Comprehensive Guide for Repairing the Cummins ISX 15 Engine

Maintaining a powerful and efficient engine requires in-depth knowledge and precise care, especially for those used in high-performance settings. This guide is dedicated to ensuring engines operate reliably over extended periods by covering essential maintenance steps and detailed diagnostic methods. Understanding the intricacies of engine upkeep is critical for preventing issues before they escalate, leading to smoother and more efficient performance.

Within this resource, we focus on key procedures for diagnosing mechanical challenges and improving the longevity of your equipment. Topics include essential servicing tasks, technical advice, and step-by-step solutions for common problems. With clear instructions, each section empowers users to handle intricate systems confidently, ensuring both safety and performance.

Additionally, we address various methods to enhance fuel efficiency, maximize power output, and minimize wear. Our aim is to provide a practical approach for technicians and operators, equipping them with the expertise to handle engines effectively under different operating conditions.

Comprehensive Guide to Engine Overhaul and Maintenance

Maintaining and restoring a high-performance engine requires attention to detail and adherence to recommended processes. This guide covers key aspects to ensure the machinery operates efficiently, reducing potential downtime and extending its overall lifespan. By following essential steps in regular upkeep and addressing any arising issues, owners can optimize both performance and reliability.

Key Steps in Engine Maintenance

Regular upkeep of large engines involves systematic inspections and scheduled servicing. Each phase includes checking specific components, such as fuel injectors, turbochargers, and air filtration systems, to prevent minor issues from escalating. Replacing worn parts promptly is crucial for sustained performance.

Essential Components and Their Maintenance

A variety of engine components require periodic attention to maintain proper functioning. Below is a summary of major parts and their recommended service practices:

| Component | Service Frequency | Maintenance Details | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Fuel Injectors | Every 50,000 miles | Inspect for wear and clean or replace if necess

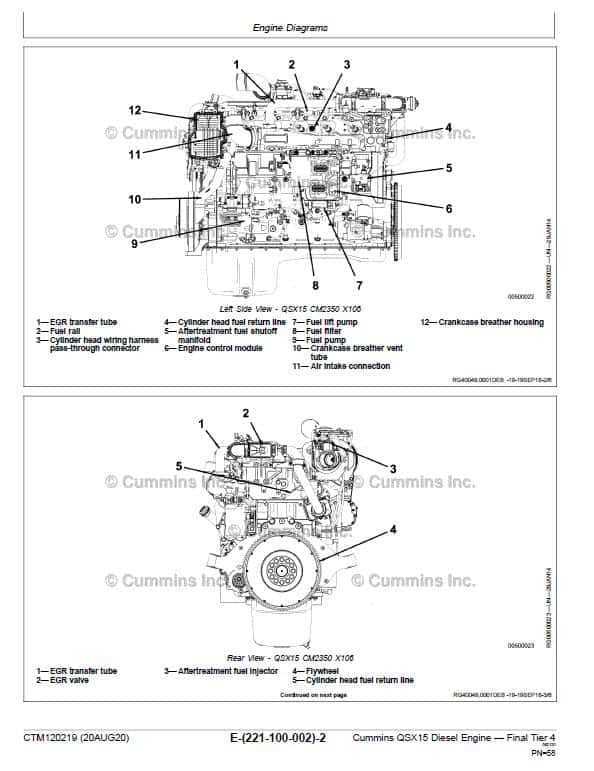

Engine Diagnostics and Troubleshooting

Effective engine diagnostics and troubleshooting are essential for maintaining optimal engine performance. By identifying early signs of potential issues, it becomes possible to prevent costly breakdowns and ensure the engine runs smoothly. Key Signs of Engine Issues

Understanding common symptoms can help in recognizing problems before they escalate. Here are some signs to monitor:

Steps for Basic Troubles

|

| Component | Function | Maintenance Frequency |

|---|---|---|

| Fuel Filter | Removes impurities from the fuel to protect injectors and pumps. | Replace every 15,000 – 20,000 miles |

| Turbocharger Care and Repair

A well-maintained turbocharger ensures optimal engine performance, fuel efficiency, and extended operational lifespan. Proper attention to the turbocharger can prevent significant issues, enhancing both safety and functionality. Below are key steps and considerations for maintaining and servicing this crucial engine component. Regular Maintenance Checks

Regular inspection is essential to monitor the condition of the turbocharger. This involves checking for any signs of wear, buildup, or possible leaks. By following these steps, you can minimize potential failures:

Cooling System Inspection TipsRegular inspection of the cooling system is essential to ensure efficient operation and prevent potential issues that could lead to overheating or system failure. A thorough check helps maintain the longevity and performance of the entire engine by identifying possible weaknesses or leaks. Check Coolant Levels: One of the primary steps is to confirm that coolant levels are within recommended limits. Low levels can reduce the system’s ability to regulate temperature effectively, potentially causing overheating. Always inspect the reservoir and refill with the appropriate type of coolant if necessary. Inspect Hoses and Connections: Hoses and connections should be closely examined for signs of wear, cracks, or leaks. Even minor cracks can lead to serious issues over time. En Lubrication System OptimizationEffective maintenance of the lubrication system is crucial for the overall performance and longevity of an engine. By implementing various strategies, one can enhance the efficiency of this vital component, ensuring smooth operation and reducing wear and tear. To achieve optimal performance, consider the following approaches: By adopting these practices, the lubrication system can be optimized for improved engine performance and reliability. Air Intake System AdjustmentsThe air intake system is a crucial component in ensuring optimal engine performance. Proper adjustments to this system can enhance airflow, improve combustion efficiency, and ultimately lead to better fuel economy and reduced emissions. Understanding the necessary modifications and their impact on overall engine function is essential for maintaining a well-operating unit. To achieve the desired performance, it is important to regularly inspect and adjust various elements of the intake system. This includes examining air filters for cleanliness, verifying that all connections are secure, and ensuring there are no leaks in the intake pathway. Making these adjustments not only extends the life of the engine but also contributes to its reliability under different operating conditions. When performing adjustments, attention should be given to the specifications set by the manufacturer. Utilizing the correct tools and following detailed procedures will facilitate accurate tuning of the air intake system. Additionally, periodic assessments of the system can help identify any wear or damage that may hinder performance, allowing for timely interventions. Electrical Component Checkup

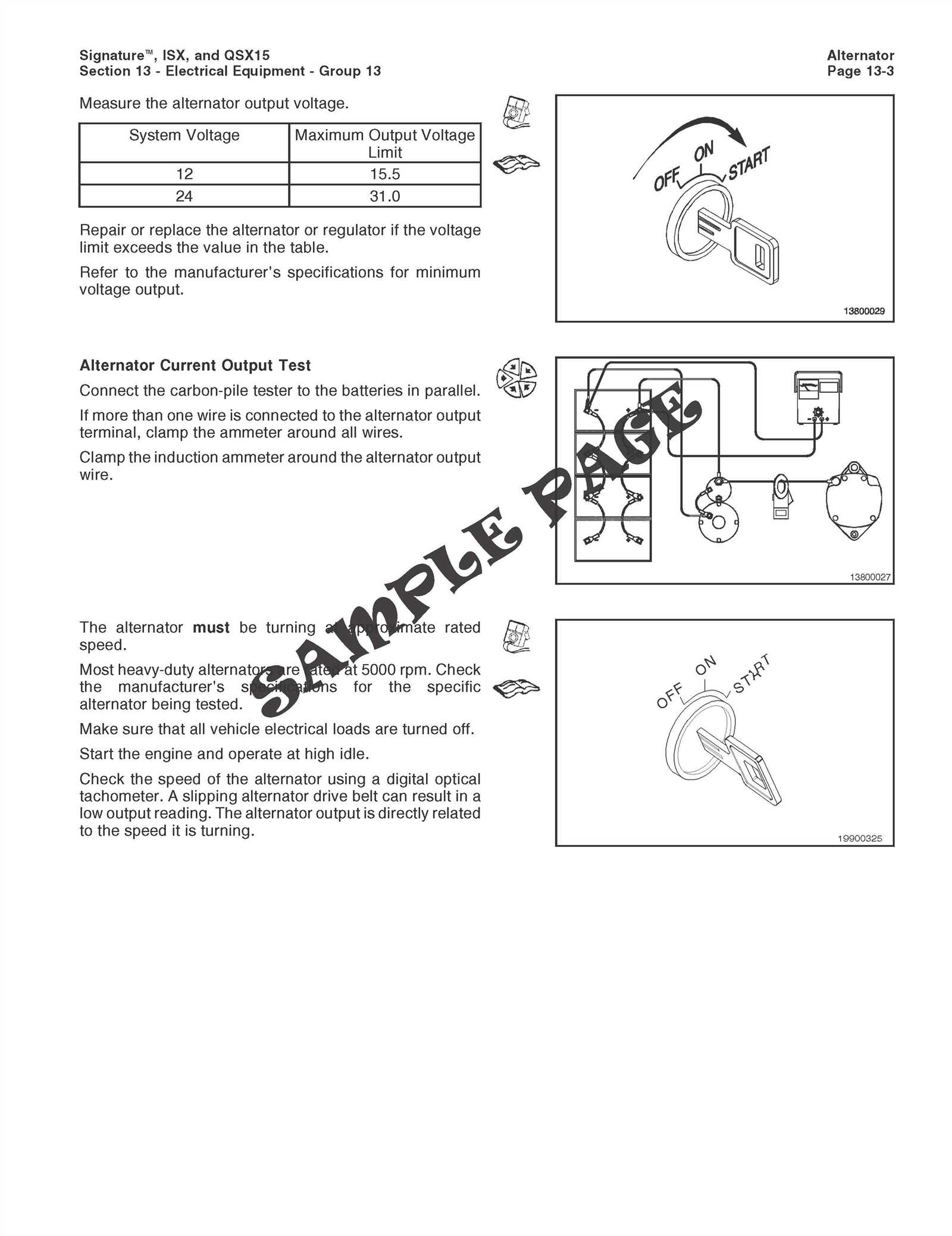

Regular evaluation of electrical components is crucial for maintaining optimal performance in any machinery. This section focuses on the importance of thorough inspections and testing of various electrical elements to ensure reliability and functionality. Proper functioning of these components is essential for the overall efficiency and longevity of the equipment. Inspection of Wiring and ConnectorsExamine all wiring and connectors for signs of wear, corrosion, or damage. Look for frayed wires, loose connections, or signs of overheating. Ensuring that all connections are secure and that wiring is intact can prevent potential electrical failures. Testing Electrical Systems

Utilize appropriate diagnostic tools to test the electrical systems. Checking voltage, resistance, and continuity can identify underlying issues before they escalate. Regular testing helps in pinpointing faulty components and facilitates timely maintenance, ensuring that all systems function seamlessly. Emission Control SolutionsEfficient management of exhaust emissions is crucial for maintaining compliance with environmental regulations and enhancing overall performance. Various innovative techniques are employed to mitigate harmful pollutants released during combustion processes. These methods not only contribute to cleaner air but also optimize engine efficiency, resulting in improved fuel economy and reduced operational costs. One of the primary strategies involves the integration of advanced after-treatment systems, designed to reduce nitrogen oxides and particulate matter. These systems utilize catalytic converters and filters that capture and neutralize harmful emissions before they exit the exhaust. Additionally, tuning the engine’s performance parameters can significantly minimize emissions, ensuring that combustion occurs more completely and efficiently. Regular monitoring and maintenance of emission control components are essential to ensure their effective operation. Routine checks can identify potential issues early, allowing for timely interventions that prevent costly repairs and maintain optimal performance levels. By implementing these emission control solutions, operators can achieve sustainable performance while adhering to stringent environmental standards. Valve Adjustment ProcedureProper regulation of the engine’s valve clearances is crucial for optimal performance and longevity. This procedure outlines the steps necessary to ensure that the valves function efficiently, reducing wear and maintaining the engine’s integrity. Following these guidelines will help in achieving the desired specifications for valve operation. Preparation Steps

Adjustment Process

Following these steps will help maintain the proper function of the valve mechanism, contributing to the overall efficiency of the engine. Transmission and Clutch Maintenance

Proper care and upkeep of the transmission and clutch system are essential for the optimal performance of any vehicle. Regular inspections and timely interventions can prevent significant issues, ensuring smooth operation and longevity. Understanding the critical components and their functionality is vital for effective maintenance practices. Routine Inspections: Regular checks of the transmission fluid level and condition should be conducted. Clean, adequate fluid is necessary for effective lubrication and cooling. Additionally, examining the clutch for wear and tear can help identify potential problems before they escalate. Fluid Changes: Changing the transmission fluid at recommended intervals is crucial. Over time, fluid can degrade and accumulate contaminants, leading to reduced efficiency and potential damage to internal components. Following the manufacturer’s guidelines for fluid specifications is essential. Adjustment and Alignment: Ensuring the clutch is correctly adjusted promotes smooth engagement and disengagement. Misalignment can cause premature wear and operational issues. Regularly checking and adjusting the linkage and pedal height contributes to a well-functioning system. Professional Assistance: For complex issues or extensive repairs, seeking help from qualified technicians is advisable. They possess the expertise and tools necessary to diagnose and address problems effectively, ensuring the transmission and clutch remain in top condition. Exhaust System RestorationThe revitalization of the exhaust system is essential for ensuring optimal engine performance and reducing harmful emissions. Proper maintenance and timely intervention can significantly enhance the longevity and efficiency of this critical component. When undertaking the restoration process, consider the following key steps:

By adhering to these steps, one can achieve a comprehensive restoration of the exhaust system, contributing to improved engine function and compliance with environmental standards. |