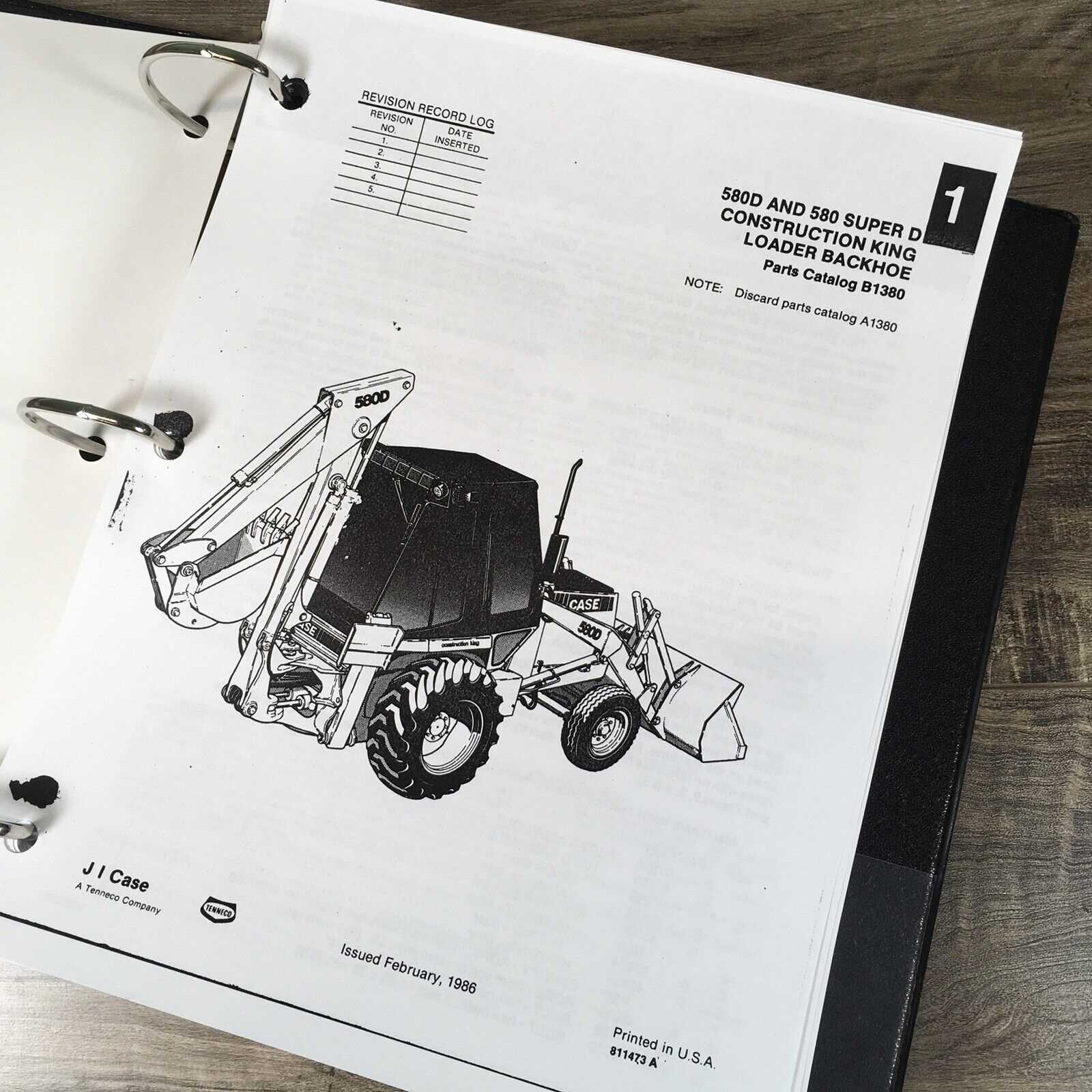

Comprehensive Guide to Repairing the Case 580D

This section provides essential insights into the upkeep and troubleshooting of specialized equipment designed for construction and agricultural tasks. Proper maintenance is crucial for ensuring optimal performance and longevity of these powerful machines.

Understanding the intricacies of your equipment can significantly enhance its operational efficiency. By following detailed guidelines and recommendations, operators can address common issues and perform necessary adjustments to keep the machinery running smoothly.

Whether you are a seasoned operator or new to the field, this guide aims to equip you with the knowledge needed to navigate maintenance challenges effectively. Emphasizing preventive measures can save time and resources, ultimately leading to improved productivity in various tasks.

This section provides a comprehensive introduction to the subject, focusing on the key characteristics and functionalities of the specified machinery. Understanding its features and operational capabilities is essential for effective maintenance and troubleshooting.

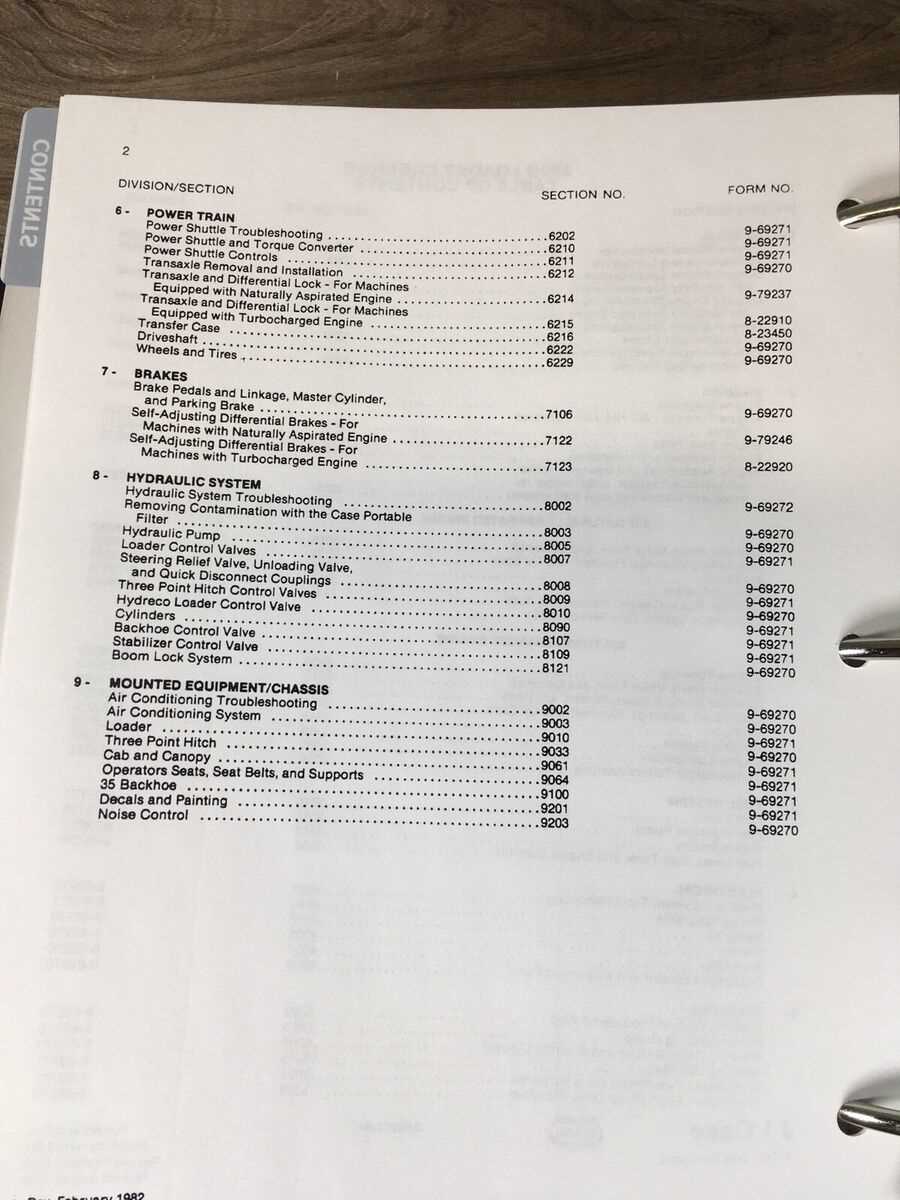

| Feature | Description |

|---|---|

| Engine Type | Powerful diesel engine designed for heavy-duty tasks. |

| Operating Weight | Robust structure ensuring stability and durability during operations. |

| Loader Capacity | High load-bearing capability for efficient material handling. |

| Transmission | Smooth gear shifts for enhanced control and performance. |

Common Issues and Troubleshooting

This section addresses frequently encountered problems and their solutions related to heavy machinery operation. Understanding these issues can enhance performance and prolong the lifespan of the equipment.

- Engine Performance:

- Difficulty starting the engine may indicate battery issues or fuel supply problems.

- Unusual noises can signal mechanical wear or loose components.

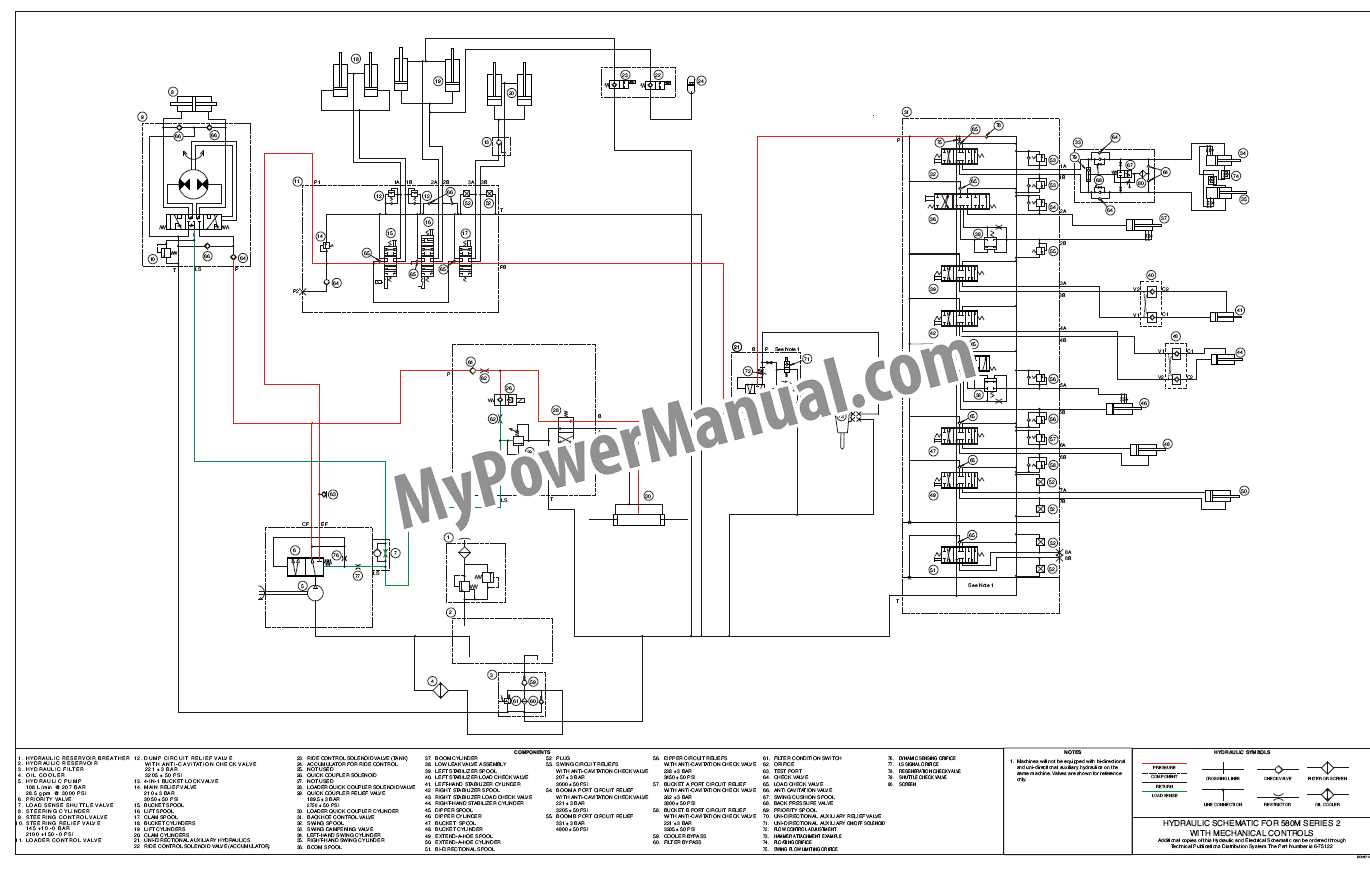

- Hydraulic System Failures:

- Insufficient power output may stem from low fluid levels or leaks in the system.

- Slow operation can suggest a clogged filter or worn pump.

- Transmission Issues:

- Shifting difficulties could be due to low fluid levels or faulty linkage.

- Overheating may result from excessive load or inadequate cooling.

Regular maintenance and prompt attention to these issues can help mitigate major repairs and ensure reliable operation.

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Following proper maintenance procedures can prevent unexpected breakdowns and enhance overall functionality.

- Perform routine inspections to identify wear and tear on critical components.

- Keep all moving parts well-lubricated to reduce friction and prevent overheating.

- Replace filters at recommended intervals to maintain optimal air and fluid quality.

- Monitor fluid levels and top up as necessary to ensure smooth operation.

- Clean the exterior regularly to prevent debris accumulation that could affect performance.

Adhering to these guidelines will contribute to improved operational efficiency and extend the life of your machinery.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to addressing common issues that may arise during the maintenance of heavy machinery. Following systematic instructions ensures effective troubleshooting and restoration of functionality.

Initial Assessment

Begin by inspecting the equipment thoroughly. Look for visible signs of wear or damage, such as leaks, cracks, or loose components. Document any irregularities, as this will aid in determining the necessary corrective actions.

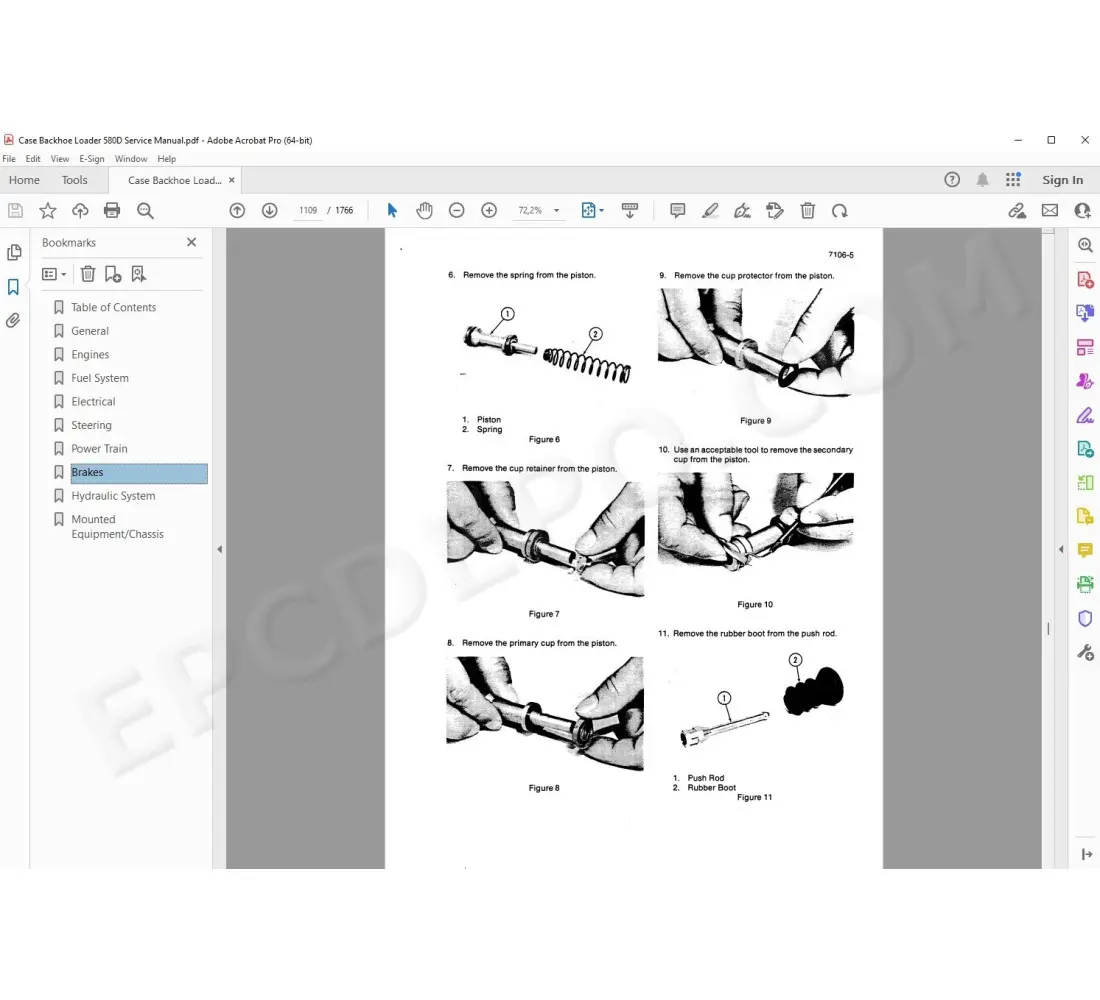

Disassembly and Inspection

Once the initial assessment is complete, proceed with disassembling the relevant parts. Use appropriate tools to avoid causing further damage. Carefully examine each component for defects. Clean parts as needed to facilitate a better evaluation of their condition.

After inspection, determine if repairs can be made or if replacement is required. Always follow the manufacturer’s guidelines to ensure safety and efficiency.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance tasks. Proper tools not only facilitate the process but also ensure safety and efficiency. A well-equipped toolkit can make troubleshooting and fixing machinery straightforward and less time-consuming.

Basic Hand Tools

- Screwdrivers: Essential for fastening and loosening screws of various sizes.

- Wrenches: Useful for tightening or loosening nuts and bolts.

- Pliers: Handy for gripping, twisting, and cutting wires.

Power Tools

- Drills: Ideal for creating holes in various materials.

- Impact Wrenches: Designed for heavy-duty tasks, providing extra torque.

- Grinders: Useful for cutting and smoothing surfaces.

Parts Replacement and Upgrades

Ensuring the longevity and efficiency of your equipment often involves timely substitutions and enhancements. Regularly assessing components can lead to improved performance and reliability, ultimately extending the lifespan of the machinery.

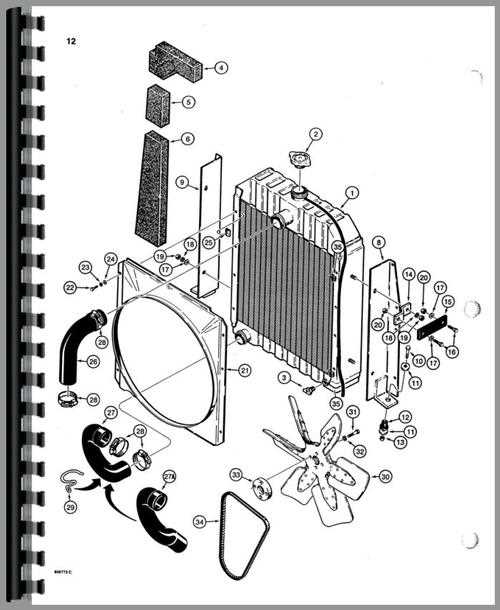

Common Components for Replacement

- Hydraulic filters

- Seals and gaskets

- Belts and hoses

- Battery

Upgrading for Enhanced Performance

- Consider using high-efficiency hydraulic fluids to boost power transfer.

- Install upgraded tires for better traction and stability.

- Evaluate the option of adding auxiliary lights for improved visibility during operation.

Regular maintenance and thoughtful upgrades not only optimize function but also contribute to safety and operational efficiency.

Safety Precautions During Repairs

Ensuring a safe environment is crucial when performing maintenance on heavy machinery. Adhering to specific guidelines minimizes risks and promotes effective work practices.

General Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and helmets.

- Keep the work area clean and free from hazards to prevent accidents.

- Ensure all tools and equipment are in good condition before use.

Emergency Procedures

- Familiarize yourself with the location of emergency exits and first aid kits.

- Have a plan in place for emergencies, including contact information for local emergency services.

- Report any unsafe conditions immediately to a supervisor or safety officer.

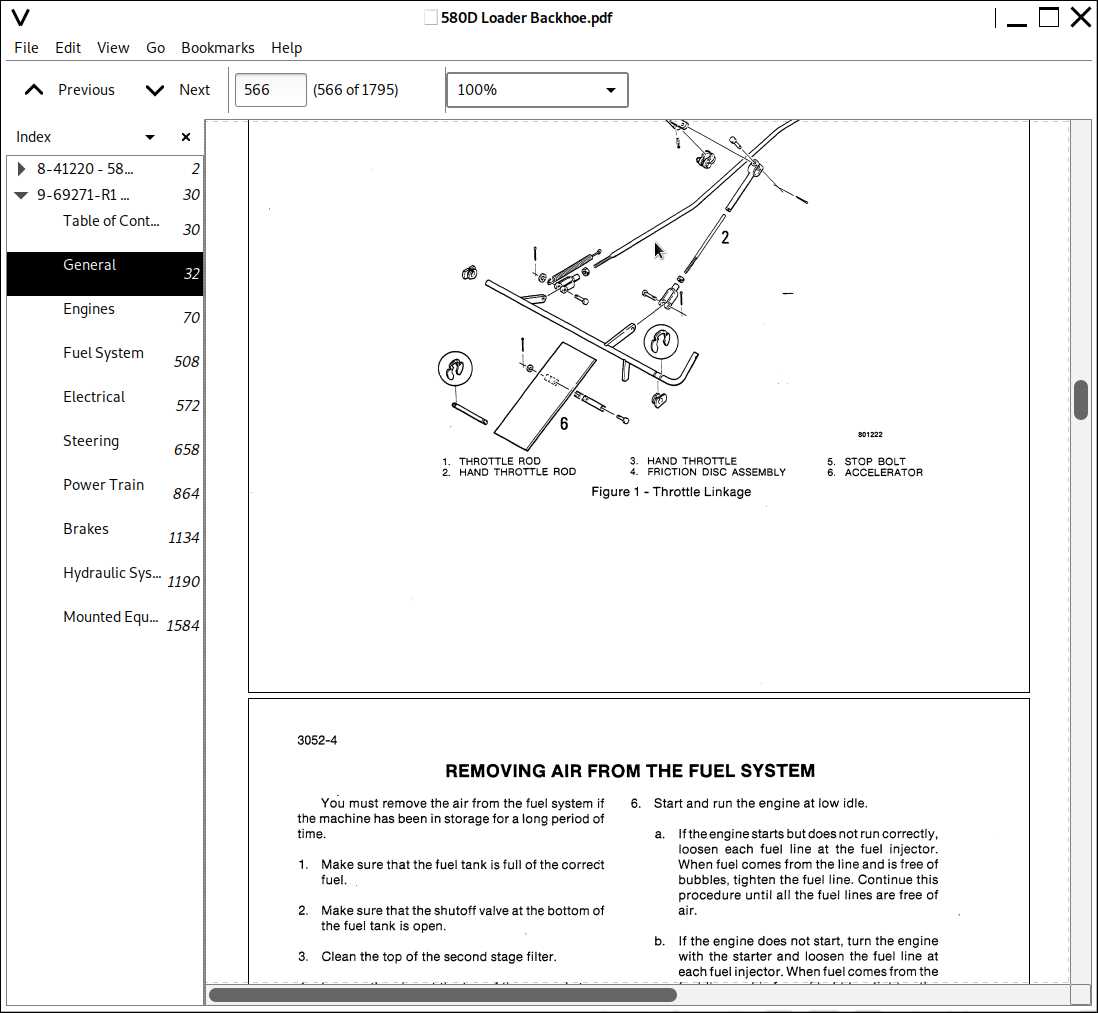

Diagnostic Techniques for Faults

Identifying issues in machinery requires a systematic approach to ensure accurate assessments. Employing effective diagnostic methods can help pinpoint problems efficiently, leading to timely solutions and minimizing downtime.

First, a thorough visual inspection is essential. Checking for visible signs of wear, loose connections, or leaks can reveal potential issues before they escalate. Additionally, utilizing multimeters and oscilloscopes allows for precise measurements of electrical systems, ensuring they function within specified parameters.

Moreover, monitoring performance metrics during operation provides insights into irregular behaviors. Comparing data against standard benchmarks enables technicians to isolate abnormalities. Finally, consulting technical resources and leveraging the experience of seasoned professionals can further enhance diagnostic accuracy.

Tips for Preventive Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to a few simple strategies, you can prevent potential issues before they arise and keep your machinery operating smoothly.

Establish a Routine Check Schedule

Creating a consistent schedule for inspections helps identify wear and tear early. Regular checks should include examining fluid levels, filters, and moving parts to ensure everything is functioning properly.

Utilize Quality Parts and Fluids

Always opt for high-quality components and fluids. Using superior materials not only enhances efficiency but also reduces the likelihood of malfunctions. Investing in quality pays off in the long run.

Service Intervals and Recommendations

Regular maintenance is essential for ensuring optimal performance and longevity of your equipment. Adhering to suggested service intervals helps in identifying potential issues early and maintaining the overall health of the machinery.

Routine Maintenance Schedule

It is advisable to follow a routine maintenance schedule that includes checking fluid levels, inspecting filters, and examining belts and hoses. These tasks should be performed at regular intervals to prevent wear and tear, ensuring smooth operation.

Best Practices for Care

In addition to regular inspections, consider implementing best practices such as keeping the machine clean, storing it properly when not in use, and using quality replacement parts. This approach not only enhances performance but also extends the lifespan of the equipment.

Technical Specifications of Case 580D

This section provides an overview of the key characteristics and performance metrics of the equipment in question. Understanding these specifications is essential for effective operation and maintenance, ensuring optimal functionality in various applications.

Engine Details

The power source is a robust unit designed for efficiency and reliability. It typically features a high horsepower rating, which contributes to impressive performance levels during operation.

Hydraulic System

The hydraulic mechanism is engineered for superior lifting capabilities and fluid movement. It encompasses a range of features that enhance precision and responsiveness, making it suitable for demanding tasks.

Where to Find Replacement Parts

Finding suitable components for machinery can be a daunting task, yet it is essential for maintaining optimal performance. Various sources offer a range of options, from online retailers to local suppliers, ensuring that you can locate what you need efficiently.

Online Retailers

Numerous websites specialize in providing parts for heavy machinery. These platforms often have extensive inventories and can deliver directly to your location.

- Manufacturer websites

- Third-party parts suppliers

- Marketplaces like eBay and Amazon

Local Suppliers

Visiting local suppliers can also be beneficial. They may have the necessary parts in stock or can order them for you.

- Authorized dealerships

- Heavy equipment repair shops

- Construction equipment rental companies