Coleman Generator Repair Guide for Efficient Troubleshooting

When it comes to ensuring a reliable source of energy in remote locations or during power outages, having a thorough comprehension of portable power devices is essential. These versatile machines serve a multitude of purposes, from recreational outings to emergency situations, making them invaluable tools for many users.

Maintaining the functionality of such equipment can significantly enhance its performance and longevity. Knowledge of common issues and their resolutions is crucial for anyone looking to maximize the potential of their device. By delving into the intricacies of these power sources, users can gain confidence in their ability to troubleshoot and address various challenges that may arise.

Exploring the different components and mechanisms involved in these systems will provide insights that facilitate better upkeep. Whether you are a novice or an experienced operator, understanding the operational principles can empower you to take control of your energy needs with ease and efficiency.

Coleman Generator Overview

This section provides a comprehensive understanding of portable power units designed for various outdoor activities and emergency situations. These devices are essential for users seeking reliable electricity supply when traditional sources are unavailable. With a focus on functionality, efficiency, and user convenience, the following details will explore the characteristics and benefits of these versatile machines.

Constructed with durable materials, these power sources are engineered to withstand challenging environments while delivering consistent performance. Their compact design ensures portability, making them ideal companions for camping trips, tailgating events, or unexpected power outages at home.

Key features often include multiple output options, allowing users to connect various appliances easily. Additionally, many models are equipped with noise reduction technology, ensuring a quieter operation that enhances user experience in serene settings. Safety measures, such as overload protection and automatic shut-off systems, further contribute to the reliability of these devices, offering peace of mind during use.

In summary, portable power units represent an essential tool for those who require a dependable energy source away from conventional outlets. Their innovative design and practical features make them suitable for a wide range of applications, ensuring users stay powered up when it matters most.

Common Issues with Coleman Generators

Portable power sources are essential for outdoor activities and emergency situations, yet they can sometimes face difficulties that hinder their performance. Understanding frequent problems can help users maintain efficiency and prolong the lifespan of their equipment.

Frequent Challenges

- Starting Issues: Difficulty in initiating the unit may stem from various factors such as fuel problems or battery depletion.

- Power Output Fluctuations: Users may notice inconsistencies in voltage, often caused by overloaded circuits or internal component failures.

- Excessive Noise: Unusual sounds can indicate mechanical issues or loose parts that require attention.

- Fuel Leaks: Leaking fuel can pose safety hazards and is commonly linked to deteriorating hoses or seals.

Maintenance Tips

- Regularly check and replace the oil to ensure optimal functioning.

- Inspect fuel lines and connectors for signs of wear.

- Clean air filters to prevent blockages that can affect performance.

- Perform routine checks on electrical components to avoid power inconsistencies.

Essential Tools for Repair

Having the right equipment is crucial when tackling any maintenance task. A well-equipped toolkit can streamline the process, ensuring that each component functions correctly. Familiarity with these instruments not only aids in efficiency but also enhances the overall quality of the work.

Basic Tools

- Wrenches: A variety of sizes is necessary to tackle different fasteners.

- Screwdrivers: Both flathead and Phillips types are essential for various screws.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Socket Set: Provides versatility for tightening or loosening nuts and bolts.

- Multimeter: Essential for diagnosing electrical issues and ensuring proper voltage levels.

Specialized Equipment

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Cleaning Supplies: Solvents and brushes help maintain components by removing dirt and debris.

- Lubricants: Vital for smooth operation and to prevent wear and tear on moving parts.

- Safety Gear: Goggles and gloves protect against hazards during maintenance.

Step-by-Step Troubleshooting Guide

This section aims to assist users in identifying and resolving common issues encountered with portable power sources. By following a systematic approach, you can efficiently diagnose problems and implement appropriate solutions.

Begin by examining the unit for any visible signs of wear or damage. A thorough inspection can reveal underlying issues that may not be immediately apparent. Below is a table summarizing typical problems and their potential causes:

| Issue | Possible Cause | Suggested Action |

|---|---|---|

| No power output | Empty fuel tank | Refill with the appropriate fuel |

| Strange noises | Loose components | Tighten all accessible bolts and screws |

| Excessive vibration | Imbalanced parts | Check for worn or damaged elements |

| Difficulty starting | Clogged air filter | Clean or replace the air filter |

| Overheating | Poor ventilation | Ensure adequate airflow around the unit |

Following these steps can lead to effective troubleshooting, ultimately restoring optimal functionality to your equipment. If problems persist, consulting a professional may be necessary for a more in-depth examination.

Replacing the Spark Plug

Maintaining optimal performance of your portable power source often involves periodic checks and replacements of key components. One of the essential parts that may require attention is the ignition element, which plays a crucial role in the efficient operation of the machine.

Signs That a Replacement Is Needed

Before proceeding with the replacement, it’s important to recognize the symptoms indicating that the ignition component is not functioning properly:

- Difficulty starting the unit

- Inefficient fuel consumption

- Unusual noise during operation

- Excessive emissions

Steps to Replace the Ignition Element

Follow these steps to ensure a smooth replacement process:

- Safety First: Disconnect the power source and ensure the machine is cool.

- Access the Element: Locate and remove the cover or shield to expose the ignition component.

- Remove the Old Component: Use the appropriate tools to unscrew and detach the old part from its housing.

- Inspect the Area: Check for any debris or damage in the vicinity before proceeding.

- Install the New Component: Secure the new ignition element in place, making sure it fits snugly.

- Reassemble: Replace the cover or shield, ensuring all screws are tightened properly.

- Test the Unit: Reconnect the power source and start the machine to verify proper operation.

Regular maintenance, including the timely replacement of the ignition component, can significantly enhance the longevity and efficiency of your equipment.

Changing the Oil Properly

Regular maintenance is essential for ensuring optimal performance and longevity of your equipment. One of the crucial tasks in this process is replacing the lubricating fluid. Properly executing this procedure not only enhances efficiency but also safeguards against potential damage.

Gather Necessary Tools and Materials

Before beginning, collect the required tools: an oil container for disposal, a wrench for the drain plug, a funnel, and a suitable replacement fluid. Ensure that the new lubricant meets the specifications outlined in your device’s guidelines for best results.

Step-by-Step Procedure

Start by allowing the machine to cool down. This step is vital to prevent burns and ensure safe handling. Once cooled, locate the drain plug, typically situated at the bottom of the tank. Using the wrench, carefully unscrew the plug and let the old fluid drain completely into the container. After draining, replace the plug securely.

Next, use the funnel to pour the new fluid into the designated fill opening. Take care not to overfill, as this can lead to complications. Once filled to the recommended level, secure the cap and check for any leaks. Regularly monitoring and changing the lubricant will significantly contribute to the effective operation of your equipment.

Fuel System Maintenance Tips

Proper upkeep of the fuel delivery system is crucial for ensuring optimal performance and longevity of your equipment. Regular checks and maintenance can prevent common issues, allowing for a smooth operation. Implementing these practices will help keep the fuel lines and components in top shape.

1. Regular Inspection: Periodically examine all fuel lines and connections for any signs of leaks or damage. Replace any worn-out parts immediately to avoid complications.

2. Fuel Quality: Always use clean, high-quality fuel. Contaminated fuel can lead to clogging and operational issues.

3. Clean Filters: Ensure that fuel filters are cleaned or replaced regularly. A clogged filter can restrict fuel flow and affect performance.

4. Stabilizers: If you store fuel for extended periods, consider using fuel stabilizers. This helps prevent degradation and keeps the fuel fresh.

5. Drain Fuel: For long-term storage, drain the fuel system to prevent buildup and corrosion inside the tank and lines.

By following these tips, you can significantly enhance the reliability and efficiency of your fuel system.

Cleaning the Air Filter

Maintaining optimal airflow is crucial for efficient operation. A clean air filter ensures that the engine receives sufficient air, preventing performance issues and prolonging its lifespan. Regular cleaning is essential to keep your equipment running smoothly.

To begin, remove the air filter carefully according to the manufacturer’s instructions. Inspect it for dirt and debris. If it appears heavily soiled, it’s time for a thorough cleaning. Rinse the filter with warm, soapy water, gently scrubbing to remove buildup. After cleaning, let it dry completely before reinstalling.

For foam filters, consider applying a light coat of oil after drying to enhance filtration efficiency. Always refer to specific guidelines for your device to ensure proper care. A well-maintained air filter significantly contributes to overall performance.

Understanding Electrical Components

Grasping the essentials of electrical elements is crucial for anyone involved in power systems. These components interact to convert, transmit, and utilize electrical energy efficiently. A solid comprehension of their functions and interrelationships can enhance maintenance and troubleshooting capabilities.

Key Components

- Resistors: Limit the flow of electric current.

- Capacitors: Store and release electrical energy.

- Inductors: Store energy in a magnetic field when current flows through.

- Diodes: Allow current to flow in one direction only.

- Transistors: Act as switches or amplifiers in circuits.

Understanding Their Roles

Each component plays a specific role:

- Resistors manage voltage and current levels.

- Capacitors smooth out fluctuations in power supply.

- Inductors are vital in filtering and energy storage.

- Diodes protect circuits from reverse polarity.

- Transistors enable complex functionalities in electronic devices.

Ultimately, familiarity with these components empowers effective troubleshooting and enhances overall system performance.

Safety Precautions During Repairs

When undertaking maintenance on equipment, ensuring personal safety and the integrity of the device is paramount. Following proper safety protocols minimizes the risk of accidents and injuries while maximizing the efficiency of the work being performed.

Personal Protective Equipment

Always wear appropriate personal protective gear, including safety goggles, gloves, and sturdy footwear. These items protect against potential hazards such as flying debris, sharp edges, and electrical shocks. In addition, consider using a dust mask to avoid inhaling harmful particles during disassembly or cleaning.

Working Environment

Ensure that the workspace is well-ventilated and free from clutter. Keep flammable materials away from the area to reduce fire risks. Utilize proper lighting to clearly see all components, which aids in preventing mistakes or oversights. If working with electrical components, ensure the power source is disconnected before starting any task to prevent unintended activation.

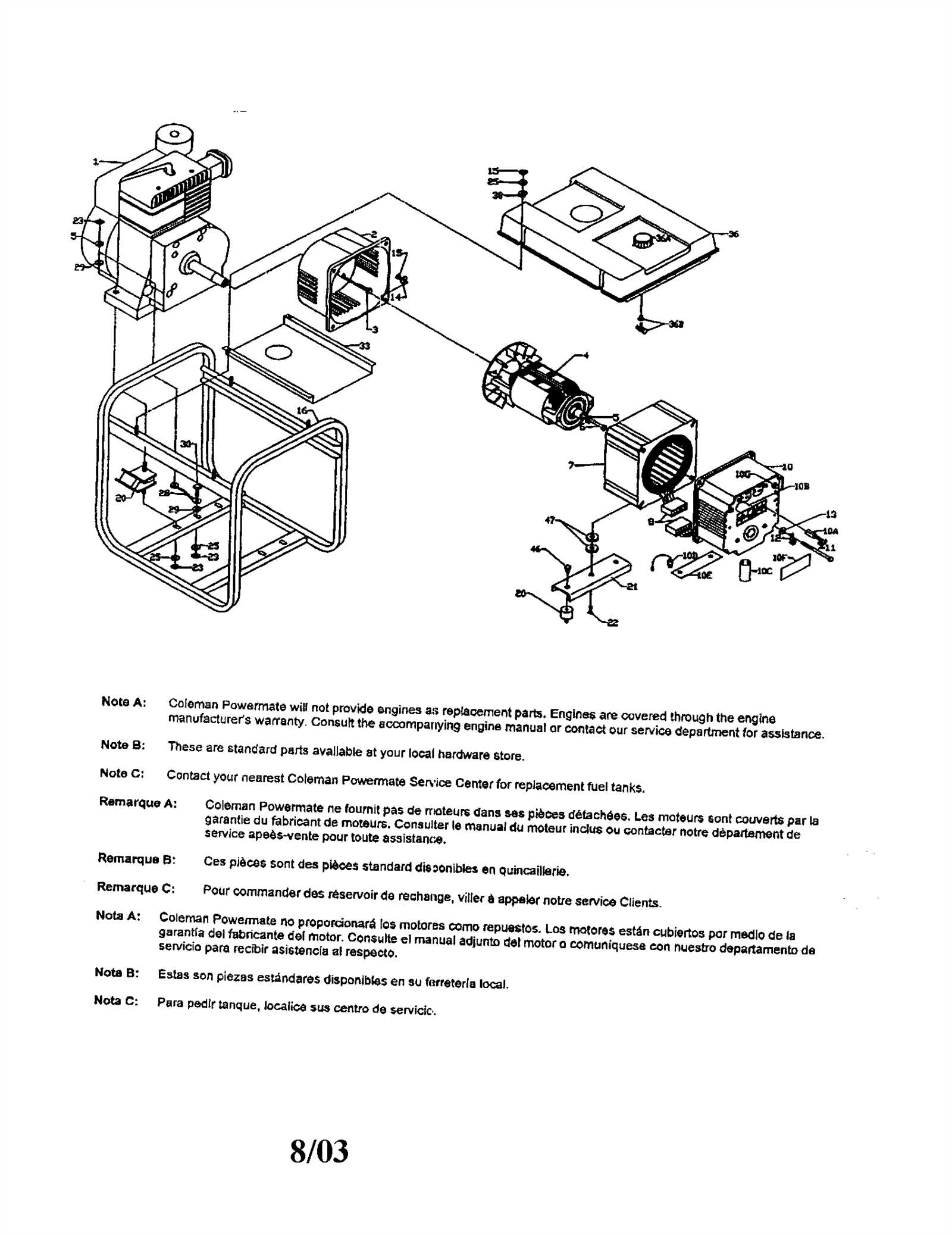

Finding Replacement Parts

Locating the necessary components for your equipment can be a straightforward process if you know where to look. Ensuring that you have the right pieces is crucial for maintaining functionality and extending the lifespan of your device. Here are some effective strategies to help you track down the parts you need.

Online Retailers and Marketplaces

One of the most accessible ways to find spare components is through online shopping platforms. Websites like Amazon or specialized parts retailers often carry a wide range of items suitable for various models. Utilize the search function and input specific part numbers or descriptions to narrow down your options.

Local Stores and Authorized Dealers

Visiting local hardware stores or authorized dealers can also yield positive results. Staff members at these establishments are often knowledgeable about the products they sell and can assist in finding the right parts. Additionally, they may have connections to suppliers who can order items not readily available in-store.

By exploring these avenues, you can enhance your chances of securing the necessary parts efficiently, ensuring your device operates smoothly for years to come.

When to Seek Professional Help

Understanding the right moment to call in an expert can save time and prevent further complications. While some issues may seem manageable, there are specific situations where professional intervention is not only beneficial but essential. Recognizing these instances can ensure safety and optimal functionality.

Signs You Should Consult an Expert

- Persistent Malfunctions: If problems recur despite attempts at troubleshooting, it’s a signal that deeper issues may exist.

- Unusual Noises: Strange sounds during operation can indicate serious internal damage or malfunction.

- Electrical Issues: Flickering lights or tripped circuits suggest electrical faults that require specialized knowledge.

- Fuel Leaks: Any sign of fuel leakage poses a safety risk and should be addressed immediately by a professional.

Benefits of Professional Assistance

- Expert Diagnosis: Professionals have the training to identify problems that may not be apparent to the untrained eye.

- Safety Assurance: Experts follow safety protocols that minimize the risk of accidents or injuries.

- Long-Term Solutions: Skilled technicians can provide durable fixes that extend the lifespan of your equipment.