Comprehensive Guide to Repairing Your Bt Pallet Jack

In the world of material handling, ensuring the smooth operation of your lifting devices is crucial for efficiency and productivity. Over time, these essential tools may require attention to maintain optimal performance and safety. This section provides a detailed overview of the necessary steps to keep your equipment in excellent condition, minimizing downtime and enhancing longevity.

Understanding the intricacies of these devices is vital for anyone involved in logistics or warehouse management. By familiarizing yourself with the components and their functions, you can identify potential issues before they escalate. This proactive approach not only extends the lifespan of your machinery but also contributes to a safer working environment.

Within this guide, you will discover a wealth of information covering various aspects of maintenance, from basic troubleshooting techniques to more advanced adjustments. Whether you are a seasoned professional or new to the field, this resource aims to empower you with the knowledge necessary to address common challenges effectively and efficiently.

Understanding Bt Pallet Jacks

In the world of material handling, the equipment designed for lifting and moving heavy loads plays a crucial role in enhancing efficiency and safety. Among these tools, a specific type stands out for its maneuverability and ease of use. This section delves into the characteristics and functionalities of this essential equipment, emphasizing its importance in various operational settings.

Key Features: The equipment is engineered for optimal performance, featuring durable construction and user-friendly controls. Its design facilitates seamless navigation in tight spaces, making it ideal for warehouses and distribution centers. The ability to lift substantial weights with minimal effort significantly reduces the risk of injury for operators.

Applications: Commonly utilized across different industries, this equipment is indispensable for transporting goods from one location to another. Whether in retail, manufacturing, or logistics, its versatility ensures that operations run smoothly and efficiently, contributing to overall productivity.

Understanding the significance of this equipment helps organizations make informed decisions regarding their material handling processes, ensuring they invest in tools that enhance operational efficiency while prioritizing safety.

Common Issues with Bt Pallet Jacks

Equipment designed for lifting and transporting heavy loads can encounter various challenges over time. Understanding these frequent problems can help users maintain optimal functionality and extend the lifespan of their devices. This section highlights typical issues that may arise, enabling proactive measures for efficient operation.

Hydraulic Problems

One of the most common challenges involves hydraulic systems. Users may notice insufficient lifting power or the inability to raise loads completely. This can often be traced back to fluid leaks or air trapped in the hydraulic lines. Regular inspection and timely replacement of hydraulic fluid can prevent these issues from escalating.

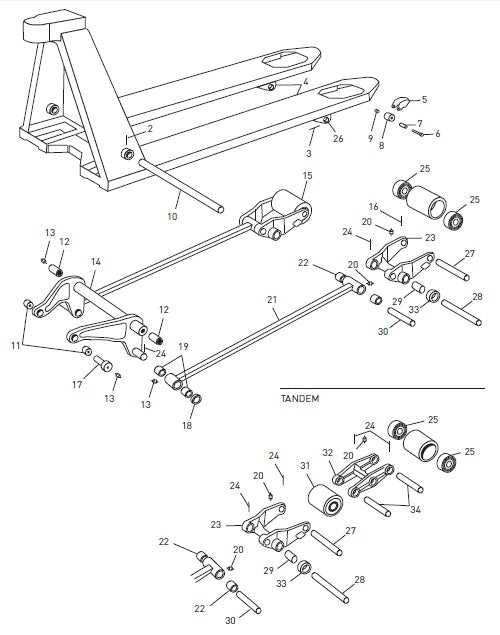

Worn Components

Another frequent concern pertains to the wear and tear of critical components. Wheels and forks can become damaged or misaligned, leading to uneven movement or difficulty steering. Regular maintenance, including checking for debris and ensuring proper alignment, is essential for smooth operation. Identifying these signs early can save time and resources.

Essential Tools for Repairing

When it comes to maintaining and restoring equipment, having the right set of tools is crucial for ensuring efficiency and effectiveness. A well-equipped workspace not only facilitates smoother operations but also enhances the overall quality of the work performed. Below are some of the fundamental instruments that every technician should have at their disposal.

Basic Tool Kit

A standard toolkit serves as the foundation for any maintenance activity. This collection typically includes various hand tools designed to handle different tasks, from simple adjustments to more complex fixes.

| Tool | Purpose |

|---|---|

| Screwdrivers | Used for fastening and loosening screws. |

| Wrenches | Ideal for gripping, fastening, and turning nuts and bolts. |

| Pliers | Essential for gripping and bending materials. |

| Socket Set | Provides versatility for various bolt sizes and types. |

Specialized Equipment

In addition to the basic toolkit, specialized instruments are often necessary for more advanced tasks. These tools allow for precise adjustments and are designed to tackle specific issues effectively.

| Tool | Purpose |

|---|---|

| Multimeter | Used for measuring electrical properties. |

| Hydraulic Lift | Facilitates lifting heavy components for better accessibility. |

| Torque Wrench | Ensures bolts are tightened to the correct specification. |

| Grease Gun | Used for lubricating moving parts to reduce friction. |

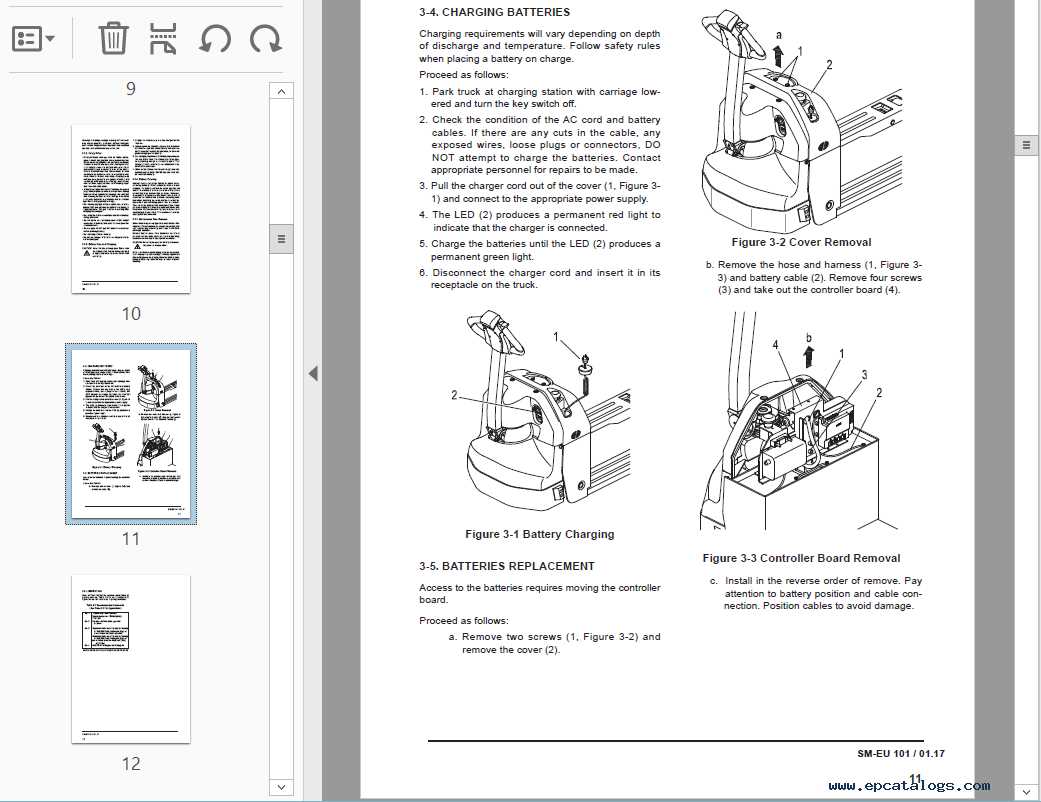

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing mechanical issues with your equipment. By following a systematic procedure, you can efficiently diagnose and resolve problems, ensuring optimal performance. Each phase is crucial, from initial assessment to final adjustments, enabling you to restore functionality effectively.

| Step | Description |

|---|---|

| 1 | Begin with a thorough inspection to identify any visible signs of wear or damage. |

| 2 | Document all findings and gather necessary tools for the subsequent steps. |

| 3 | Disassemble the unit carefully, ensuring to note the placement of each component. |

| 4 | Clean all parts, removing debris and any contaminants that may affect performance. |

| 5 | Inspect each component for damage and replace any that do not meet specifications. |

| 6 | Reassemble the equipment, ensuring that all parts are correctly aligned and secured. |

| 7 | Conduct a functional test to verify that all systems operate as intended. |

| 8 | Finalize by documenting the work performed and any additional observations for future reference. |

Maintenance Tips for Longevity

Ensuring the durability of your equipment is crucial for optimal performance and minimizing unexpected breakdowns. Regular upkeep not only extends the life of your machinery but also enhances its efficiency. Below are some essential practices to keep in mind for maintaining your gear in peak condition.

| Tip | Description |

|---|---|

| Regular Inspection | Perform routine checks for wear and tear, paying attention to wheels, steering, and overall structure. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and prevent damage. |

| Cleanliness | Keep the equipment clean and free from debris, which can hinder performance and lead to deterioration. |

| Battery Maintenance | For electric models, ensure the battery is charged correctly and terminals are clean to avoid power issues. |

| Operator Training | Provide comprehensive training to operators to avoid misuse and ensure proper handling techniques. |

By adhering to these maintenance strategies, you can significantly increase the lifespan and reliability of your equipment, leading to smoother operations and reduced costs over time.

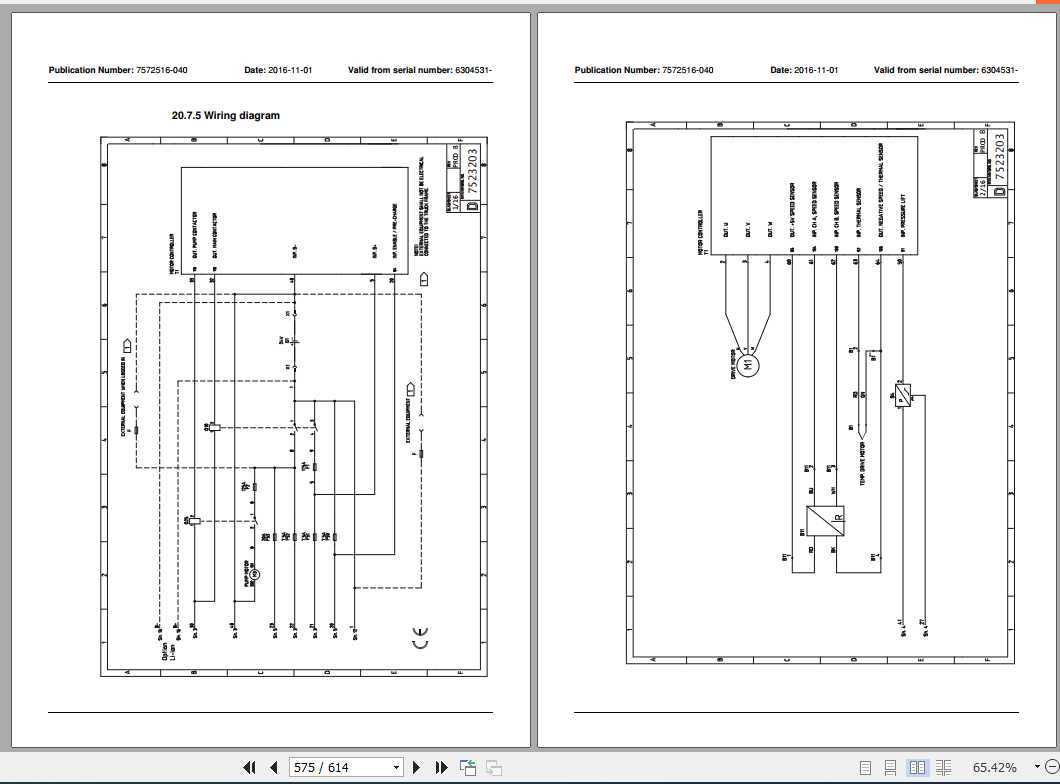

Identifying Electrical Problems

Recognizing issues related to electrical systems is crucial for maintaining optimal performance and ensuring safety. Understanding the signs of malfunction can prevent further complications and prolong the lifespan of the equipment. This section outlines key indicators and methods for diagnosing electrical faults effectively.

Common Symptoms of Electrical Malfunctions

Users may notice unusual behaviors, such as inconsistent operation or unexpected shutdowns. Flickering lights or failure to respond to controls often indicate underlying electrical issues. Additionally, unusual noises or overheating components can signal potential failures, warranting immediate attention.

Diagnostic Techniques

To accurately assess electrical conditions, start with visual inspections of wiring and connections for signs of wear or damage. Utilizing multimeters can help measure voltage and continuity, revealing hidden faults. Furthermore, consulting the circuit diagrams can assist in tracing issues back to their source, allowing for targeted troubleshooting.

Hydraulic System Troubleshooting

The hydraulic system is a crucial component that ensures efficient operation and handling capabilities of the equipment. When issues arise within this system, it can lead to decreased performance and reliability. Understanding common problems and their solutions is essential for maintaining optimal functionality.

Below are some common issues encountered in hydraulic systems, along with potential causes and recommended solutions:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Insufficient lifting power | Low hydraulic fluid level, air in the system | Check fluid level and refill if necessary; bleed the system to remove air |

| Leaking fluid | Deteriorated seals or hoses | Inspect and replace damaged seals or hoses |

| Slow or unresponsive movement | Blocked filters, worn pump | Clean or replace filters; check pump for wear and replace if needed |

| Unusual noises during operation | Low fluid levels, air in the system | Refill hydraulic fluid and bleed the system |

Regular maintenance and timely intervention can prevent most hydraulic issues from escalating, ensuring that the equipment remains in good working condition.

When to Seek Professional Help

Understanding when to engage a specialist can significantly impact the longevity and efficiency of your equipment. Certain situations require a deeper level of expertise that goes beyond basic troubleshooting.

Signs of Serious Issues: If you notice persistent operational problems or unusual sounds, it may indicate a deeper malfunction. Ignoring these signs can lead to greater damage.

Complex Repairs: Tasks that involve intricate components or specialized tools often necessitate professional intervention. Attempting these repairs without proper knowledge can be risky.

Warranty Considerations: If your device is under warranty, it’s crucial to follow guidelines regarding professional service. Unauthorized repairs may void your coverage.

Ultimately, seeking help when needed can ensure safety and enhance performance, protecting your investment in the long run.

Safety Precautions During Repairs

Ensuring a safe environment while performing maintenance on equipment is crucial. Proper precautions not only protect the technician but also extend the lifespan of the machinery. Adhering to safety measures minimizes the risk of accidents and injuries, creating a secure workspace.

Before beginning any servicing tasks, it is essential to familiarize oneself with the specific guidelines and recommendations provided by the manufacturer. This knowledge can prevent unforeseen hazards and ensure a thorough understanding of the machinery involved.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear, including gloves, goggles, and safety shoes, to protect against injuries. |

| Workspace Organization | Maintain a clutter-free area to avoid tripping hazards and ensure easy access to tools and parts. |

| Electrical Safety | Disconnect power sources before starting work to prevent electrical shock and ensure safe handling of components. |

| Tool Inspection | Check tools for damage or wear before use to avoid malfunction and enhance safety during tasks. |

| Emergency Preparedness | Know the location of first aid kits and emergency exits, and be prepared for potential incidents. |

By implementing these safety measures, individuals can significantly reduce risks associated with maintenance work, promoting a culture of safety and efficiency in the workplace.

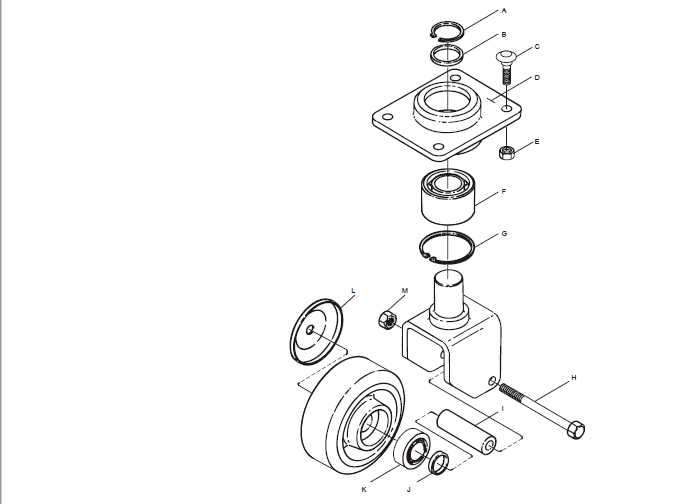

Parts Replacement Guidelines

When maintaining equipment, ensuring the proper functioning of components is crucial for optimal performance and safety. This section outlines essential practices for replacing parts, helping to extend the lifespan of your machinery while minimizing downtime.

Identification of Components

Before commencing the replacement process, accurately identify the components that require attention. Utilize the manufacturer’s specifications to verify compatibility and ensure that the new parts meet all necessary standards. Labeling old components can also assist in the reassembly process, preventing confusion.

Step-by-Step Replacement Process

Begin by disconnecting the equipment from any power sources to ensure safety. Next, carefully remove the old parts, taking note of their positioning and connections. When installing new components, follow the manufacturer’s guidelines closely, ensuring all fittings are secure and that no tools are left behind. Finally, conduct a thorough inspection to confirm everything is in place before reactivating the machinery.