Briggs Stratton 10A902 Repair Guide

This section provides essential insights into the upkeep and troubleshooting of small power units, ensuring optimal performance and longevity. Understanding the intricacies of these machines is vital for effective operation and maintenance.

Regular maintenance is crucial for any engine, as it not only enhances efficiency but also prevents unexpected breakdowns. This guide offers step-by-step instructions and tips to address common issues that users may encounter.

For those looking to improve their understanding, familiarity with components and their functions will be beneficial. Proper techniques for adjustments and care will be highlighted, empowering users to tackle maintenance with confidence.

Understanding the intricacies of your power unit is essential for effective maintenance and optimal performance. This section aims to provide insights into the essential features and characteristics that define your specific engine variant, helping you navigate its components with ease.

Key aspects to consider when familiarizing yourself with your engine include:

- Identification: Recognizing the unique attributes of your model is crucial for sourcing parts and resources.

- Components: Familiarity with various parts and their functions can enhance your ability to troubleshoot issues effectively.

- Specifications: Understanding the technical specifications aids in proper maintenance and operational efficiency.

- Usage Guidelines: Following the recommended practices ensures longevity and reliability of the engine.

By grasping these fundamental elements, you will be better equipped to handle maintenance tasks and address potential challenges that may arise during operation.

Common Issues with Briggs Stratton Engines

Engines from this manufacturer are known for their reliability, yet they may encounter a range of challenges over time. Understanding these potential problems can help users maintain optimal performance and longevity.

| Issue | Description | Possible Solutions |

|---|---|---|

| Hard Starting | Difficulty in starting the engine, often due to fuel or ignition issues. | Check the fuel quality, inspect the spark plug, and ensure the battery is charged. |

| Excessive Vibration | Unusual shaking during operation, which may indicate misalignment or damage. | Examine the mounting bolts, inspect for damaged components, and balance the blades. |

| Overheating | Engines can become excessively hot, which may lead to severe damage if not addressed. | Ensure proper cooling by checking the air intake and cleaning any debris from the fins. |

| Fuel Leaks | Leaks can occur from various fuel lines, leading to safety hazards and performance issues. | Inspect all connections and replace any damaged hoses or seals. |

Essential Tools for Repairs

When tackling maintenance tasks, having the right instruments is crucial for ensuring efficiency and effectiveness. A well-equipped toolkit can significantly simplify the process, allowing for smoother operations and better outcomes. Below are some fundamental items that every enthusiast should consider including in their collection.

Basic Hand Tools

- Wrenches: A variety of sizes will help tackle different fasteners.

- Screwdrivers: Both flathead and Phillips types are essential for various applications.

- Pliers: Useful for gripping, twisting, and cutting wire.

Specialized Equipment

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Great for diagnosing electrical issues and ensuring proper connections.

- Compression Tester: Helps assess engine performance by measuring cylinder pressure.

Step-by-Step Maintenance Procedures

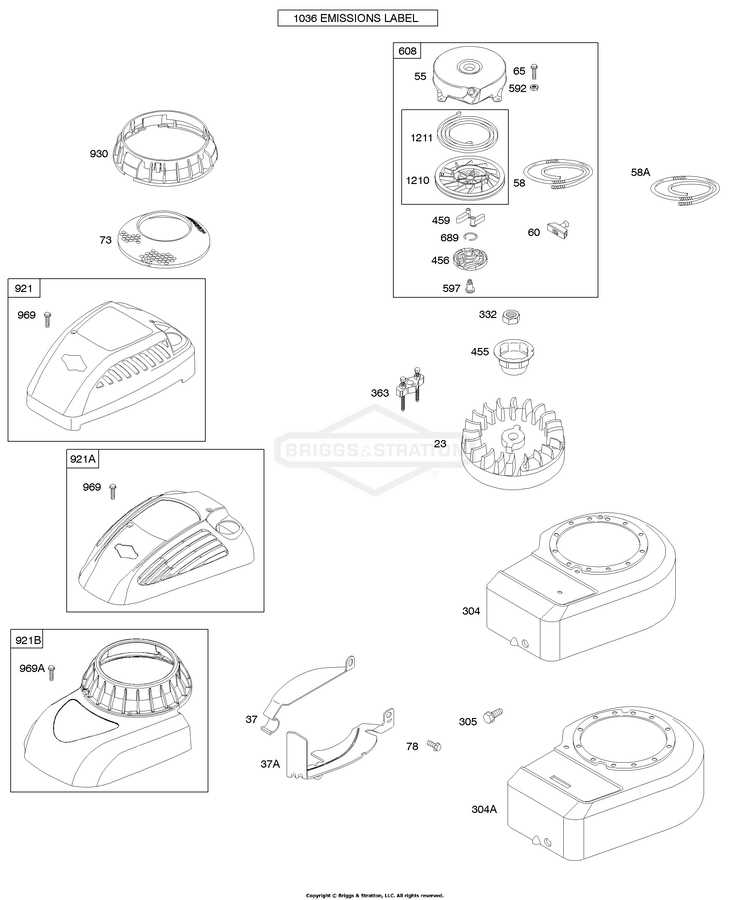

Proper upkeep of your engine is essential for optimal performance and longevity. Following a systematic approach to maintenance ensures that all critical components function smoothly and efficiently. This section outlines essential procedures that can help maintain the engine’s reliability and performance.

1. Inspect and Clean the Air Filter

Begin by removing the air filter cover and taking out the filter. Inspect it for dirt and debris. If it’s excessively dirty, clean it with soapy water and let it dry completely before reinserting. A clean air filter promotes better airflow and engine efficiency.

2. Change the Oil

Drain the old oil by removing the drain plug and allow it to fully empty into a suitable container. Replace the drain plug and refill with fresh oil according to the manufacturer’s specifications. Regular oil changes reduce engine wear and maintain optimal performance.

3. Spark Plug Maintenance

Remove the spark plug using a socket wrench. Inspect the electrode for wear and deposits. Clean or replace it if necessary. A properly functioning spark plug ensures efficient combustion and reliable starting.

4. Fuel System Check

Examine the fuel lines for cracks or leaks. Replace any damaged sections. Ensure the fuel filter is clean, as a clogged filter can restrict fuel flow and affect engine performance. Use fresh fuel to prevent buildup of deposits.

5. Blade Sharpening

If applicable, remove the blade and sharpen it using a file or grinder. A sharp blade provides a clean cut, which promotes healthier grass. Reinstall the blade securely before starting the engine.

By following these maintenance steps regularly, you can enhance the performance and lifespan of your engine, ensuring it operates efficiently when needed.

Diagnosing Engine Performance Problems

Identifying issues related to engine efficiency is crucial for ensuring optimal functionality. This process involves systematically evaluating various components to pinpoint the root cause of diminished performance. By employing a structured approach, one can enhance both reliability and longevity.

Common Symptoms of Poor Performance

Engines exhibiting lackluster performance may display several telltale signs. Reduced power output is often a primary indicator, which may manifest as sluggish acceleration or difficulty maintaining speed. Additionally, irregular engine sounds, such as knocking or excessive vibration, can signify underlying problems that require immediate attention.

Step-by-Step Diagnostic Approach

To effectively diagnose performance issues, begin with a thorough inspection of the fuel system. Check for clogged filters or inadequate fuel delivery, as these can significantly impact engine operation. Next, evaluate the ignition system for faulty spark plugs or wiring, as these elements play a vital role in combustion efficiency. Finally, assess the air intake and exhaust systems to ensure proper airflow, which is essential for optimal engine performance.

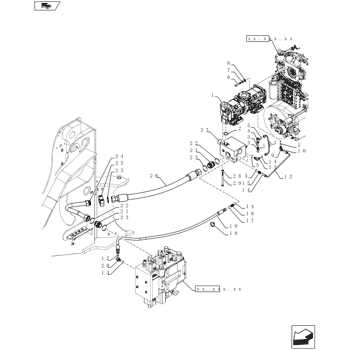

Fuel System Troubleshooting Tips

Ensuring optimal performance of your engine requires careful attention to the fuel system. A properly functioning fuel system is crucial for efficient operation, and identifying potential issues early can prevent more significant problems down the line.

1. Check Fuel Quality: Always start by examining the fuel itself. Contaminated or stale fuel can cause starting difficulties and poor performance. Consider draining old fuel and replacing it with fresh, clean fuel that meets the manufacturer’s specifications.

2. Inspect Fuel Lines: Damaged or cracked fuel lines can lead to leaks, resulting in inadequate fuel delivery. Regularly inspect these lines for any signs of wear or deterioration and replace them as necessary.

3. Examine the Fuel Filter: A clogged fuel filter can restrict fuel flow, causing the engine to stall or run inefficiently. Check the filter regularly and replace it if you notice any signs of blockage or discoloration.

4. Assess the Fuel Pump: If the engine struggles to start or runs inconsistently, the fuel pump may be failing. Listen for unusual noises and check for proper operation to ensure the pump delivers fuel effectively.

5. Clean the Carburetor: Build-up of debris in the carburetor can disrupt the fuel-air mixture, leading to poor engine performance. Regular cleaning and maintenance can help maintain smooth operation.

Electrical Components Inspection Guide

This section provides essential guidance for evaluating the various electrical elements within your machinery. Understanding how to properly assess these components ensures optimal performance and longevity of the device.

When inspecting electrical components, consider the following key areas:

- Connections: Examine all wiring and connectors for signs of wear, corrosion, or loose fittings. Secure connections are crucial for effective functionality.

- Insulation: Check for any damage to the insulation on wires. Frayed or cracked insulation can lead to shorts or failures.

- Voltage Levels: Use a multimeter to verify that the voltage levels are within the specified range. Irregular readings may indicate underlying issues.

- Switch Functionality: Test all switches to ensure they operate smoothly and correctly. A faulty switch can disrupt overall performance.

- Grounding: Ensure that all components are properly grounded to prevent electrical shock or equipment damage.

By following these inspection guidelines, you can maintain the reliability of your equipment and address any potential electrical problems before they escalate.

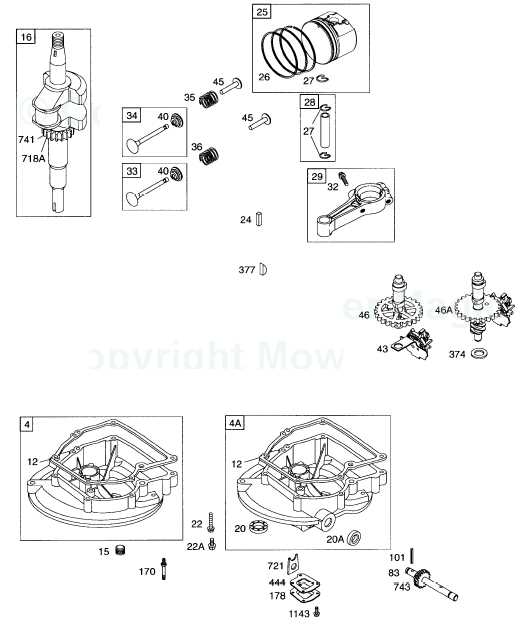

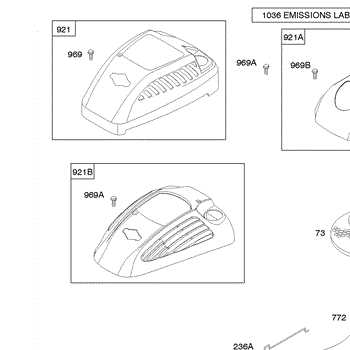

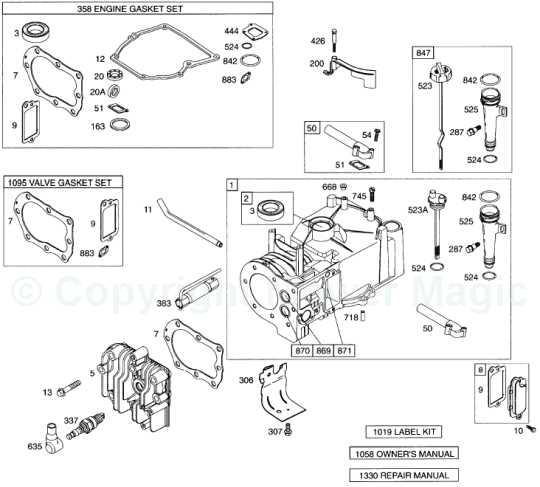

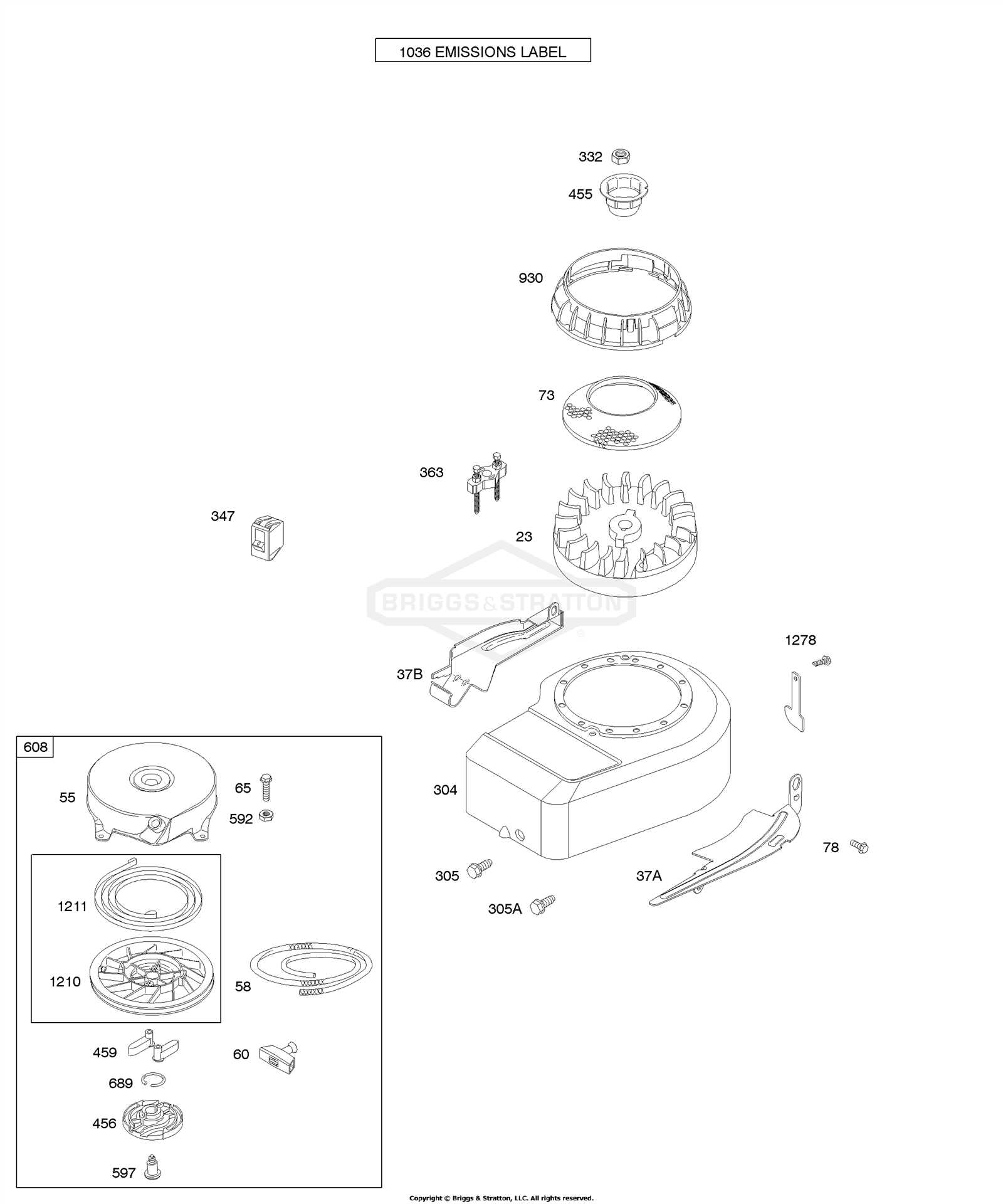

Replacing Key Engine Parts

Maintaining the performance of a small engine often requires the replacement of essential components. Understanding the signs that indicate a need for these replacements can significantly enhance the longevity and efficiency of the equipment. This section outlines the process and considerations for swapping out vital engine parts.

Identifying Components for Replacement

Before proceeding with any replacements, it’s crucial to identify which parts may be worn or malfunctioning. Common components that often require attention include the spark plug, air filter, and fuel lines. Regular inspection can help determine when these elements should be changed to maintain optimal performance.

Replacement Procedure

When preparing to replace engine parts, ensure you have the right tools and components on hand. Here’s a brief guide:

| Part | Replacement Steps |

|---|---|

| Spark Plug | Remove the old spark plug using a socket wrench. Install the new plug and tighten it securely. |

| Air Filter | Open the air filter cover, take out the old filter, and insert the new one, ensuring a snug fit. |

| Fuel Line | Disconnect the old line from the fuel tank and carburetor. Attach the new line, ensuring there are no leaks. |

By following these steps, you can effectively maintain and improve the functionality of your engine, ensuring it runs smoothly for years to come.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, it is essential to prioritize safety. Ensuring a secure environment not only protects the individual performing the work but also prevents potential damage to the equipment. Following a set of guidelines can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Utilizing appropriate personal protective gear is vital. This includes wearing safety goggles to shield the eyes from debris, gloves to protect the hands from sharp objects and chemicals, and sturdy footwear to provide support and protection. Always ensure that clothing is fitted and does not have loose ends that could get caught in moving parts.

Work Area Organization

Maintaining a well-organized workspace is crucial. Keep tools and materials neatly arranged to minimize hazards. Ensure that the area is free from clutter, as this can lead to tripping or accidental contact with equipment. Additionally, proper lighting should be provided to enhance visibility, allowing for more accurate and safer work.

Recommended Maintenance Schedule

Establishing a consistent maintenance routine is essential for ensuring optimal performance and longevity of your equipment. By adhering to a planned schedule, you can prevent common issues and enhance the efficiency of your machinery.

Regular Checks

It is advisable to conduct periodic inspections of various components. This includes examining the oil levels, checking for any signs of wear, and ensuring that all parts are functioning properly. Regularly replacing filters and fluids can significantly improve the overall operation.

Seasonal Servicing

Seasonal servicing should be scheduled to prepare your equipment for the upcoming usage period. This may involve a thorough cleaning, lubrication of moving parts, and replacement of any worn components. Following these guidelines will help maintain peak performance and reliability throughout the year.

Upgrading Your Engine Performance

Enhancing the efficiency and power of your engine can significantly improve its overall performance. By focusing on key areas, you can unlock the full potential of your equipment, ensuring a smoother and more responsive operation.

Here are some effective strategies to consider:

- Regular Maintenance: Keeping your engine well-maintained is crucial. This includes routine oil changes, filter replacements, and spark plug inspections.

- Fuel Quality: Using high-quality fuel can make a noticeable difference. Opt for fuel that meets the specifications recommended for your engine.

- Airflow Improvement: Enhancing the airflow into your engine can increase combustion efficiency. Consider upgrading the air intake system for better performance.

- Exhaust System Optimization: A well-designed exhaust system can improve the expulsion of gases, contributing to better engine output. Evaluate options for a more efficient exhaust setup.

- Tuning: Adjusting engine settings can lead to improved power delivery. Consider consulting a professional for tuning services tailored to your specific needs.

Implementing these upgrades can lead to a noticeable boost in your engine’s performance, making it more capable and efficient in its tasks.

Resources for Further Assistance

When dealing with maintenance or troubleshooting of outdoor power equipment, accessing reliable information can significantly enhance your understanding and efficiency. This section provides valuable resources that can guide you in resolving issues or improving your knowledge.

- Online Forums: Participate in community discussions where enthusiasts share experiences and solutions.

- Manufacturer Websites: Explore official websites for product specifications, troubleshooting guides, and instructional videos.

- Local Repair Shops: Consult with local technicians who can offer hands-on assistance and advice tailored to your equipment.

- Instructional Books: Look for literature that covers maintenance techniques and best practices for similar machinery.

- Social Media Groups: Join groups dedicated to outdoor equipment where members frequently exchange tips and support.

Utilizing these resources can empower you to tackle challenges effectively and enhance your overall proficiency with your equipment.