Comprehensive Guide to Cummins 855 Repair Manual

Ensuring the longevity and efficiency of your heavy machinery requires a comprehensive understanding of its intricate systems. This guide aims to provide vital insights and practical steps for troubleshooting and upkeep, catering to both seasoned professionals and newcomers in the field. With a focus on enhancing performance and reducing downtime, this resource is an invaluable companion for anyone working with large diesel engines.

By delving into the nuances of engine operation, users can identify common issues and apply effective solutions. This text covers a range of topics, from routine inspections to more complex adjustments, equipping readers with the knowledge to maintain optimal functionality. Whether you are looking to extend the life of your equipment or simply seeking to improve your skills, this guide serves as a trusted reference.

Furthermore, it emphasizes the importance of following systematic procedures and utilizing appropriate tools for each task. Clarity in communication and detailed explanations will assist in understanding various components and their roles within the engine. Engaging with this material will foster a deeper appreciation for mechanical systems and empower users to tackle challenges with confidence.

Understanding the Cummins 855 Engine

This section explores the intricacies of a powerful engine renowned for its durability and efficiency in heavy-duty applications. It combines advanced engineering with robust components, making it a preferred choice for various industrial uses.

The design of this engine focuses on optimal performance and reliability, featuring a strong block and high-quality materials. Its configuration allows for easy maintenance and operation, which is essential for users seeking longevity in demanding environments.

Moreover, the engine’s versatility makes it suitable for multiple vehicles, ranging from trucks to construction equipment. Understanding its mechanics and specifications is crucial for maximizing its potential and ensuring smooth functionality in the field.

Overall, a comprehensive grasp of this engine’s features can lead to improved operational efficiency and reduced downtime, underscoring its significance in the industry.

Key Specifications of the Cummins 855

This section outlines the essential characteristics of a notable engine model, providing crucial information for understanding its performance and operational capabilities. The data presented here will aid technicians and enthusiasts alike in grasping the fundamentals that define this powerful unit.

Engine Configuration

The engine features a robust inline design with six cylinders, ensuring smooth operation and enhanced torque delivery. This configuration is optimized for heavy-duty applications, making it a preferred choice for various industrial uses.

Performance Metrics

With a displacement of approximately 14 liters, this powerhouse generates impressive horsepower, reaching up to 400 HP, along with a significant torque output that enhances its usability in demanding conditions. The combination of these metrics results in excellent performance across a range of tasks.

Key specifications:

- Number of cylinders: 6

- Displacement: 14 liters

- Maximum horsepower: 400 HP

- Torque: High torque for optimal performance

Common Issues with the Cummins 855

Engines of this type are known for their reliability and power, yet they can encounter various challenges over time. Understanding these common issues is crucial for maintaining optimal performance and longevity. Below are some typical problems owners may face and how they can be addressed.

Typical Problems

- Overheating: This issue often stems from inadequate coolant flow, blocked radiators, or faulty thermostats.

- Oil Leaks: Seals and gaskets can wear out, leading to leaks that affect performance and environmental safety.

- Fuel System Troubles: Clogged filters or failing injectors can lead to poor fuel delivery and engine performance.

- Electrical Failures: Wiring issues or sensor malfunctions may result in erratic engine behavior.

Preventive Measures

- Regularly check and replace coolant to prevent overheating.

- Inspect seals and gaskets for wear, replacing them as needed.

- Maintain clean fuel filters and inspect injectors periodically.

- Conduct routine electrical system checks to catch issues early.

Addressing these common concerns proactively can significantly enhance the engine’s reliability and efficiency, ensuring smooth operation for years to come.

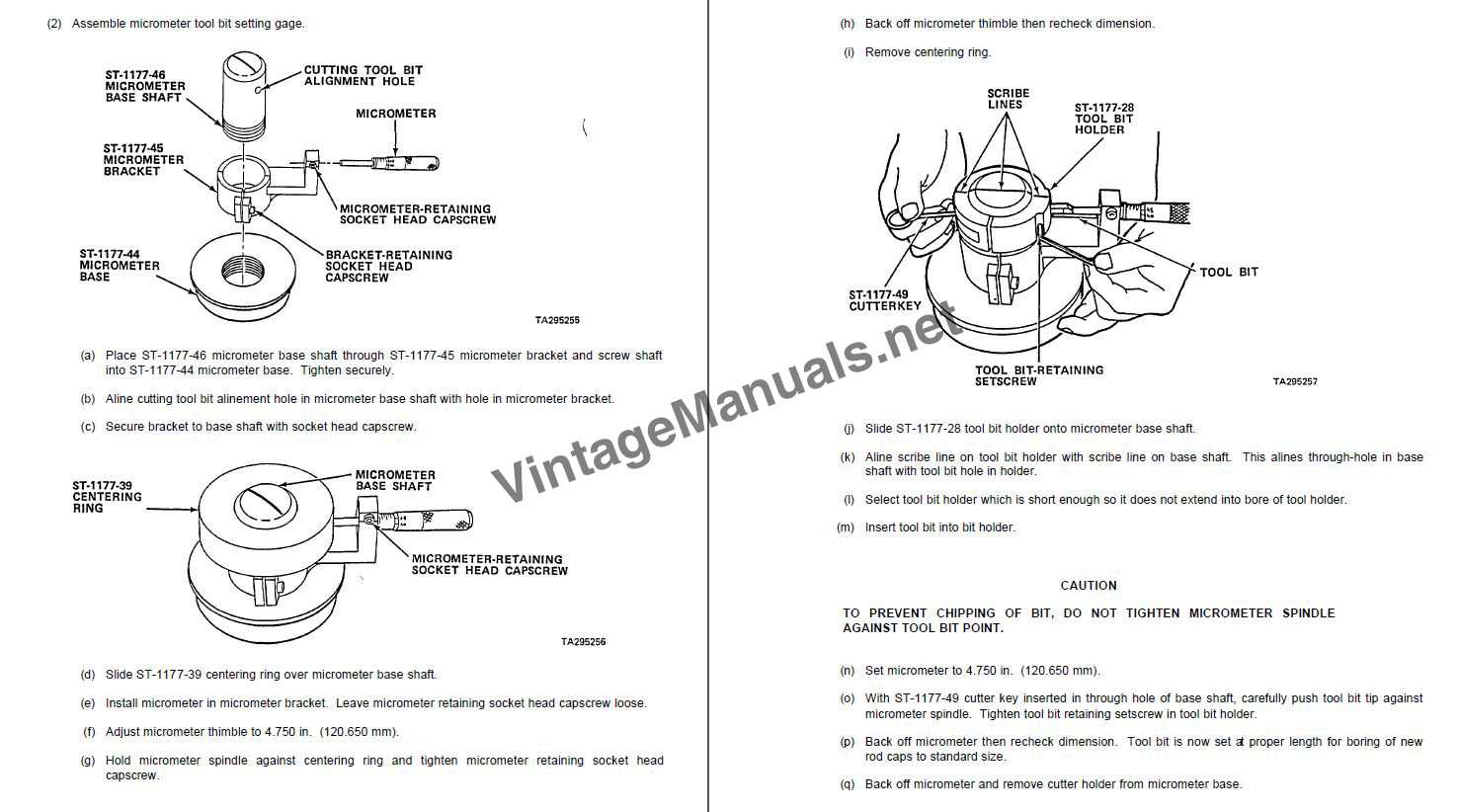

Tools Needed for Repair Tasks

When undertaking maintenance or troubleshooting procedures, having the right equipment is essential for achieving optimal results. The following section outlines various implements that are fundamental for effective servicing, ensuring both efficiency and safety throughout the process.

Essential Hand Tools

A well-equipped toolkit is the backbone of any service task. Common items include wrenches, screwdrivers, and pliers, each serving specific functions that facilitate disassembly and assembly. Socket sets are also crucial, as they provide the versatility needed for various fasteners. Additionally, torque wrenches are indispensable for applying the correct force to bolts, preventing damage or failure.

Specialized Equipment

In some instances, specialized gear may be required to address specific issues. For instance, compression testers help assess engine performance, while oil pressure gauges are vital for monitoring lubrication systems. Diagnostic scanners can also prove invaluable, allowing for the identification of electronic faults that might not be immediately visible. Ensuring that you have access to these tools will enhance your capability to perform comprehensive evaluations and repairs.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing issues related to heavy-duty engines. By following a structured process, one can effectively diagnose problems, perform maintenance tasks, and ensure optimal performance. Each step is designed to guide you through essential procedures, from initial inspection to final adjustments.

| Step | Description |

|---|---|

| 1 | Begin with a thorough visual inspection of the engine components for any signs of wear or damage. |

| 2 | Check fluid levels, including oil, coolant, and fuel, to ensure they are within recommended ranges. |

| 3 | Utilize diagnostic tools to read error codes and assess performance metrics. |

| 4 | Remove any obstructing parts to gain access to the areas needing attention. |

| 5 | Replace worn or faulty components based on your findings from previous steps. |

| 6 | Reassemble the engine, ensuring all parts are securely fastened and aligned correctly. |

| 7 | Conduct a final inspection, then start the engine to verify proper operation. |

Maintenance Tips for Longevity

Ensuring the extended lifespan of heavy machinery requires consistent attention to its upkeep. Proper care not only enhances performance but also prevents costly breakdowns. By following a few essential practices, operators can maximize efficiency and reliability over time.

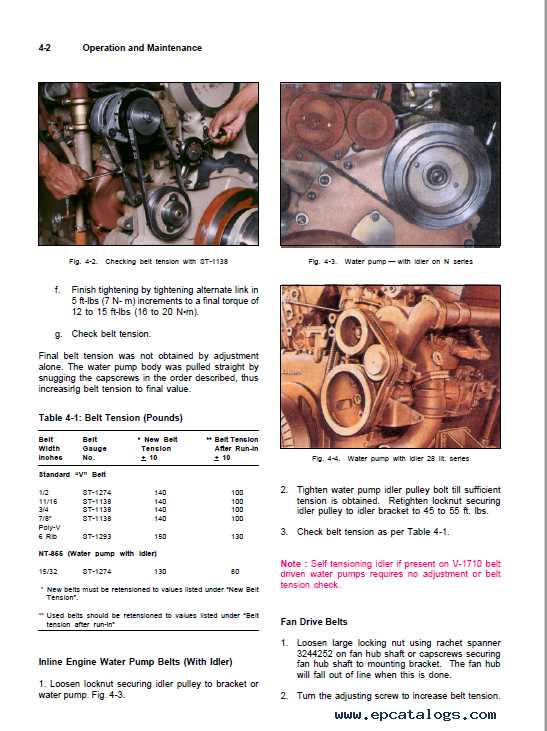

Regular fluid checks are crucial; ensure oil and coolant levels are within recommended ranges. Replace filters periodically to maintain optimal operation. Additionally, inspecting belts and hoses for wear can prevent unexpected failures.

Routine cleaning of components helps to remove dirt and debris, reducing wear on critical parts. Establishing a regular schedule for these tasks can greatly enhance the machine’s durability and functionality.

Monitoring usage patterns is also beneficial. Understanding how the equipment is utilized can inform maintenance needs and help in adjusting operation to avoid unnecessary strain. This proactive approach ultimately leads to a longer, more productive life for the machinery.

Replacing Engine Components Effectively

Efficiently replacing engine parts is crucial for maintaining optimal performance and longevity. Understanding the proper techniques and processes not only enhances functionality but also minimizes the risk of future complications. This section outlines essential practices to ensure that every component is installed correctly and operates seamlessly within the engine system.

Preparation is Key: Before beginning the replacement process, it is vital to gather all necessary tools and components. A well-organized workspace can significantly improve efficiency. Additionally, reviewing technical specifications and guidelines will provide clarity on the requirements for each part.

Step-by-Step Approach: Following a methodical approach is essential. Begin by carefully removing the old components, taking note of their arrangement and connections. This attention to detail will aid in the installation of the new parts. Always ensure that the surfaces are clean and free of debris before placing new components.

Proper Torque Settings: Utilizing the correct torque settings when fastening components is imperative. Over-tightening or under-tightening can lead to severe issues, including leaks or mechanical failure. Refer to the specifications to ensure each part is secured appropriately.

Testing and Verification: After completing the replacement, conducting a thorough test is crucial. Running the engine and observing for any irregularities can help identify potential problems early. Making adjustments as needed will ensure that the new components function as intended.

In summary, effective component replacement requires careful planning, attention to detail, and adherence to best practices. By following these guidelines, you can enhance the reliability and efficiency of your engine system.

Diagnosing Performance Problems

Identifying issues related to engine efficiency is crucial for optimal operation. A systematic approach allows for pinpointing specific factors that may lead to reduced performance. Whether it’s loss of power, increased fuel consumption, or unusual noises, understanding these symptoms can aid in effective troubleshooting.

Common Symptoms and Their Implications

Engine performance issues can manifest in various ways. Below is a table summarizing common symptoms and their potential causes:

| Symptom | Potential Cause |

|---|---|

| Loss of Power | Blocked air filter or fuel supply issues |

| Increased Fuel Consumption | Improper fuel mixture or injector malfunction |

| Unusual Noises | Worn components or loose fittings |

| Overheating | Cooling system failure or low fluid levels |

Steps for Troubleshooting

To effectively diagnose these issues, begin with a visual inspection. Check for leaks, loose connections, and any signs of wear. Next, employ diagnostic tools to assess performance metrics, ensuring all systems operate within specified parameters. Regular maintenance records can also provide insights into recurring problems, facilitating a more efficient troubleshooting process.

Safety Precautions During Repairs

Ensuring a secure working environment is crucial when undertaking any maintenance task. Proper precautions not only protect the individual performing the work but also safeguard the equipment and surrounding personnel. Adhering to established safety measures minimizes the risk of accidents and enhances the overall efficiency of the task.

Essential Safety Guidelines

Before commencing any service, it’s vital to familiarize yourself with key safety practices. Here are some fundamental guidelines to consider:

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, including gloves, goggles, and steel-toed boots, to protect against hazards. |

| Work Area Organization | Keep the workspace tidy and free from clutter to reduce the risk of trips and falls. |

| Tools Inspection | Regularly check tools for wear and damage to ensure they function safely and effectively. |

| Emergency Procedures | Be familiar with emergency protocols, including the location of first aid kits and fire extinguishers. |

Additional Considerations

Beyond basic safety measures, specific attention should be given to the environment in which maintenance is performed. Ensure adequate ventilation when working with chemicals and be aware of any potential hazards related to electrical components. Staying vigilant and prepared can greatly enhance safety outcomes during maintenance activities.

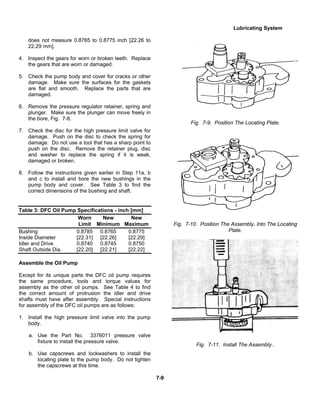

Recommended Lubricants and Fluids

Choosing the right lubricants and fluids is essential for optimal performance and longevity of heavy-duty engines. The proper selection ensures that all components operate smoothly, reducing wear and preventing overheating. This section provides guidance on suitable products to maintain efficiency and reliability.

| Fluid Type | Recommended Specifications | Notes |

|---|---|---|

| Engine Oil | SAE 15W-40, API CK-4 | High thermal stability and excellent protection against wear. |

| Transmission Fluid | DEXRON VI, Mercon LV | Ensures smooth shifting and optimal performance. |

| Coolant | Extended Life Antifreeze/Coolant | Prevents corrosion and provides excellent heat transfer. |

| Grease | NLGI Grade 2 | Provides lubrication in high-load applications. |

| Fuel Additive | Anti-gel and Cetane Booster | Improves fuel stability and engine performance. |

Utilizing these recommended products can significantly enhance the overall functionality of your engine, ensuring it operates at its best under various conditions. Regular maintenance with the appropriate fluids will also contribute to extended service intervals and reduced operational costs.

Understanding Wiring and Electrical Systems

The effective functioning of any mechanical system relies heavily on its electrical components. A thorough comprehension of wiring and electrical networks is essential for diagnosing issues, ensuring reliable operation, and maintaining efficiency. This section aims to clarify the various aspects of electrical configurations and the significance of proper management.

Electrical systems typically consist of several key elements:

- Wires and Cables: Conductors that transmit electrical current, available in various gauges and insulation types.

- Connectors: Components that establish electrical connections, ensuring secure and efficient transmission of power.

- Fuses and Breakers: Safety devices designed to protect the system from overloads and short circuits.

- Sensors: Devices that monitor various parameters and relay information to control systems for adjustments.

- Control Units: Centralized hubs that manage electrical signals and dictate system operations.

Understanding the function of each element is crucial for troubleshooting and repairs. Regular inspections and adherence to wiring diagrams can prevent potential failures. Additionally, familiarity with safety protocols is vital when working with electrical systems to avoid hazards.

To maintain optimal performance, consider the following best practices:

- Regularly inspect wiring for signs of wear or damage.

- Ensure all connections are tight and free from corrosion.

- Replace fuses and breakers promptly if they are tripped or blown.

- Utilize proper tools and techniques when working on electrical components.

- Consult technical documentation for specifications and wiring diagrams.

In conclusion, a solid grasp of electrical systems is integral to the longevity and reliability of mechanical setups. By prioritizing maintenance and safety, operators can enhance performance and minimize unexpected failures.

Resources for Further Learning

Expanding your knowledge on engine maintenance and troubleshooting can significantly enhance your skills and confidence. Various resources are available to help individuals dive deeper into the intricacies of machinery, offering both theoretical insights and practical applications. Whether you are a beginner or looking to refine your expertise, these materials can serve as valuable tools in your learning journey.

Online Courses and Webinars

Numerous platforms provide comprehensive courses focused on engine systems and maintenance techniques. Engaging in interactive webinars can also connect you with industry experts, allowing for real-time questions and discussions. These resources are designed to cater to different skill levels, ensuring that everyone can benefit from the content.

Books and Technical Guides

Investing in well-regarded literature can provide a solid foundation of knowledge. Look for books that cover both fundamental concepts and advanced topics in engine mechanics. Technical guides often include diagrams, troubleshooting tips, and detailed procedures that are essential for hands-on practice.