Comprehensive Guide to Repairing the Bosch 11224VSR

In the world of power tools, understanding the intricacies of operation and upkeep is essential for optimal performance and longevity. This section delves into the various aspects of maintaining a high-performance tool, focusing on techniques that enhance reliability and functionality. Proper knowledge can make a significant difference in the efficiency of tasks at hand.

The importance of regular upkeep cannot be overstated. By familiarizing oneself with essential components and their respective functions, users can ensure that their equipment remains in peak condition. Moreover, being equipped with troubleshooting skills allows for quicker resolution of common issues, reducing downtime and frustration.

This resource serves as a detailed reference, guiding users through essential procedures, common pitfalls, and effective solutions. Whether you’re a seasoned professional or a novice enthusiast, understanding these principles will empower you to handle challenges confidently and effectively.

Bosch 11224VSR Overview

This section provides a comprehensive examination of a widely recognized tool designed for both professionals and DIY enthusiasts. Known for its durability and versatility, this device excels in a variety of applications, ensuring efficient performance in demanding environments.

Key Features

Equipped with advanced technology, this model offers powerful functionality, making it suitable for various tasks. Its lightweight design enhances portability, while the ergonomic handle ensures comfort during extended use. Additionally, the tool’s innovative features facilitate easy operation and maintenance.

Applications

This versatile instrument is ideal for drilling and chiseling in multiple materials, such as concrete and masonry. Whether for construction projects or home improvement tasks, its adaptability makes it an essential addition to any toolkit.

Key Features of the Model

This section highlights the essential attributes of the power tool, showcasing its design and functionality. Understanding these characteristics can enhance user experience and improve efficiency during tasks.

The following table summarizes the primary features that set this device apart in the market:

| Feature | Description |

|---|---|

| Power Output | Equipped with a robust motor that delivers exceptional power for demanding applications. |

| Weight | Lightweight construction facilitates ease of handling and reduces user fatigue. |

| Durability | Engineered with high-quality materials to withstand tough working conditions. |

| Versatility | Compatible with a range of accessories for various applications, enhancing its utility. |

| User-Friendly Design | Features ergonomic grips and controls for comfortable operation over extended periods. |

Common Issues and Troubleshooting Tips

When using power tools, encountering problems can be a common experience. Understanding typical complications and how to address them is essential for maintaining performance and prolonging the lifespan of your equipment.

1. Excessive Vibration: If you notice significant vibration during operation, it may indicate a misalignment or wear of components. Ensure that all parts are securely attached and check for any signs of damage.

2. Overheating: An overheating tool can result from prolonged use or inadequate ventilation. Allow the equipment to cool down regularly and ensure that air vents are unobstructed for proper airflow.

3. Reduced Power: If the tool lacks power, inspect the power source for issues. A faulty extension cord or an inadequate electrical supply can lead to poor performance. Ensure all connections are secure.

4. Unusual Noises: Strange sounds often signal underlying problems. Listen for grinding or squeaking noises, which could indicate worn bearings or a lack of lubrication. Addressing these issues promptly can prevent further damage.

5. Difficulty Starting: If the tool struggles to start, check the trigger mechanism and ensure that safety features are disengaged. A faulty switch may require replacement to restore functionality.

Regular maintenance and attention to these common issues can greatly enhance your tool’s reliability and efficiency.

Step-by-Step Repair Process

This section outlines a systematic approach to troubleshooting and restoring functionality to your equipment. Following a structured procedure can enhance efficiency and ensure that all issues are addressed thoroughly.

1. Preparation: Begin by gathering all necessary tools and components. Ensure a clean workspace to facilitate a smooth workflow.

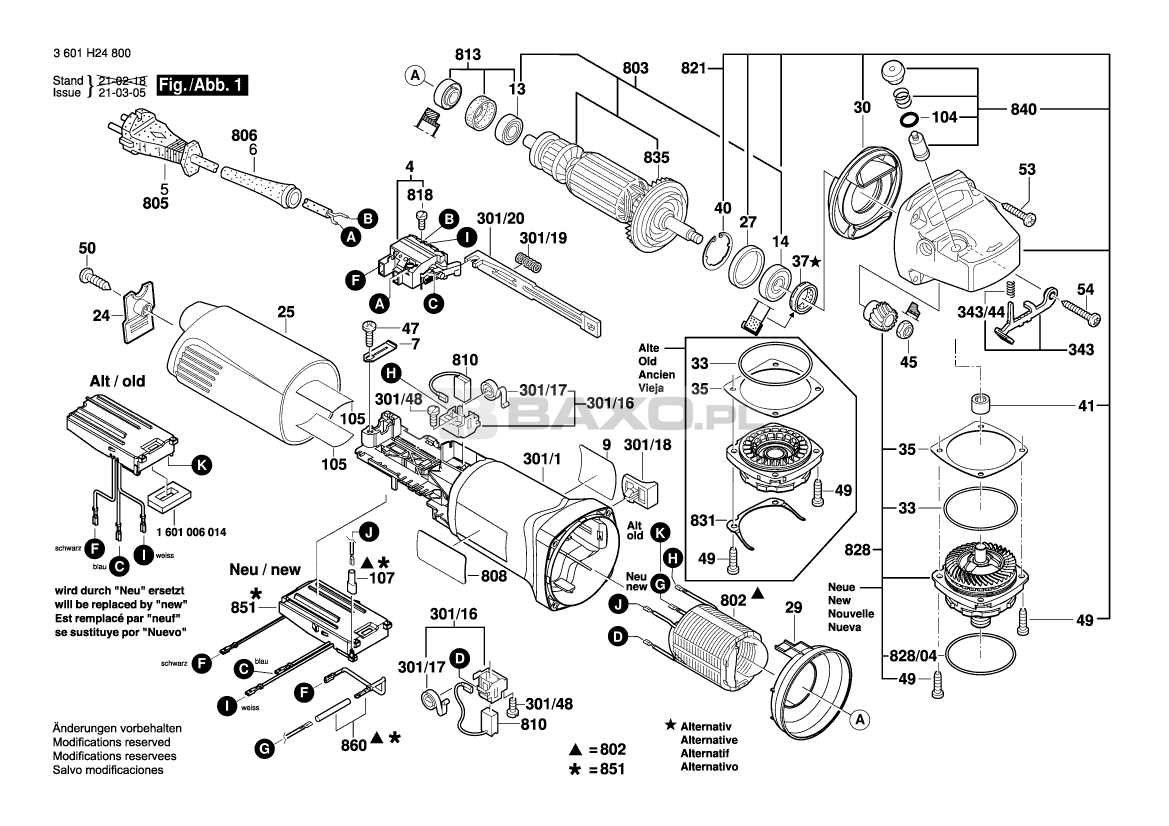

2. Disassembly: Carefully take apart the device, documenting each step. Keep track of screws and small parts to avoid losing them during the process.

3. Inspection: Examine all components for signs of wear or damage. Look for broken parts, loose connections, or any debris that may hinder performance.

4. Replacement: Identify any defective elements and replace them with new or refurbished parts. Ensure that all replacements are compatible and securely fitted.

5. Reassembly: Gradually reassemble the device, following the notes made during disassembly. Double-check each connection to ensure proper alignment.

6. Testing: Once reassembled, power on the device to test its functionality. Monitor for any unusual sounds or malfunctions during operation.

7. Final Checks: Conduct a thorough examination of the device after testing. Confirm that all functions are working correctly and that there are no remaining issues.

By adhering to this detailed guide, you can effectively restore your equipment, minimizing downtime and maximizing performance.

Required Tools for Repairs

When undertaking maintenance tasks, having the right instruments is essential for effective and efficient work. The appropriate equipment not only facilitates the process but also ensures that the job is completed to a high standard. Below is a list of necessary tools that will aid in achieving successful outcomes during the service procedures.

Basic Tools

To start, basic hand tools are indispensable. A set of screwdrivers, including both flat and Phillips types, is vital for loosening and tightening various components. Additionally, a quality wrench set is crucial for securing bolts and nuts. Pliers also play a significant role in gripping and twisting tasks, while a measuring tape helps in assessing dimensions accurately.

Power Tools and Accessories

Incorporating power tools can greatly enhance efficiency. A reliable drill is essential for creating holes and driving screws quickly. Furthermore, an angle grinder may be useful for cutting and shaping materials. Don’t forget to stock up on replacement bits and accessories that are compatible with your equipment to ensure smooth operation throughout the project.

Replacement Parts Availability

Ensuring the continued functionality of power tools often requires access to suitable components. The availability of these essential parts is crucial for maintaining optimal performance and extending the lifespan of the equipment. Users can benefit from a variety of sources that offer compatible components tailored to specific models.

Many manufacturers and authorized distributors provide a comprehensive range of parts designed for easy replacement. This can include everything from motor components to housing elements, ensuring that users can find exactly what they need to complete repairs effectively. Additionally, online marketplaces and specialty retailers often stock both original and aftermarket options, allowing for flexibility based on budget and availability.

For those seeking specific items, it is advisable to consult with knowledgeable suppliers who can assist in identifying the correct parts. Utilizing user forums and online communities can also yield valuable insights regarding availability and compatibility, as well as recommendations for reputable sources. This proactive approach helps in swiftly addressing any maintenance needs, ensuring tools remain reliable and efficient.

Maintenance Best Practices

Proper upkeep of tools and equipment is essential for ensuring longevity and optimal performance. Regular attention to maintenance not only extends the life of the device but also enhances safety and efficiency during usage. Implementing a systematic approach to care can prevent costly repairs and operational downtimes.

Regular Inspection

Frequent checks are crucial for identifying wear and tear. Incorporate the following practices:

- Examine components for signs of damage or deterioration.

- Ensure that all parts are secure and functioning as intended.

- Check for unusual noises or vibrations during operation.

Cleaning Procedures

Keeping equipment clean is vital for optimal functionality. Follow these cleaning tips:

- Remove dust and debris from all accessible areas.

- Use appropriate cleaning solutions for specific materials.

- Regularly inspect filters and replace them as needed.

By adhering to these best practices, users can significantly improve the performance and durability of their tools, ensuring they remain reliable and efficient for years to come.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount for both personal well-being and the integrity of the equipment. Proper precautions can prevent accidents and minimize risks associated with power tools and machinery. Adhering to safety protocols not only protects the individual but also enhances the efficiency of the work being performed.

Before starting any task, it is essential to gather the necessary protective gear, such as safety goggles, gloves, and ear protection. This equipment acts as a barrier against potential hazards, ensuring that the individual is shielded from flying debris, sharp objects, or loud noises. Furthermore, a tidy workspace significantly reduces the likelihood of accidents, so keeping tools and materials organized is crucial.

It is also important to disconnect the power source before beginning any disassembly. This simple yet effective step prevents unintentional activation of the equipment, which could lead to severe injuries. Additionally, familiarizing oneself with the specific features and functions of the device can enhance safety measures, as understanding how it operates helps identify potential dangers.

Finally, being aware of one’s own limits is essential. If a task seems too complex or poses a risk, seeking assistance from a qualified professional is a wise choice. Remember, safety should always be the top priority in any maintenance endeavor.

Disassembly Guide for Users

This section provides a comprehensive overview for individuals looking to disassemble their equipment safely and efficiently. By following the outlined steps, users can access internal components, perform necessary maintenance, or troubleshoot issues effectively. Proper disassembly is essential to avoid damage and ensure that all parts are handled with care.

Step 1: Preparation

Before beginning the disassembly process, gather all required tools and ensure a clean workspace. It is advisable to have screwdrivers, pliers, and other essential instruments ready. Additionally, reviewing the original assembly design may help in understanding how components fit together.

Step 2: Power Off

Ensure that the device is completely powered off and unplugged from any power sources. This precaution prevents electrical shocks and protects both the user and the equipment.

Step 3: Remove External Covers

Begin by carefully removing any external casings or covers. This may involve unscrewing several fasteners. Keep these screws organized to facilitate reassembly later. Use gentle pressure to avoid cracking or damaging plastic components.

Step 4: Access Internal Components

Once the outer casing is removed, identify the internal parts you wish to examine or service. Follow any diagrams if available, and proceed with caution, as certain components may be sensitive or fragile.

Step 5: Document the Process

As you disassemble, consider taking notes or photographs of each step. This documentation will assist in reassembly and ensure that no components are misplaced.

Step 6: Complete the Disassembly

Continue to remove additional parts as needed, keeping track of how each piece fits together. Take your time to avoid making mistakes that could complicate the reassembly process.

Wiring Diagram and Connections

This section provides an overview of the electrical schematic and interconnections essential for the proper functioning of the tool. Understanding the layout and connections is crucial for effective troubleshooting and maintenance.

The wiring diagram illustrates the relationships between various components, showcasing how power flows through the device. It highlights the specific terminals and connections that need to be addressed during any servicing. Familiarity with this schematic enables users to identify potential issues and ensures that all parts are correctly connected.

Key connections include:

- Power supply terminals – Essential for delivering electricity to the system.

- Control switches – Allow for the management of the tool’s functions.

- Ground connections – Vital for safety, preventing electrical faults.

When working with the electrical components, always refer to the wiring diagram for guidance. Proper adherence to this schematic will facilitate repairs and enhance the longevity of the equipment.

Understanding Manufacturer Warranty

A manufacturer warranty serves as a safeguard for consumers, providing assurance regarding the quality and durability of a product. This agreement typically covers specific defects and malfunctions that may arise during normal usage, ensuring that customers receive the support they need in case of issues.

Key aspects of a manufacturer warranty include:

- Duration: Most warranties specify a fixed period during which coverage is applicable, often ranging from one to several years.

- Coverage: The warranty generally details what types of damages or defects are included, such as material or workmanship issues.

- Exclusions: It is crucial to understand what is not covered by the warranty, which often includes damage resulting from misuse or accidents.

- Claim Process: Familiarizing oneself with the steps to file a claim can help streamline the resolution of any issues that may arise.

Understanding the terms of the warranty can empower consumers, ensuring they are aware of their rights and the responsibilities of the manufacturer. This knowledge enhances the overall ownership experience, allowing individuals to make informed decisions when purchasing products.

Customer Reviews and Feedback

This section explores the experiences and insights shared by users of the tool, highlighting their satisfaction levels and areas for improvement. Feedback from customers can provide valuable perspectives that help potential buyers make informed decisions.

Overall Satisfaction

Many users express a high level of contentment with the product’s performance and reliability. The device’s efficiency in handling various tasks has been noted as a significant advantage, with several customers emphasizing its durability and robust construction. Positive remarks often highlight its user-friendly design, making it accessible for both beginners and experienced individuals.

Areas for Improvement

While feedback is generally favorable, some customers point out certain limitations. Issues such as weight and portability have been mentioned, suggesting that enhancements in these areas could improve overall usability. Additionally, a few users have indicated that a more comprehensive set of features would further enhance the tool’s versatility. Constructive criticism serves as a reminder that continuous improvement is essential in meeting user expectations.