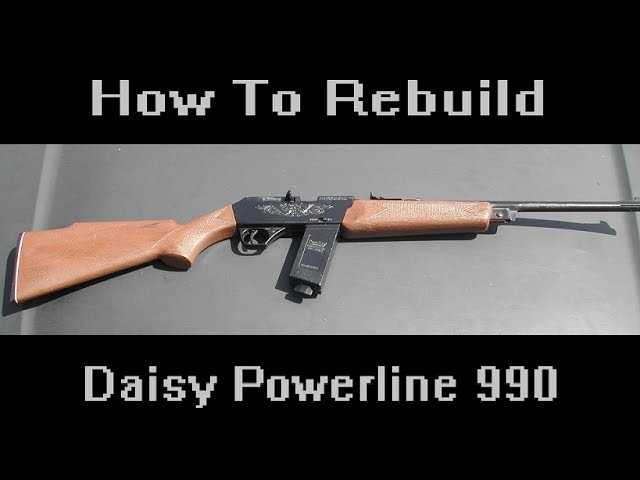

Daisy Model 96 Comprehensive Repair Guide

This section offers a thorough exploration of essential techniques and insights necessary for the upkeep of a popular air-powered device. Whether you’re a novice or an experienced user, understanding the intricacies of functionality and performance can greatly enhance your overall experience.

Delving into common challenges faced by enthusiasts, this guide provides step-by-step approaches to address typical issues that may arise over time. By familiarizing yourself with key components and their roles, you can ensure optimal operation and longevity.

Equipped with practical tips and detailed procedures, this resource aims to empower users with the knowledge to confidently manage their equipment. Emphasizing safety and efficiency, it is designed to support both routine maintenance and more complex troubleshooting tasks.

Daisy Model 96 Overview

This section provides a comprehensive look at a well-known air-powered firearm, focusing on its features, specifications, and historical significance. The piece has gained popularity due to its reliability and ease of use, making it a favorite among enthusiasts and newcomers alike.

Key Features

The air weapon is equipped with a robust construction that ensures durability and performance. It typically includes a smooth bore barrel designed for accuracy and consistency, along with a convenient loading mechanism that allows for quick reloading. Additionally, the adjustable sights enhance precision during target practice.

Historical Significance

This air-powered device has a rich heritage, tracing its origins back to the mid-20th century. Its introduction marked a significant development in recreational shooting, providing a safe and enjoyable way for individuals to engage with the sport. Over the years, it has become a symbol of quality craftsmanship and innovative design.

Common Issues and Solutions

This section addresses frequently encountered challenges and their corresponding remedies, aimed at enhancing performance and longevity. Understanding these common problems can help users maintain their equipment effectively and ensure optimal functionality.

Typical Challenges

- Inconsistent performance

- Difficulty in loading mechanisms

- Misalignment of components

- Frequent jams

Recommended Solutions

-

Inconsistent performance:

Regularly clean and lubricate the internal parts to ensure smooth operation. Check for any wear and replace components as needed.

-

Difficulty in loading mechanisms:

Inspect the loading area for obstructions and debris. Ensure that all parts are aligned correctly and functioning without hindrance.

-

Misalignment of components:

Realign parts by carefully adjusting their positions. Consult the guidelines for proper alignment techniques.

-

Frequent jams:

Clear any blockages and check the feed path. Use compatible materials to minimize the chance of jamming.

Tools Needed for Repair

When undertaking the task of fixing air rifles, having the right equipment is crucial for a successful outcome. The appropriate instruments not only facilitate the process but also ensure safety and precision. This section outlines essential tools that will help in addressing various issues effectively.

First and foremost, a comprehensive set of screwdrivers is indispensable, as different screws require specific heads for proper removal and installation. Additionally, pliers can be invaluable for gripping and manipulating small components, making them easier to handle. A reliable set of wrenches is also important for loosening or tightening bolts, ensuring that all parts are secured correctly.

For more intricate work, having a precision knife or scalpel can assist in delicate tasks, such as cutting away old seals or materials. Furthermore, a cleaning kit is essential for maintaining the internals, preventing debris buildup that could hinder performance. Lastly, a magnifying glass or jeweler’s loupe can prove helpful for inspecting small parts and identifying any wear or damage that might not be immediately visible.

Step-by-Step Disassembly Guide

This section provides a comprehensive walkthrough for carefully taking apart the specified device. Understanding each step is crucial for effective reassembly and ensuring that all components are handled with care. Follow the instructions closely to avoid any damage during the process.

Preparation

Before beginning the disassembly, gather all necessary tools and materials. A clean, well-lit workspace is essential for maintaining organization and visibility throughout the procedure. The following tools are recommended:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing screws of various sizes |

| Pliers | For gripping and pulling components |

| Tweezers | For handling small parts |

| Container | To keep screws and small pieces organized |

Disassembly Steps

Follow these steps to effectively disassemble the unit:

- Remove the outer casing by locating and unscrewing all visible screws.

- Carefully detach any clips or fasteners that hold the casing in place.

- Lift the casing off gently to avoid damaging internal components.

- Identify and unscrew any additional parts, noting their arrangement.

- Store removed components in the container to keep track of all pieces.

By adhering to this guide, you can systematically take apart the device, paving the way for further examination or maintenance. Always ensure to work patiently and methodically to avoid unnecessary complications.

Reassembly Techniques Explained

Reassembling a device requires precision and a systematic approach to ensure all components fit together seamlessly. Each step is crucial in restoring functionality while maintaining the integrity of the unit. Understanding effective techniques can significantly enhance the reassembly process, leading to a successful outcome.

Key Considerations

Before starting the reassembly, it is essential to review the disassembly process and ensure that all parts are accounted for. This includes verifying that no components are damaged and that any necessary replacements are ready. Organizing the workspace can also prevent confusion during assembly.

Steps for Effective Reassembly

Follow these outlined steps to facilitate a smooth reassembly:

| Step | Description |

|---|---|

| 1 | Inspect all parts for wear and damage before beginning. |

| 2 | Gather all necessary tools and components in an orderly fashion. |

| 3 | Begin with the largest components, ensuring a stable foundation. |

| 4 | Follow the reverse order of disassembly, referring to notes if needed. |

| 5 | Test fit parts progressively to avoid forcing components together. |

| 6 | Secure all screws and fasteners to ensure structural integrity. |

By adhering to these strategies, the reassembly process can be made more efficient, reducing the risk of errors and ensuring optimal performance upon completion.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment involves consistent care and attention. Adopting best practices in upkeep can significantly enhance performance and extend its lifespan. By following a few essential guidelines, you can keep your device in optimal condition for years to come.

Regular Inspection

Routine examinations help identify wear and tear before they escalate into major issues. Look for signs of damage, corrosion, or any loose components. Addressing these minor problems promptly can prevent costly repairs down the line.

Proper Cleaning Techniques

Maintaining cleanliness is vital for operational efficiency. Utilize appropriate cleaning solutions and tools to remove debris and dirt. Avoid harsh chemicals that may cause harm to the surface or internal mechanisms.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Inspection | Monthly | Check for damage and wear. |

| Cleaning | Every use | Use gentle, recommended cleaners. |

| Lubrication | Every 6 months | Apply suitable lubricant to moving parts. |

| Storage | After each use | Store in a dry, cool place. |

Replacing Key Components

In any mechanical system, the longevity and performance heavily depend on the condition of its essential parts. When these components wear out or become faulty, addressing the issue promptly can significantly enhance functionality and ensure a smoother operation. This section focuses on the fundamental aspects of component substitution, providing insights into the process and considerations involved.

Identifying Components is the first step in the replacement process. Recognizing which parts are critical for the overall performance allows for targeted interventions. Regular inspections can help pinpoint wear and tear, enabling timely action before more extensive damage occurs.

Tools and Preparation are crucial for a successful replacement. Having the right equipment on hand not only simplifies the process but also minimizes the risk of damaging surrounding parts. Before beginning, ensure that all necessary tools are organized and that the workspace is clean and well-lit.

Step-by-Step Replacement involves carefully removing the faulty component and replacing it with a new one. Follow a systematic approach to avoid mistakes: remove screws or fasteners, gently detach the old part, and securely install the new one. Double-check connections to confirm everything is fitted properly.

Testing and Maintenance are vital after the replacement is complete. Once new components are in place, performing a thorough test ensures that the system operates as intended. Additionally, regular maintenance can prevent future issues, prolonging the life of the newly installed parts.

Upgrades for Enhanced Performance

Improving the functionality of your air-powered device can significantly enhance your overall shooting experience. Various enhancements can lead to increased accuracy, reliability, and efficiency, allowing you to achieve better results during practice or competitions.

One effective way to boost performance is by upgrading the internal components. Replacing stock parts with higher-quality alternatives can result in smoother operation and improved power output. Precision valves and spring kits are popular choices that can provide a noticeable difference in shot consistency and velocity.

Additionally, consider optimizing the barrel. A match-grade barrel can enhance accuracy, while proper cleaning and maintenance of existing barrels ensure they function at their best. Using high-grade ammunition tailored for your device can also contribute to more precise shooting.

Ergonomics play a crucial role in performance as well. Upgrading grips or stocks for better comfort and handling can lead to improved aim and reduced fatigue during extended use. Custom accessories like sights or scopes can help in acquiring targets faster and with greater precision.

Lastly, maintaining a consistent power source is vital. Regularly checking and replacing seals or O-rings ensures that air pressure remains optimal, preventing leaks and maintaining efficiency. By focusing on these enhancements, you can unlock the full potential of your equipment and enjoy a superior shooting experience.

Safety Precautions During Repair

Ensuring a secure environment is crucial when undertaking maintenance tasks on any mechanical device. Adhering to proper safety measures not only protects the individual performing the work but also helps maintain the integrity of the equipment. By following established guidelines, one can prevent accidents and ensure a smooth workflow.

Essential Gear

Wearing appropriate personal protective equipment is paramount. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges, and ear protection if noise levels are high. Proper footwear should also be considered to provide support and prevent slipping.

Work Area Considerations

Maintaining a tidy and organized workspace can significantly reduce hazards. Ensure that the area is well-lit and free from clutter. Always keep tools and parts within reach to minimize the risk of accidents. Additionally, it’s wise to have a first aid kit readily available in case of minor injuries.

Resources for Further Assistance

When tackling issues with your device, having access to reliable resources can make a significant difference. Whether you’re seeking guidance for troubleshooting, upgrades, or maintenance, various platforms and communities can offer the support you need.

Here are some valuable sources you might consider exploring:

- Online Forums: Joining specialized discussion boards can provide insights from experienced users who have faced similar challenges.

- Video Tutorials: Platforms like YouTube host numerous channels dedicated to instructional content that can visually guide you through complex processes.

- User Groups: Local or online communities can connect you with fellow enthusiasts who share tips and best practices.

- Technical Support Services: Many companies offer customer support lines or chat services for direct assistance with specific inquiries.

- Documentation Resources: Searching for comprehensive guides or articles that detail common problems can be a quick way to find solutions.

Utilizing these resources will enhance your understanding and help you effectively manage any challenges you may encounter.