Comprehensive Guide to Bolens BL410 Repair

Understanding the upkeep of outdoor machinery is essential for ensuring optimal performance and longevity. This section focuses on the key procedures and guidelines that every owner should follow to maintain their equipment effectively. Proper care not only enhances functionality but also helps prevent potential issues that could arise from neglect.

From routine checks to troubleshooting common problems, this guide provides valuable insights into best practices. By familiarizing yourself with the necessary steps for maintenance, you can significantly improve the efficiency of your machinery. Whether you are addressing minor adjustments or preparing for seasonal changes, having a comprehensive approach will serve you well.

Explore the various aspects of servicing your equipment, including essential tools, recommended techniques, and safety precautions. With the right knowledge and preparation, you can ensure that your outdoor machinery remains in peak condition, ready to tackle any task at hand.

When operating garden equipment, users often encounter various challenges that can hinder performance and usability. Understanding these common problems can help in troubleshooting and maintaining the machinery effectively.

- Engine Start Failures: Difficulty in starting the engine is a frequent complaint. This can stem from issues such as stale fuel, dead batteries, or faulty ignition components.

- Overheating: Machines may overheat during operation, leading to performance drops. This can occur due to inadequate cooling or blocked air vents.

- Unusual Noises: Users often report strange sounds during operation, which can indicate problems with internal components or improper assembly.

- Vibration Issues: Excessive vibration can affect handling and cause discomfort. This may result from unbalanced parts or loose attachments.

- Stalling: Frequent stalling during use can disrupt tasks. This may be caused by fuel delivery issues or engine malfunctions.

Identifying these common issues is the first step towards effective resolution and ensuring smooth operation in the long run.

Step-by-Step Repair Procedures

This section outlines the systematic approach to addressing issues that may arise with your equipment. Following these detailed steps will help ensure effective troubleshooting and resolution of common problems.

-

Preparation: Gather all necessary tools and components before starting the process.

-

Safety First: Disconnect the power source to avoid any accidents during the maintenance procedure.

-

Diagnosis: Identify the specific issue by observing the device’s performance and any unusual sounds.

-

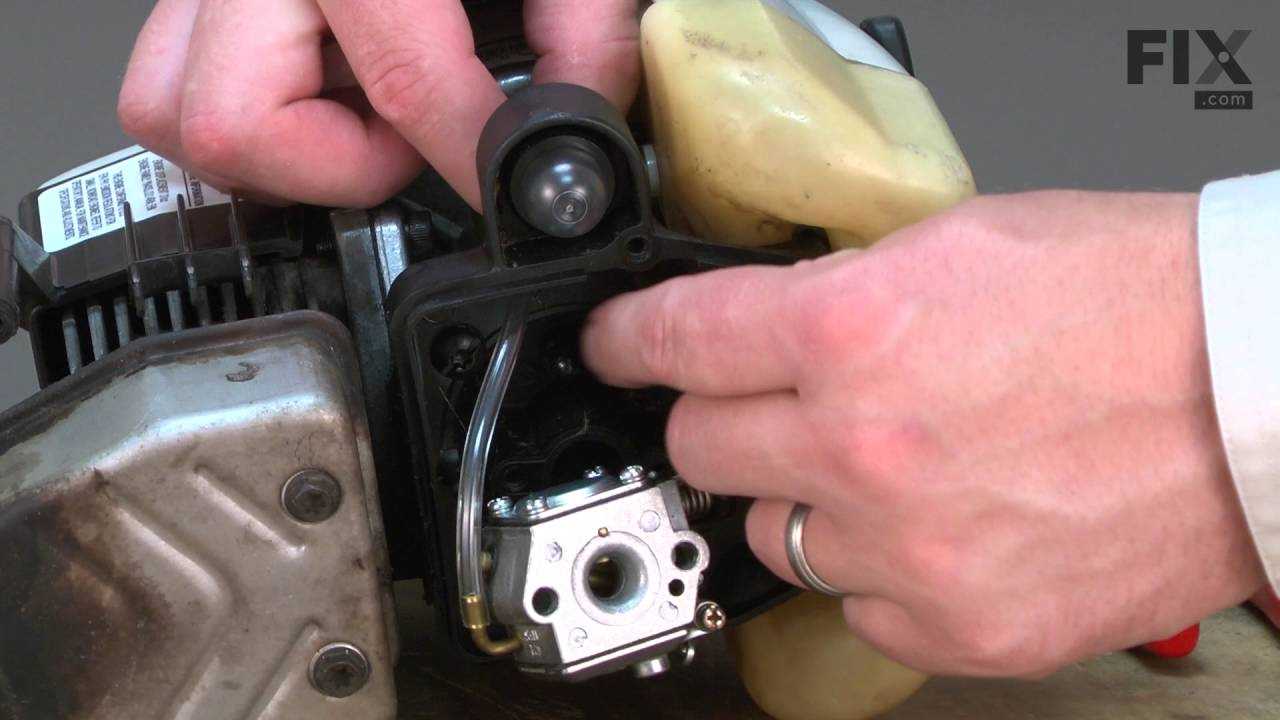

Disassembly: Carefully remove any panels or covers to access the internal components.

-

Inspection: Examine the parts for signs of wear or damage. Pay close attention to connections and moving elements.

-

Replacement: If any parts are found to be defective, replace them with compatible alternatives.

-

Reassembly: Once all necessary repairs are completed, reassemble the device carefully, ensuring all screws and components are securely fastened.

-

Testing: Reconnect the power and test the equipment to confirm that the issue has been resolved.

-

Final Check: Monitor the device during initial operation to ensure it functions smoothly.

Essential Tools for Maintenance

Effective upkeep of your equipment relies heavily on having the right tools at your disposal. Proper instruments not only enhance efficiency but also ensure safety during operation. This section highlights crucial items that can facilitate regular care and troubleshooting.

Basic Hand Tools

Fundamental hand tools are indispensable for everyday tasks. A well-equipped toolkit should include:

| Tool | Purpose |

|---|---|

| Screwdrivers | Tightening and loosening screws |

| Wrenches | Adjusting nuts and bolts |

| Pliers | Gripping and bending materials |

| Hammer | Driving nails and securing components |

Specialized Equipment

In addition to basic tools, specialized equipment can greatly aid in maintenance tasks. Consider adding the following:

| Tool | Purpose |

|---|---|

| Multimeter | Measuring electrical parameters |

| Torque wrench | Ensuring proper tension on fasteners |

| Oil can | Lubricating moving parts |

| Cleaning brushes | Removing debris and buildup |

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both personal well-being and effective work. Proper precautions help prevent accidents and injuries, allowing for a smoother and more productive experience. Understanding and implementing these guidelines is essential for anyone involved in technical adjustments or servicing machinery.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is a fundamental aspect of staying safe. This includes items such as gloves, safety goggles, and sturdy footwear. Gloves protect hands from sharp edges and chemical exposure, while goggles shield eyes from dust and debris. Proper footwear can prevent slips and provide support during lengthy tasks.

Work Area Organization

Maintaining an organized workspace contributes significantly to safety. Clear away any unnecessary items that could cause tripping hazards. Ensure that tools and equipment are stored properly when not in use, minimizing the risk of accidents. Effective organization not only enhances safety but also improves efficiency.

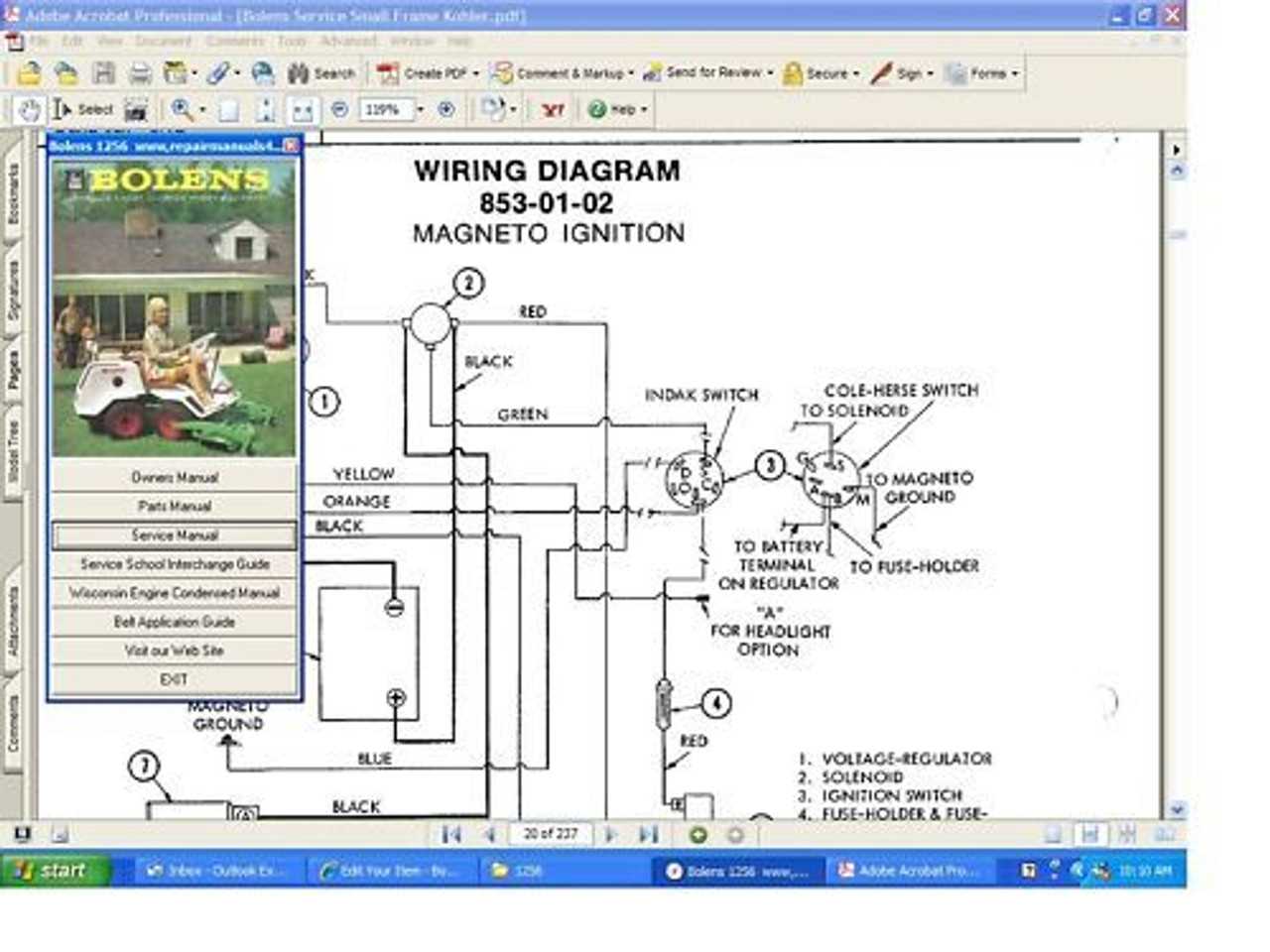

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for maintaining optimal performance of your equipment. By understanding common symptoms and applying systematic approaches, you can effectively diagnose and remedy various faults that may arise.

Common Symptoms of Electrical Issues

- Device fails to start or respond

- Intermittent operation or unexpected shutdowns

- Unusual noises or smells indicating potential hazards

Steps for Diagnosis

- Check power sources and connections to ensure they are secure and functional.

- Inspect fuses and circuit breakers for any signs of damage or tripping.

- Examine wiring for signs of wear, corrosion, or disconnections.

- Utilize a multimeter to test voltage and continuity at various points.

- Consult component specifications to verify proper operation parameters.

By following these guidelines, you can systematically address electrical challenges, ensuring the longevity and efficiency of your machinery.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of the machine. By following simple yet effective practices, you can significantly reduce the likelihood of unexpected breakdowns.

Regular Cleaning: Keeping the exterior and interior components clean is crucial. Dirt and debris can lead to inefficiencies and premature wear. Use a soft brush or cloth to remove dust and grime from surfaces, and periodically inspect for any buildup in hard-to-reach areas.

Check Fluid Levels: Maintaining proper fluid levels is essential for optimal operation. Regularly inspect oil, fuel, and coolant levels, topping them off as necessary. Replacing fluids according to the manufacturer’s recommendations can prevent overheating and mechanical failures.

Inspect Belts and Cables: Over time, belts and cables can wear out or become loose. Regularly check their condition, looking for signs of fraying or cracking. Tightening or replacing these components promptly can prevent larger issues down the line.

Sharpening Blades: For equipment with cutting components, keeping blades sharp is vital for efficiency and safety. Dull blades can strain the engine, leading to decreased performance. Regularly sharpening blades ensures cleaner cuts and reduces operational stress.

Storage Considerations: When not in use, proper storage can prevent damage from environmental factors. Keep the equipment in a dry, sheltered area, away from extreme temperatures. Covering it can provide additional protection from dust and moisture.

By incorporating these practices into your routine, you can enhance the longevity and reliability of your equipment, ensuring it serves you well for years to come.

Replacing Worn-Out Components

Over time, various parts of machinery can experience wear and tear, leading to decreased performance and efficiency. Addressing these issues promptly can prevent further damage and ensure the equipment operates smoothly. Identifying which components need replacement is crucial for maintaining optimal functionality.

Identifying Worn Parts

Regular inspection is essential to detect components that are no longer functioning as intended. Look for signs such as unusual noises, vibrations, or decreased efficiency. Components like belts, blades, and filters often exhibit visible wear, which can serve as indicators for replacement.

Replacement Process

Once worn parts are identified, follow a systematic approach to replacement. First, consult the specifications for the necessary components to ensure compatibility. Gather the required tools, and proceed to safely remove the old parts, taking care to follow safety protocols. After the installation of new components, perform a thorough check to confirm everything is functioning correctly.

Understanding the Engine Specifications

Engine specifications play a crucial role in determining the performance and efficiency of any machinery. By comprehensively analyzing these details, users can gain insights into how to maximize the functionality of their equipment.

- Type of Engine: The classification of the engine, such as two-stroke or four-stroke, affects power output and fuel consumption.

- Displacement: This measurement indicates the engine’s capacity and is directly linked to its power potential.

- Power Output: Typically expressed in horsepower or kilowatts, this value helps evaluate the overall strength of the engine.

- Torque: This specification reflects the engine’s ability to perform work, especially at low RPMs.

- Fuel Type: Knowing whether the engine operates on gasoline, diesel, or alternative fuels is essential for maintenance.

Understanding these aspects not only aids in the efficient use of the machinery but also enhances the overall user experience and longevity of the equipment.

Parts Identification and Diagrams

Understanding the components of a machine is crucial for effective maintenance and troubleshooting. This section provides an overview of the various elements that make up the equipment, along with visual representations to aid in identification and assembly.

Key parts include:

- Engine Assembly

- Transmission System

- Cutting Deck

- Wheels and Tires

- Control Panel

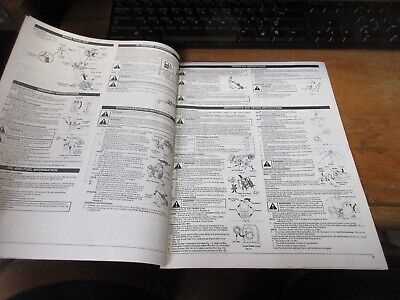

Diagrams play a vital role in illustrating the relationships and placements of these components. Below are some common diagram types you might encounter:

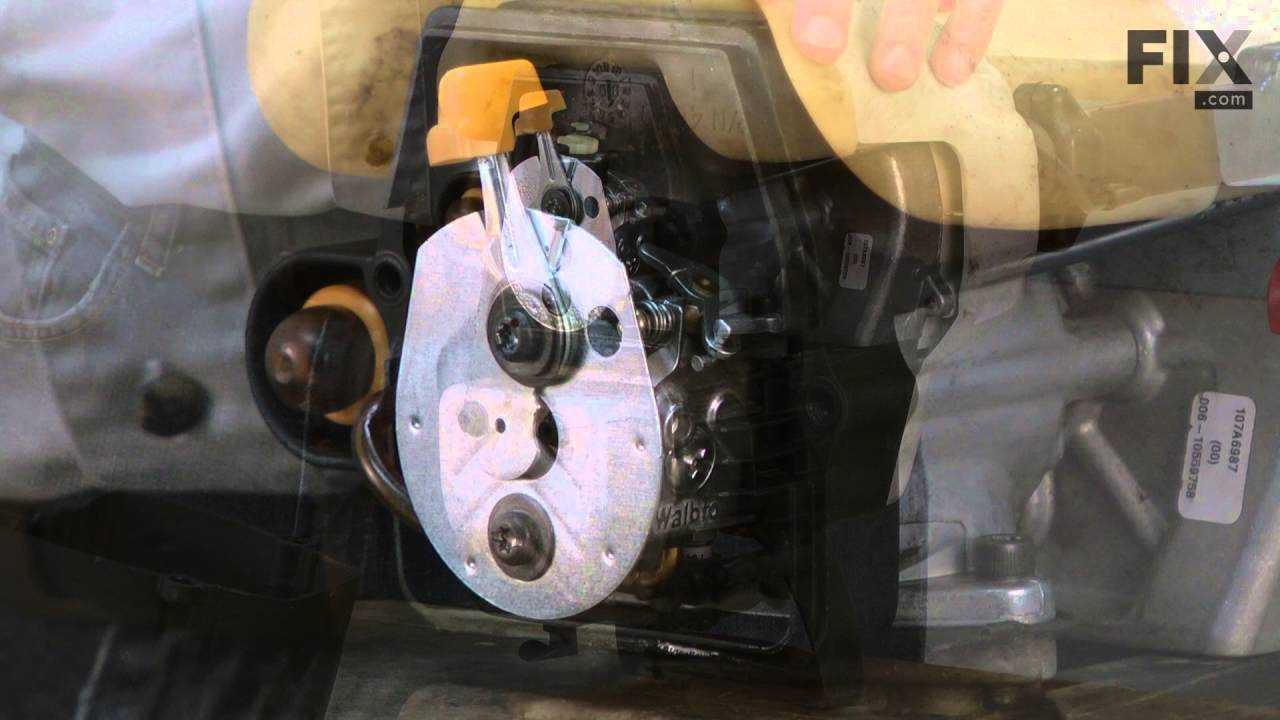

- Exploded View Diagrams: These show all parts separated, making it easier to see how they fit together.

- Schematic Diagrams: Useful for understanding the electrical connections and flow of the system.

- Assembly Diagrams: Step-by-step visuals that guide the reassembly of parts.

Familiarizing yourself with these elements will enhance your ability to perform maintenance tasks effectively and efficiently.

Where to Find Replacement Parts

Finding suitable components for your outdoor equipment can significantly enhance its longevity and performance. Whether you need to replace a worn-out piece or upgrade for better functionality, knowing where to source these items is crucial.

Here are several options to consider when searching for replacement parts:

- Online Retailers: Numerous websites specialize in outdoor equipment parts, offering a wide selection at competitive prices. Check user reviews to ensure reliability.

- Manufacturer’s Website: Visiting the official site can provide direct access to authentic components specifically designed for your equipment.

- Local Hardware Stores: Many local retailers stock a variety of parts for common models. It’s often helpful to bring the original piece to ensure you find the correct match.

- Specialty Shops: Stores that focus on outdoor machinery may carry unique or hard-to-find components, catering to specific needs.

- Online Marketplaces: Platforms like eBay or Amazon can have listings from multiple sellers, sometimes offering used parts at lower prices.

Consider these resources to efficiently locate the necessary components for your equipment, ensuring optimal performance for years to come.

Customer Support and Resources

Accessing reliable assistance and information is essential for anyone navigating the complexities of equipment maintenance and troubleshooting. This section aims to provide users with essential contacts and helpful materials to ensure optimal performance and resolution of any issues that may arise.

Support Channels

For personalized assistance, various support channels are available. Users can reach out to customer service via phone or email for expert guidance. Additionally, online forums and community groups can serve as valuable resources where individuals share experiences and solutions.

Helpful Documentation

Comprehensive resources, including detailed guides and FAQs, can greatly enhance understanding and usability. These documents often cover common concerns, best practices for upkeep, and troubleshooting steps to address typical challenges. Utilizing these materials can empower users to effectively manage their equipment.