Comprehensive Guide to Repairing the Craftsman DLT 3000

When it comes to maintaining outdoor equipment, understanding the essential components and their functionalities is crucial. This section offers a comprehensive overview of techniques and strategies for ensuring optimal performance and longevity of your machinery.

Regular upkeep plays a significant role in preventing issues before they arise. By familiarizing yourself with common challenges and their solutions, you can enhance the efficiency of your equipment and minimize downtime.

In this guide, you will discover practical tips for diagnosing faults, conducting routine checks, and executing necessary adjustments. By empowering yourself with knowledge, you will be better equipped to handle potential complications and maintain your equipment in peak condition.

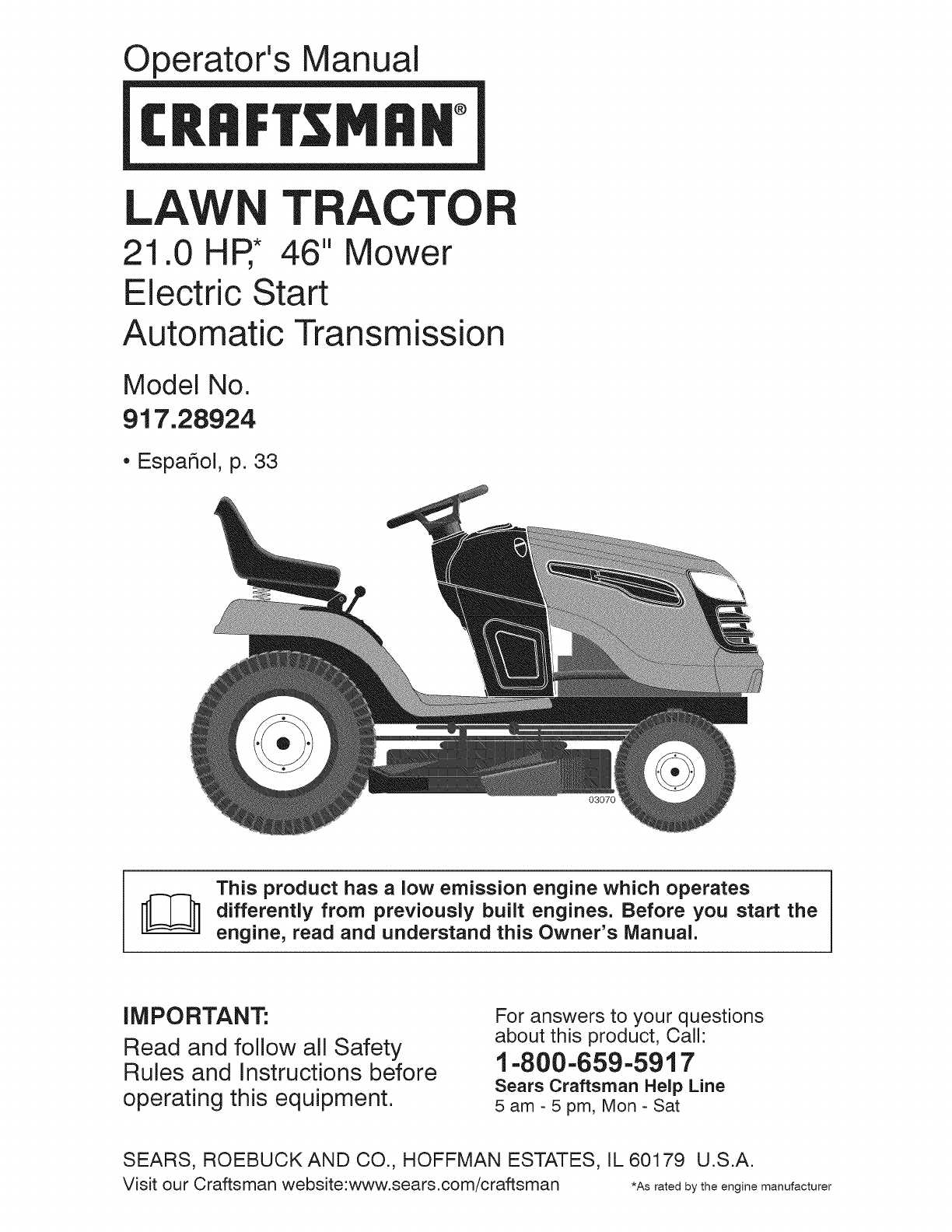

Understanding the Craftsman DLT 3000

This section aims to provide insights into a specific type of outdoor machinery designed for efficient lawn maintenance. With its advanced features and user-friendly design, this equipment has become a popular choice among enthusiasts and professionals alike.

Key Features

- Powerful engine for enhanced performance

- Ergonomic controls for ease of use

- Durable construction ensuring longevity

- Versatile attachments for various tasks

Maintenance Tips

- Regularly check and change the oil to ensure optimal engine performance.

- Inspect the blades for wear and replace as needed to maintain cutting efficiency.

- Keep the air filter clean to promote proper airflow.

- Store the unit in a dry place to prevent rust and corrosion.

Common Issues and Symptoms

Identifying frequent problems with machinery is crucial for effective maintenance and troubleshooting. This section outlines typical malfunctions and their associated indicators that users may encounter, enabling quicker diagnosis and resolution.

Engine Performance Problems

One of the most prevalent concerns involves difficulties with the engine’s functionality. Users may notice symptoms such as sputtering, difficulty starting, or unusual noises, which can indicate issues ranging from fuel delivery problems to ignition system failures.

Electrical System Failures

Another common area of concern is the electrical system. Signs of malfunction may include flickering lights, non-responsive controls, or complete power loss. These symptoms often point to wiring issues, battery problems, or faulty connections that require immediate attention.

Tools Required for Repairs

To effectively address maintenance tasks, it is essential to have a selection of appropriate instruments at hand. The right tools not only facilitate the process but also enhance precision, ensuring that each task is executed with care and efficiency. Having a well-equipped workspace can make all the difference when tackling various issues.

Essential Instruments

Key devices often include wrenches, screwdrivers, and pliers. These foundational tools provide the versatility needed for a wide range of tasks. It is advisable to have both metric and standard sizes available, as this allows for compatibility with various components.

Specialized Equipment

In addition to basic tools, certain specialized equipment may be beneficial. Diagnostic tools such as multimeters or pressure gauges can assist in identifying specific problems. Furthermore, having access to a sturdy workbench and adequate lighting can greatly improve the overall repair experience.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing and resolving common issues encountered during the operation of your equipment. By following these steps, you can efficiently identify problems and apply appropriate solutions, ensuring optimal performance.

| Step | Description | Possible Solutions |

|---|---|---|

| 1 | Check Power Supply | Ensure the device is connected to a working outlet and verify that the power switch is in the “on” position. |

| 2 | Inspect Connections | Examine all cables and connectors for damage or loose connections that may disrupt functionality. |

| 3 | Examine Indicators | Observe any warning lights or error codes displayed on the unit and consult the reference guide for specific meanings. |

| 4 | Assess Performance Issues | Note any unusual sounds or vibrations, and check for signs of overheating or malfunction. |

| 5 | Consult Documentation | Refer to the provided reference materials for detailed troubleshooting steps and diagrams tailored to specific concerns. |

Engine Maintenance and Care

Proper upkeep of the power source is essential for optimal performance and longevity. Regular attention to specific components can prevent issues and enhance efficiency. This section outlines crucial practices for maintaining the heart of your machinery.

Regular Inspection

Frequent assessments of the engine are vital. Check for any signs of wear, leaks, or unusual noises. Early detection can save time and resources in the long run.

Cleaning and Lubrication

Keeping the engine clean is necessary to avoid dirt accumulation, which can affect performance. Regular lubrication of moving parts ensures smooth operation and reduces friction.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect for leaks | Monthly | Check seals and gaskets |

| Change oil | Every 50 hours | Use recommended oil type |

| Clean air filter | Every 25 hours | Replace if damaged |

| Check spark plug | Every 100 hours | Replace if worn |

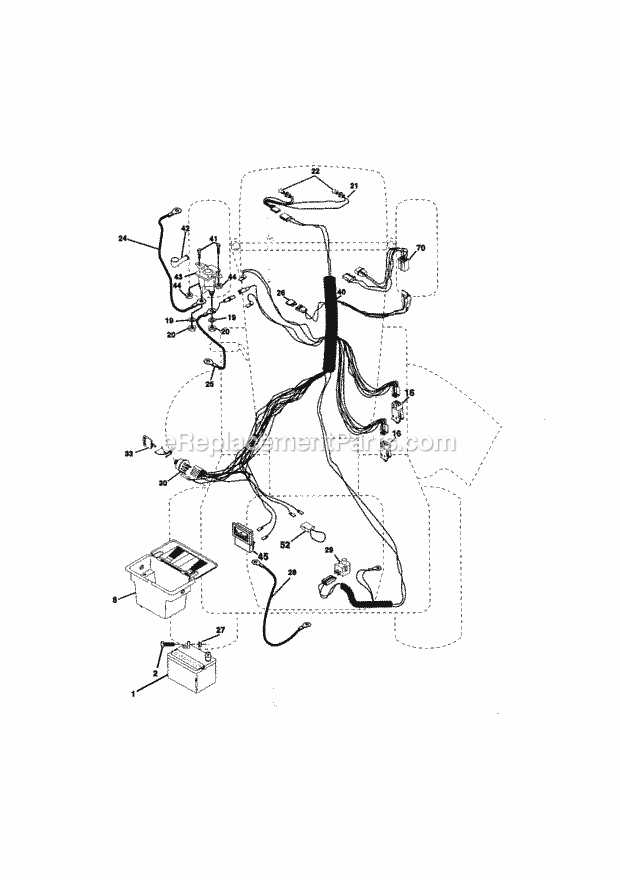

Electrical System Checks

Assessing the functionality of the electrical framework is essential for ensuring optimal performance and safety. This section outlines crucial procedures to verify the integrity of the connections and components within the system.

Visual Inspection

Begin with a thorough visual examination of all wiring and connectors. Look for signs of wear, corrosion, or damage that could impede proper operation. Ensure that all connections are secure and free from any obstructions.

Voltage Testing

Utilize a multimeter to measure voltage at key points in the system. This will help identify any inconsistencies or failures in power delivery. Regular testing can prevent future issues and enhance reliability.

Deck Adjustments and Maintenance

Proper alignment and upkeep of the cutting surface are essential for optimal performance and longevity of your equipment. Regular checks and adjustments help ensure an even cut and enhance the overall efficiency of the machine.

Importance of Deck Alignment

Maintaining correct alignment minimizes wear and tear on the blades and enhances the quality of the cut. Here are key steps to ensure proper alignment:

- Check the level of the deck using a flat surface.

- Adjust the height on each side to achieve a balanced position.

- Inspect for any debris that may affect the alignment.

Routine Maintenance Tasks

Regular maintenance tasks are crucial for the continued performance of the cutting apparatus. Consider the following practices:

- Clean the deck thoroughly after each use to prevent grass buildup.

- Sharpen blades regularly to maintain cutting efficiency.

- Inspect and replace any worn or damaged components promptly.

Following these guidelines will help prolong the life of your machinery and improve its cutting performance.

Transmission and Drive Components

This section delves into the essential elements responsible for power transfer and motion within the system. Understanding these components is crucial for maintaining optimal performance and efficiency.

The transmission plays a vital role in modulating the power generated by the engine, allowing for smooth acceleration and deceleration. It consists of various gears and shafts that work together to adjust torque and speed according to operational demands.

Equally important are the drive components, which include the belts, chains, and axles that connect the transmission to the wheels. These elements ensure that the generated power is effectively delivered, enabling movement and maneuverability.

Regular inspection of these parts is essential, as wear and tear can lead to performance issues. Maintaining proper alignment and tension in the drive components can prevent unnecessary strain, ultimately extending the lifespan of the entire system.

Blade Replacement and Sharpening

Ensuring optimal performance of cutting tools requires regular maintenance, particularly focusing on the replacement and honing of blades. This process not only enhances efficiency but also extends the lifespan of the equipment.

When it comes to changing the cutting edge, following proper procedures is crucial. Here’s a step-by-step guide:

- Gather the necessary tools, including a wrench, safety gloves, and a replacement blade.

- Disconnect the power source to prevent accidental activation.

- Remove any protective covers or guards as required.

- Loosen and detach the old blade using the wrench.

- Carefully install the new blade, ensuring it is securely fastened.

- Replace any guards and reconnect the power source.

Regular sharpening is equally important for maintaining cutting efficiency. Follow these tips for effective honing:

- Use a sharpening tool or stone specifically designed for the blade material.

- Maintain a consistent angle while sharpening for even results.

- Test the sharpness by making a few test cuts on scrap material.

- Clean the blade after sharpening to remove any debris or metal filings.

By adhering to these guidelines for blade replacement and sharpening, users can ensure their cutting equipment operates at peak performance, resulting in better outcomes for all tasks.

Fuel System Diagnostics

Effective evaluation of the fuel system is crucial for optimal engine performance. This process involves identifying issues related to fuel delivery, pressure regulation, and overall system integrity. A thorough assessment can help diagnose common problems, ensuring the unit operates efficiently.

Identifying Symptoms

Users may encounter various signs indicating fuel system malfunctions. Common symptoms include difficulty starting, irregular engine performance, or stalling. Recognizing these indicators is essential for timely troubleshooting.

Testing Procedures

Performing a series of diagnostic tests can reveal underlying issues. Start by checking the fuel pressure with a gauge to ensure it meets specifications. Next, inspect fuel lines for leaks and verify the integrity of connectors. Utilizing a fuel injector cleaner can also help in identifying clogging or blockage problems.

By following these guidelines, individuals can effectively diagnose and address fuel system issues, leading to improved performance and longevity of the engine.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent accidents and injuries. Adopting a careful approach not only protects the individual performing the work but also extends the lifespan of the equipment involved. Understanding and implementing appropriate safety measures is crucial for a successful and hazard-free experience.

Personal Protective Equipment

Utilizing proper personal protective gear is vital. This includes gloves to shield hands from sharp edges, safety goggles to protect eyes from debris, and sturdy footwear to prevent foot injuries. Always choose equipment that fits well and is designed for the specific task at hand.

Work Area Organization

Maintaining a clean and organized workspace is fundamental. Remove any unnecessary items that could pose tripping hazards. Ensure that tools and materials are easily accessible and stored correctly after use. This practice not only enhances safety but also improves efficiency during tasks.

Resources for Further Assistance

When seeking support for technical challenges, various avenues are available to enhance your understanding and resolve issues effectively. These resources can guide you through troubleshooting, provide insights, and connect you with experts in the field.

Online Forums: Engaging with online communities can be invaluable. Platforms dedicated to enthusiasts and professionals alike offer a wealth of shared knowledge. Users often discuss common problems, share solutions, and provide tips based on personal experiences.

Instructional Videos: Visual aids can simplify complex concepts. Numerous tutorial videos on platforms like YouTube cover a wide range of topics, demonstrating step-by-step procedures that can help clarify any uncertainties.

Manufacturer Support: Direct assistance from the original producer is a reliable option. Most manufacturers maintain customer service lines and dedicated websites where users can access FAQs, technical documents, and contact support representatives for personalized help.

Local Repair Shops: For hands-on assistance, consider reaching out to local professionals who specialize in similar products. Their expertise can provide practical solutions and personalized guidance tailored to specific needs.

Books and Guides: Comprehensive literature on related subjects can deepen your knowledge. Consider acquiring books that cover maintenance and troubleshooting techniques relevant to your equipment.