Comprehensive Guide to Bosch Injection Pump Repair

Efficient operation of a vehicle relies heavily on its fuel distribution mechanisms. These intricate devices play a crucial role in ensuring that the engine receives the correct amount of fuel at the right time. Proper maintenance of these components is essential for optimal performance and longevity.

Over time, wear and tear can lead to various issues, affecting both the functionality and efficiency of the system. Recognizing common problems and understanding the intricacies of these systems can empower vehicle owners and technicians alike to address concerns proactively.

This guide serves as a comprehensive resource, detailing essential procedures and techniques for servicing these vital elements. By following the outlined steps, individuals can enhance their knowledge and skills, leading to better performance and reliability of their vehicles.

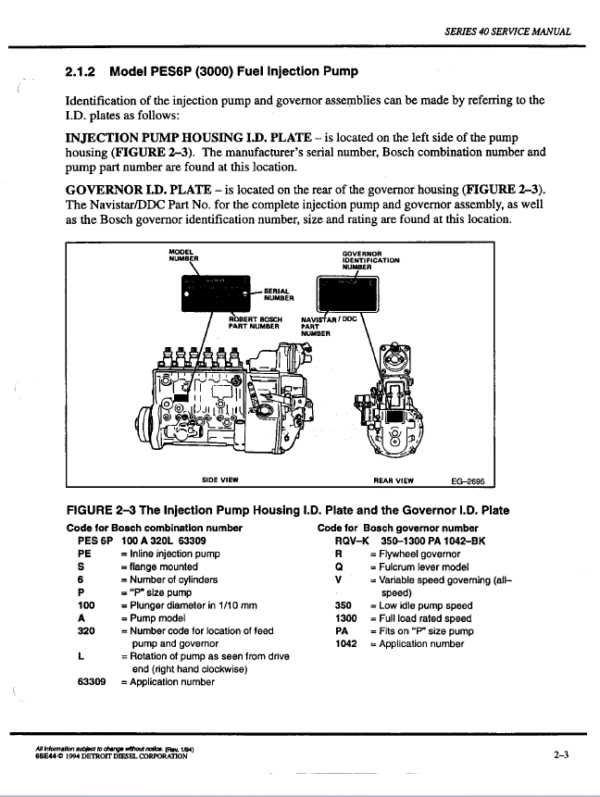

Bosch Injection Pump Overview

This section delves into the essential components and functionalities of a specific fuel delivery system designed for optimizing engine performance. It highlights the significance of precise fuel management in achieving efficiency and reliability in various automotive applications.

Functionality and Design

The device operates by precisely metering the amount of fuel delivered to the combustion chamber. Its innovative design ensures optimal atomization, which is crucial for efficient combustion. By utilizing advanced technology, the system adapts to varying operating conditions, enhancing overall engine performance.

Maintenance and Performance

Regular upkeep is vital to ensure longevity and peak efficiency. Attention to wear and tear can prevent potential issues that may arise from improper function. Moreover, understanding the system’s operation can help users identify performance fluctuations, leading to timely interventions.

In summary, mastering the intricacies of this fuel delivery system can significantly impact vehicle performance, making knowledge of its components and upkeep practices invaluable for enthusiasts and professionals alike.

Common Issues with Bosch Pumps

Understanding frequent challenges with fuel delivery systems can significantly enhance performance and longevity. Addressing these problems promptly ensures efficient operation and reduces the risk of extensive damage.

- Leaks: Seals and gaskets may degrade over time, leading to fluid loss.

- Air Entrapment: Air in the system can cause erratic performance and misfiring.

- Clogging: Particulate matter can accumulate, restricting flow and efficiency.

- Pressure Fluctuations: Inconsistent pressure can result from various mechanical failures.

- Electrical Failures: Issues with the electronic components may disrupt operation.

Regular maintenance and timely diagnostics are essential to mitigate these issues and maintain optimal functionality.

Tools Needed for Repair

When undertaking the task of servicing fuel delivery systems, having the right instruments is essential for achieving optimal results. Proper tools ensure that the components are handled safely and effectively, reducing the risk of damage and ensuring a smooth process.

- Wrenches: A set of combination wrenches will be necessary for loosening and tightening various fittings.

- Screwdrivers: Both flathead and Phillips screwdrivers in multiple sizes are crucial for accessing different parts.

- Socket Set: A complete socket set will help in tackling nuts and bolts that require more torque.

- Torque Wrench: This tool is vital for applying the correct amount of force to fasteners to avoid over-tightening.

In addition to the basic tools, specialized equipment may also be needed for specific tasks:

- Fuel Pressure Gauge: This allows for accurate measurement of system pressure during diagnostics.

- Cleaning Kit: A set of brushes and solvents for cleaning components is essential to maintain performance.

- Calibration Tools: These are necessary for ensuring that settings are adjusted correctly after servicing.

- Safety Gear: Gloves and goggles should be worn to protect against harmful substances and potential hazards.

Having these tools at your disposal will facilitate a more efficient and effective service process, ultimately leading to improved functionality of the system being worked on.

Step-by-Step Repair Process

This section provides a detailed approach to restoring fuel delivery mechanisms. By following a systematic method, you can ensure optimal functionality and longevity of the components involved.

1. Preparation: Gather all necessary tools and components before beginning the process. This includes wrenches, seals, and cleaning supplies.

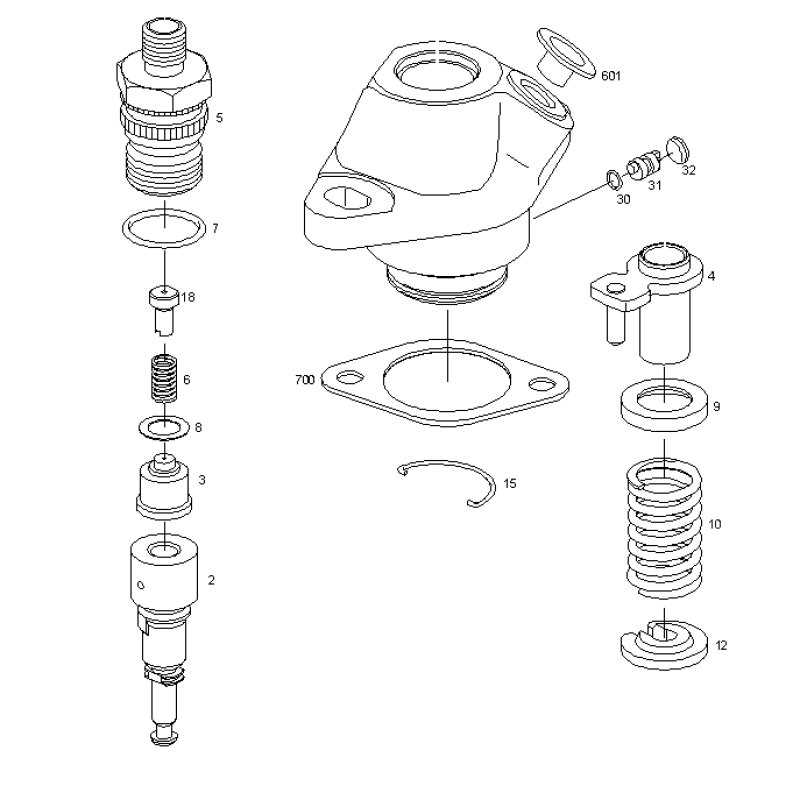

2. Disassembly: Carefully take apart the unit, noting the arrangement of parts. Use a clean workspace to avoid losing any small components.

3. Inspection: Examine each piece for wear and damage. Look for cracks, corrosion, or any irregularities that may affect performance.

4. Cleaning: Clean all components thoroughly to remove dirt and old residue. Use appropriate solvents and ensure all parts are dry before reassembly.

5. Replacement: Replace any worn or damaged parts with new, compatible pieces. Pay close attention to specifications to maintain efficiency.

6. Reassembly: Put the unit back together in the reverse order of disassembly. Ensure each part is securely fastened to prevent future issues.

7. Testing: Once reassembled, test the functionality under controlled conditions. Monitor for any leaks or irregular operation.

8. Final Adjustments: Make any necessary adjustments based on testing results to achieve optimal performance.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of complex mechanical systems requires regular attention and care. Implementing a few essential practices can significantly extend the lifespan of these components, allowing them to function efficiently over the years.

Regular Inspection

Conducting frequent checks is crucial to identify any signs of wear or damage early on. Look for leaks, unusual noises, or changes in performance. Addressing these issues promptly can prevent more severe problems down the line.

Proper Lubrication

Maintaining adequate lubrication is vital for smooth operation. Use the recommended types of oils and greases to minimize friction and wear. Regularly check and replenish lubrication levels to ensure all moving parts are adequately protected.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Look for leaks and wear |

| Lubrication Check | Every 3 Months | Ensure proper oil levels |

| Performance Testing | Every 6 Months | Assess efficiency and responsiveness |

Identifying Pump Failures

Recognizing the signs of malfunction in a fuel delivery system is crucial for maintaining optimal engine performance. Early detection of issues can prevent extensive damage and costly repairs. This section will explore common indicators of failure, allowing for timely intervention and corrective measures.

Common Symptoms of Malfunction

One of the first signs of trouble may be irregular engine behavior, such as stalling, misfiring, or reduced power output. These symptoms often point to inadequate fuel supply, which can stem from internal faults or external blockages. Additionally, unusual noises during operation, such as knocking or hissing, may suggest mechanical wear or component failure.

Diagnostic Techniques

To accurately diagnose issues, thorough inspections are essential. Visual assessments can reveal leaks or cracks in the housing. Pressure tests may also be employed to check for proper functioning under load. Utilizing diagnostic tools and software can provide deeper insights into the system’s performance, helping to pinpoint the exact nature of the malfunction.

Testing and Calibration Procedures

This section outlines the essential methods for evaluating and fine-tuning the performance of fuel delivery systems. Accurate assessment and adjustment are crucial for ensuring optimal operation and longevity of the equipment.

Follow these steps to conduct effective testing and calibration:

- Preparation:

- Gather necessary tools and equipment.

- Ensure the work area is clean and safe.

- Review technical specifications and guidelines.

- Initial Testing:

- Start the unit and observe its operation.

- Check for any unusual sounds or vibrations.

- Measure baseline performance metrics.

- Calibration:

- Adjust settings according to manufacturer specifications.

- Utilize calibration tools to verify accuracy.

- Document changes and results for future reference.

- Final Assessment:

- Conduct a comprehensive evaluation post-calibration.

- Compare results to initial performance metrics.

- Ensure all adjustments meet operational standards.

Regular testing and calibration are vital for maintaining system efficiency and reliability. Implementing these procedures can significantly enhance performance and reduce the risk of future issues.

Replacement Parts and Sources

When undertaking maintenance or restoration of precision fuel delivery systems, sourcing the right components is crucial for optimal performance and longevity. This section outlines various options for acquiring essential parts and highlights reliable sources for procurement.

| Part Type | Description | Recommended Suppliers |

|---|---|---|

| Seals and Gaskets | Critical for preventing leaks and ensuring efficient operation. | Local auto parts stores, online marketplaces |

| Valves | Regulate fuel flow and pressure, vital for system functionality. | Specialized fuel system suppliers, OEM distributors |

| Filters | Ensure cleanliness of fuel, protecting sensitive components. | Automotive supply chains, e-commerce platforms |

| Electronic Components | Control unit replacements and sensors for optimal performance. | Electronics retailers, manufacturer websites |

| Rebuild Kits | Comprehensive kits containing various components for overhaul. | Specialty shops, online retailers |

Ensuring access to quality replacement parts is essential for maintaining system efficiency. Engage with reputable suppliers to guarantee the reliability of components, enhancing the overall functionality of the system.

Safety Precautions During Repair

When undertaking maintenance tasks on complex mechanical systems, it is crucial to prioritize safety to prevent accidents and ensure a successful outcome. Following proper guidelines not only protects the technician but also preserves the integrity of the equipment being serviced. Adhering to safety protocols minimizes risks and promotes a secure working environment.

Essential Safety Measures

Before commencing any maintenance activities, it is important to consider the following safety measures:

| Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Wear appropriate gear such as gloves, goggles, and masks to shield against harmful substances. |

| Work Area | Maintain a clean and organized workspace to avoid tripping hazards and ensure easy access to tools. |

| Proper Tools | Utilize the right tools for the task to prevent damage and ensure efficiency. |

| Ventilation | Ensure adequate airflow in the workspace, especially when working with volatile substances. |

Emergency Preparedness

Being prepared for emergencies is vital. Ensure that first aid supplies are accessible and that all personnel are familiar with emergency protocols. Additionally, having a fire extinguisher on hand and knowing how to use it can be critical in case of an incident. Regular training on safety procedures enhances awareness and readiness.

When to Seek Professional Help

Understanding the complexities of your vehicle’s fuel delivery system is essential for maintaining its performance. While some issues can be resolved through basic troubleshooting and minor adjustments, there are instances when enlisting the expertise of a qualified technician is the wisest choice. Recognizing these moments can save you time, money, and potential damage to your vehicle.

Signs of Advanced Issues

If you notice persistent symptoms such as irregular engine performance, unusual noises, or leaks that do not improve with simple fixes, it is time to consult a professional. Diagnostic tools and specialized knowledge are often required to identify underlying problems that are not immediately apparent.

Safety Concerns

Any situation that poses a risk to your safety or the safety of others should be addressed by an expert. Fuel system malfunctions can lead to hazardous conditions, including fire risks or severe engine damage. Trusting a skilled mechanic ensures that your vehicle is not only functional but also safe to operate.