Coleman Powermate 4000 Generator Repair Guide

In the realm of portable energy sources, ensuring optimal performance and longevity is paramount for users. This section delves into the essential aspects of upkeep and common issues encountered with these versatile machines. Understanding the intricacies of functionality can significantly enhance the user experience and reliability of these valuable assets.

From routine checks to advanced troubleshooting techniques, mastering the operational nuances is crucial. Users will gain insights into various components and systems, enabling them to identify potential malfunctions and address them effectively. A proactive approach not only minimizes downtime but also maximizes the unit’s efficiency in providing necessary power during critical moments.

Moreover, having a comprehensive resource at hand can empower owners to take charge of their equipment. With detailed guidance, the process of maintaining and optimizing performance becomes more accessible, transforming the task into a straightforward endeavor. Whether dealing with minor glitches or preparing for seasonal use, this guide serves as a valuable companion for all power unit enthusiasts.

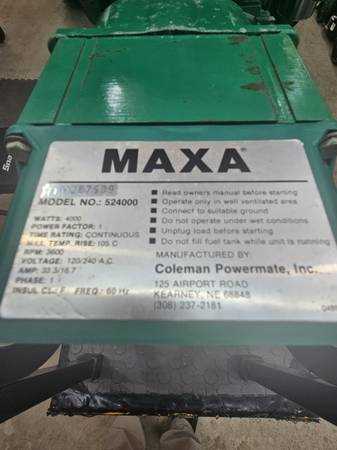

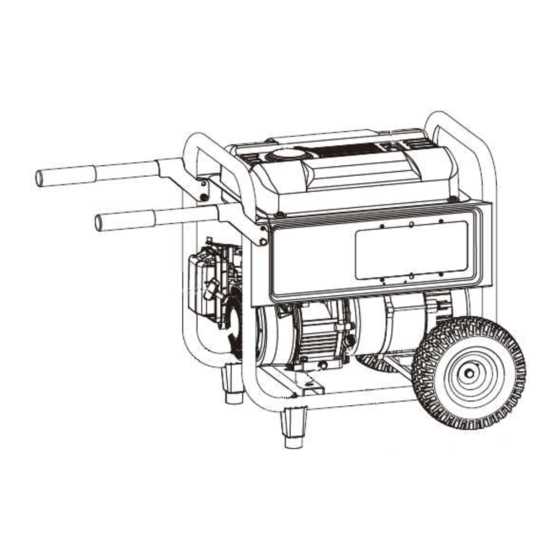

Coleman Powermate 4000 Overview

This section provides a comprehensive overview of a popular portable power source, highlighting its features, functionalities, and advantages. Understanding these aspects is essential for anyone considering the integration of such equipment into their outdoor or emergency setups.

The unit is designed to deliver reliable energy for various applications, making it a favored choice among enthusiasts and professionals alike. Key elements include:

- Power Output: Capable of generating substantial wattage, making it suitable for running multiple devices.

- Durability: Built to withstand outdoor conditions, ensuring longevity and consistent performance.

- Portability: Lightweight and equipped with wheels, allowing for easy transport to different locations.

- Ease of Use: Features intuitive controls and setup, enabling quick operation for users of all skill levels.

Additionally, this device is equipped with safety features to protect both the equipment and users, ensuring a worry-free experience. Regular maintenance can enhance its performance and extend its lifespan, making it a worthwhile investment for anyone in need of a dependable power supply.

Common Generator Issues and Solutions

Understanding typical problems that can arise with portable power sources is essential for maintaining their efficiency and longevity. From performance drops to unusual noises, identifying these issues promptly can save time and resources. This section outlines frequent challenges users face and offers practical solutions to enhance reliability.

Frequent Starting Problems

One of the most common complaints is difficulty in starting the unit. This can be caused by various factors, including fuel quality, battery issues, or spark plug failures. To address these:

- Check fuel freshness: Ensure that the fuel is not stale. If it has been sitting for a long time, replace it with fresh gasoline.

- Inspect the battery: Ensure that connections are clean and secure, and consider replacing the battery if it shows signs of wear.

- Examine the spark plug: Remove and clean the spark plug; replace it if it appears damaged or excessively worn.

Inconsistent Power Output

Users may also encounter fluctuations in power delivery, which can affect connected devices. This issue might stem from overloading, fuel supply interruptions, or internal component failures. Solutions include:

- Avoid overloading: Make sure that the total wattage of devices does not exceed the power source’s capacity.

- Inspect fuel lines: Ensure there are no blockages or leaks in the fuel delivery system.

- Check internal components: If problems persist, consider consulting a professional to evaluate and repair any internal faults.

Essential Tools for Repairing Generators

When it comes to maintaining and fixing portable power units, having the right equipment is crucial. Various instruments and supplies facilitate efficient troubleshooting and ensure optimal performance. Here are some indispensable tools that every technician should have on hand.

- Multimeter: This device is essential for measuring voltage, current, and resistance, allowing for accurate diagnostics of electrical components.

- Wrenches: A set of adjustable and socket wrenches helps in loosening and tightening bolts and nuts, essential for accessing internal parts.

- Screwdrivers: Both flat-head and Phillips screwdrivers are necessary for removing and securing screws in various assemblies.

- Pliers: Needle-nose and slip-joint pliers assist in gripping, twisting, and cutting wires, making them versatile for repairs.

- Fuel System Cleaner: This product aids in maintaining fuel lines and carburetors, ensuring that the engine runs smoothly.

In addition to these tools, consider the following items for a complete toolkit:

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Safety Gear: Always wear gloves and goggles to protect yourself while working on machinery.

- Flashlight: A bright light source is vital for inspecting dark areas and ensuring thorough checks.

- Oil Filter Wrench: Essential for changing the oil and maintaining engine health.

- Cleaning Brushes: Useful for clearing debris from components to maintain performance.

Equipping yourself with these fundamental tools will significantly enhance your ability to diagnose and fix issues effectively, leading to improved reliability and longevity of your power equipment.

Step-by-Step Troubleshooting Guide

This guide provides a comprehensive approach to diagnosing common issues that may arise with your portable power source. Following these steps can help you identify problems systematically, ensuring effective resolution without unnecessary confusion.

1. Initial Assessment: Begin by examining the unit for any visible signs of damage or wear. Check connections and ensure that all components are securely attached.

2. Fuel Check: Verify that the fuel tank is filled with the appropriate type of fuel. Stale or contaminated fuel can lead to operational issues.

3. Battery Inspection: If the equipment features an electric start, inspect the battery for charge levels and corrosion. Clean the terminals if needed.

4. Oil Level Evaluation: Check the oil level using the dipstick. Low oil can cause performance problems, so ensure it is within the recommended range.

5. Spark Plug Examination: Remove and inspect the spark plug for wear or carbon buildup. A damaged spark plug may need replacement to restore functionality.

6. Air Filter Cleaning: A clogged air filter can hinder performance. Remove it and clean or replace it to ensure proper airflow.

7. Load Testing: If the unit starts but doesn’t perform under load, test it with different devices to determine if the issue is related to specific equipment or the power source itself.

8. Electrical System Review: Examine the circuit breaker and fuses for any tripped switches or blown fuses, which can interrupt the flow of electricity.

9. Performance Monitoring: Once all checks are complete, run the equipment and observe for any irregular sounds or vibrations that might indicate deeper issues.

10. Consult Documentation: If problems persist after following these steps, refer to the product’s technical documentation for more detailed guidance specific to your model.

Maintenance Tips for Longevity

Ensuring the durability of your portable power source requires consistent upkeep and attention. Regular maintenance not only enhances performance but also extends the lifespan of the equipment. Implementing simple care routines can prevent minor issues from escalating into significant problems, ensuring reliable operation when needed most.

Regular Inspection

Conducting routine checks is essential. Look for signs of wear and tear, such as frayed wires or loose connections. Ensure that all components are securely fastened and free from corrosion. Pay attention to the fuel system; inspect for leaks and ensure that filters are clean to facilitate optimal performance.

Proper Storage

When not in use, storing the unit properly can significantly impact its longevity. Keep it in a dry, cool place to prevent moisture buildup. Consider using a cover to protect against dust and debris. Before long-term storage, drain fuel to avoid degradation and start the unit occasionally to keep the internal parts lubricated.

Emphasizing these maintenance practices will contribute to the effective functioning of your equipment, allowing it to serve you reliably over the years. Remember, a little attention goes a long way in preserving your investment.

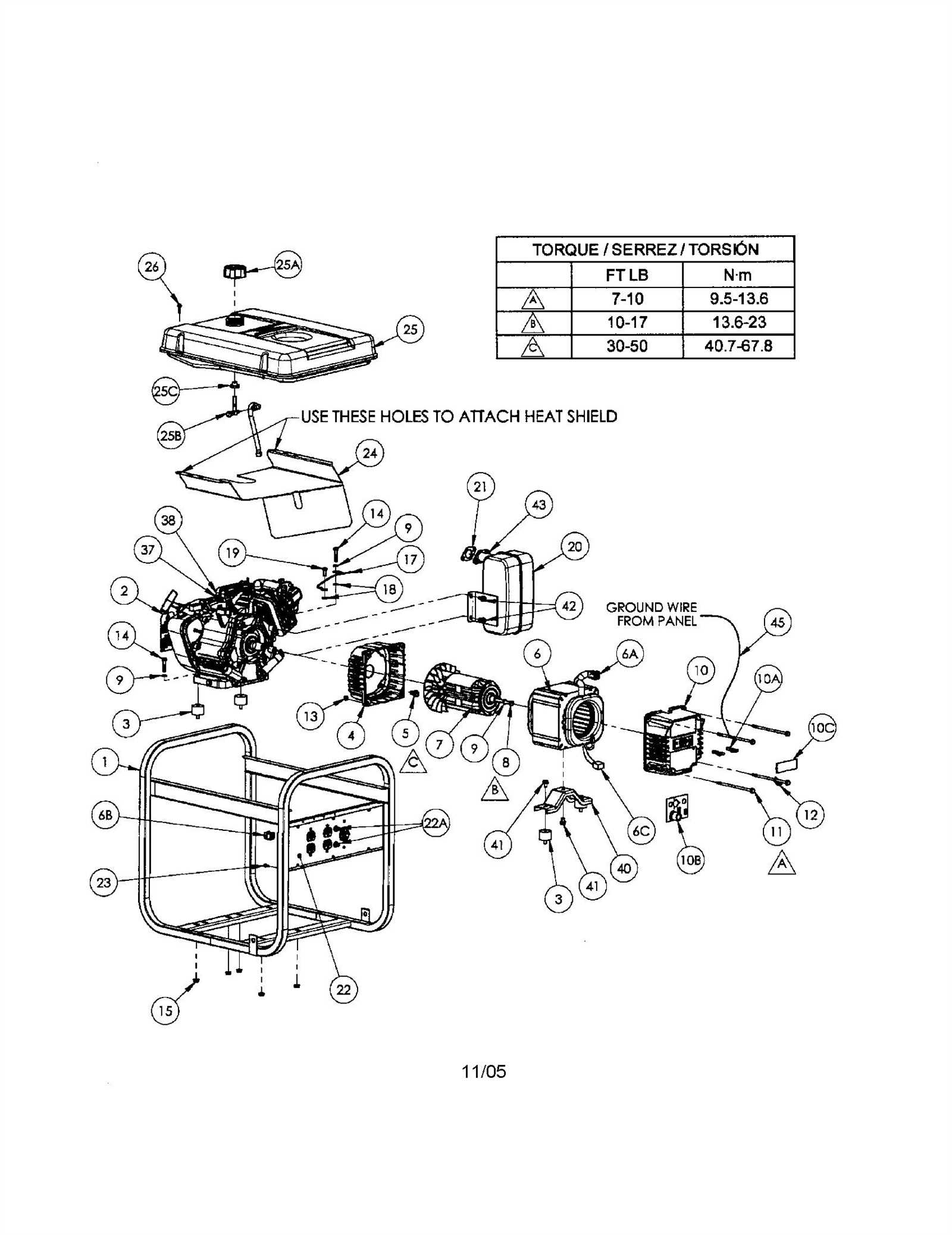

Replacing Key Components Explained

Maintaining optimal performance of portable power sources often requires the replacement of essential parts. Understanding the process of component substitution can significantly enhance functionality and extend the lifespan of the equipment. This section will delve into the most critical elements that may need attention and how to effectively carry out their replacement.

One of the first components to consider is the fuel system. Over time, fuel lines can deteriorate, leading to leaks or blockages. Replacing these lines is crucial for ensuring efficient fuel delivery. Additionally, filters should be inspected and swapped out periodically to prevent impurities from clogging the system.

The ignition system is another vital area. Spark plugs, in particular, play a key role in starting the unit. If performance issues arise, checking and replacing spark plugs can often resolve these problems. Ensuring the ignition components are in good condition is essential for reliable operation.

Electrical connections also warrant attention. Worn or corroded wires can cause power loss and erratic performance. Replacing damaged cables and connectors helps maintain a stable electrical flow, ensuring the unit operates smoothly.

Lastly, the oil system is fundamental for the internal workings. Regularly replacing the oil and oil filter helps keep the engine clean and running efficiently. Neglecting this aspect can lead to significant wear and tear over time.

By systematically addressing these key components, users can maintain their equipment in peak condition, ensuring reliable performance and longevity.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance tasks is crucial for both personal well-being and the longevity of the equipment. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. It is essential to take necessary precautions before beginning any service work.

Preparation and Environment

Before starting any servicing, make sure to work in a well-ventilated area. Clear the workspace of unnecessary items to avoid tripping hazards. Wear appropriate protective gear, including gloves and safety glasses, to shield against potential injuries. Additionally, ensure that all tools are in good condition and suitable for the job.

Electrical Safety

When dealing with electrical components, always disconnect the power source before attempting any inspection or adjustments. Use insulated tools to prevent electric shocks, and be mindful of any exposed wires. If unsure about the electrical systems, consult a professional to avoid dangerous situations.

Identifying Electrical Problems Easily

Recognizing electrical issues promptly can save time and prevent further complications. Understanding the symptoms of malfunctions is crucial for effective troubleshooting. By observing specific indicators, users can pinpoint the source of the problem and address it efficiently.

Start by checking for unusual noises or vibrations that may indicate loose components or internal wear. Inspect connections and wiring for signs of damage, corrosion, or loose terminals. These physical inspections can often reveal hidden issues before they escalate.

Another key aspect is monitoring performance changes. Diminished power output or irregular behavior when in use can signal underlying faults. Utilizing basic testing tools, such as multimeters, can provide valuable insights into voltage levels and continuity, helping to confirm suspicions regarding electrical integrity.

Documenting any fluctuations in performance or odd occurrences can also assist in identifying patterns. This information is vital for a thorough diagnosis and can guide further investigation or professional assistance if necessary.

Lastly, always ensure that safety precautions are in place when working with electrical systems. Properly following guidelines can mitigate risks and ensure a safer working environment while troubleshooting issues.

When to Seek Professional Help

Determining when to call in a specialist can save time, effort, and potential harm. Some situations require a deeper understanding of complex systems that may be beyond basic troubleshooting. Recognizing these instances is crucial for ensuring safe and effective resolution of issues.

Consider seeking professional assistance in the following scenarios:

- Persistent Problems: If the issue continues despite your best efforts, it may be time to consult an expert.

- Unusual Sounds: Strange noises can indicate underlying issues that may require specialized knowledge to diagnose.

- Visible Damage: If you notice physical damage or signs of wear, it’s important to have a professional assess the extent of the problem.

- Electrical Issues: Complications involving electrical components should be handled by someone trained in that area to avoid safety hazards.

- Lack of Experience: If you feel uncomfortable or unsure about attempting a fix, it’s wise to reach out to someone who has the necessary expertise.

In summary, when faced with complex challenges, it’s better to err on the side of caution and seek help from qualified individuals who can ensure everything is addressed properly and safely.

Understanding Warranty and Support Options

When investing in portable power solutions, it’s essential to grasp the available warranty and support features. These elements provide users with assurance and guidance, ensuring that they can address any issues that may arise during the product’s lifespan. Understanding the terms and conditions of these offerings is crucial for making informed decisions.

Warranty coverage typically includes specific durations during which repairs or replacements are provided at no additional cost. It’s important to carefully review what is encompassed within this protection, as certain components may have different terms. Additionally, some manufacturers may offer extended warranty plans, allowing for further peace of mind.

Beyond warranty provisions, customer support plays a vital role in user satisfaction. This may include access to online resources, troubleshooting guides, and responsive customer service teams. Utilizing these resources can significantly enhance the ownership experience and help resolve issues quickly. Engaging with the support channels can also lead to valuable insights regarding maintenance and optimal usage practices.

In summary, familiarizing oneself with warranty and support options is not only a smart investment strategy but also a way to ensure long-term satisfaction with your purchase. A thorough understanding of these aspects can empower users to utilize their equipment effectively and confidently.