Cub Cadet Snow Blower Repair Guide

Effective upkeep of your winter machinery is essential for optimal performance during the colder months. This section provides valuable insights into the maintenance processes that will help extend the lifespan and functionality of your outdoor tools. By understanding the intricacies of these machines, users can ensure reliable operation when they need it most.

Whether you are dealing with mechanical issues or routine servicing, having access to comprehensive guidance is crucial. This resource offers detailed instructions on troubleshooting, adjusting, and fine-tuning your equipment. By familiarizing yourself with the various components and their functions, you can address challenges with confidence and skill.

Moreover, embracing a proactive approach to equipment maintenance not only enhances performance but also promotes safety during operation. Implementing recommended practices will allow you to tackle winter conditions effectively, ensuring your machinery is always ready for action. Explore the forthcoming sections for in-depth information and practical advice on keeping your winter tools in top shape.

Essential Tools for Maintenance

Maintaining your equipment requires the right set of instruments to ensure its optimal performance and longevity. By using appropriate tools, you can effectively carry out necessary tasks, troubleshoot issues, and keep your machinery in excellent condition. Below is a list of vital tools that every owner should have for regular upkeep.

Basic Hand Tools

- Screwdrivers: A set of various sizes and types, including flathead and Phillips, is essential for loosening and tightening screws.

- Wrenches: Adjustable and socket wrenches allow for easy manipulation of nuts and bolts.

- Pliers: Useful for gripping, twisting, and cutting wire or other materials.

- Hammer: A reliable tool for driving nails and making adjustments.

Specialized Equipment

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Oil Can: Essential for lubricating moving parts to prevent wear and tear.

- Grease Gun: Used for applying grease to bearings and other components.

- Diagnostic Tools: Digital multimeters and gauges help identify electrical issues and performance metrics.

Having these essential instruments at your disposal will enable you to perform maintenance tasks efficiently and effectively, ultimately enhancing the reliability of your equipment.

Common Issues with Snow Blowers

Winter equipment is essential for maintaining pathways and driveways during the colder months. However, various problems can arise with these machines, hindering their effectiveness. Identifying and addressing these concerns promptly can save time and effort, ensuring smooth operation.

Frequent Problems

- Engine Fails to Start

- Uneven or Insufficient Discharge

- Stalling During Operation

- Difficulty in Maneuvering

- Excessive Vibration and Noise

Troubleshooting Steps

- Check fuel levels and quality.

- Inspect the ignition system and spark plug.

- Examine the auger and impeller for blockages.

- Ensure all belts are tight and in good condition.

- Look for loose bolts and connections.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues that may arise during the operation of your equipment. By following a structured process, you can identify and resolve common problems effectively, ensuring optimal performance.

1. Check the Power Source: Begin by verifying that the unit is connected to a reliable power source. Inspect the power cord for any signs of damage or wear. Ensure that the outlet is functioning correctly by testing it with another device.

2. Inspect the Fuel System: Examine the fuel tank for adequate levels of fuel. If the fuel is stale or contaminated, replace it with fresh fuel. Additionally, check the fuel lines for blockages or leaks that may impede flow.

3. Examine the Controls: Ensure that all controls are functioning as intended. Look for any stuck or broken levers and confirm that the settings are appropriate for the task at hand. Adjustments may be necessary if the controls are misaligned.

4. Review the Belts and Cables: Inspect the belts and cables for wear, fraying, or breaks. Proper tension is crucial for optimal operation. Replace any damaged components to prevent further issues.

5. Clean and Clear the Mechanism: Accumulated debris can hinder performance. Remove any blockages from the housing and moving parts. Cleaning should be done carefully to avoid damaging sensitive components.

6. Test the Operation: After performing the checks and maintenance, test the unit to see if the issues have been resolved. If problems persist, consider seeking professional assistance for more complex troubleshooting.

Following these steps will enhance your understanding of the equipment and facilitate effective problem-solving, promoting longevity and reliability.

How to Change Spark Plugs

Replacing ignition components is essential for maintaining optimal engine performance. This task ensures that the engine runs smoothly and efficiently, preventing potential starting issues and enhancing fuel economy. This guide will walk you through the steps to effectively change these crucial components.

Tools and Materials Needed

Before starting, gather the following tools and materials:

| Item | Description |

|---|---|

| Socket wrench | A tool for loosening and tightening nuts and bolts. |

| Spark plug socket | A specialized socket designed to fit over spark plugs. |

| Replacement spark plugs | New ignition components compatible with your engine. |

| Torque wrench | A tool for applying a specific torque to fasteners. |

| Dielectric grease | Lubricant used to protect electrical connections. |

Steps to Replace Ignition Components

Follow these steps to change the ignition components:

- Ensure the engine is turned off and completely cool.

- Remove the engine cover, if applicable, to access the ignition components.

- Use the socket wrench and spark plug socket to carefully unscrew the old component.

- Inspect the removed part for wear or damage.

- Install the new component, applying dielectric grease to the threads if desired.

- Tighten the new component using a torque wrench to the manufacturer’s specified torque setting.

- Reattach the engine cover and ensure all tools are removed from the area.

Winter Preparation and Care Tips

As the colder months approach, ensuring that your outdoor equipment is ready for the challenges ahead is crucial. Proper maintenance and preparation can enhance performance and prolong the lifespan of your machinery. This section outlines essential strategies to help you effectively prepare for winter, ensuring that everything operates smoothly when the need arises.

Essential Maintenance Steps

Begin by thoroughly inspecting your equipment for any signs of wear or damage. Check the fuel system, ensuring that it is clean and free from contaminants. Replace any worn-out parts, and consider changing the oil to ensure optimal functioning. Additionally, sharpen blades and ensure all moving parts are lubricated to minimize friction and enhance efficiency.

Storing Equipment Properly

When the season is over, proper storage is key to maintaining your tools in good condition. Clean the equipment to remove any debris, dirt, or moisture that could lead to rust or corrosion. Store in a dry, sheltered area, and consider using a protective cover to prevent dust accumulation. This proactive approach will ensure your machinery is ready to go when winter returns.

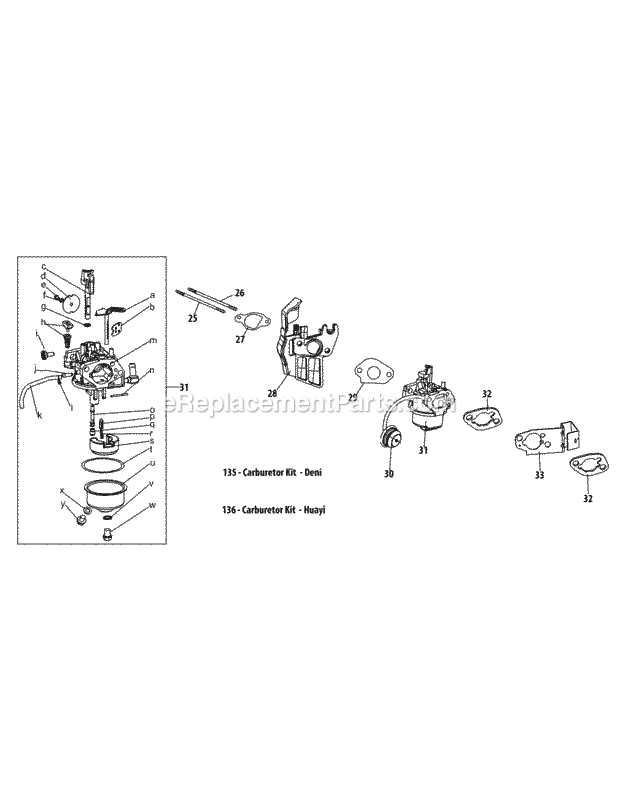

Fuel System Maintenance Procedures

Proper upkeep of the fuel system is essential for ensuring optimal performance and longevity of the equipment. Regular checks and maintenance activities help prevent issues related to fuel delivery, enhancing the efficiency and reliability of the machine during operation.

Below are the key steps involved in maintaining the fuel system:

| Procedure | Description | Frequency |

|---|---|---|

| Inspect Fuel Lines | Check for cracks, leaks, or wear in fuel lines to ensure secure fuel delivery. | Every season |

| Clean Fuel Filter | Remove and clean the fuel filter to prevent blockages and ensure smooth fuel flow. | Every 25 hours of use |

| Check Fuel Quality | Examine the fuel for any signs of contamination or degradation. | Before each use |

| Replace Fuel Filter | Replace the fuel filter if it appears dirty or clogged to maintain optimal performance. | Annually |

| Drain Old Fuel | Remove any old fuel that may have been sitting in the tank for an extended period. | At the end of the season |

Adhering to these maintenance procedures will significantly enhance the performance and reliability of the equipment, ensuring a smooth operation throughout its lifespan.

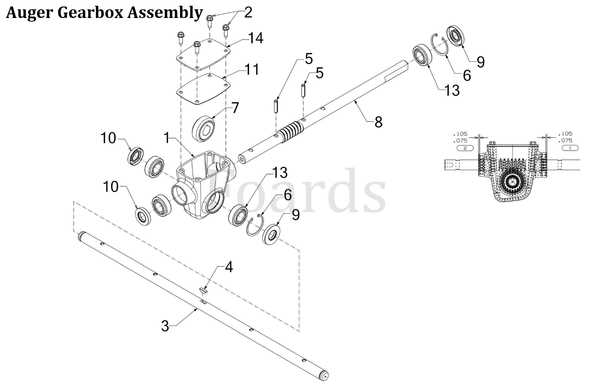

Understanding Drive System Components

The drive system of outdoor equipment plays a crucial role in ensuring efficient operation and maneuverability. By grasping the various elements involved in this mechanism, users can enhance their understanding of functionality and potential troubleshooting techniques. Key components work in harmony to transfer power from the engine to the wheels, allowing for seamless movement across different terrains.

In this section, we will delve into the essential components that comprise the drive system, focusing on their functions and interconnections. Recognizing the significance of each part will aid in better maintenance and optimal performance.

| Component | Description | Function |

|---|---|---|

| Transmission | A mechanism that regulates power from the engine to the wheels. | Allows the operator to adjust speed and torque as needed. |

| Drive Belt | A flexible loop that transmits power from the engine to the transmission. | Ensures smooth power transfer and helps in speed adjustments. |

| Wheels | The circular components that facilitate movement over surfaces. | Provide traction and support the weight of the equipment. |

| Axles | Bars that connect the wheels to the transmission. | Help in distributing power evenly to the wheels. |

| Gear Assembly | A set of gears that alter the speed and direction of movement. | Enhances control and performance in varying conditions. |

Clearing Blockages Safely

Effective removal of obstructions is crucial for maintaining optimal performance in equipment designed for handling winter conditions. Ensuring that these devices function smoothly requires a careful approach to address any interruptions that may arise during operation.

Safety should be your top priority when tackling any form of blockage. Before proceeding, always disconnect the power source to avoid accidental activation. This precaution will help protect both the user and the machinery.

When facing a blockage, never use your hands to remove debris directly. Instead, utilize appropriate tools such as a wooden stick or a similar item designed for this purpose. This method minimizes the risk of injury and keeps fingers away from moving parts.

After clearing the obstruction, conduct a thorough inspection of the equipment to ensure no residual materials are left behind. Regular maintenance and awareness of potential blockages can greatly enhance the longevity and reliability of your machine.

Replacing Worn Blades Effectively

Maintaining optimal performance is crucial for any outdoor equipment. One common issue that arises over time is the wear of the cutting components. Addressing this problem promptly ensures efficiency and prolongs the lifespan of your machinery. This section provides a comprehensive guide to effectively replacing these critical elements.

Before starting the replacement process, consider the following steps:

- Gather Necessary Tools: Ensure you have the right tools on hand, including wrenches, a socket set, and safety gear.

- Power Off the Equipment: Always disconnect the power source to prevent accidental starts.

- Inspect the Blades: Check for signs of wear and tear, such as chips, cracks, or bending.

Once you are prepared, follow these instructions to replace the blades:

- Remove the Old Blades: Use appropriate tools to detach the worn blades from their housing carefully.

- Clean the Area: Remove any debris or buildup from the mounting area to ensure a proper fit for the new components.

- Install New Blades: Align the new blades with the mounting holes and secure them tightly.

- Test the Installation: Reconnect the power and conduct a test run to ensure everything operates smoothly.

Regular maintenance of the cutting elements not only enhances performance but also contributes to the overall safety and reliability of your machinery. Make it a routine to check for wear periodically, and address any issues immediately to keep your equipment functioning at its best.

Adjusting Belt Tension for Efficiency

Maintaining the proper tension on the drive components is essential for optimal performance and longevity of the equipment. When the tension is correctly set, it ensures efficient power transfer, reduces wear on parts, and enhances overall functionality. This section will guide you through the process of fine-tuning the belt tension to achieve the best results.

Importance of Proper Tension

Correct tension is vital for several reasons:

- Prevents slippage, which can lead to power loss.

- Minimizes wear and tear on belts and pulleys.

- Enhances efficiency and responsiveness of the unit.

Steps to Adjust Tension

- Gather necessary tools, including a wrench and a tension gauge.

- Locate the tension adjustment mechanism, typically found near the drive assembly.

- Loosen the bolts securing the belt guide.

- Use the tension gauge to check the current tension; compare it to the manufacturer’s specifications.

- If adjustment is needed, tighten or loosen the tensioning mechanism accordingly.

- Once adjusted, recheck the tension to ensure it meets the specified level.

- Tighten the bolts to secure the guide in place.

By following these steps, you will ensure that the drive components operate efficiently, leading to improved performance and reduced maintenance needs.

Regular Inspection and Maintenance Checklist

To ensure optimal performance and longevity of your equipment, it’s essential to adhere to a systematic approach to checking and maintaining its various components. This routine not only enhances functionality but also prevents potential issues that may arise during operation.

| Task | Frequency | Notes |

|---|---|---|

| Check oil levels | Before each use | Ensure the engine has sufficient lubrication. |

| Inspect fuel system | Monthly | Look for leaks or blockages in the fuel lines. |

| Examine belts and cables | Every season | Replace any worn or damaged components. |

| Clean air filter | Monthly | A clogged filter can affect engine performance. |

| Check spark plug | Every 50 hours of operation | Replace if worn or fouled. |

| Inspect housing and components | After each use | Look for debris and clean as necessary. |