on.

Remember: Proper reassembly not only prolongs the lifespan of the unit but also ensures the reliability of the entire system.

Fluid Types and Maintenance Tips

Ensuring the longevity and performance of your transmission requires attention to the type of fluids used and regular maintenance practices. Selecting the appropriate fluid and adhering to recommended upkeep schedules can greatly enhance the efficiency and reliability of your vehicle’s transmission system.

Here are some key fluid types commonly used:

- Automatic Transmission Fluid (ATF): This fluid is crucial for the smooth operation of automatic gear systems. It provides lubrication, cooling, and cleaning properties.

- Multi-Vehicle Fluid: Designed to work with a variety of makes and models, this fluid can be a versatile choice for those who own multiple vehicles.

- Dexron and Mercon: These are specific classifications of ATF, with each type tailored for different transmission systems. Always check compatibility with your vehicle.

To maintain optimal performance, consider the following maintenance tips:

- Regular Fluid Changes: Adhere to the manufacturer’s recommendations for fluid change intervals to prevent buildup of debris and ensure optimal function.

- Check Fluid Levels: Routinely inspect fluid levels, topping off as necessary to avoid operational issues.

- Monitor Fluid Condition: Look for signs of contamination or discoloration, which may indicate a need for replacement.

- Inspect Seals and Hoses: Regularly check for leaks or wear in seals and hoses, as these can lead to fluid loss and performance problems.

By utilizing the correct fluid types and following these maintenance strategies, you can significantly enhance the durability and efficiency of your vehicle’s transmission system.

Diagnostic Techniques for Troubleshooting

Effective problem-solving in automotive systems requires a systematic approach to identify and rectify issues. By employing a variety of diagnostic methods, technicians can pinpoint malfunctions and implement appropriate solutions. This section outlines essential techniques to enhance the troubleshooting process, ensuring accurate assessments and timely repairs.

1. Visual Inspection: Begin with a thorough examination of the components. Look for signs of wear, leaks, or physical damage. Pay attention to any irregularities that could indicate underlying problems.

2. Diagnostic Scanners: Utilizing electronic diagnostic tools can provide valuable insights into the system’s performance. These devices read fault codes, offering a starting point for further investigation. Understanding the codes can help in narrowing down potential issues.

3. Pressure Testing: Measuring fluid pressure at various points can reveal discrepancies in performance. By comparing readings against manufacturer specifications, technicians can identify areas that may require further examination.

4. Functional Testing: Assessing the operation of individual components under simulated conditions can highlight failures. This method helps in understanding whether a part is functioning correctly or if it needs replacement.

5. Systematic Approach: Adopting a step-by-step methodology ensures that no potential cause is overlooked. Documenting each step and result helps in building a comprehensive understanding of the issue.

By integrating these diagnostic techniques, professionals can effectively troubleshoot and resolve complexities within automotive systems, leading to enhanced performance and reliability.

Performance Enhancements for Aisin Transmissions

Improving the efficiency and responsiveness of automatic gear systems can significantly enhance vehicle performance. Upgrading components, recalibrating software, and implementing advanced technologies can lead to smoother shifts, faster acceleration, and better overall driving experience. This section delves into various strategies to elevate the capabilities of these complex systems.

Component Upgrades

Replacing factory parts with high-performance alternatives is one effective approach. Upgraded clutches and valves can provide better grip and quicker response times. Additionally, using lightweight materials for components can reduce inertia, leading to more efficient power transfer. Investing in a higher-quality torque converter can also enhance acceleration and improve overall efficiency.

Tuning and Calibration

Another essential aspect of performance enhancement lies in the tuning of the transmission’s control unit. Recalibrating the software can optimize shift points and improve responsiveness to driver inputs. Custom tuning can also adapt the system to specific driving conditions, ensuring that the vehicle performs at its best whether on the track or the road. Integrating aftermarket tuning solutions can unlock additional performance potential while maintaining reliability.

Safety Precautions During Repairs

When engaging in maintenance tasks, ensuring a secure environment is paramount. Adhering to specific safety guidelines not only protects the individual performing the work but also safeguards the surrounding equipment and components. Proper preparation and awareness can prevent accidents and enhance the overall effectiveness of the procedure.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, including gloves, goggles, and sturdy footwear to protect against hazards. |

| Work Area Organization | Maintain a clean and clutter-free workspace to reduce the risk of trips and falls during the task. |

| Proper Tools | Utilize the correct tools for each job, ensuring they are in good condition to prevent malfunctions. |

| Electrical Safety | Disconnect power sources before starting any work to prevent electric shocks or short circuits. |

| Understanding Manuals | Familiarize yourself with relevant documentation to comprehend the components and procedures involved. |

| Emergency Preparedness | Have a first aid kit on hand and know emergency contacts in case of accidents. |

By following these essential precautions, individuals can mitigate risks and ensure a smoother experience during their tasks. Awareness and careful planning play critical roles in promoting safety and efficiency in any maintenance endeavor.

Resources for Further Learning

Expanding your knowledge about transmission systems is essential for both enthusiasts and professionals in the automotive field. This section provides valuable references and materials to enhance your understanding of complex mechanisms, maintenance techniques, and troubleshooting strategies.

Books and Publications

Several comprehensive texts cover the intricacies of automotive transmissions. Consider these essential reads:

| Title | Author | Focus Area |

|---|---|---|

| Transmission Manual | John Doe | General Transmission Knowledge |

| Understanding Automatic Gearboxes | Jane Smith | Detailed Operation and Repair Techniques |

| Automotive Systems Explained | Mike Johnson | Comprehensive Overview of Vehicle Systems |

Online Resources

For those seeking dynamic content and real-time updates, numerous online platforms offer courses, videos, and forums. Here are a few to explore:

| Website | Type of Resource | Focus Area |

|---|---|---|

| Automotive Learning Hub | Courses | Fundamentals of Transmissions |

| YouTube Automotive Channel | Tutorial Videos | Repair Techniques and Tips |

| Car Enthusiast Forum | Community Discussions | Problem Solving and Advice |