Comprehensive Guide to Craftsman Rototiller Repairs

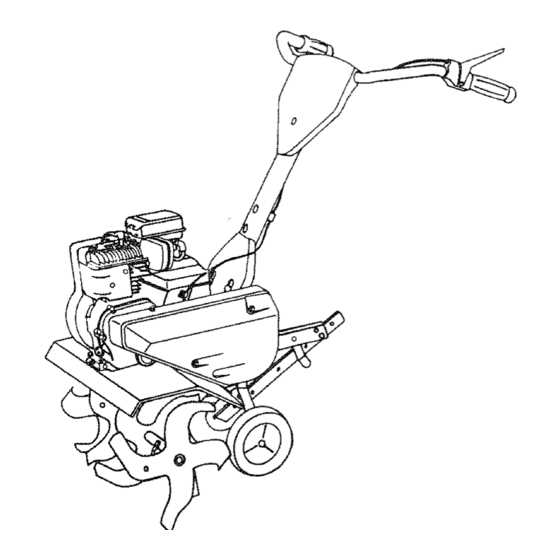

Understanding how to maintain and troubleshoot gardening equipment is essential for achieving optimal performance. This guide focuses on the intricacies of servicing these machines, ensuring they operate smoothly and efficiently. Regular attention to various components can significantly extend the lifespan of your equipment.

Throughout this section, you will discover valuable insights into identifying common issues, performing routine checks, and implementing effective solutions. Whether you are a novice or an experienced user, mastering these techniques will enhance your gardening experience and promote successful cultivation.

By prioritizing proper upkeep and addressing concerns promptly, you not only improve the functionality of your machinery but also contribute to the overall success of your gardening endeavors. Engaging with this information will empower you to take control of your tools and maximize their potential in your outdoor projects.

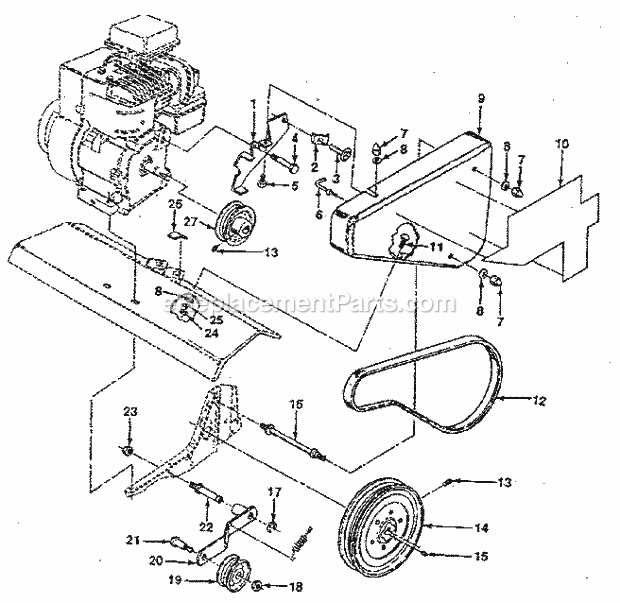

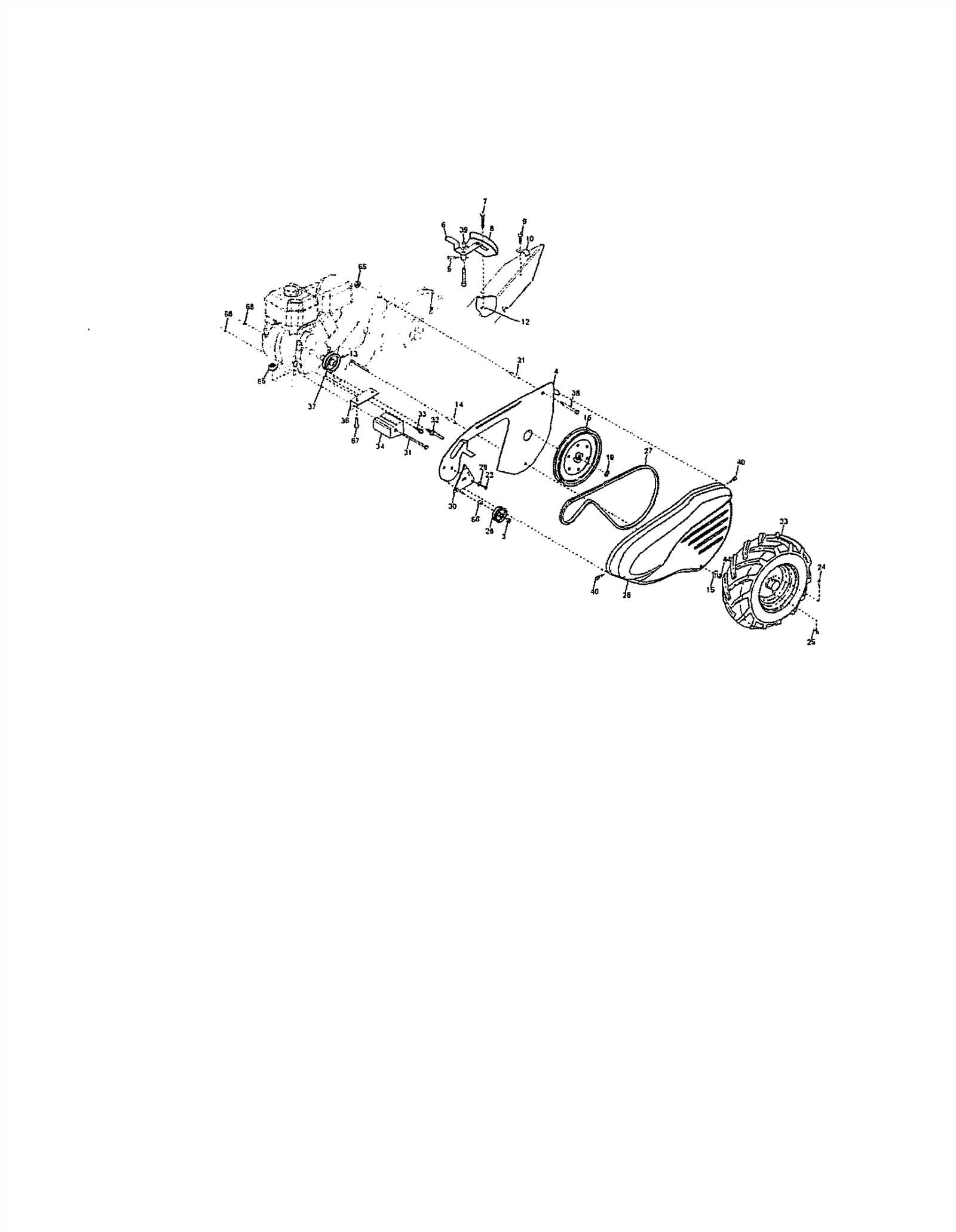

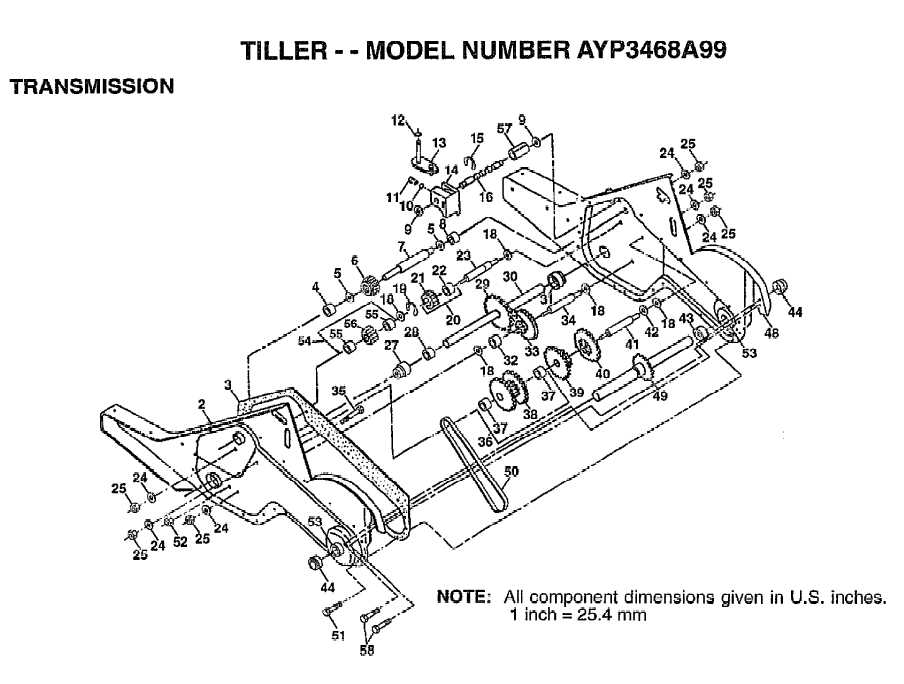

Understanding the various elements of your gardening machine is crucial for effective maintenance and troubleshooting. Each component plays a vital role in the overall functionality, influencing performance and efficiency during operation. By familiarizing yourself with these parts, you can ensure smoother usage and identify potential issues before they escalate.

Key Components Overview

The primary elements of your gardening device include the engine, transmission, tines, and handles. Each of these components serves a specific function, and understanding them can enhance your ability to address any problems that may arise.

Table of Components and Functions

| Component | Function |

|---|---|

| Engine | Powers the machine, enabling movement and operation of tines. |

| Transmission | Transfers power from the engine to the wheels and tines. |

| Tines | Breaks up soil, allowing for easier cultivation and aeration. |

| Handles | Provides control and maneuverability for the user during operation. |

Common Issues and Symptoms

Understanding the typical challenges and their corresponding indicators can significantly enhance troubleshooting efforts. Various mechanical devices may exhibit signs of wear or malfunction, impacting their overall performance. Recognizing these symptoms early on can lead to timely interventions and restore functionality.

One frequent issue is engine difficulty starting. This can manifest as unusual noises or prolonged cranking without ignition. Potential causes include fuel supply problems, electrical failures, or air filter blockages.

Another common symptom is inconsistent operation, where the device may run erratically or stall unexpectedly. This may be attributed to issues such as improper fuel mixtures, carburetor malfunctions, or ignition system faults.

Vibration and excessive noise are also indicators of underlying problems. These can arise from loose components, worn belts, or damaged blades. Addressing these concerns promptly can prevent further damage and ensure safe operation.

Lastly, poor tilling performance may suggest that the machinery is not engaging properly with the soil. This could be caused by blade dullness, incorrect depth settings, or soil conditions that exceed the equipment’s capacity. Identifying these factors early can enhance efficiency and achieve desired results.

Routine Maintenance Tips

Keeping your gardening equipment in optimal condition ensures efficient performance and extends its lifespan. Regular upkeep is essential for smooth operation and can help prevent unexpected breakdowns. Here are some key practices to follow.

Regular Inspection

Conduct periodic checks on the machine’s components to identify wear and tear. Look for any signs of damage, rust, or loose parts. Addressing these issues early can save time and resources in the long run.

Cleaning and Lubrication

After each use, clean the equipment thoroughly to remove dirt and debris. Additionally, apply appropriate lubricants to moving parts to reduce friction and ensure smooth functionality. This simple step can greatly enhance the overall performance of the machinery.

Tools Needed for Repairs

When it comes to maintaining and restoring garden machinery, having the right instruments is essential for efficient and effective work. Each task may require specific items, but there are fundamental tools that every enthusiast should keep on hand to facilitate repairs and ensure optimal performance of equipment.

Essential Hand Tools

Basic hand tools play a crucial role in the upkeep of garden equipment. A set of wrenches is vital for loosening and tightening various components, while screwdrivers are necessary for accessing intricate parts. Additionally, a pair of pliers can assist in gripping or twisting components securely, ensuring a thorough fix.

Power Tools for Efficiency

Incorporating power tools can significantly enhance the efficiency of maintenance tasks. A cordless drill is invaluable for quickly removing screws and bolts, while an angle grinder can be useful for cutting or grinding down parts that may need adjustment. Using these electric tools not only saves time but also reduces physical strain during the repair process.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues encountered with tilling equipment. By following a structured process, users can efficiently diagnose problems and implement solutions to restore optimal functionality.

Common Issues and Symptoms

- Engine fails to start

- Loss of power during operation

- Unusual noises or vibrations

- Inconsistent tilling depth

- Fuel leaks or blockages

Troubleshooting Steps

- Check fuel level and ensure it’s fresh and clean.

- Inspect the spark plug for wear and carbon buildup; replace if necessary.

- Examine air filters for dirt and debris; clean or replace as needed.

- Verify that all connections are secure and free of corrosion.

- Adjust throttle settings for optimal performance.

By methodically addressing each potential issue, users can effectively restore their equipment to peak condition, ensuring reliable operation for future tasks.

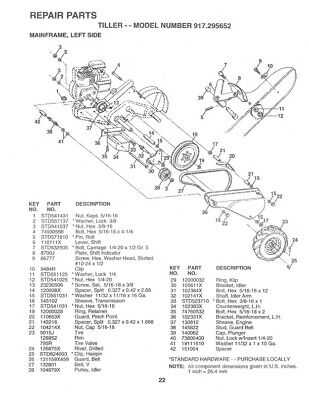

Replacing Worn-Out Parts

Maintaining the efficiency and performance of your gardening equipment often requires the timely substitution of outdated components. Recognizing when parts have degraded is crucial for ensuring optimal functionality and extending the lifespan of the machine.

Signs that a component may need replacing include:

- Unusual noises during operation

- Decreased performance or power

- Visible wear, such as cracks or deformation

- Increased vibrations

To effectively replace outdated components, follow these guidelines:

- Identify the worn-out part by performing a thorough inspection.

- Acquire high-quality replacements that match the specifications of your device.

- Utilize the necessary tools for disassembly, ensuring safety precautions are taken.

- Carefully install the new part, following the manufacturer’s recommendations.

- Test the equipment post-installation to verify proper operation.

Regularly monitoring and replacing worn components will not only enhance performance but also prevent potential failures, ensuring your gardening tasks are completed efficiently.

Safety Precautions While Repairing

Ensuring safety during maintenance tasks is essential to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks associated with handling equipment. It is crucial to familiarize oneself with safety measures before beginning any work.

Wear Appropriate Gear: Always use protective clothing, including gloves and safety goggles. This gear helps shield against potential hazards, such as sharp objects or flying debris.

Disconnect Power Sources: Before starting any servicing, ensure that all power sources are disconnected. This step prevents unintentional activation, which could lead to serious injuries.

Work in a Well-Ventilated Area: Proper ventilation is vital when working with machines that may emit harmful fumes. Ensure adequate airflow to minimize exposure to any toxic substances.

Keep Workspace Organized: An orderly work environment is essential for safety. Remove clutter and ensure that all tools are stored properly to avoid tripping hazards.

Follow Manufacturer Guidelines: Always refer to the provided guidelines for any specific safety instructions. Understanding the equipment’s design and functions will enhance overall safety during maintenance tasks.

Cleaning and Care Techniques

Maintaining your gardening equipment is essential for ensuring optimal performance and longevity. Proper cleaning and care not only enhance the efficiency of your tools but also prevent premature wear and tear, ultimately saving you time and money. Implementing a regular maintenance routine can significantly improve the functionality of your machinery.

Begin by thoroughly cleaning the exterior after each use. Remove any soil, grass clippings, and debris that may have accumulated during operation. A soft brush or cloth can effectively dislodge stubborn particles without damaging the surface. For more extensive clean-ups, a gentle wash with soapy water is advisable, followed by rinsing and drying to prevent rust formation.

Inspecting and maintaining moving parts is equally important. Regularly lubricate gears, bearings, and any other mechanisms that require it to ensure smooth operation. Check for wear on belts and chains, replacing them if necessary to avoid breakdowns. Additionally, keep an eye on the fuel system, ensuring that fuel lines are free from clogs and that filters are clean.

Finally, store your equipment in a dry, sheltered area to protect it from the elements. Using a cover can shield it from dust and moisture, further extending its lifespan. By adhering to these cleaning and care techniques, you can ensure your gardening tools remain reliable and effective for years to come.

Adjusting Engine Settings

Optimizing the engine’s performance is crucial for achieving efficient operation and prolonging the lifespan of your equipment. Proper adjustments can enhance power output, fuel efficiency, and overall functionality, ensuring that the machine operates smoothly under various conditions.

Understanding the Key Adjustments

Several key areas need attention when fine-tuning the engine settings:

- Idle Speed: This determines how smoothly the engine runs at low RPMs. A properly set idle speed prevents stalling and enhances responsiveness.

- Throttle Control: Adjusting the throttle affects acceleration and overall power delivery. Ensuring it operates within optimal ranges is essential.

- Mixture Ratio: The air-fuel mixture plays a significant role in combustion efficiency. Adjustments here can prevent issues like poor starting or excessive exhaust smoke.

Steps for Adjustment

To make the necessary adjustments, follow these steps:

- Start the engine and let it warm up to operating temperature.

- Locate the idle speed adjustment screw, usually found on the carburetor.

- Turn the screw clockwise to increase idle speed and counterclockwise to decrease it.

- Test the throttle response by accelerating and observing the performance.

- Adjust the mixture screw until the engine runs smoothly without sputtering.

Regularly checking and adjusting these settings will help maintain optimal performance and prevent future issues. Always consult the manufacturer’s guidelines for specific recommendations tailored to your equipment.

Enhancing Performance and Efficiency

Improving the functionality and productivity of gardening equipment is essential for achieving optimal results in landscaping and soil preparation. Various adjustments and maintenance practices can significantly elevate the machine’s capabilities, ensuring it operates at its best.

Regular Maintenance: Consistent upkeep is crucial for sustaining performance. Cleaning air filters, changing spark plugs, and ensuring the fuel system is free of contaminants are vital steps that can prevent potential issues and enhance reliability.

Adjusting Settings: Fine-tuning settings such as depth control and speed can lead to more effective operation. Understanding the specific requirements of different soil types allows users to modify their approach, resulting in better penetration and turnover.

Utilizing Quality Fuel: The type of fuel used can have a substantial impact on efficiency. Opting for high-quality fuel with appropriate octane ratings ensures smoother operation and can extend the life of the equipment.

Regular Inspection: Periodically examining the components for wear and tear helps identify any potential problems before they escalate. Addressing issues early on can prevent costly repairs and ensure uninterrupted functionality.

Resources for Further Assistance

For individuals seeking additional support and information related to equipment maintenance and troubleshooting, numerous resources are available. These tools can help enhance your understanding and skills, ensuring effective operation and longevity of your machinery.

Consider exploring various online platforms, community forums, and local workshops dedicated to machinery enthusiasts. These environments often provide valuable insights and practical advice from experienced users.

| Resource Type | Description | Example |

|---|---|---|

| Online Forums | Communities where users share tips, experiences, and solutions. | Reddit, GardenWeb |

| Video Tutorials | Visual guides on maintenance and common fixes. | YouTube, Vimeo |

| Local Workshops | Hands-on classes for practical learning and skill development. | Community colleges, garden centers |

| Manufacturer Websites | Official sites providing specifications and user guides. | Manufacturer’s homepage |