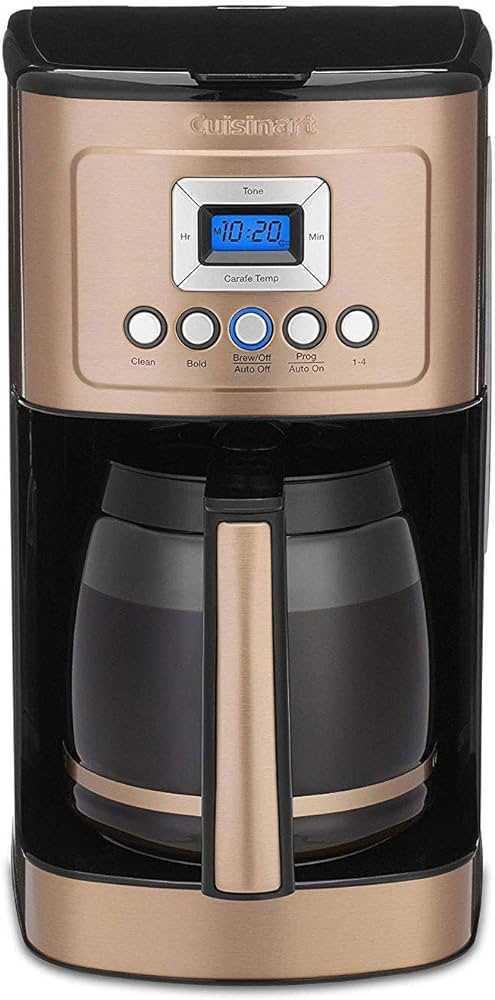

Comprehensive Guide to Fixing the Cuisinart SS 700

Over time, even the most reliable brewing devices may encounter issues that can affect their performance. Addressing these challenges with the right approach can enhance the longevity and efficiency of your coffee maker. This guide provides a clear and practical roadmap to ensure your machine continues delivering the perfect cup every day.

Understanding the core components and mechanisms of your coffee system is key to diagnosing any functionality issues. From tackling common blockages to maintaining optimal water flow, this manual walks you through various processes step by step. By following these insights, you’ll be able to handle potential malfunctions confidently and keep your equipment in top condition.

Whether you’re noticing changes in taste, temperature, or overall operation, this resource covers essential techniques to troubleshoot effectively. With a focus on maintenance and performance, you’ll find tips and recommendations designed to address frequent problems while improving the durability and reliability of your brewing experience.

Cuisinart SS-700 Repair Guide

In this section, we’ll explore effective ways to troubleshoot and maintain your brewing device, ensuring it continues to function efficiently. Whether facing minor issues or more complex functionality concerns, simple maintenance can often restore optimal performance and extend the device’s lifespan.

Common Malfunctions and Solutions

Many users encounter occasional problems, such as unexpected shutdowns or issues with brewing cycles. To address these, start by checking connections and ensuring that components are clean and well-fitted. Regularly cleaning internal parts can prevent clogging and improve overall flow. For more persistent concerns, resetting the machine or adjusting certain settings may resolve the issue.

Tips for Prolonged Use

To keep your machine in top shape, routine upkeep is essential. Monthly descaling, for instance, can prevent mineral buildup that affects water flow. Additionally, avoid overfilling water reservoirs to ensure steady operation and reduce wear on parts. By incorporating these practices, you help maintain a reliable brew experience over time.

Identifying Common Issues with SS-700

Understanding the usual challenges that can arise with your brewing machine helps in maintaining its efficiency and longevity. By recognizing frequent malfunctions, users can take simple steps to keep their machine performing optimally and troubleshoot minor issues at home.

Power and Startup Difficulties

- Machine Fails to Turn On: Check the power source to ensure it’s securely connected. A loose plug or a faulty outlet may be causing the issue.

- Unresponsive Controls: If buttons do not respond, resetting the system may solve the problem. Some models have a reset feature accessible through the main menu.

- Startup Delays: In cases where the machine takes longer to start, a buildup of internal residue may be the cause, requiring a thorough cleaning.

Performance and Brewing Issues

- Inconsistent Brew Temperature: If beverages seem cooler than expected, descaling the unit could help regulate the temperature.

- Weak or Diluted Drinks: This issue can occur when the brewing settings are improperly adjusted or if the water reservoir is not seated correctly.

- Water Leakage: Leakage might be due to an improperly sealed water tank or buildup at the connections. Regular cleaning of seals and connections can prevent this.

Addressing these common issues promptly not only improves the functionality of your machine but also extends its lifespan. Regular maintenance and minor adjustments can significantly enhance your brewing experience.

Step-by-Step Disassembly Process

In this section, we will go through the detailed steps to carefully take apart your brewing device, allowing you to access and address internal components that may require cleaning or replacement. This guide provides clear instructions to ensure that each part is handled properly to avoid any damage during the process.

| Step | Action | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Unplug the device and ensure it is fully cool. Safety precautions are essential to avoid any potential hazards. | ||||||||||||

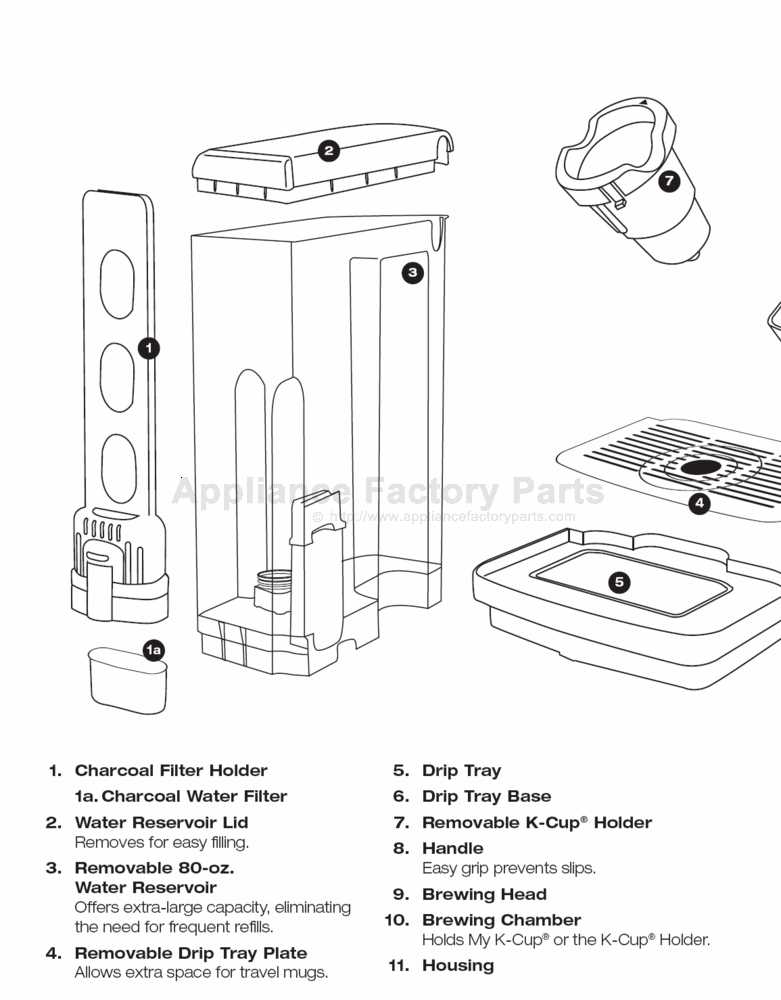

| 2 | Remove the water reservoir and lid. Set these aside for thorough cleaning or inspection. | ||||||||||||

| 3 | Detach the drip tray and any removable holders for pods or filters. Clean these separately for best results. | ||||||||||||

| 4 | Carefully access the internal screws located under the main casing. Use a compatible screwdriver to prevent stripping the screws. | ||||||||||||

| 5 | Once screws are removed, gently separate the outer housing,

Essential Tools for Effective RepairsHaving the right equipment is crucial for completing any restoration task smoothly and efficiently. Proper tools not only make the job easier but also help ensure a successful outcome by minimizing risks of further issues. Basic Toolkit EssentialsStarting with a fundamental toolkit allows for handling a variety of adjustments and fixes. Below are key items recommended for general tasks:

Advanced Tools for Detailed WorkFor more precise adjustments, having specialized equipment can make a noticeable difference. Consider adding the following tools for detailed handling:

Equipping yourself with these essentials can streamline the process and enhance results, providing confidence for tackling various projects with ease. How to Fix Water Leakage ProblemsWater leakage can be a common issue that affects coffee machines over time, often caused by wear on internal seals or blockages in water lines. Recognizing the primary sources of these leaks can make troubleshooting simpler and help extend the life of the machine. Identify the Source of the LeakBegin by examining the water reservoir and connections. Ensure all parts are securely positioned and check for any visible cracks. Sometimes, loose fittings or small cracks in the reservoir can cause gradual leakage. Another common area for inspection is the water intake valve, where improper alignment or debris can disrupt the seal, leading to leaks. Clean and Check the Internal ComponentsIf no external cause is apparent, it may be necessary to inspect internal components. Sediment build-up within water lines or near heating elements can cause pressure irregularities, often resulting in leaks. To prevent this, regularly clean these areas and inspect for signs of wear. For minor issues, replacing seals or cleaning internal parts can often restore the machine’s proper function. Understanding the Heating Element System

The heating element system plays a crucial role in the operation of coffee machines, ensuring that water reaches the optimal temperature for brewing. This component is responsible for generating and maintaining heat, which is vital for achieving the desired flavor and strength of the beverage. A thorough understanding of how this system functions can help in troubleshooting and maintaining the appliance effectively. Heating elements typically operate through electrical resistance, converting electrical energy into heat. This process can be impacted by various factors, including mineral buildup, wear over time, and electrical issues. Recognizing the signs of malfunction, such as inconsistent brewing temperatures or slow heating, can aid users in addressing problems before they escalate.

Regular maintenance of the heating element system not only extends the lifespan of the appliance but also enhances the quality of brewed beverages. By following proper care guidelines and being aware of potential issues, users can enjoy consistent performance from their coffee-making equipment. Replacing the Pump for Optimal PerformanceMaintaining the efficiency of your appliance is crucial for ensuring a seamless experience. One of the vital components that may require attention over time is the pump. When it begins to show signs of wear, replacing it can restore functionality and enhance overall performance. Here are some indicators that suggest a pump replacement may be necessary:

To successfully replace the pump, follow these steps:

After the replacement, run a test cycle to confirm that the pump operates correctly. Regular maintenance and timely replacements will help keep your appliance functioning at its best. Repairing Control Panel MalfunctionsThe control panel is a crucial component of any kitchen appliance, enabling users to operate various functions seamlessly. When issues arise with the control interface, it can hinder the overall performance and usability of the device. Understanding the common problems and their solutions can help restore functionality and enhance the user experience. Common Issues with the Control Interface

Troubleshooting Steps

Cleaning and Maintenance Tips for LongevityRegular upkeep and proper care are essential for ensuring the durability and optimal performance of your kitchen appliance. By following a few straightforward practices, you can extend its lifespan and maintain its efficiency, making your cooking experience more enjoyable. Here are some effective cleaning strategies:

In addition to cleaning, consider these maintenance tips:

By incorporating these practices into your routine, you can significantly enhance the longevity and performance of your kitchen appliance. Troubleshooting Power Supply FailuresPower supply issues can be a common concern for many appliances. Identifying and resolving these problems is essential to ensure optimal performance and longevity. This section provides guidance on how to address power-related complications effectively. Identifying Symptoms of Power IssuesBegin by observing the signs that indicate a potential power failure. Common symptoms may include the appliance not turning on, unusual noises, or intermittent operation. Paying attention to these indicators can help in diagnosing the underlying issue more accurately. Steps for Resolution

To address power supply failures, follow these steps:

By following these troubleshooting steps, users can effectively address and resolve power supply issues, ensuring their appliance functions smoothly. Restoring Proper Brew TemperatureMaintaining the optimal temperature during the brewing process is essential for achieving a rich and flavorful cup of coffee. If the beverage isn’t reaching the desired heat level, it can negatively impact the extraction of flavors and aromas. This section will guide you through steps to restore the correct brewing temperature in your machine. First, ensure that the appliance is clean and free of any buildup, which can affect its performance. Regular descaling is vital, as mineral deposits can hinder the heating elements. Utilize a suitable descaling solution to eliminate any obstructions and restore efficient operation. Next, check the water reservoir for proper filling. Insufficient water levels can lead to inadequate heating. Ensure that the tank is filled according to the manufacturer’s specifications for optimal performance. Additionally, allow the unit to preheat sufficiently before brewing, as this helps achieve the correct temperature. If issues persist, consider testing the appliance with a thermometer to measure the actual brew temperature. This can help identify if the machine is operating within the desired range. Should you discover significant discrepancies, further troubleshooting or consultation with a professional may be necessary to ensure the device functions as intended. Reassembling Your SS-700 After Repair

After addressing issues with your coffee brewing machine, putting it back together correctly is crucial for its functionality. This section will guide you through the reassembly process, ensuring each component is in its rightful place to restore optimal performance. Begin by organizing all the parts you removed during the disassembly. This will help you keep track of everything and prevent missing any essential components. It’s beneficial to refer to any notes or images taken during the earlier stages, as they can serve as a valuable reference. Next, start by positioning the base of the unit on a stable surface. Carefully place the water reservoir back onto the base, ensuring that it fits securely. Follow this by reattaching the brewing assembly. Make sure all connections are aligned properly to avoid leaks or malfunctions. Once the main components are reconnected, proceed to secure any screws or fasteners you initially removed. Tightening them adequately will ensure the integrity of the assembly. Be cautious not to overtighten, as this could damage the parts. Finally, conduct a thorough inspection of the unit. Check for any loose parts or misalignments. Once satisfied, plug the machine in and perform a test run without coffee to confirm that everything operates smoothly. This careful approach will help prolong the lifespan of your device and enhance your brewing experience. |