Cessna 172 Structural Repair Manual Guide

In the realm of aviation, the integrity of an aircraft’s framework is paramount to ensuring safe and efficient flight operations. This section delves into the essential principles and methodologies involved in addressing issues related to the physical structure of aircraft. Mastery of these techniques is crucial for aviation professionals dedicated to maintaining peak performance and safety standards.

Through a detailed exploration of restoration protocols, technicians can enhance their proficiency in diagnosing and rectifying various structural anomalies. By adhering to established practices, they not only preserve the longevity of the aircraft but also safeguard the lives of those aboard. This comprehensive overview provides invaluable insights into the systematic approach required for effective framework maintenance.

Furthermore, the guidelines discussed herein are designed to equip professionals with the knowledge necessary for performing intricate tasks. By understanding the underlying concepts and techniques, practitioners can ensure that each component meets the stringent safety criteria set forth by regulatory bodies. The commitment to excellence in structural upkeep is what defines the aviation industry and elevates the standards of air travel.

Cessna 172 Overview

This section provides a comprehensive introduction to a widely recognized light aircraft, detailing its features, specifications, and the context in which it operates. This model has earned a reputation for reliability and ease of use, making it a preferred choice among both novice and experienced pilots.

General Features

- High-wing configuration for improved visibility and stability

- Robust design that ensures durability and longevity

- Seating capacity typically accommodates four occupants

- Equipped with a single-engine layout for simplicity in operation

Specifications

- Maximum Takeoff Weight: Approximately 2,550 pounds

- Engine Power: Ranges from 140 to 180 horsepower, depending on the variant

- Cruising Speed: Around 120 knots

- Range: Approximately 600 nautical miles, providing substantial flight capability

This aircraft serves a multitude of purposes, from flight training to personal travel, thanks to its versatility and user-friendly characteristics. Understanding its fundamentals is essential for those involved in its maintenance and operation.

Importance of Structural Repair Manuals

Comprehensive documentation is crucial in aviation maintenance and safety. Such resources provide vital guidelines that ensure the integrity and longevity of aircraft components. By adhering to these detailed instructions, technicians can perform necessary interventions with precision, maintaining the overall performance and safety of the aircraft.

Key Benefits

- Safety Assurance: Following established procedures minimizes risks associated with maintenance tasks.

- Consistency: Standardized protocols lead to uniformity in maintenance practices across various aircraft.

- Efficiency: Clear instructions help technicians complete tasks in a timely manner, reducing downtime.

- Compliance: Adhering to documented guidelines ensures alignment with regulatory requirements.

Essential Components

- Technical Specifications: Detailed descriptions of materials and methods are crucial for accurate execution.

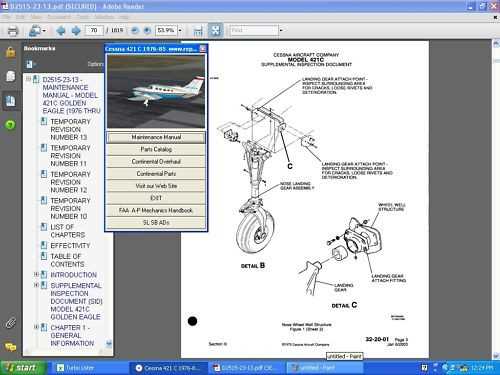

- Illustrations: Visual aids enhance understanding and aid in complex procedures.

- Step-by-Step Procedures: Clear sequences help prevent errors during maintenance activities.

- Checklist: Verifying tasks against a list ensures all necessary actions are completed.

In summary, having access to thorough documentation is indispensable for effective maintenance practices. It not only enhances safety but also ensures that all work is performed to the highest standards, thereby prolonging the life of the aircraft.

Common Structural Issues in Cessna 172

Aviation maintenance often encounters various challenges that can affect the integrity of light aircraft. Identifying and addressing these issues is crucial for ensuring safety and prolonging the lifespan of the aircraft. This section explores frequent problems that operators may face, along with their implications and recommended solutions.

| Issue | Description | Recommended Action |

|---|---|---|

| Corrosion | Oxidation that affects metal components, often due to moisture exposure. | Regular inspections and application of protective coatings. |

| Fatigue Cracks | Micro-fractures that develop from repeated stress over time. | Thoroughly monitor affected areas and conduct appropriate repairs. |

| Delamination | Separation of composite materials, compromising structural integrity. | Assess the extent of damage and consider replacement of components. |

| Impact Damage | Dents or deformations resulting from collisions or rough landings. | Evaluate and repair any significant surface imperfections. |

| Fastener Issues | Loosening or failure of rivets and bolts can lead to structural weaknesses. | Inspect and tighten fasteners regularly; replace as necessary. |

Materials Used in Aircraft Repairs

In the aviation industry, the selection of appropriate substances for restoration processes is crucial for ensuring safety, longevity, and performance. Various elements play a significant role in maintaining the structural integrity of aerial vehicles, allowing them to withstand the stresses encountered during operation. Understanding these materials and their applications is essential for effective maintenance and refurbishment.

Commonly Used Materials

- Aluminum Alloys: Lightweight and resistant to corrosion, aluminum alloys are extensively used in the construction of airframes and components.

- Steel: Known for its strength and durability, steel is often employed in high-stress areas where resilience is paramount.

- Composite Materials: These include carbon fiber and fiberglass, which offer excellent strength-to-weight ratios and are increasingly popular in modern aircraft designs.

- Adhesives: Advanced bonding agents are used to join various materials, providing strength and flexibility in repairs.

- Sealants: Essential for preventing moisture ingress, these materials help maintain the airworthiness of the aircraft.

Considerations for Material Selection

- Weight: Lighter materials contribute to better fuel efficiency and performance.

- Corrosion Resistance: Materials that withstand environmental factors enhance longevity.

- Cost: Budget considerations can influence the choice of materials without compromising safety.

- Compatibility: Selected materials must work well with existing components to ensure structural integrity.

Repair Techniques and Methods

This section outlines various approaches and practices for restoring airframe integrity. Emphasizing safety and reliability, it explores the fundamental strategies that ensure structural components are effectively addressed. Techniques range from simple patching to more complex reinforcement methods, tailored to the specific needs of the aircraft.

Common Approaches

One widely used method involves the application of bonding agents and composite materials, which enhance the strength of existing structures. Adhesive bonding provides a seamless connection between parts, minimizing stress concentrations. In instances where metal fatigue is present, metal replacement becomes essential, often requiring precise cutting and fitting of new components.

Advanced Techniques

For more severe damage, welding techniques can be employed to fuse materials back together, ensuring the original design specifications are met. Additionally, stress analysis may be conducted to identify potential failure points, guiding the selection of the most suitable method for restoration. Implementing these advanced strategies ensures the longevity and safety of the airframe.

Tools Required for Structural Repairs

Effective restoration of airframe components relies heavily on the appropriate instruments and equipment. Utilizing the right tools not only enhances efficiency but also ensures safety and accuracy during the refurbishment process. Each task demands specific gear tailored to the material and nature of the work being undertaken.

Essential Hand Tools

A well-equipped toolkit is fundamental for any project involving airframe modifications. Basic items such as wrenches, pliers, screwdrivers, and hammers are crucial. Additionally, precision tools like calipers and micrometers help achieve exact measurements, while files and sanders ensure smooth finishes on surfaces prior to further treatment.

Power and Specialty Equipment

In many cases, power tools are indispensable for larger tasks. Drills, grinders, and saws can significantly expedite the process. Specialty items, such as rivet guns and pneumatic tools, provide the necessary force and precision for critical applications. Furthermore, personal protective equipment (PPE) is essential to ensure the safety of the technician during all phases of the project.

Safety Precautions During Repair

Ensuring a secure working environment is paramount when undertaking any form of maintenance on aviation equipment. Adhering to safety guidelines not only protects the technician but also preserves the integrity of the aircraft. Proper precautions can prevent accidents and minimize risks associated with the task at hand.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear, including gloves, safety goggles, and ear protection. These items safeguard against various hazards such as chemicals, sharp objects, and excessive noise.

Before starting any procedure, it is vital to conduct a thorough hazard assessment. Identify potential dangers in the workspace, such as loose tools, slippery surfaces, or overhead hazards. Ensuring a tidy environment can greatly reduce the likelihood of incidents.

When handling materials and tools, always follow manufacturer guidelines for safe usage. Improper handling can lead to injuries or damage to the aircraft. Additionally, familiarize yourself with the emergency procedures relevant to your working area, ensuring swift action in case of unforeseen events.

Finally, maintain effective communication with your team. Clear dialogue about tasks, potential risks, and progress ensures that everyone is aware and can act accordingly. A culture of safety is created through shared responsibility, leading to a more efficient and secure working atmosphere.

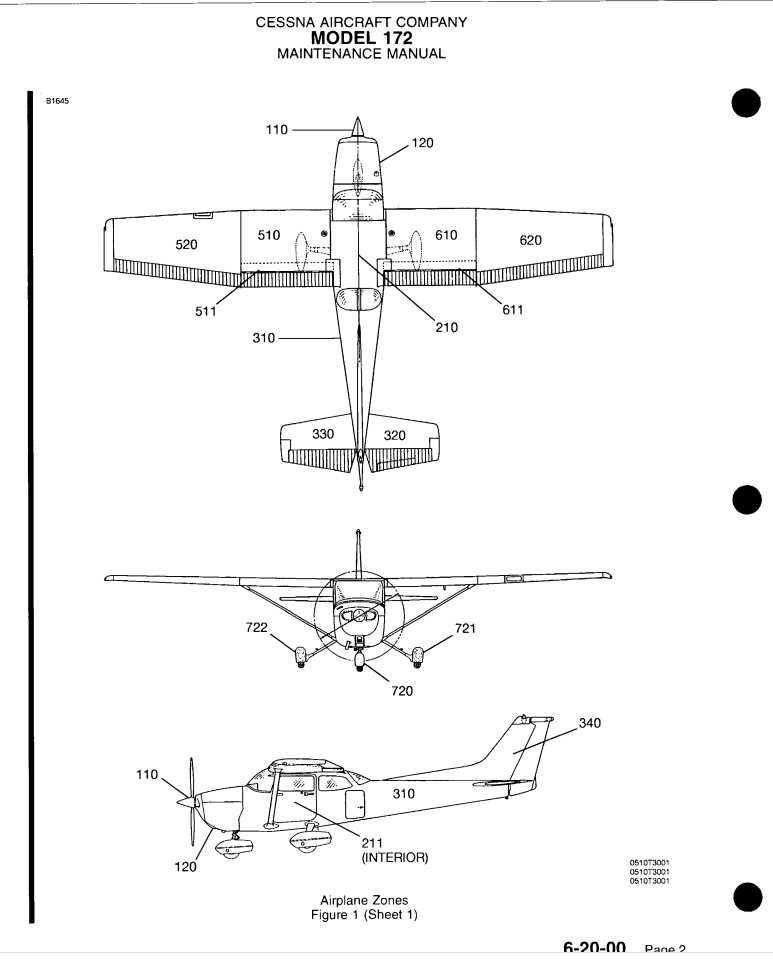

Inspection Procedures for Cessna 172

The process of assessing the integrity and functionality of an aircraft is crucial for ensuring safety and performance. This section outlines essential practices for thoroughly examining the airframe and systems to identify any signs of wear, damage, or non-compliance with standards. Regular inspections play a pivotal role in maintaining operational reliability and extending the lifespan of the aircraft.

Visual Examination

A comprehensive visual inspection is the first step in the assessment procedure. Inspectors should look for any obvious signs of damage, such as cracks, corrosion, or deformation in the structure. Special attention should be given to critical areas including the wings, fuselage, and control surfaces. Utilizing a bright light source can aid in identifying surface imperfections that may otherwise go unnoticed.

Non-Destructive Testing (NDT)

In addition to visual checks, employing non-destructive testing techniques is vital for a deeper analysis of the aircraft’s condition. Methods such as ultrasonic testing, magnetic particle inspection, and dye penetrant testing can reveal internal flaws without causing any harm. These procedures should be carried out by certified personnel to ensure accuracy and reliability in detecting potential issues.

Understanding Load Factors

Load factors are crucial in aviation, reflecting the relationship between the forces acting on an aircraft and its structural integrity. These factors determine how well an airframe can withstand various stresses during flight maneuvers, impacting both safety and performance. Recognizing the significance of these forces helps in assessing the durability and reliability of aircraft design.

Definition and Importance

In essence, load factors quantify the stress exerted on an aircraft during different phases of flight, including ascent, descent, and turns. Understanding these elements is vital for pilots and engineers alike, as they play a pivotal role in ensuring that the airframe can endure the dynamic conditions it encounters. Exceeding recommended limits can lead to structural failures, making knowledge of these parameters essential for maintenance and operation.

Types of Load Factors

Load factors can be classified into several categories, including static and dynamic loads. Static loads refer to forces that are constant, such as the weight of the aircraft, while dynamic loads result from movement and can fluctuate significantly during maneuvers. Pilots must be aware of how these factors influence aircraft behavior, especially in critical situations like turbulence or abrupt changes in altitude.

Calculation and Application

Calculating load factors involves understanding the relationship between weight and aerodynamic forces. The ratio of lift to weight is a fundamental aspect, as it dictates how the aircraft responds to inputs. Properly managing load factors contributes to effective flight operations, enhancing overall safety. Engineers utilize this knowledge to design and test airframes, ensuring they can accommodate the stresses encountered during flight.

Conclusion

A comprehensive understanding of load factors is indispensable for anyone involved in aviation. By grasping the implications of these forces, both pilots and engineers can work together to maintain the highest standards of safety and performance, ensuring that the aircraft remains reliable under various conditions.

Compliance with FAA Regulations

Adhering to the standards set by the Federal Aviation Administration is essential for maintaining safety and airworthiness. These regulations provide a framework for ensuring that all aviation activities meet the necessary requirements for operational integrity and reliability.

Importance of Compliance

Following FAA guidelines is critical for various reasons:

- Ensures safety for crew and passengers.

- Protects the investment in aircraft assets.

- Facilitates smoother operations within the aviation community.

- Avoids potential legal issues and penalties.

Key Areas of Focus

When seeking to comply with FAA regulations, several areas require attention:

- Documentation: Maintaining accurate records of inspections, modifications, and maintenance activities.

- Training: Ensuring all personnel are adequately trained and certified to perform their tasks.

- Inspections: Conducting regular checks to confirm that all components meet the required standards.

- Reporting: Promptly reporting any incidents or discrepancies to the relevant authorities.

Incorporating these practices into operational procedures not only enhances safety but also fosters a culture of responsibility and accountability within the aviation industry.

Maintenance Best Practices

Ensuring the longevity and safety of aviation equipment requires adherence to a set of well-defined practices. Regular attention to detail and systematic checks can prevent minor issues from escalating into significant problems. The following guidelines will help in maintaining optimal performance and structural integrity.

Regular Inspections

Conducting frequent examinations is crucial. These assessments should cover all critical components and systems, focusing on identifying wear and tear before it leads to failure. Documenting findings meticulously helps in tracking the equipment’s condition over time, enabling timely interventions.

Proper Documentation

Maintaining accurate records of all maintenance activities is essential. This includes noting repairs, replacements, and routine checks. Such documentation not only aids in ensuring compliance with safety regulations but also provides valuable insight into the history of the equipment, which can inform future maintenance decisions.

Emphasizing safety through consistent practices will enhance operational reliability and extend the lifespan of aviation assets. By integrating these methods into routine operations, operators can significantly reduce the risk of unexpected failures.

Resources for Further Learning

Expanding your knowledge in aviation maintenance and design can greatly enhance your skills and understanding. A variety of materials and platforms are available to support your learning journey, from textbooks to online courses. Below are some recommended resources that can provide valuable insights and deepen your expertise.

Books and Publications

- Aviation Maintenance Technician Handbook

- Airframe and Powerplant Mechanics Textbook

- Aircraft Structural Design Guide

Online Courses and Tutorials

- Coursera: Aviation Management Courses

- edX: Aircraft Maintenance Fundamentals

- YouTube: Hands-On Maintenance Tutorials

Utilizing these resources will enhance your practical skills and theoretical understanding, ensuring you stay informed about the latest techniques and standards in the field.