Comprehensive Guide to Craftsman DLS 3500 Repair

Maintaining outdoor machinery is essential for optimal performance and longevity. This section provides a thorough overview of essential procedures and guidelines to help users navigate various challenges that may arise during operation. Understanding the intricacies of equipment upkeep is vital for anyone looking to extend the life of their investment.

In this resource, you will discover detailed insights into the common issues that can occur with your machinery and how to effectively address them. From straightforward adjustments to more complex fixes, each aspect is designed to empower users with the knowledge needed to tackle maintenance tasks confidently.

Additionally, practical tips and tricks are included to enhance your experience and ensure that your equipment operates smoothly. Whether you are a seasoned user or a newcomer, this guide serves as a valuable companion, fostering a deeper connection with your tools and enhancing your overall proficiency.

Craftsman DLS 3500 Overview

This section provides an overview of a specific type of equipment designed for outdoor maintenance tasks. It combines durability and functionality, making it suitable for a variety of gardening and landscaping activities. The machine features a robust build and user-friendly controls, ensuring efficiency and ease of use for both professionals and hobbyists.

Equipped with advanced technology, this tool enhances performance and reliability. It is engineered to handle diverse terrains and conditions, providing a smooth experience for users. Understanding its components and features is crucial for maximizing its potential.

| Feature | Description |

|---|---|

| Power Source | Utilizes a powerful engine designed for optimal performance. |

| Cutting Width | Offers a wide cutting path for efficient coverage. |

| Control System | User-friendly interface for easy operation. |

| Build Quality | Constructed with high-grade materials for longevity. |

| Maintenance | Designed for simple upkeep to ensure lasting functionality. |

Common Issues with the DLS 3500

Every mechanical device may experience certain challenges over time, which can affect its overall functionality and performance. Understanding these potential problems can help users address issues more effectively and maintain optimal operation.

- Starting Difficulties: Users may encounter issues when attempting to initiate the machine. This could stem from various factors, including electrical connections or fuel supply.

- Unusual Noises: Unexpected sounds during operation often indicate underlying mechanical problems. These noises might suggest wear and tear on components or misalignment.

- Power Loss: A noticeable decrease in power output can hinder performance. This issue might arise from clogged filters or insufficient maintenance.

- Overheating: If the device runs excessively hot, it could lead to potential damage. Proper ventilation and cooling are essential to prevent this issue.

Identifying and addressing these concerns promptly can extend the lifespan of the equipment and ensure it operates efficiently.

Essential Tools for Repairs

To effectively address maintenance and troubleshooting tasks, having the right set of instruments is crucial. The following items not only facilitate efficient work but also ensure safety and precision during the process. Understanding which tools are necessary can significantly enhance the quality of any project.

Basic Hand Tools

Hand tools are fundamental for any task, providing the necessary leverage and control. Here is a list of essential hand tools that every enthusiast should have:

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for fastening and loosening screws of various types. |

| Wrench Set | Essential for tightening and loosening nuts and bolts. |

| Pliers | Ideal for gripping, twisting, and cutting wires. |

Power Tools

In addition to hand tools, power tools can greatly speed up tasks and improve efficiency. The following power tools are highly recommended:

| Tool | Function |

|---|---|

| Drill | Used for creating holes or driving screws into various materials. |

| Saw | Effective for cutting through different materials with ease. |

| Sander | Helps in smoothing surfaces and preparing them for finishing. |

Step-by-Step Repair Procedures

This section outlines a series of systematic actions designed to troubleshoot and fix various issues commonly encountered with this particular model. By following these organized steps, users can effectively address problems, ensuring optimal performance and longevity.

Begin by gathering the necessary tools and materials. Having everything ready will streamline the process and minimize interruptions.

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent any electrical hazards. |

| 2 | Inspect all components visually for any signs of wear or damage. |

| 3 | Carefully remove the affected part, taking note of how it is connected. |

| 4 | Replace or repair the component as necessary, ensuring a secure fit. |

| 5 | Reassemble the unit, checking for any loose connections. |

| 6 | Reconnect the power source and test the system to verify functionality. |

By adhering to these outlined procedures, users can ensure a thorough and effective resolution to common issues, enhancing the overall efficiency of the equipment.

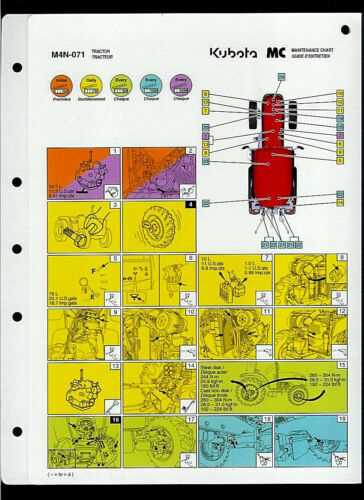

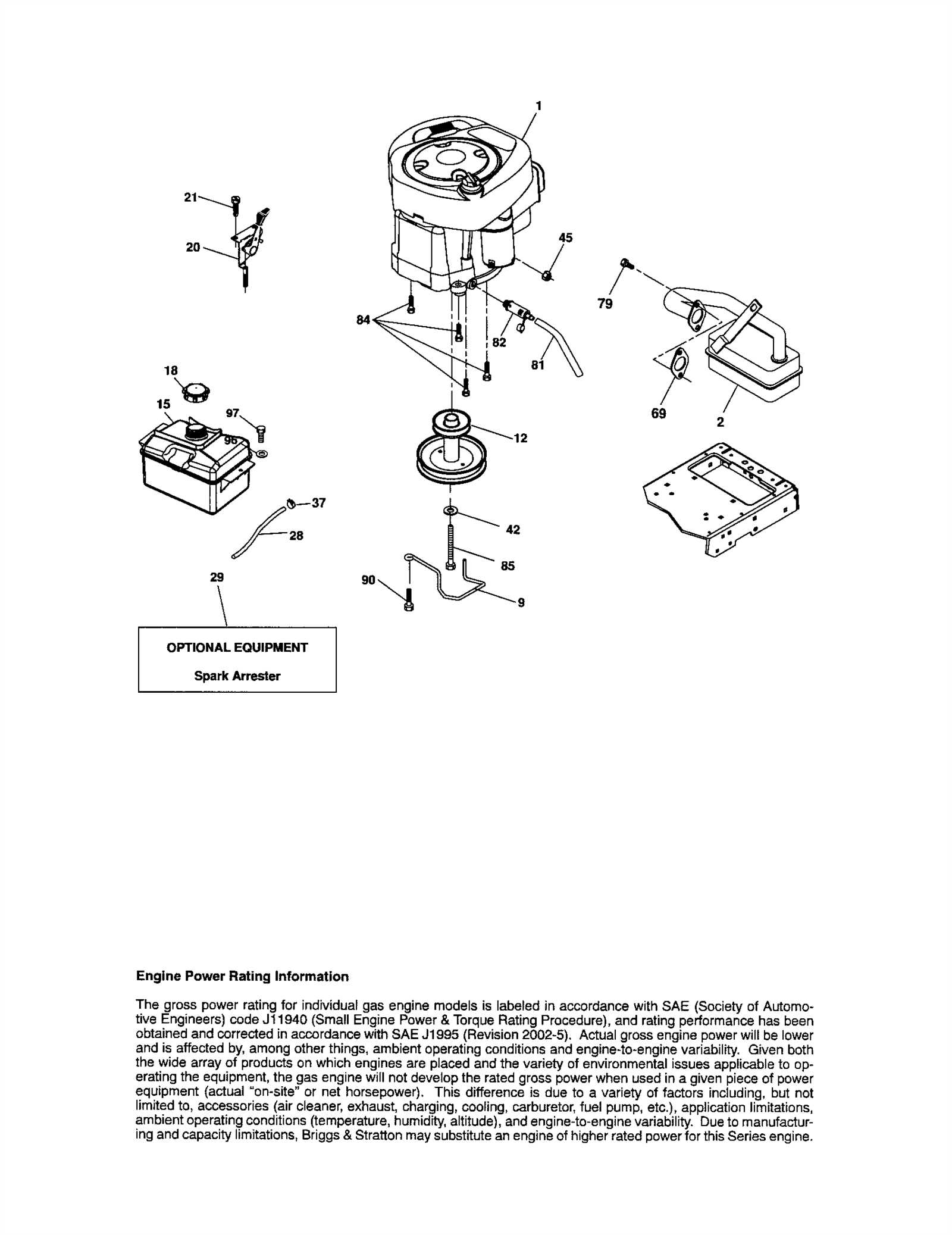

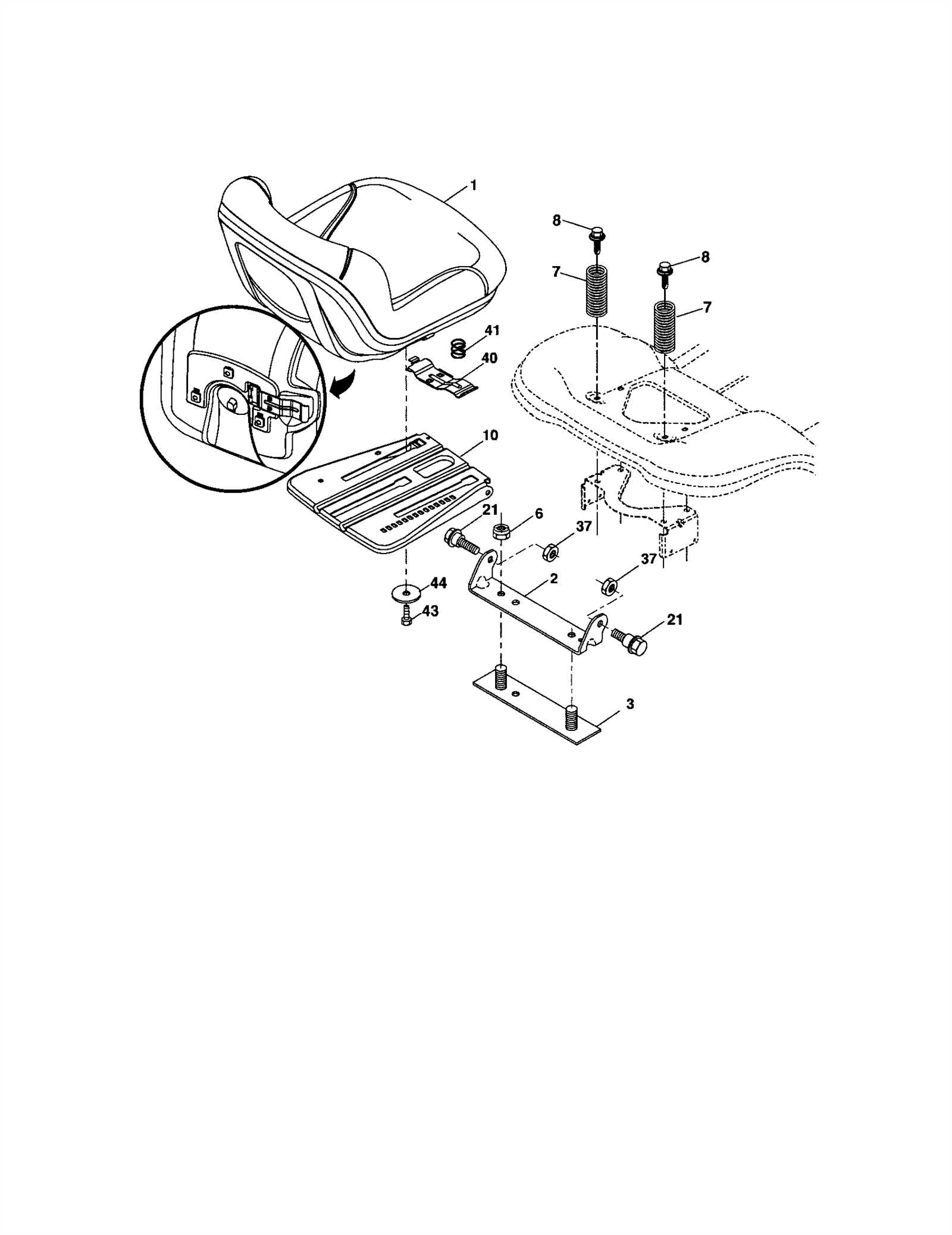

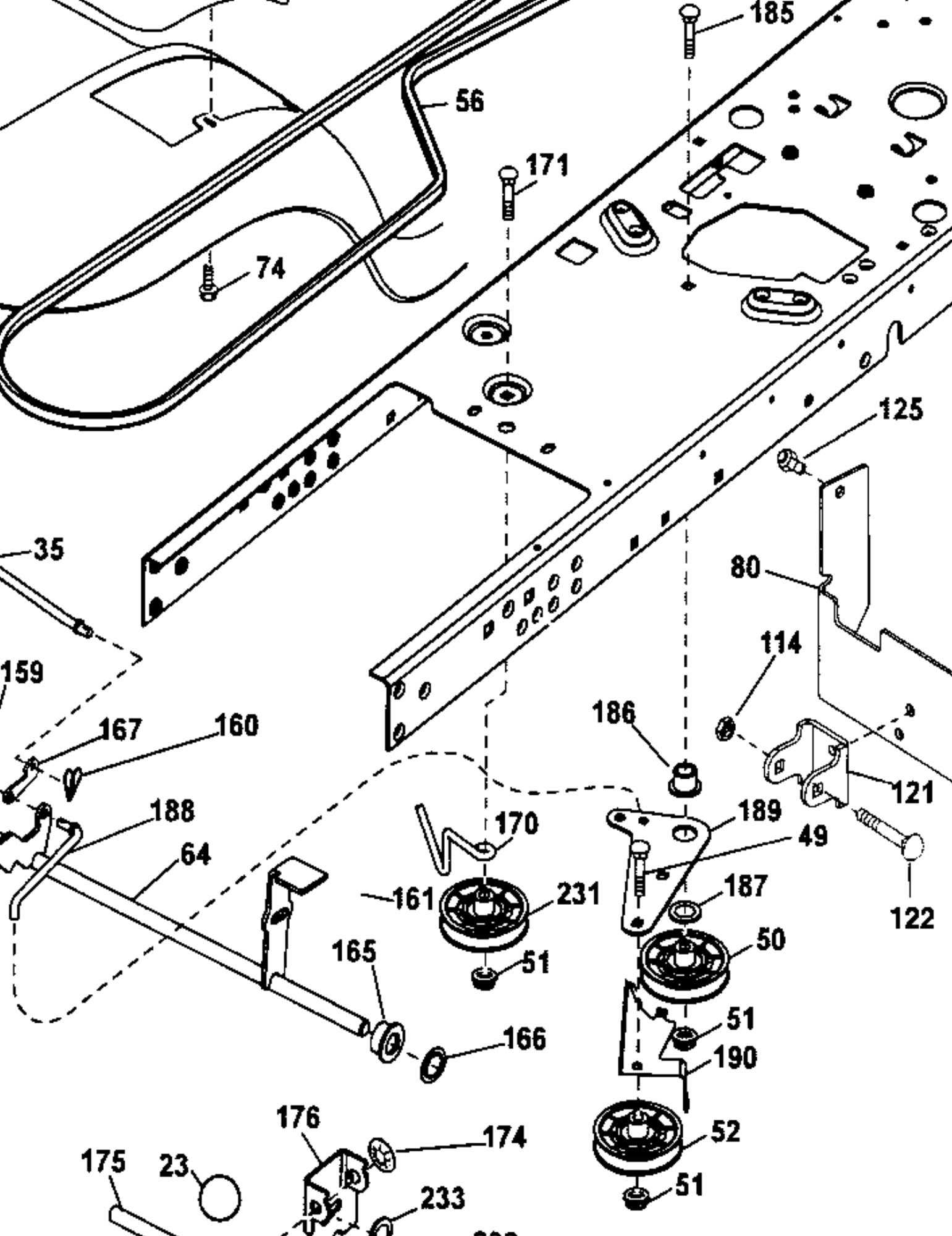

Understanding the DLS 3500 Parts

When it comes to maintaining and troubleshooting equipment, a solid grasp of its components is essential. Each element plays a crucial role in ensuring the device operates smoothly and efficiently. Familiarity with these parts not only aids in diagnosing issues but also helps in enhancing overall performance.

The core assembly typically comprises several integral units, including the engine, transmission, and electrical systems. These segments work in unison to facilitate various functions, from powering the device to controlling its movements. Recognizing the specific duties of each unit allows users to identify potential areas of concern more effectively.

Additionally, understanding the connectivity between these components is vital. Many parts rely on secure connections and proper alignment to function optimally. By examining how these elements interact, one can preemptively address wear and tear, ultimately prolonging the lifespan of the machinery.

Maintenance Tips for Longevity

Ensuring the lasting performance of your equipment requires regular attention and care. Implementing a consistent maintenance routine can prevent unexpected breakdowns and extend the lifespan of your tools. Simple practices can make a significant difference in their overall functionality.

1. Regular Cleaning: Keeping your machinery clean is essential. Dust and debris can accumulate, leading to inefficient operation. Use a soft brush or cloth to wipe down surfaces and remove any buildup that may hinder performance.

2. Lubrication: Proper lubrication is crucial for smooth operation. Regularly apply suitable lubricants to moving parts to reduce friction and wear. This step helps maintain efficiency and prevents overheating.

3. Inspection: Conduct routine inspections to identify any signs of wear or damage. Check belts, hoses, and electrical connections for any issues that could affect performance. Addressing minor problems early can prevent larger complications down the road.

4. Storage: When not in use, store your tools in a dry, safe environment. Protect them from extreme temperatures and moisture, which can cause corrosion or damage. Using protective covers can also help maintain their condition.

5. Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for maintenance. Following these guidelines ensures you are taking the appropriate steps for optimal care, tailored specifically to your equipment.

Troubleshooting Electrical Problems

Addressing electrical issues is essential for maintaining optimal performance in your equipment. Identifying the source of these malfunctions can prevent further damage and ensure smooth operation. Here are some common areas to check when diagnosing electrical difficulties.

Common Symptoms

- Device fails to power on

- Intermittent power loss

- Unusual noises or smells

- Flickering lights

Steps for Diagnosis

- Check the power source: Ensure the outlet is functioning and the power cord is undamaged.

- Inspect fuses and circuit breakers: Replace any blown fuses or reset tripped breakers.

- Examine connections: Look for loose or corroded connections that may disrupt the flow of electricity.

- Test components: Use a multimeter to verify the functionality of various electrical parts.

By methodically assessing these aspects, you can effectively pinpoint and address electrical challenges, restoring your device to proper working condition.

Replacing Key Components Safely

When it comes to maintaining machinery, ensuring the safe replacement of vital parts is crucial for optimal performance. This process not only extends the lifespan of the equipment but also minimizes the risk of accidents and malfunctions. Understanding the right procedures and tools is essential for a smooth replacement process.

Preparation Steps

Before beginning any replacement task, proper preparation can significantly impact safety and efficiency. Here are essential steps to follow:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent accidental startups. |

| 2 | Gather the necessary tools and replacement parts to avoid interruptions. |

| 3 | Wear appropriate safety gear, including gloves and goggles. |

Execution of Replacement

Once you are well-prepared, executing the replacement of components can be approached methodically. Begin by carefully removing the old part, taking note of its positioning and connections. When installing the new component, ensure it is securely fastened and properly aligned to avoid operational issues. After installation, double-check all connections and reattach the power source.

Preventive Care for Optimal Performance

Maintaining equipment in top condition requires regular attention and care. By following a systematic approach to upkeep, users can ensure longevity and efficiency, minimizing the risk of unexpected breakdowns and costly repairs. This proactive strategy not only enhances performance but also contributes to a safer operating environment.

Key Practices for Maintenance

- Regular Cleaning: Remove debris and dust from surfaces to prevent buildup that can hinder performance.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear.

- Inspection: Conduct periodic checks for wear and tear, paying close attention to critical components.

- Calibration: Ensure that all settings and adjustments are correct for optimal functionality.

Monitoring and Adjustments

- Keep a log of maintenance activities to track performance and identify trends.

- Adjust settings as necessary based on observed performance metrics.

- Replace worn components promptly to avoid further damage and ensure efficiency.

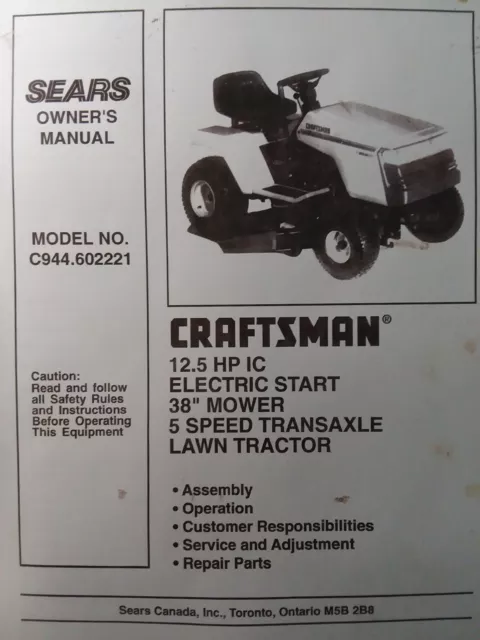

FAQs About Craftsman DLS 3500

This section addresses common inquiries related to a specific model of lawn maintenance equipment. Whether you are seeking guidance on troubleshooting, part replacement, or general usage, you’ll find valuable information here.

What should I do if the engine won’t start?

First, ensure that there is fuel in the tank and that it meets the manufacturer’s specifications. Check the battery for charge and inspect the ignition system for any faults. If these elements are functioning correctly, consider examining the starter and electrical connections.

How often should I change the oil?

It is recommended to change the oil after the initial 5 hours of operation, followed by regular changes every 50 hours. Keeping the engine lubricated helps maintain performance and longevity.

What type of maintenance is required for the blades?

Regularly inspect the cutting blades for sharpness and any signs of wear. Sharpen or replace them as necessary to ensure efficient cutting. Additionally, clean the blades after each use to prevent grass buildup.

Where can I find replacement parts?

Replacement components can typically be purchased through authorized dealers or online marketplaces specializing in outdoor equipment. Ensure that any parts acquired are compatible with your specific model.

Resources for Further Assistance

Accessing reliable sources can significantly enhance your troubleshooting experience. Whether you’re facing common issues or require specialized guidance, a variety of platforms are available to assist you. Below is a selection of resources that may prove beneficial.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Communities where enthusiasts share advice and solutions. | Visit Forum |

| Video Tutorials | Step-by-step guides that visually demonstrate common repairs. | Watch Videos |

| Official Support | Direct assistance from the manufacturer’s customer service. | Contact Support |

| DIY Blogs | Informative articles written by experienced users with tips and tricks. | Read Blog |

Customer Reviews and Feedback

This section highlights the experiences and insights of users who have interacted with the product. Feedback from customers can provide valuable information regarding performance, durability, and ease of use, helping potential buyers make informed decisions.

Overall, users appreciate the reliability and functionality of the equipment. Here are some common themes found in customer comments:

- Many users have noted the ease of assembly, making it accessible for both novices and seasoned enthusiasts.

- Feedback often highlights the efficiency and effectiveness during operation, especially for various tasks.

- Several reviews commend the design, which combines practicality with a user-friendly interface.

However, some customers have expressed concerns regarding specific aspects:

- Issues with certain components wearing out over time have been mentioned, emphasizing the need for regular maintenance.

- A few users found the instructional materials lacking detail, suggesting that more comprehensive guidance would be beneficial.

- Some individuals reported challenges with customer service responsiveness when seeking assistance.

In summary, while the feedback is largely positive, it also reflects areas for improvement, ensuring that future enhancements can be made based on user experiences.