Comprehensive Guide to Briggs and Stratton Repair Manual

Maintaining outdoor power equipment is crucial for ensuring its longevity and optimal performance. A well-functioning engine not only enhances productivity but also minimizes the risk of unexpected breakdowns. This comprehensive resource offers valuable insights into troubleshooting, routine care, and intricate adjustments that can help users keep their machines in peak condition.

Understanding the mechanics behind engine operation is fundamental for anyone looking to extend the life of their equipment. By delving into various aspects of upkeep, including parts identification and common issues, individuals can empower themselves with the knowledge to tackle challenges effectively. This guide aims to equip users with the necessary tools to navigate through maintenance tasks confidently.

Whether you’re a seasoned professional or a novice enthusiast, mastering the art of engine upkeep can save time and resources. From seasonal checks to detailed repairs, having access to clear instructions and expert tips will make the process much more manageable. Embrace the opportunity to learn and enhance your skills in maintaining your outdoor machinery.

Understanding Briggs & Stratton Engines

Familiarity with small engine technology is essential for anyone looking to maintain or operate outdoor power equipment effectively. These engines, known for their reliability and versatility, power various tools and machines, from lawn mowers to generators. Understanding their components and functionality can enhance performance and longevity, allowing users to tackle maintenance tasks with confidence.

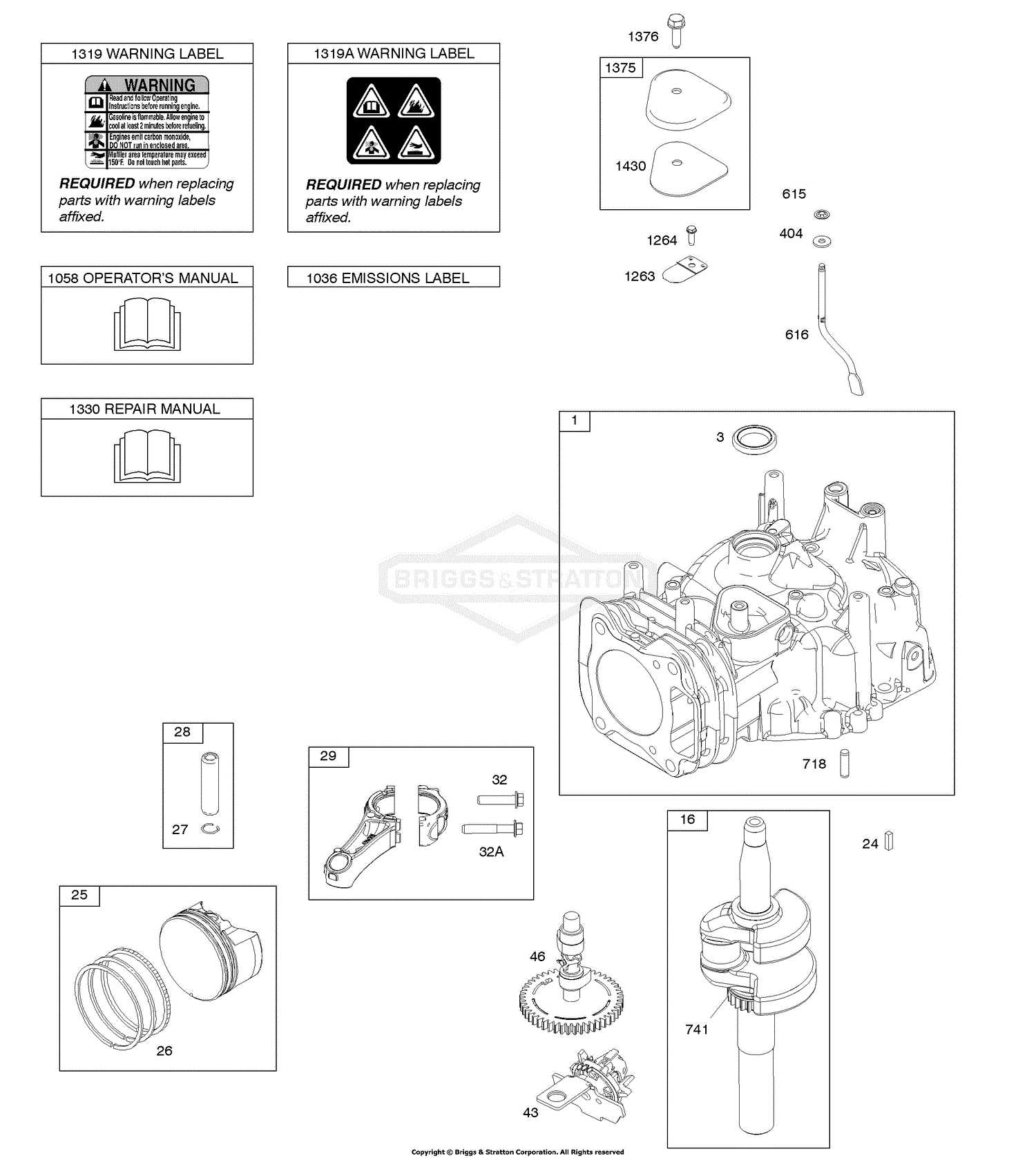

The core of these power units lies in their design and engineering. Each engine consists of several critical parts that work in unison to convert fuel into mechanical energy. Gaining insight into these components can aid in troubleshooting and optimizing performance.

| Component | Description |

|---|---|

| Carburetor | Mixes air and fuel for combustion. |

| Piston | Moves up and down to create compression. |

| Crankshaft | Converts linear motion of the piston into rotational motion. |

| Spark Plug | Ignites the air-fuel mixture for combustion. |

| Fuel Tank | Holds the gasoline or fuel needed for operation. |

Each of these components plays a vital role in ensuring optimal operation. Regular checks and maintenance of these parts can prevent many common issues and extend the engine’s service life. With proper understanding, users can effectively manage their equipment, ensuring it runs smoothly and efficiently.

Common Problems and Solutions

When dealing with small engines, several issues can arise that may hinder performance and efficiency. Understanding these typical challenges and their remedies can save time and ensure smooth operation. Below, we outline frequent malfunctions and practical fixes to keep your machinery running optimally.

Issue: Engine Won’t Start

One of the most common complaints is when the engine fails to ignite. This could be due to a drained battery, dirty spark plugs, or an empty fuel tank. To resolve this, check the battery’s charge, clean or replace the spark plugs, and ensure there is sufficient fuel.

Issue: Rough Idle or Stalling

If the engine runs inconsistently or stalls frequently, it may indicate a clogged air filter or fuel line. Inspect these components and clean or replace them as needed to restore smooth operation.

Issue: Excessive Smoke

Seeing smoke can be alarming, and it usually points to oil leaking into the combustion chamber or a rich fuel mixture. To address this, check the oil levels and condition, and adjust the carburetor settings to achieve the correct fuel-air ratio.

Issue: Overheating

Engines can overheat for various reasons, such as low coolant levels or blocked vents. Ensure the coolant is topped up and that vents are clear to promote proper airflow, preventing potential damage.

By identifying these common problems and implementing the suggested solutions, users can maintain their equipment effectively and prolong its lifespan.

Essential Tools for Engine Repair

When working on small machinery, having the right instruments at your disposal is crucial for ensuring efficiency and accuracy. This collection of essential gear allows for effective troubleshooting, maintenance, and enhancement of engine performance. From basic hand tools to specialized equipment, each item plays a significant role in the overall process of machine upkeep.

Basic Hand Tools

Starting with the fundamentals, a set of hand tools is indispensable. Wrenches, screwdrivers, and pliers are the core items you will frequently use. These tools facilitate the loosening and tightening of various components, allowing for straightforward access to internal parts. A good-quality ratchet set can significantly speed up your work, enabling quick changes and adjustments without the hassle of manually switching tools.

Specialized Equipment

In addition to hand tools, certain specialized instruments enhance precision and ease of work. Torque wrenches are essential for applying the correct tension to bolts, ensuring that everything is securely fastened. A compression tester is another vital device, helping to assess the engine’s health by measuring the pressure within the cylinders. Investing in these specialized tools will lead to more thorough diagnostics and a better understanding of your machinery’s needs.

Step-by-Step Maintenance Procedures

Regular upkeep of outdoor power equipment ensures optimal performance and longevity. By following systematic maintenance steps, users can prevent common issues and enhance efficiency. This section outlines essential procedures to keep your machinery in top shape.

| Task | Frequency | Tools Needed |

|---|---|---|

| Check Oil Level | Every Use | Dipstick |

| Change Oil | Every 50 Hours | Wrench, Oil Container |

| Inspect Air Filter | Every 25 Hours | Cleaning Brush |

| Sharpen Blades | Seasonally | File, Wrench |

| Check Spark Plug | Annually | Socket Wrench |

Following these structured maintenance tasks will not only prolong the life of your equipment but also ensure that it operates safely and efficiently. Make it a habit to adhere to these guidelines for best results.

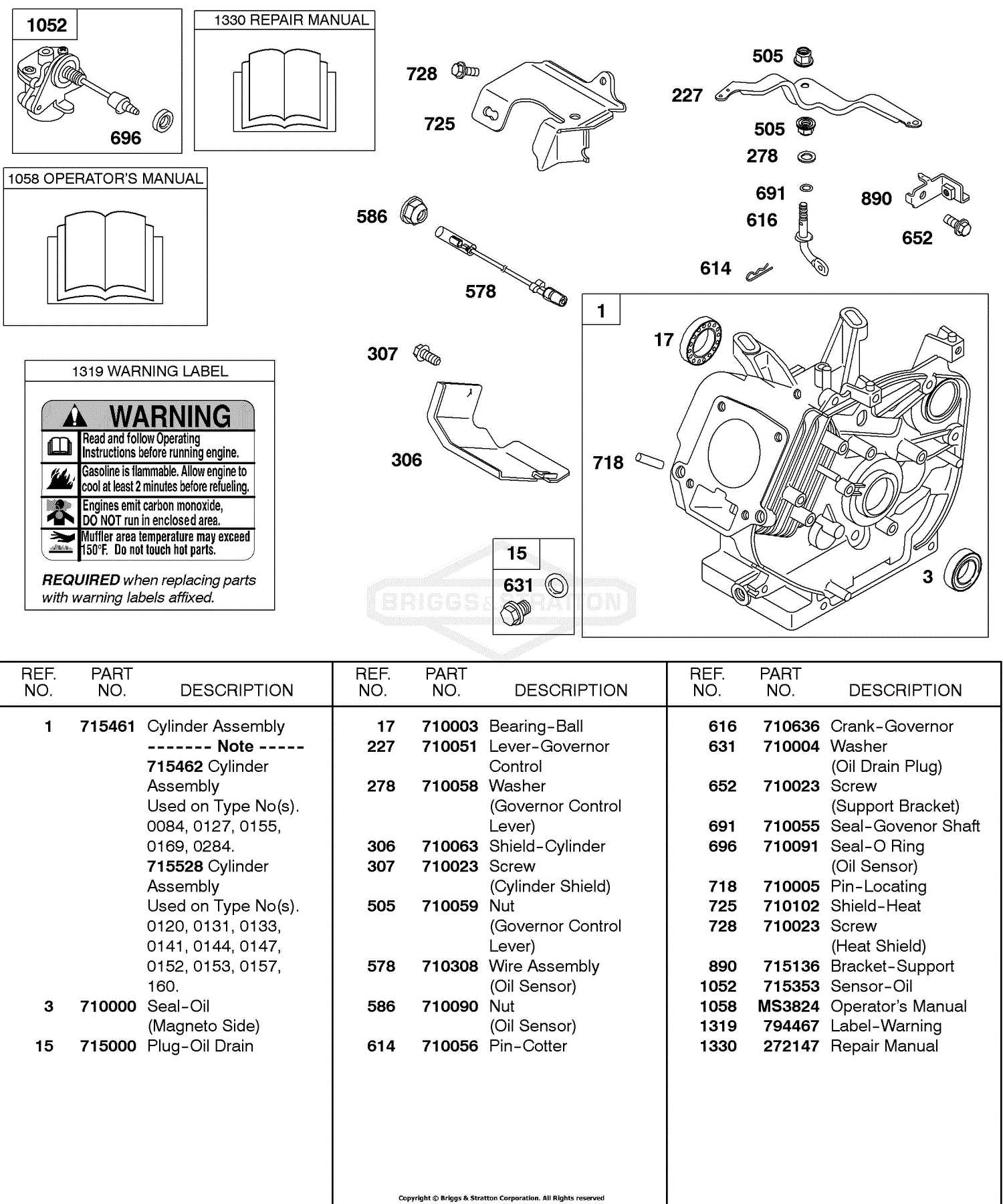

Identifying Engine Model Numbers

Understanding how to recognize engine model numbers is crucial for effective maintenance and troubleshooting. Each engine is assigned a unique identifier that provides essential information about its specifications and components. By knowing how to locate and interpret these numbers, users can ensure they are obtaining the correct parts and service for their specific engine type.

Where to Find the Model Number

The model number can typically be found on the engine itself. Common locations include the engine’s housing, near the spark plug, or on the starter cover. Familiarizing yourself with these areas can save time during identification.

Importance of Accurate Identification

Accurate identification is vital for ensuring compatibility with replacement parts and accessories. Misidentifying the model can lead to errors in ordering parts, resulting in delays and increased costs. Therefore, always double-check the model number before making a purchase.

| Location | Description |

|---|---|

| Engine Housing | Look for a label or embossed number on the side of the engine. |

| Near Spark Plug | Some models feature the number close to the spark plug area for easy access. |

| Starter Cover | Check under or beside the starter cover for identification details. |

Safety Precautions During Repairs

Ensuring personal safety while undertaking maintenance tasks is essential. Proper precautions can prevent accidents and injuries, creating a secure environment for any work to be performed. Familiarity with safety measures not only protects the individual but also contributes to the longevity of the equipment.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure the work area is well-ventilated and free from clutter to minimize hazards.

- Disconnect the power source before beginning any work to prevent accidental starts.

- Keep tools organized and within reach to avoid unnecessary movements that could lead to injuries.

Handling Hazardous Materials

- Store chemicals and fuels in labeled containers away from direct sunlight and heat sources.

- Read labels and safety data sheets for proper handling and first-aid measures.

- Dispose of waste materials according to local regulations to ensure environmental safety.

- In case of spills, use appropriate absorbent materials and clean up immediately to prevent slips and falls.

How to Replace Key Components

Maintaining the functionality of small engines involves occasional component replacement. This section provides a straightforward guide to help you navigate the process efficiently. Understanding how to swap out essential parts can enhance performance and extend the lifespan of your equipment.

Essential Tools and Materials

- Screwdriver set

- Wrench or socket set

- Replacement parts

- Oil and cleaning supplies

- Safety gear (gloves, goggles)

Steps for Component Replacement

- Ensure the engine is turned off and cool.

- Disconnect the spark plug wire to prevent accidental ignition.

- Remove any housing or covers to access the component.

- Carefully detach the faulty part using appropriate tools.

- Install the new component, ensuring it fits securely.

- Reassemble the housing or covers.

- Reconnect the spark plug wire and test the engine.

Diagnostic Techniques for Engine Issues

Identifying problems within an engine requires a systematic approach that incorporates observation, analysis, and testing. Utilizing effective diagnostic methods can significantly enhance the troubleshooting process, allowing for quicker resolution of performance issues and improved overall efficiency.

Visual Inspection: Begin with a thorough visual examination of the engine. Look for any signs of wear, leaks, or damage to components. Check hoses, belts, and connections for cracks or fraying. A careful assessment can often reveal obvious issues that need immediate attention.

Listening for Anomalies: Pay close attention to the sounds produced by the engine during operation. Unusual noises, such as knocking, rattling, or hissing, can indicate specific problems. By diagnosing the nature of these sounds, one can narrow down the potential issues affecting the engine’s performance.

Testing Compression: A compression test is a crucial method to determine the health of the engine’s internal components. Low compression readings in one or more cylinders may point to problems like worn piston rings or faulty valves. Conducting this test can provide vital information about the engine’s mechanical state.

Fuel System Assessment: Evaluating the fuel delivery system is essential. Inspect filters, lines, and injectors for blockages or leaks. Ensuring that fuel reaches the engine efficiently can resolve a multitude of performance issues and improve starting reliability.

Electrical System Check: Examine the electrical components, including spark plugs, ignition coils, and wiring connections. A faulty electrical system can cause misfires or prevent the engine from starting altogether. Testing these components for continuity and proper function is a key diagnostic step.

By applying these techniques methodically, one can effectively diagnose and address engine issues, ensuring optimal performance and longevity of the machinery.

Benefits of Regular Maintenance

Routine upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. By consistently checking and servicing equipment, users can prevent minor issues from escalating into major problems, ultimately saving time and resources. Regular attention to maintenance tasks can significantly enhance the reliability of the machinery, making it a worthwhile investment for any operator.

Enhanced Performance

Regular attention to machinery leads to improved efficiency and functionality. When components are kept clean and well-lubricated, they operate more smoothly, allowing the equipment to perform at its best. This not only maximizes output but also minimizes the risk of unexpected breakdowns that can disrupt operations.

Cost Savings

Investing in consistent maintenance can result in significant financial benefits. By addressing small issues early on, operators can avoid costly repairs and replacements later. Furthermore, well-maintained equipment often consumes less fuel and operates more efficiently, contributing to lower operational costs over time.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining optimal performance. There are various sources where one can obtain high-quality parts that ensure longevity and reliability. Understanding where to look will help streamline the process and save time and effort.

Authorized Dealers

One of the most reliable options is to visit authorized dealers. These outlets often have a comprehensive inventory of original components, ensuring compatibility and quality. Additionally, staff at these locations can provide expert advice on which parts are best suited for your needs.

Online Retailers

The internet is a valuable resource for finding parts. Numerous online retailers specialize in equipment components, offering a wide selection at competitive prices. Be sure to check customer reviews and ratings to ensure you’re purchasing from reputable vendors. Many sites also provide helpful diagrams and descriptions to assist you in making informed choices.