Aquabot Turbo Repair Guide for Optimal Performance

Maintaining the efficiency and longevity of your aquatic maintenance device is crucial for optimal performance. This section aims to provide comprehensive insights into troubleshooting and enhancing the functionality of your pool cleaning equipment. By understanding the common issues and their resolutions, you can ensure a clean and inviting swimming environment.

In the following passages, you will discover detailed instructions and best practices tailored to address various challenges faced by users. Whether you’re experiencing reduced suction power or navigation difficulties, the information presented here will guide you through the necessary steps to restore your unit to its prime condition.

Equipped with knowledge and practical tips, you’ll be empowered to tackle any problem that arises. Understanding the mechanics and care requirements of your device not only enhances its performance but also extends its lifespan, ensuring countless enjoyable moments in your pool.

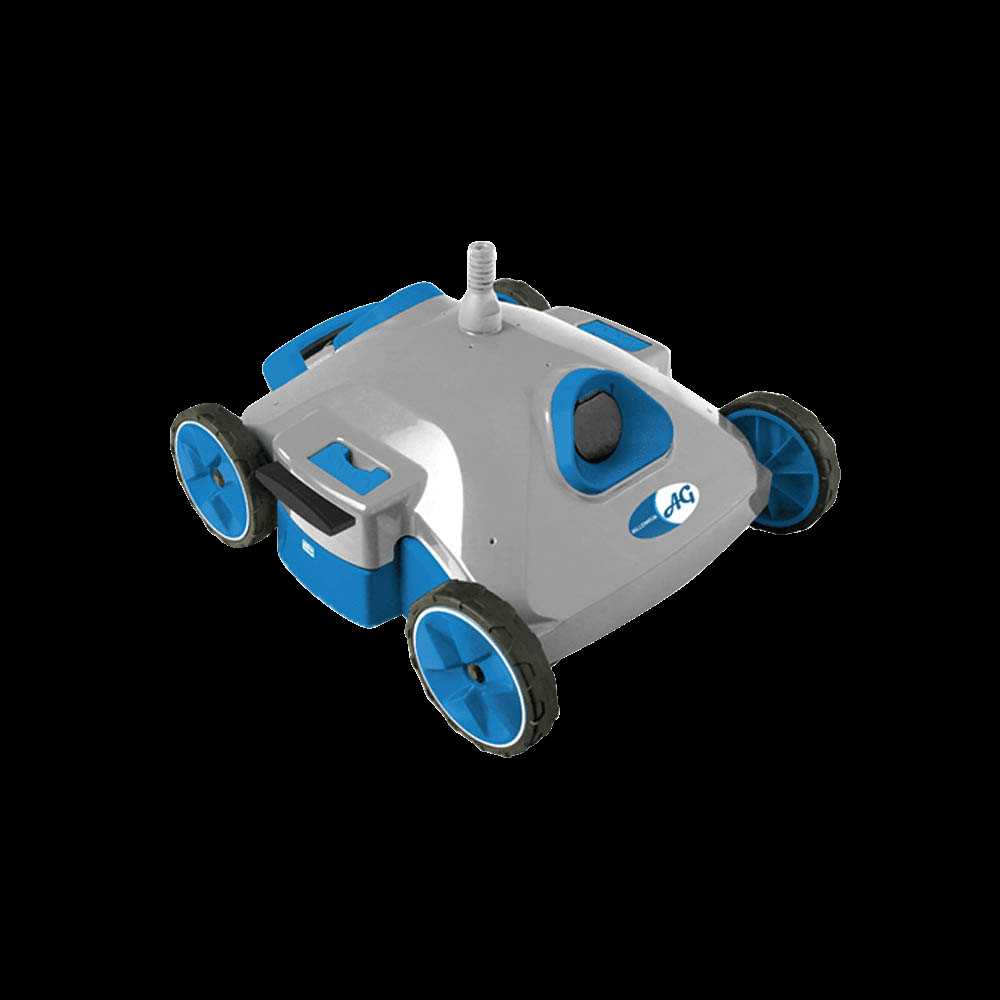

Aquabot Turbo Overview

This section provides a comprehensive insight into a popular robotic pool cleaner designed for optimal efficiency and ease of use. With its advanced technology and innovative features, it simplifies the task of maintaining a pristine swimming environment.

Key Features: The device is equipped with powerful suction capabilities, ensuring that debris of all sizes is effectively removed from various surfaces, including tiles and vinyl. Its intelligent navigation system allows for systematic coverage, reducing the chances of missed spots and ensuring thorough cleaning.

Ease of Use: Designed with user convenience in mind, the unit is lightweight and easy to handle. Users can initiate cleaning cycles with minimal effort, and the device operates independently, allowing owners to enjoy their leisure time without the hassle of manual intervention.

Energy Efficiency: Another notable aspect is its energy-efficient operation. The cleaner is engineered to consume minimal power while delivering maximum performance, making it an environmentally friendly choice for pool maintenance.

In conclusion, this robotic cleaner stands out due to its combination of innovative technology, user-friendly features, and energy-saving design, making it an excellent option for pool owners looking to enhance their cleaning routine.

Common Issues with Aquabot Turbo

Understanding frequent problems with robotic cleaners can significantly enhance their performance and longevity. Below are some typical challenges users may encounter, along with their potential causes and solutions.

- Inconsistent Cleaning Performance

This issue often arises from clogged filters or worn brushes. Regular maintenance is essential to ensure optimal operation.

- Unit Not Turning On

If the device fails to power up, check the power supply and ensure that the connections are secure. A faulty power cord can also be the culprit.

- Navigation Problems

Sometimes, the machine may struggle to navigate efficiently. This can be due to obstructions in its path or issues with the sensors. Ensure the area is clear and check the sensor functionality.

- Water Leakage

Leaks can occur due to damaged seals or improper assembly. Inspect the seals for wear and replace them if necessary.

- Battery Issues

Battery performance may degrade over time, resulting in shorter cleaning cycles. Consider replacing the battery if you notice a significant drop in runtime.

By being aware of these common issues, users can take proactive measures to maintain their robotic cleaners and ensure they continue to function effectively.

Essential Tools for Repairs

When it comes to maintaining aquatic cleaning devices, having the right equipment is crucial. Proper tools can significantly enhance efficiency and accuracy during maintenance tasks, ensuring that your device operates at its best. Below is a guide to the fundamental implements that will aid in the upkeep process.

1. Screwdrivers: A set of both flathead and Phillips screwdrivers is indispensable. These tools are essential for accessing internal components and securing them back in place after adjustments.

2. Wrenches: Adjustable and socket wrenches allow for the loosening and tightening of various bolts and nuts. This versatility is important for tackling different parts within the device.

3. Pliers: Needle-nose and standard pliers are helpful for gripping, bending, and cutting wires or small components, making them vital for precision tasks.

4. Multimeter: This device is essential for diagnosing electrical issues. It helps measure voltage, current, and resistance, allowing for effective troubleshooting of any electrical faults.

5. Cleaning Supplies: Brushes, cloths, and mild cleaning agents are necessary for maintaining surfaces and removing debris. Keeping components clean prolongs their lifespan and enhances performance.

6. Safety Gear: Goggles, gloves, and masks protect against potential hazards during maintenance work. Prioritizing safety is key to a successful upkeep experience.

Equipped with these tools, you will be well-prepared to tackle various tasks related to the maintenance of your aquatic cleaning device, ensuring it remains in optimal condition.

Step-by-Step Troubleshooting Guide

This section provides a structured approach to identifying and resolving common issues encountered with your device. By following a systematic process, you can efficiently pinpoint problems and implement effective solutions, ensuring optimal performance.

Initial Assessment

Begin by examining the power source and connections. Ensure that the unit is properly plugged in and that there are no visible damages to the cord. Check for any error indicators on the display, which may provide clues regarding the malfunction. If everything appears normal, move on to inspecting the internal components.

Component Examination

Open the access panel and carefully inspect critical parts such as filters and brushes. Clean or replace any components that show signs of wear or blockage. Additionally, verify that all connections are secure and free from corrosion. After completing these checks, reassemble the unit and test its functionality.

Replacing the Filter Cartridge

Maintaining optimal performance of your cleaning device requires regular replacement of the filtration component. This process ensures that debris and contaminants are effectively captured, enhancing efficiency and prolonging the unit’s lifespan.

- Gather necessary tools: a replacement cartridge and a screwdriver.

- Power off the device and unplug it for safety.

- Locate the filter compartment, usually situated on the underside or rear.

- Remove the cover by unscrewing any fasteners.

- Take out the old filter cartridge, ensuring no debris falls into the compartment.

- Insert the new cartridge, making sure it fits securely.

- Reattach the cover and tighten any screws.

After replacing the cartridge, turn on the device to confirm proper operation. Regular checks will help maintain peak functionality.

Motor Maintenance Tips

Ensuring the longevity and efficiency of your device’s engine is essential for optimal performance. Regular upkeep can prevent common issues, enhance functionality, and save you from costly replacements. Below are key practices to keep your motor running smoothly.

Regular Inspection

Conducting routine checks can help identify potential problems early. Look for signs of wear, unusual noises, or leaks that might indicate underlying issues.

Proper Lubrication

Maintaining appropriate lubrication is crucial for reducing friction and wear. Use high-quality oil suited for your specific engine type to ensure peak performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for leaks and wear |

| Oil Change | Every 50 hours | Use recommended oil type |

| Filter Replacement | Every 100 hours | Keep airflow optimal |

| Battery Check | Monthly | Ensure connections are secure |

Cleaning the Drive Belts

Maintaining the performance of your aquatic cleaner involves ensuring that all components are free of debris and buildup. Among these, the drive belts play a crucial role in facilitating movement. Regular cleaning of these parts not only extends their lifespan but also enhances the overall efficiency of the device.

To begin the cleaning process, first, ensure the device is powered off and disconnected from any power source. Carefully access the area where the belts are located, following the manufacturer’s guidelines. Once exposed, inspect the belts for any signs of wear or damage. Use a soft brush or cloth to remove any dirt, algae, or other residues that may have accumulated. Be thorough, as even small particles can hinder performance.

After cleaning, check the tension of the belts to ensure they are appropriately adjusted. If they appear too loose or too tight, consider making the necessary adjustments or replacing them if needed. Regular inspections and maintenance of the drive belts will contribute significantly to the smooth operation and longevity of your cleaning unit.

Water Pump Replacement Process

Replacing the water circulation device is a crucial task for maintaining optimal performance in any aquatic cleaning system. This procedure ensures that the fluid flow remains uninterrupted, allowing the unit to operate efficiently and effectively. Understanding the steps involved in this process can help you achieve a successful replacement without complications.

Step 1: Preparation

Begin by gathering all necessary tools and replacement parts. Ensure you have a suitable workspace that is clean and well-lit. Disconnect the unit from its power source to prevent any accidental operation during the procedure.

Step 2: Accessing the Component

Carefully remove any protective covers or panels that obstruct access to the water circulation device. Use appropriate tools to unscrew and detach these parts, keeping them organized for reassembly.

Step 3: Disconnecting the Old Unit

Once you have clear access, disconnect the hoses and electrical connections linked to the existing device. Take note of the arrangement to ensure proper reconnection later. Dispose of the old component responsibly.

Step 4: Installing the New Device

Position the new water circulation device in place, ensuring it aligns correctly with the existing fittings. Reconnect the hoses and electrical connections, making sure they are secure to prevent leaks or malfunctions.

Step 5: Final Assembly

Reattach any covers or panels you removed earlier. Double-check that all connections are tight and that there are no loose parts. It’s essential to verify that everything is in place before proceeding to the next step.

Step 6: Testing

Reconnect the power source and turn on the system. Observe the operation of the new water circulation device, checking for any unusual noises or leaks. Conduct a thorough inspection to ensure everything is functioning as intended.

Conclusion

By following these steps, you can successfully replace the water circulation device and restore the efficiency of your system. Regular maintenance and timely replacement of components are key to prolonging the life of your aquatic equipment.

Electrical System Check Procedures

This section outlines essential steps for evaluating the electrical components of your device. A thorough inspection ensures optimal performance and longevity, identifying any issues that may disrupt functionality. Following a systematic approach will help maintain efficiency and reliability in operation.

Visual Inspection

Begin with a comprehensive visual assessment of all electrical connections and components. Look for signs of wear, corrosion, or loose wires. Ensure that terminals are securely attached and free from debris. This initial check can often reveal obvious problems that may require immediate attention.

Functional Testing

After completing the visual inspection, proceed with functional tests to assess the operation of electrical systems. Use a multimeter to measure voltage and continuity at various points in the circuit. Confirm that each component operates within specified parameters, and note any discrepancies that may indicate underlying issues.

How to Reassemble After Repairs

Putting everything back together after servicing is a crucial step that ensures optimal performance and longevity. Following a systematic approach will help you avoid common pitfalls and make the process smoother.

Step-by-Step Assembly

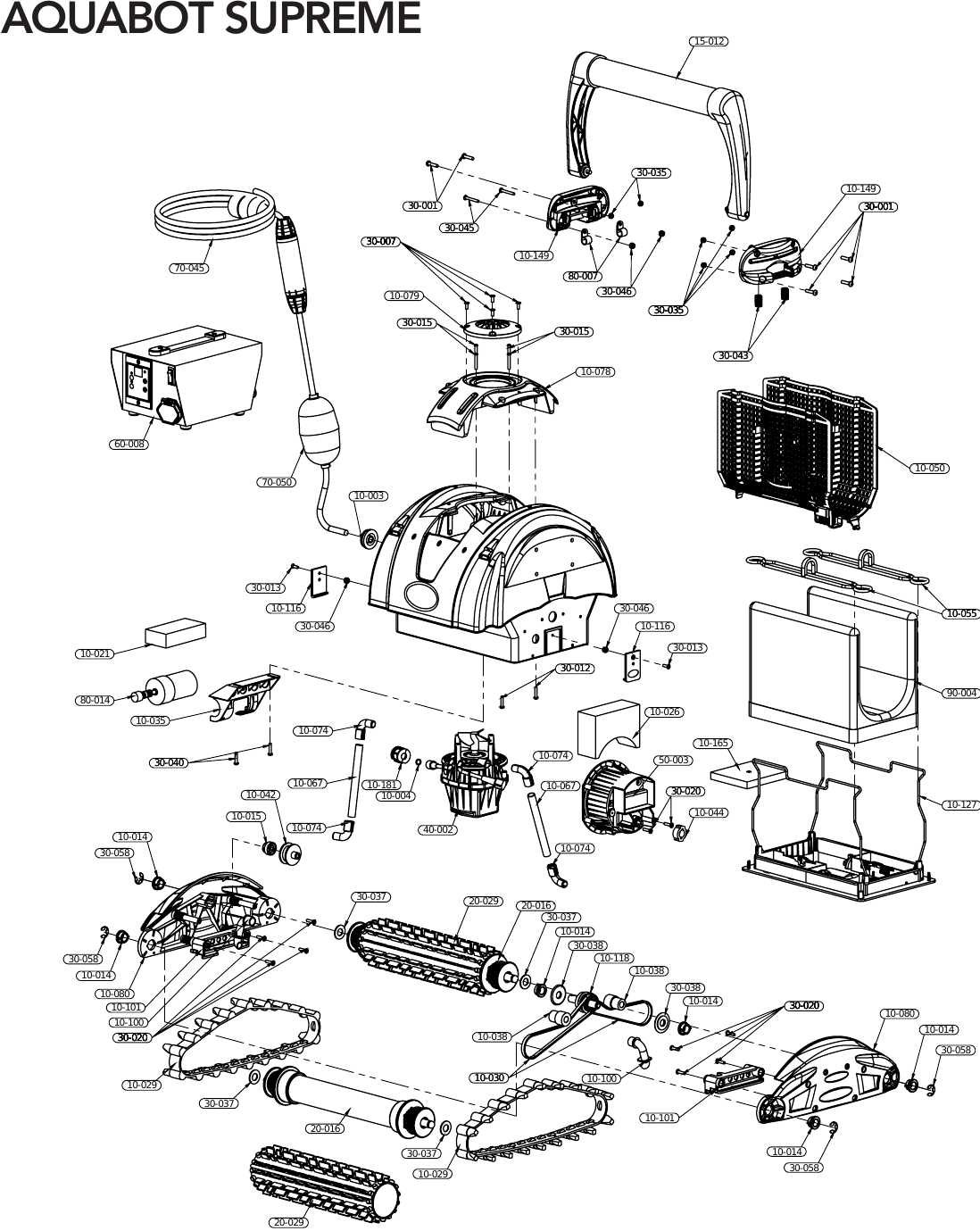

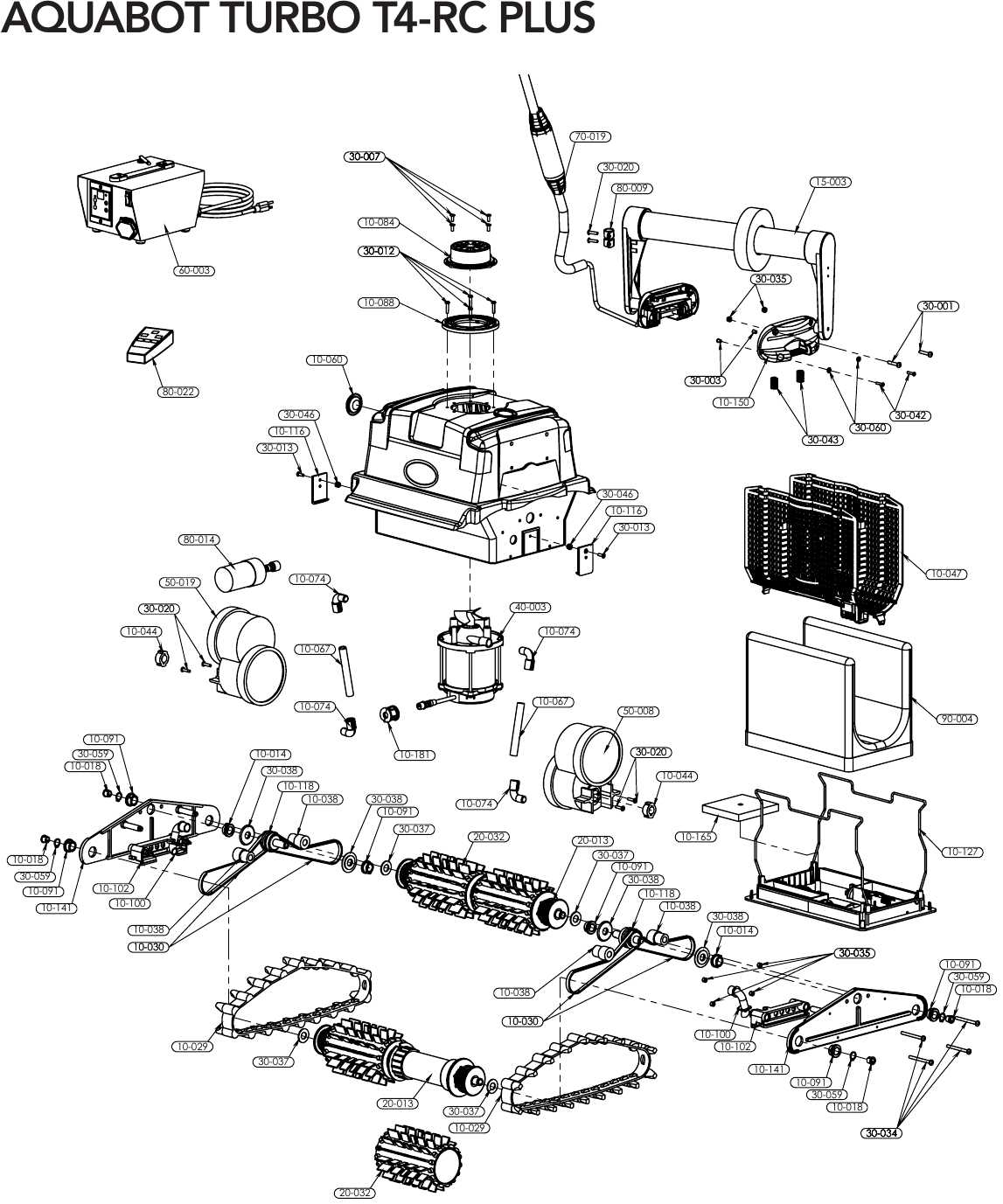

Begin by organizing all components and tools. Reference any notes or diagrams taken during disassembly. Start with the main body, ensuring all seals and fittings are properly aligned before securing them. Gradually add other parts, checking each connection for stability.

Final Checks

Once reassembly is complete, conduct thorough inspections to confirm everything is in place. Test the unit to verify that all functions operate as expected. Address any issues immediately to achieve the best performance.

Preventive Maintenance Practices

Regular upkeep is essential to ensure the longevity and optimal performance of your equipment. Implementing systematic procedures not only helps in identifying potential issues before they escalate but also enhances efficiency and reduces downtime. By adhering to a well-structured maintenance schedule, users can enjoy a more reliable and effective operation.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Weekly | Check for any visible signs of wear, damage, or leaks. |

| Filter Cleaning | Monthly | Remove and clean filters to ensure proper airflow and prevent blockages. |

| Lubrication of Moving Parts | Monthly | Apply lubricant to all moving components to reduce friction and wear. |

| Electrical System Check | Quarterly | Inspect wiring and connections for any signs of corrosion or damage. |

| Calibration of Sensors | Bi-Annually | Ensure all sensors are functioning accurately for optimal performance. |

| Full System Evaluation | Annually | Conduct a comprehensive assessment of the entire system to identify any potential upgrades or repairs needed. |

By following these proactive measures, users can mitigate risks and extend the operational lifespan of their equipment. Consistent attention to maintenance routines plays a critical role in enhancing overall functionality and preventing unforeseen complications.

Frequently Asked Repair Questions

This section addresses common inquiries related to the maintenance and troubleshooting of pool cleaning devices. Here, you will find answers to frequently encountered issues, helping you to understand and resolve them efficiently.

Common Issues and Solutions

- Device not operating:

- Check the power supply and ensure it is plugged in.

- Inspect the on/off switch for functionality.

- Look for any visible damage to the cord.

- Cleaning performance is poor:

- Examine the filter for clogs and clean or replace as necessary.

- Ensure the wheels and brushes are in good condition.

- Check for any obstructions in the path of the device.

- Unusual noises:

- Listen for any grinding sounds that may indicate debris stuck in moving parts.

- Inspect the motor area for loose components.

Maintenance Tips

- Regularly clean the filters after each use to maintain optimal performance.

- Store the unit in a dry, sheltered location to protect it from the elements.

- Conduct periodic inspections to identify wear and tear before it becomes a significant issue.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining optimal performance. Understanding the best sources can save time and ensure you acquire the correct items needed for upgrades or fixes.

Here are some reliable options for sourcing replacement parts:

| Source | Description |

|---|---|

| Manufacturer’s Website | Official sites often provide direct access to original components, ensuring compatibility and quality. |

| Authorized Dealers | Certified sellers can offer a wide range of parts and may provide warranties on their products. |

| Online Retailers | Web-based marketplaces can offer competitive pricing and a variety of options, making them convenient for quick purchases. |

| Local Repair Shops | Neighborhood repair centers may stock common parts and offer expert advice on installation and compatibility. |

| Second-Hand Marketplaces | Used parts can often be found at lower prices; however, it’s important to ensure they are in good condition. |

Exploring these avenues can help you find the parts you need to keep your equipment functioning effectively.