Comprehensive Guide to Repairing the Atwood Model 8535 IV DCLP

In the realm of equipment servicing, understanding the intricacies of a particular apparatus is crucial for ensuring its longevity and optimal performance. This segment delves into essential techniques and procedures that empower users to address common challenges effectively. By familiarizing oneself with the operational nuances, one can enhance both functionality and safety.

Key components of the system often require close attention to detail, and recognizing potential issues early can save time and resources. The following sections provide insight into the typical malfunctions that may arise, as well as practical solutions for resolving them. Emphasizing a proactive approach can significantly mitigate the risk of future complications.

With the right knowledge and tools at your disposal, maintaining and troubleshooting the unit becomes an achievable task. This guide serves as a valuable resource, equipping users with the necessary information to navigate the complexities of their equipment confidently. Embrace the journey of understanding and mastering your device for an enhanced operational experience.

Understanding the Atwood Model 8535-IV-DCLP

This section explores a specific heating system designed for mobile applications, highlighting its key components, functionality, and maintenance practices. A deep understanding of such systems is crucial for effective operation and longevity.

Key Features

- Compact and lightweight design

- Efficient heating capabilities

- Advanced control mechanisms

- Compatibility with various fuel types

Functionality Overview

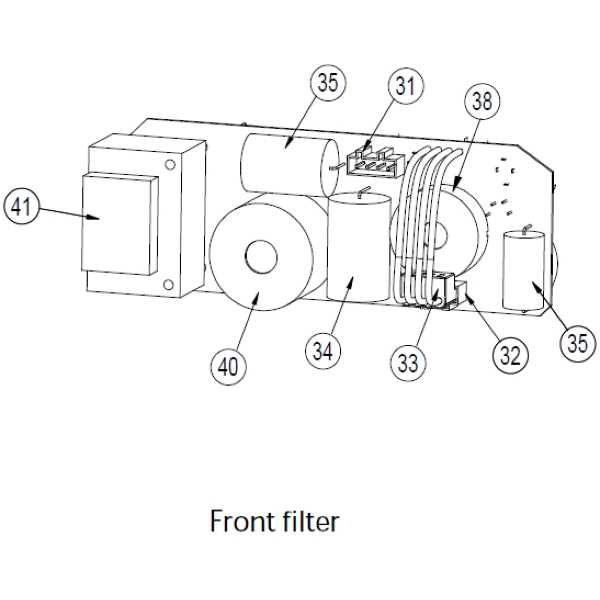

The system operates by converting fuel into heat energy, which is then distributed throughout the designated area. The primary components include:

- Combustion chamber

- Heat exchanger

- Control panel

- Exhaust system

Understanding each component’s role is essential for troubleshooting and optimizing performance.

Common Issues with Atwood 8535-IV-DCLP

Various complications can arise with heating appliances, leading to inefficiencies and performance problems. Understanding these common issues can help in troubleshooting and maintaining optimal functionality.

Frequent Problems

- Insufficient heating: This can be caused by faulty thermostats or malfunctioning heating elements.

- Strange noises: Unusual sounds may indicate loose components or build-up of debris.

- Fluctuating temperatures: Inconsistent heating may arise from sensor issues or airflow restrictions.

- Power failures: A lack of power supply could stem from wiring problems or circuit malfunctions.

Troubleshooting Tips

- Check electrical connections for any signs of wear or damage.

- Inspect the thermostat settings to ensure they are correctly adjusted.

- Examine the heating elements for signs of corrosion or failure.

- Ensure proper ventilation to avoid airflow blockages.

Essential Tools for Repairing Atwood Units

Having the right equipment is crucial for maintaining and troubleshooting heating appliances effectively. A well-equipped toolkit not only streamlines the process but also ensures safety and precision during any undertaking. Below is a curated list of indispensable items that every technician should have on hand when addressing issues related to these units.

Basic Hand Tools

- Wrenches (adjustable and socket)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and regular)

- Wire cutters and strippers

- Utility knife

Diagnostic and Safety Equipment

- Multimeter for electrical testing

- Manometer for pressure readings

- Thermometer for temperature measurements

- Safety goggles and gloves

- Fire extinguisher (class B)

By having these essential tools readily available, one can efficiently address any malfunctions and maintain optimal performance in heating systems. Always prioritize safety and adhere to best practices while working on these devices.

Step-by-Step Repair Process Overview

This section provides a detailed roadmap for troubleshooting and restoring functionality to a specific device. By following a systematic approach, users can identify issues, implement solutions, and ensure the equipment operates optimally.

Begin by gathering the necessary tools and materials. It’s essential to have everything on hand to avoid interruptions during the procedure. Next, consult the initial diagnostics to pinpoint the root cause of the malfunction. This will guide the subsequent steps effectively.

Once the problem is identified, disassemble the unit carefully, taking note of each component’s placement. Cleaning any debris and examining parts for wear or damage is crucial. Afterward, replace or repair any faulty elements as required, ensuring that replacements meet specified standards.

Reassembly should be done methodically, verifying that all connections are secure. Finally, conduct a thorough testing phase to confirm that the device is functioning correctly. This structured process not only facilitates efficient resolution of issues but also enhances the longevity of the equipment.

Electrical Troubleshooting Techniques

Identifying and resolving electrical issues requires a systematic approach. Effective techniques can significantly enhance the efficiency of diagnosing problems, ensuring a swift return to optimal functioning. A solid understanding of electrical components and their interactions forms the foundation for successful troubleshooting.

Understanding Circuit Functionality

A thorough grasp of how circuits operate is crucial. Begin by reviewing circuit diagrams to familiarize yourself with the layout and connections. Checking voltage levels and continuity at various points can help pinpoint faults. Utilizing multimeters to measure resistance and current flow will aid in verifying the health of components.

Common Diagnostic Tools

Employing the right tools can simplify the troubleshooting process. A digital multimeter is invaluable for checking voltage, current, and resistance. Additionally, an oscilloscope can provide insights into waveforms, allowing for a deeper analysis of electrical signals. Other useful tools include clamp meters for current measurement and test lights for quick checks of power presence.

Fluid System Maintenance Tips

Regular upkeep of fluid systems is essential to ensure optimal performance and longevity. Proper maintenance helps prevent costly failures and enhances efficiency. Here are some effective strategies to maintain fluid systems effectively.

Routine Checks

- Inspect fluid levels regularly to avoid dry running and ensure optimal operation.

- Check for leaks in hoses and connections, as even small leaks can lead to significant issues over time.

- Monitor fluid quality, looking for signs of contamination or degradation.

Maintenance Procedures

- Flush the system periodically to remove debris and contaminants.

- Replace filters according to the manufacturer’s guidelines to maintain fluid purity.

- Use only recommended fluids and additives to ensure compatibility and performance.

By following these maintenance tips, you can help extend the life of your fluid systems and ensure they function efficiently under all conditions.

Identifying Mechanical Failures

Recognizing mechanical issues is crucial for maintaining the optimal performance of equipment. Various symptoms can indicate potential problems, and understanding these signs can help in diagnosing faults early, preventing further damage and costly repairs.

Common Symptoms of Mechanical Issues

Mechanical failures often manifest through distinct indicators. Here are some common signs to look for:

| Symptom | Possible Cause |

|---|---|

| Unusual noises | Worn components or misalignment |

| Decreased performance | Clogged parts or insufficient lubrication |

| Visible damage | Corrosion, cracks, or wear |

| Overheating | Blocked airflow or faulty bearings |

Steps to Diagnose Issues

To effectively identify mechanical failures, follow these steps:

- Observe and note any irregular sounds or changes in operation.

- Conduct a visual inspection for signs of wear or damage.

- Check for any leaks or unusual vibrations during operation.

- Consult technical resources for guidance on specific components.

Preventative Maintenance Strategies

Implementing effective maintenance strategies is crucial for ensuring the longevity and optimal performance of equipment. Regularly scheduled tasks not only minimize unexpected breakdowns but also enhance efficiency and safety. A proactive approach allows for the identification of potential issues before they escalate into costly repairs, ultimately contributing to smoother operations.

| Maintenance Activity | Frequency | Description |

|---|---|---|

| Visual Inspections | Weekly | Check for leaks, corrosion, and any visible wear or damage to components. |

| Cleaning | Monthly | Remove debris and contaminants from the unit to prevent overheating and malfunction. |

| Lubrication | Quarterly | Apply appropriate lubricants to moving parts to reduce friction and wear. |

| Electrical System Checks | Biannually | Inspect wiring, connections, and components for signs of wear or damage. |

| Functional Testing | Annually | Perform tests to ensure all systems are operating within specified parameters. |

Adopting these practices not only safeguards the equipment but also optimizes its operational capabilities, ensuring it meets performance standards over time. By dedicating resources to preventative strategies, organizations can significantly enhance reliability and reduce total cost of ownership.

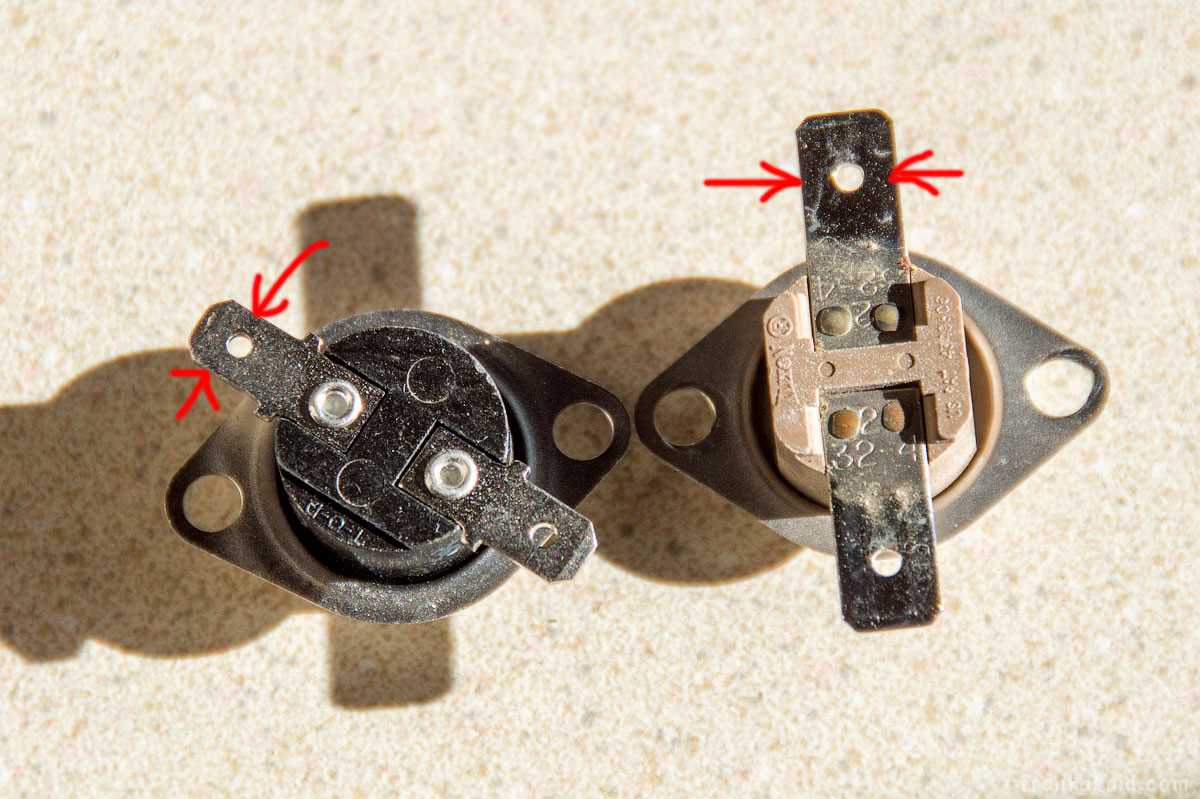

How to Replace Faulty Components

Replacing malfunctioning parts is essential for restoring optimal performance in any mechanical system. This process involves identifying the defective elements, sourcing appropriate replacements, and ensuring proper installation. Below are the key steps to effectively carry out this task.

- Identify the Problem:

- Perform a thorough inspection to determine which components are not functioning correctly.

- Utilize diagnostic tools if necessary to pinpoint the issues.

- Gather Necessary Tools and Materials:

- Prepare the required tools such as screwdrivers, wrenches, and pliers.

- Ensure you have the correct replacement parts compatible with the system.

- Safety First:

- Disconnect the power source to prevent any accidents during the replacement process.

- Wear appropriate safety gear, including gloves and goggles.

- Remove the Faulty Component:

- Carefully detach the defective part, taking note of how it is connected.

- Keep track of any screws or fasteners for reassembly.

- Install the New Component:

- Position the new part in place, ensuring it aligns correctly.

- Tighten all connections securely without overdoing it.

- Test the System:

- Reconnect the power source and conduct tests to verify that the issue is resolved.

- Monitor the new component for any irregularities during operation.

By following these steps, you can ensure a smooth replacement process, enhancing the reliability and functionality of your system.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect individuals performing the work but also safeguard the equipment and surrounding environment. Awareness of potential hazards and adherence to safety protocols are essential for a successful outcome.

Before beginning any service, it’s important to familiarize oneself with the equipment and its specific requirements. This knowledge helps in identifying risks and implementing suitable measures to mitigate them.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate personal protective equipment such as gloves, goggles, and masks to shield against debris and harmful substances. |

| Ensure Proper Ventilation | Work in a well-ventilated area to avoid inhalation of fumes and reduce the risk of fire hazards. |

| Disconnect Power Supply | Before commencing any task, make sure to disconnect the power source to prevent accidental activation of the device. |

| Keep a Clean Workspace | Maintain a tidy work area to minimize tripping hazards and ensure that tools and materials are easily accessible. |

| Read Documentation | Consult relevant literature to understand procedures and safety guidelines specific to the equipment. |

By adhering to these safety measures, individuals can significantly reduce the likelihood of incidents and ensure a smoother maintenance process. Prioritizing safety is a vital aspect of any technical endeavor.

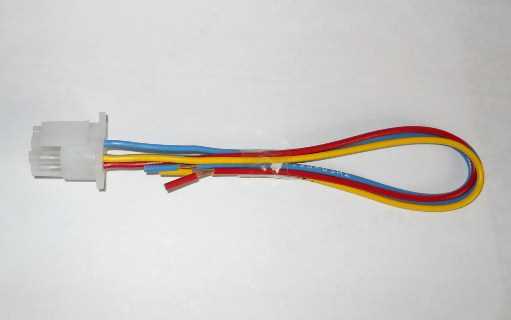

Understanding Wiring Diagrams

Wiring diagrams are essential tools for anyone involved in the maintenance or troubleshooting of electrical systems. These graphical representations provide a clear and concise way to visualize the connections between various components, making it easier to identify potential issues and understand the flow of electricity.

Clarity and Organization are the primary benefits of wiring diagrams. By depicting the arrangement of wires and components, they simplify complex systems into manageable sections. This organization helps technicians quickly locate specific elements, facilitating efficient repairs and modifications.

Types of Symbols used in these diagrams are standardized, ensuring consistency across different designs. Familiarity with these symbols is crucial, as they represent various elements like switches, connectors, and power sources. Recognizing these icons allows for quicker comprehension of the overall system layout.

Moreover, wiring diagrams often include color coding, which further aids in distinguishing between different types of wires and their functions. Understanding the significance of colors can help in accurately tracing circuits and diagnosing faults.

In summary, mastering the interpretation of wiring diagrams is vital for effective electrical system management. With practice, individuals can develop the skills necessary to navigate these diagrams with confidence, ultimately leading to enhanced troubleshooting and repair capabilities.

Recommended Replacement Parts and Sources

When maintaining or restoring a heating unit, it’s essential to have access to high-quality replacement components. This section outlines key parts that may require substitution over time and suggests reliable sources for procurement. Ensuring that you use compatible and durable elements will help prolong the lifespan of your equipment and maintain optimal performance.

| Part Name | Description | Recommended Supplier |

|---|---|---|

| Ignition Module | Essential for the ignition process, responsible for starting the heating cycle. | HeatWave Supplies |

| Burner Assembly | Facilitates the combustion of fuel, critical for efficient operation. | PartsPro Direct |

| Thermostat | Monitors and regulates temperature, ensuring consistent heating. | Climate Control Depot |

| Blower Fan | Distributes heated air throughout the space, improving comfort. | AirFlow Solutions |

| Exhaust Vent | Directs exhaust gases safely outside, crucial for safety and efficiency. | Safety First Parts |

Utilizing these suggested parts from reputable suppliers will ensure that your heating unit operates safely and effectively. Always verify compatibility with your specific equipment before making any purchases.

Frequently Asked Questions About Repairs

This section aims to address common inquiries regarding maintenance and troubleshooting for specific appliances. By providing clear answers, we hope to assist users in understanding the essential aspects of upkeep and resolving issues effectively.

What are the most common issues encountered?

Users frequently report problems such as leaks, unusual noises, or failure to ignite. Identifying these issues early can prevent more significant complications.

How can I determine if my appliance needs servicing?

Signs that servicing may be required include inconsistent performance, visible wear, or error messages. If the appliance does not function as expected, it’s advisable to seek further assistance.

Is it safe to attempt repairs myself?

While some minor adjustments can be handled independently, it’s crucial to evaluate your skill level and the complexity of the task. For intricate problems, professional help is recommended.

What tools will I need for common fixes?

Basic tools such as screwdrivers, wrenches, and pliers are often sufficient for simple tasks. However, specialized equipment may be necessary for more complicated repairs.

How often should I perform maintenance?

Regular inspections and upkeep should be conducted at least once a year to ensure optimal performance and longevity. More frequent checks may be required based on usage.

Where can I find replacement parts?

Replacement components can typically be purchased from authorized dealers, online retailers, or local hardware stores. Ensure that the parts are compatible with your specific appliance.

What warranty options are available?

Most products come with a warranty that covers specific defects and failures. Reviewing the warranty terms can clarify what repairs are included and for how long.