Comprehensive Repair Guide for Briggs and Stratton Model 130202

Maintaining small engines is crucial for ensuring their longevity and optimal performance. Understanding the intricacies of these machines can prevent common issues and enhance their efficiency. This guide serves as a valuable resource for those looking to troubleshoot and resolve typical problems encountered in the field.

Step-by-step instructions provide clarity on various tasks, from basic upkeep to more complex interventions. Whether you are an experienced technician or a novice enthusiast, having access to detailed information can significantly simplify the process of engine care. Knowledge of specific components and their functions is essential for effective maintenance.

Proactive care not only extends the life of the equipment but also improves overall safety and reliability. Familiarity with diagnostic techniques and repair strategies equips users with the tools needed to tackle issues head-on. By following this comprehensive guide, you can ensure your engine remains in peak condition for years to come.

Overview of Briggs and Stratton 130202

This section provides a comprehensive understanding of a specific small engine commonly utilized in various applications. Designed for durability and performance, this engine is widely recognized in the market for its reliability and efficiency. It is essential for users to grasp the fundamental features and specifications that set it apart from other models.

| Feature | Description |

|---|---|

| Engine Type | Single-cylinder, four-stroke engine |

| Displacement | Overhead valve design |

| Power Output | Rated horsepower around 4 to 5 HP |

| Fuel Type | Gasoline with a specific octane rating |

| Application | Used in lawnmowers, pressure washers, and various outdoor equipment |

Understanding these aspects is crucial for maintenance and troubleshooting, ensuring optimal performance in its designated roles. This engine exemplifies a balance between efficiency and power, making it a popular choice among users who demand reliability in their equipment.

Common Issues with Model 130202

This section addresses frequent problems encountered with this specific engine type. Understanding these challenges can significantly enhance troubleshooting and maintenance efforts.

Fuel System Problems

Issues with fuel delivery are prevalent, often stemming from clogged filters or stale gasoline. Regular inspection of the fuel lines and tank is essential to ensure optimal performance. Replacing filters periodically can prevent potential blockages and keep the engine running smoothly.

Starting Difficulties

Many users report struggles with starting the engine, which can be attributed to faulty spark plugs or battery issues. Checking the ignition system is crucial, as well as ensuring the battery is charged and connections are secure. Regular maintenance can help mitigate these starting challenges.

Essential Tools for Repairing Engines

When working on engines, having the right equipment is crucial for efficient maintenance and troubleshooting. A well-equipped toolkit not only enhances the repair process but also ensures safety and accuracy. Understanding the necessary instruments can significantly improve the outcome of any mechanical task.

Basic Tools Required

Every engine enthusiast should have a set of fundamental tools that facilitate various repair activities. These items are versatile and essential for both minor adjustments and major overhauls.

| Tool | Description |

|---|---|

| Wrenches | Used for tightening and loosening nuts and bolts. |

| Screwdrivers | Essential for adjusting screws of different types. |

| Pliers | Helpful for gripping and manipulating small parts. |

| Socket Set | Provides a range of sizes for various fasteners. |

| Torque Wrench | Ensures proper tightening of components to avoid damage. |

Advanced Equipment for Complex Repairs

For those tackling more intricate tasks, additional specialized tools can make a significant difference. Investing in advanced equipment can streamline complex procedures and enhance overall efficiency.

| Tool | Description |

|---|---|

| Compression Tester | Measures the compression levels in cylinders to assess engine health. |

| Fuel Pressure Gauge | Checks fuel system pressure for optimal performance. |

| Diagnostic Scanner | Reads error codes and monitors engine performance. |

| Work Light | Illuminates dark areas for better visibility during repairs. |

| Engine Hoist | Facilitates the lifting of heavy engine components safely. |

Step-by-Step Repair Process

This section outlines a comprehensive procedure to troubleshoot and fix common issues encountered in small engines. Following a systematic approach ensures effective resolution of problems while minimizing the risk of further complications.

1. Gather Necessary Tools and Parts: Before starting, collect all essential tools such as wrenches, screwdrivers, and replacement components. Having everything on hand will streamline the process.

2. Safety Precautions: Always prioritize safety by wearing protective gear. Disconnect the power source and ensure the engine is cool before proceeding with any maintenance tasks.

3. Inspect the Engine: Begin by visually examining the unit for any obvious signs of damage or wear. Check for leaks, loose connections, or frayed wires that may indicate underlying issues.

4. Clean the Components: Use a suitable cleaner to remove dirt and debris from the engine parts. Keeping surfaces clean helps in identifying problems more easily and improves the performance of the engine.

5. Replace Worn Parts: Identify any components that show significant wear or damage. Replace these parts with new ones to ensure optimal functionality. Consult a parts list if necessary.

6. Reassemble the Unit: Carefully reassemble the engine, ensuring all parts are correctly positioned and secured. Double-check connections to avoid any misalignment.

7. Test the Engine: Once reassembled, reconnect the power source and conduct a test run. Observe the performance and listen for any unusual noises that might indicate further issues.

8. Final Adjustments: Make any necessary adjustments based on the test results. This may involve tuning the carburetor or adjusting the throttle settings for optimal operation.

By following these detailed steps, you can effectively address and resolve engine issues, ensuring reliable performance for your equipment.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. By following a few essential practices, you can enhance performance and extend the lifespan of your machine. Regular upkeep not only prevents issues but also promotes efficiency during operation.

First, always check and change the oil at the recommended intervals. Clean oil is vital for smooth functioning and helps reduce wear on internal components. Additionally, inspect air filters regularly and replace them as needed to maintain optimal airflow and prevent debris from entering the system.

Keep the exterior clean by removing dirt and debris, especially around cooling fins. This prevents overheating and maintains proper airflow. Moreover, inspect spark plugs for wear and replace them to ensure reliable ignition and efficient fuel usage.

Finally, store your equipment in a dry place to protect it from the elements. During prolonged periods of inactivity, consider running the machine briefly to keep the parts lubricated. Following these guidelines will lead to improved performance and a longer lifespan for your equipment.

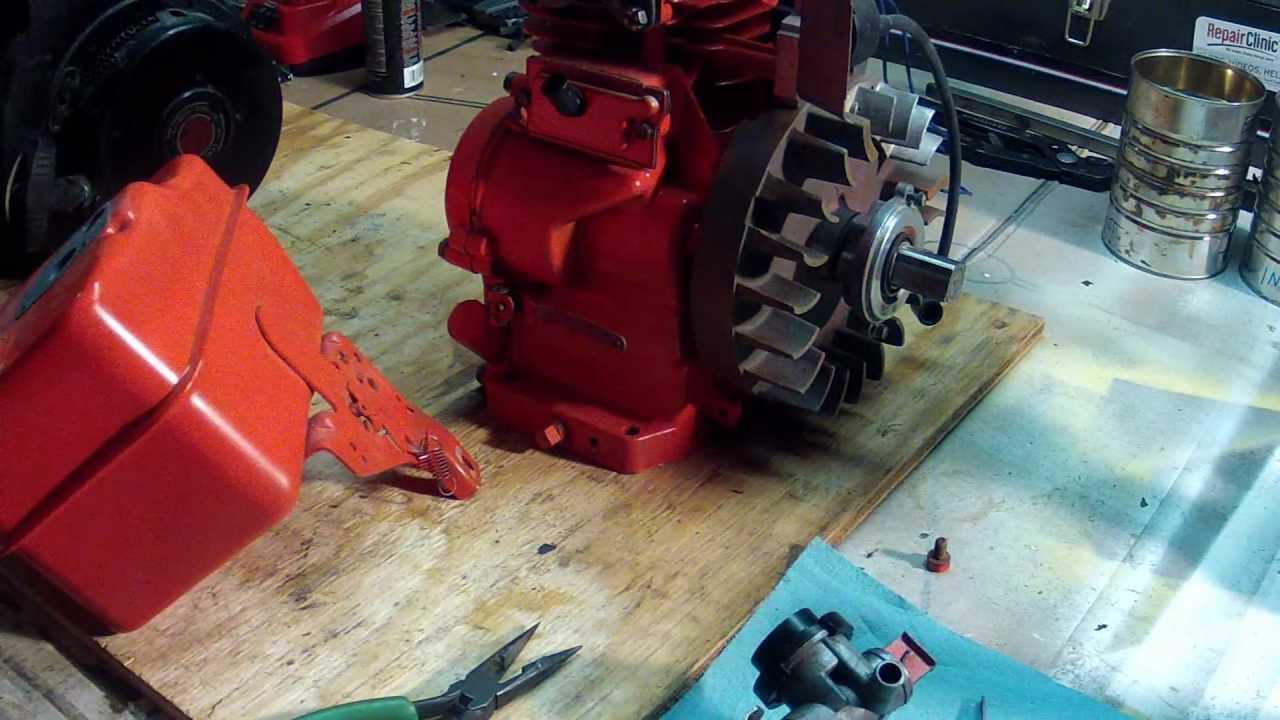

Identifying Engine Components Easily

Understanding the various parts of a power unit is essential for effective maintenance and troubleshooting. This knowledge helps users recognize components, diagnose issues, and perform necessary adjustments or replacements with confidence.

Key Components to Recognize

- Cylinder: The chamber where fuel and air mix, allowing combustion to occur.

- Piston: Moves up and down within the cylinder, converting combustion energy into mechanical work.

- Crankshaft: Transforms the linear motion of the piston into rotational motion.

- Flywheel: Stores rotational energy and stabilizes engine speed during operation.

- Carburetor: Mixes air and fuel in the right proportions for efficient combustion.

- Ignition System: Provides the spark needed to ignite the air-fuel mixture.

Tips for Easy Identification

- Familiarize yourself with diagrams and schematics of the engine layout.

- Use color coding or labels for different parts if you’re working on assembly or disassembly.

- Refer to a parts list or inventory to ensure all components are accounted for.

- Practice identifying parts by their function, which will help reinforce your understanding.

By learning to identify these components, you can ensure smoother operation and longevity of the power unit, making maintenance tasks much simpler.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety and the proper functioning of equipment is paramount. Familiarizing oneself with potential hazards and implementing protective measures can significantly reduce the risk of accidents. Following guidelines not only safeguards the individual but also contributes to the longevity and efficiency of the machinery.

First and foremost, it is essential to wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and sturdy footwear to shield against potential injuries. Additionally, long sleeves and trousers can provide further protection from sharp edges and moving parts.

Before starting any work, always disconnect the power source. This step is critical to prevent accidental activation of the equipment, which could lead to severe injuries. Ensure that all tools are in good condition and suitable for the tasks at hand, as using damaged or inappropriate tools can compromise safety.

Furthermore, maintain a clean and organized workspace. Clutter can lead to slips and falls, so it is advisable to keep the area free of unnecessary items. Proper lighting is also vital to ensure clear visibility while working on intricate components.

Finally, be aware of any specific safety instructions provided by the manufacturer. These guidelines are designed to address unique characteristics of the machinery and can provide crucial information for safe handling. By adhering to these precautions, you can create a safer environment and facilitate effective maintenance.

Replacing Key Engine Parts

Maintaining engine performance often necessitates the replacement of essential components. Identifying which parts require attention is crucial for ensuring optimal functionality and longevity. This section provides guidance on the key elements that may need to be swapped out during maintenance.

Common components that often require replacement include the piston, valves, and gaskets. Each of these parts plays a vital role in the engine’s overall operation, and their wear can lead to decreased performance or even failure. Below is a summary of these parts, along with signs that indicate they may need replacing.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Piston | Loss of compression, unusual noises | Ensure proper fit and lubrication |

| Valves | Rough idling, decreased power | Check alignment and sealing |

| Gaskets | Leaks, overheating | Clean surfaces thoroughly before installation |

By staying vigilant and replacing worn parts promptly, you can significantly enhance the reliability and performance of your engine. Regular checks and maintenance will contribute to a smoother operation and reduce the likelihood of more extensive repairs in the future.

Troubleshooting Engine Performance Problems

Addressing performance issues in small engines can be crucial for maintaining efficiency and reliability. Identifying the root causes of poor operation is essential for restoring optimal functionality. This guide provides key steps to troubleshoot common performance challenges.

Start by assessing the following factors:

- Fuel Quality: Ensure the fuel is fresh and free from contaminants. Old or dirty fuel can lead to poor combustion.

- Air Filter Condition: Check the air filter for clogs. A dirty filter restricts airflow, impacting engine performance.

- Spark Plug Status: Inspect the spark plug for wear or carbon buildup. A faulty plug can cause misfires and decreased power.

Next, evaluate the following systems:

- Fuel System: Look for leaks or blockages in the fuel lines and carburetor. Proper fuel flow is essential for engine function.

- Ignition System: Test the ignition coil and wiring for continuity. Issues here can prevent the engine from starting or running smoothly.

- Compression Levels: Use a compression gauge to check for adequate pressure. Low compression can indicate internal wear or damage.

Finally, consider environmental factors:

- Operating Conditions: Extreme temperatures can affect engine performance. Ensure the engine is suitable for the environment in which it operates.

- Load Management: Avoid overloading the engine, as excessive strain can lead to performance degradation.

By systematically evaluating these aspects, you can effectively diagnose and address performance issues, ensuring the engine runs smoothly and efficiently.

Resources for Additional Support

When tackling maintenance or troubleshooting for your equipment, accessing reliable resources can significantly enhance your experience. Various platforms and tools are available to provide assistance, whether through online forums, user guides, or specialized support services. Utilizing these resources can ensure that you receive accurate information and solutions tailored to your specific needs.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Engage with communities of enthusiasts and experts who share tips and advice. | Visit Forum |

| User Manuals | Access comprehensive guides that outline specifications, parts, and troubleshooting steps. | View Manuals |

| Video Tutorials | Watch step-by-step videos demonstrating repairs and maintenance tasks. | Watch Tutorials |

| Customer Support | Contact professional services for personalized assistance and inquiries. | Contact Support |

Understanding Engine Specifications

When it comes to the performance and functionality of small engines, grasping the specifications is essential. These details provide insights into the capabilities, efficiency, and maintenance needs of the engine, guiding users in optimal usage and care.

Key specifications typically include aspects such as displacement, power output, torque, and fuel type. Each of these elements plays a crucial role in determining how the engine operates under various conditions. For instance, displacement refers to the total volume of the engine’s cylinders, influencing its power and efficiency.

Understanding power output helps users gauge the engine’s performance for specific tasks. Higher power ratings generally indicate a stronger engine, suitable for more demanding applications. Similarly, torque is critical for tasks requiring sustained force, affecting the engine’s ability to perform under load.

Lastly, knowing the recommended fuel type ensures optimal performance and longevity. Using the appropriate fuel prevents potential damage and enhances efficiency, ultimately leading to a more reliable engine operation.

Frequently Asked Questions about Repairs

This section addresses common inquiries regarding maintenance and troubleshooting for small engines. Understanding these frequently asked questions can help users efficiently resolve issues and enhance their knowledge of proper care techniques.

| Question | Answer |

|---|---|

| What are the signs that my engine needs servicing? | Indicators may include unusual noises, reduced performance, or difficulty starting. |

| How often should I perform maintenance? | Regular checks are recommended every 25-50 hours of operation, or at least annually. |

| What tools are necessary for basic upkeep? | A set of wrenches, screwdrivers, spark plug socket, and a multimeter are essential. |

| Can I fix fuel-related issues myself? | Yes, checking for blockages and ensuring the correct fuel mixture can often resolve such problems. |

| When should I consult a professional technician? | If the problem persists despite your efforts, or if you encounter complex issues, professional help is advisable. |