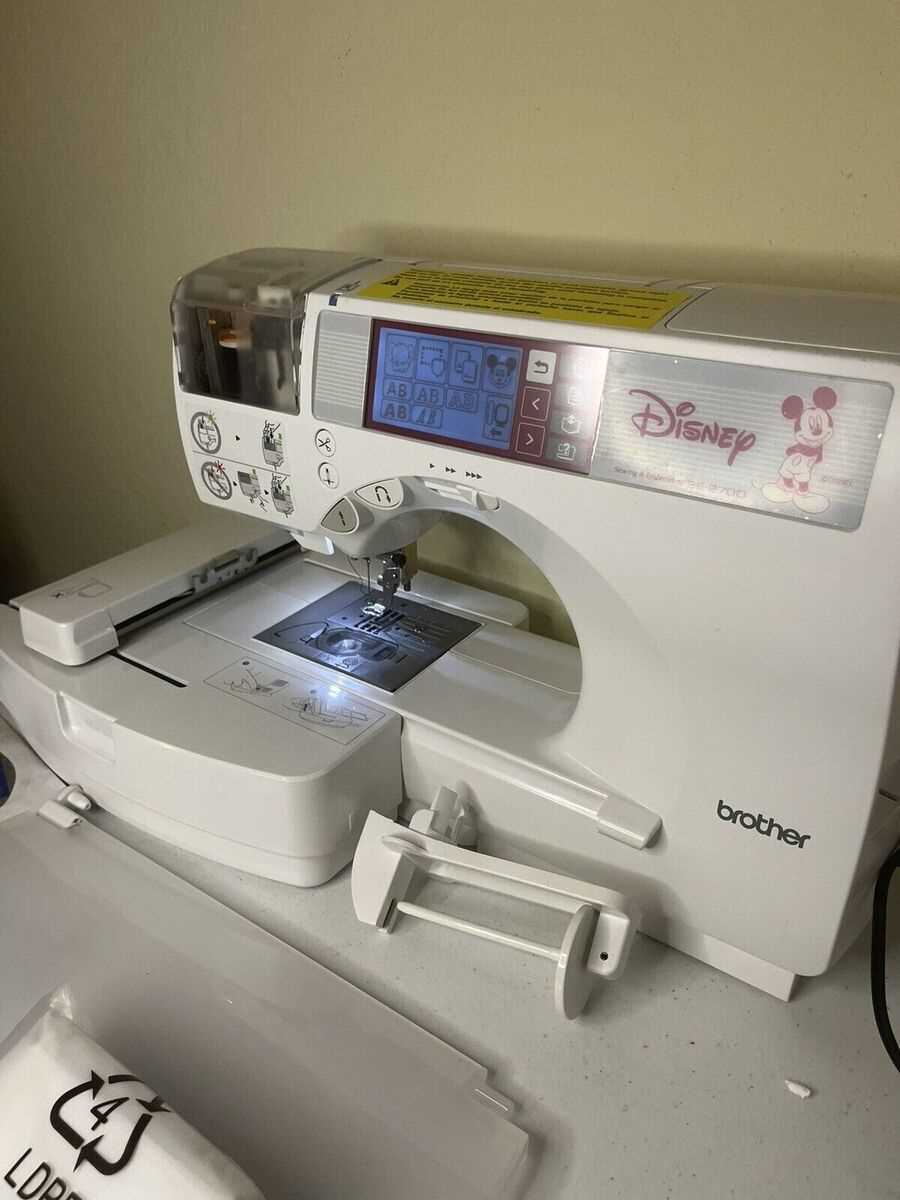

Guide to Repairing Brother SE 270D

Every sewing enthusiast understands the importance of proper upkeep for their devices. Regular maintenance not only enhances performance but also extends the lifespan of your equipment. This section delves into essential practices that can help you maintain your machine effectively, ensuring it operates smoothly and efficiently.

It is crucial to familiarize yourself with the inner workings of your sewing device. Knowing how to address common issues can save time and prevent potential frustrations. This guide will provide you with insights into troubleshooting typical problems, empowering you to handle your equipment with confidence.

By implementing straightforward care routines and understanding the mechanics behind your machine, you can enjoy a seamless sewing experience. With the right knowledge at your fingertips, you will be better equipped to keep your sewing companion in optimal condition.

Understanding the Brother SE 270D

This section delves into the features and functionalities of a specific model known for its versatility and user-friendly interface. It is designed to cater to both novice and experienced users, making it a popular choice among enthusiasts and professionals alike.

Key Features

Users can benefit from a range of functions that enhance their crafting experience. From embroidery capabilities to various stitching options, this model is equipped to meet diverse needs.

| Feature | Description |

|---|---|

| Embroidery Designs | Includes a selection of built-in designs, allowing for creative personalization. |

| Stitch Options | Offers multiple stitch types for various sewing applications. |

| User Interface | Intuitive controls that simplify the operation for all skill levels. |

Maintenance Tips

To ensure longevity, regular upkeep is essential. Users should follow best practices for cleaning and servicing to maintain optimal performance over time.

Common Issues with the Machine

This section discusses frequent problems encountered by users of this type of stitching device. Understanding these issues can help in troubleshooting and enhancing the overall experience of operation.

Frequent Malfunctions

- Thread Jamming: A common occurrence where the thread gets tangled or stuck, leading to disrupted stitching.

- Skipped Stitches: This happens when the needle fails to pick up the thread correctly, resulting in uneven patterns.

- Tension Problems: Incorrect thread tension can cause loose or overly tight stitches.

Maintenance Tips

- Regular Cleaning: Keep the machine free from lint and dust to prevent blockages.

- Proper Needle Replacement: Change the needle as needed to avoid performance issues.

- Thread Quality: Use high-quality thread to minimize breakage and ensure smooth operation.

Step-by-Step Repair Guide

This section provides a comprehensive approach to resolving issues with your sewing device. By following these instructions, you can identify problems and perform necessary actions to restore functionality.

Identifying Common Issues

- Check for thread jams.

- Inspect the needle for damage.

- Ensure proper tension settings.

- Verify that the bobbin is correctly installed.

Tools and Materials Needed

- Screwdriver for disassembly.

- Replacement needles.

- Lubricating oil for moving parts.

- Cleaning brush for dust removal.

With the right tools at hand, you can proceed to troubleshoot and resolve any complications effectively.

Essential Tools for Maintenance

Proper upkeep of any device requires a selection of crucial instruments that facilitate efficient performance and longevity. Utilizing the right tools not only enhances functionality but also ensures safety during maintenance tasks.

Basic Hand Tools

- Philips and flathead screwdrivers

- Wrenches of various sizes

- Pliers for gripping and bending

- Cutters for precise adjustments

Specialized Equipment

- Cleaning brushes for delicate parts

- Lubricants to reduce friction

- Measuring tools for accurate calibration

- Replacement components to ensure optimal operation

How to Replace the Needle

Replacing the sewing needle is a crucial maintenance task that ensures your machine operates smoothly and produces high-quality stitches. Properly changing the needle can prevent fabric snags and uneven stitching, ultimately enhancing your sewing experience.

Follow these steps to effectively replace the needle in your sewing apparatus:

| Step | Description |

|---|---|

| 1 | Turn off the machine and unplug it to ensure safety during the process. |

| 2 | Loosen the needle clamp screw using a screwdriver or your fingers. |

| 3 | Remove the old needle carefully from the clamp. |

| 4 | Take the new needle, ensuring it matches the correct type for your machine. |

| 5 | Insert the new needle into the clamp with the flat side facing the back. |

| 6 | Tighten the needle clamp screw securely to hold the needle in place. |

| 7 | Plug in the machine and test it with a scrap piece of fabric to ensure everything is functioning correctly. |

Troubleshooting Threading Problems

Threading issues can often hinder the sewing process, causing frustration for users. Understanding common problems and their solutions is crucial for achieving smooth operation. This section provides insights into diagnosing and fixing these challenges effectively.

Common Threading Issues

Several factors can contribute to threading complications. The following table outlines these issues along with potential causes and solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Thread Breaks | Poor quality thread or incorrect tension | Switch to a higher quality thread and adjust the tension settings. |

| Thread Snags | Incorrect threading path or damaged components | Re-thread the machine according to the manual and inspect for any worn parts. |

| Skipped Stitches | Needle issues or improper threading | Replace the needle and ensure the threading is done correctly. |

Tips for Effective Threading

Regular maintenance and careful attention to detail can prevent many threading problems. Always ensure that the machine is clean and lubricated, and follow the threading instructions closely to maintain optimal performance.

Cleaning and Lubricating the Device

Regular maintenance of your sewing equipment is essential for ensuring optimal performance and longevity. Cleaning and lubricating various components helps prevent wear and tear, allowing the machine to function smoothly.

Cleaning the Machine

Follow these steps for effective cleaning:

- Turn off the device and unplug it from the power source.

- Remove the needle and presser foot for easier access.

- Use a soft brush to remove dust and lint from the bobbin area and feed dogs.

- Wipe down the exterior surfaces with a damp cloth to eliminate dirt and grime.

Lubrication Process

Proper lubrication enhances the performance of moving parts:

- Identify the lubrication points as indicated in the product documentation.

- Apply a few drops of suitable sewing machine oil to each point.

- Run the machine for a few minutes to distribute the oil evenly.

Updating the Machine’s Firmware

Keeping your device’s software up to date is essential for ensuring optimal performance and access to the latest features. Firmware updates can resolve bugs, improve functionality, and enhance overall user experience.

Steps to Update the Firmware

To begin the updating process, first check the manufacturer’s website for the latest firmware version. Download the appropriate file for your model, ensuring it is compatible. Next, connect the machine to your computer using a USB cable or Wi-Fi, depending on the model’s capabilities.

Installing the Update

Once the device is connected, open the downloaded file and follow the on-screen instructions. Ensure that the machine remains powered on throughout the process to avoid interruptions. After the installation is complete, restart the device to apply the changes. Regularly checking for updates can help maintain your equipment’s efficiency.

Replacing Worn-Out Parts

Maintaining the functionality of any sewing machine involves timely replacement of components that have worn down over time. Neglecting this task can lead to decreased performance and, ultimately, machine failure. Regular inspections can help identify parts that require attention, ensuring that the equipment operates smoothly and efficiently.

When considering the replacement of worn-out components, follow these steps:

- Identify the Parts: Regularly check for signs of wear on critical components such as needles, bobbins, and belts.

- Gather Necessary Tools: Prepare the tools required for the replacement process, including screwdrivers, pliers, and replacement parts.

- Consult Documentation: Refer to the user guide for specific instructions on accessing and replacing the identified components.

- Perform the Replacement: Carefully remove the worn-out part and install the new one, ensuring it fits securely.

- Test the Machine: After replacement, conduct a thorough test to verify that the machine is functioning properly.

By addressing the replacement of worn components proactively, users can extend the lifespan of their sewing machines and maintain optimal performance.

Adjusting Tension for Optimal Performance

Proper tension is crucial for achieving the best results in stitching projects. Balancing the thread tension ensures even stitches and prevents common issues such as puckering or thread breakage. This section will explore techniques for fine-tuning the tension on your sewing device to enhance performance and maintain fabric integrity.

Understanding Thread Tension

Thread tension refers to the tightness or looseness of the threads as they pass through the machine. Each fabric type may require a different tension setting to achieve optimal results. For instance, heavier materials often need higher tension, while lighter fabrics may benefit from a more relaxed setting. Knowing how to adjust these settings can significantly improve the quality of your stitching.

Steps to Adjust Tension

Begin by testing the tension with a sample piece of fabric similar to your project. If the stitches appear uneven or if the fabric is gathering, you may need to adjust the tension dial. Start with small increments, testing after each adjustment. Remember to keep the tension balanced for both the upper and lower threads. Regular maintenance and adjustments will ensure your sewing experience is smooth and efficient.

Finding Compatible Accessories

When seeking accessories for your sewing machine, it is essential to ensure compatibility to maximize functionality and efficiency. Using the right tools not only enhances performance but also extends the lifespan of your equipment.

To find suitable accessories, consider the following tips:

- Check the manufacturer’s specifications for recommended items.

- Look for user reviews and ratings to gauge compatibility and quality.

- Consult with local retailers or online forums for advice from experienced users.

- Examine the connection types and sizes to ensure a proper fit.

By following these guidelines, you can confidently select accessories that complement your sewing machine, enhancing your overall sewing experience.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both the technician and the equipment. Proper precautions help prevent accidents and promote a secure working environment. Familiarizing oneself with essential guidelines can significantly reduce risks while enhancing the efficiency of the process.

General Safety Guidelines

Always begin by disconnecting the device from its power source to eliminate electrical hazards. Utilize appropriate personal protective equipment, such as gloves and goggles, to shield against potential injuries. Keeping the workspace tidy and well-lit is essential for maintaining focus and preventing mishaps.

Handling Tools and Components

Use tools specifically designed for the task at hand, ensuring they are in good condition. Avoid forcing any parts, as this could lead to damage or personal injury. When handling small components, be mindful of their potential to cause cuts or other injuries.