Dewalt DW735 Repair Guide for Optimal Performance

When it comes to maintaining essential woodworking equipment, understanding the intricacies of its operation is crucial for optimal performance. Ensuring that your tools remain in top condition not only enhances their longevity but also improves the quality of your projects. A well-maintained machine can significantly increase efficiency, saving both time and effort.

This guide offers detailed insights into troubleshooting common issues and performing routine upkeep tasks. By familiarizing yourself with the essential components and their functions, you can tackle minor challenges confidently. Moreover, knowing how to address potential problems before they escalate is invaluable for any craftsman.

In addition to routine checks and adjustments, this resource will provide step-by-step instructions for specific repairs and enhancements. Whether you’re a seasoned professional or an enthusiastic novice, this information is designed to empower you to take control of your tool’s performance. Get ready to dive into a world of practical knowledge that will keep your equipment running smoothly.

Dewalt DW735 Overview

This section provides a comprehensive insight into a popular woodworking tool known for its efficiency and precision. Designed to enhance the woodworking experience, this machine offers various features that cater to both amateur and professional craftsmen. Understanding its capabilities and specifications can greatly assist users in maximizing their productivity.

Key Features

The tool boasts a powerful motor, enabling it to handle a range of materials with ease. Its dual-speed settings allow for versatility, making it suitable for different types of woodworking projects. Additionally, the integrated dust collection system ensures a cleaner workspace, while the adjustable table height enhances user convenience.

Performance and Applications

This equipment excels in delivering smooth, finished surfaces, which is crucial for high-quality woodworking. Ideal for planing lumber, it can also be utilized for various applications, including cabinetry and furniture making. Its robust design ensures durability, making it a reliable choice for those looking to invest in a long-lasting tool.

Common Issues with Dewalt DW735

Many users of this popular woodworking tool encounter various challenges during operation. Identifying and understanding these common problems can help enhance the overall experience and efficiency of the device.

1. Feed Issues: One frequent concern is related to material feeding. Users may notice that wood does not feed smoothly, which can lead to uneven cuts. This often results from improper alignment or debris accumulation in the feed mechanism.

2. Knife Dullness: Over time, the cutting blades can become dull, impacting performance. A noticeable decrease in cutting quality is a sign that the blades need to be sharpened or replaced.

3. Motor Overheating: Another common issue is the motor overheating during prolonged use. This can be caused by excessive load or lack of proper ventilation. It’s important to allow the machine to cool down and ensure that airflow is not obstructed.

4. Electrical Problems: Users may also experience electrical issues, such as the device not starting. This can stem from faulty wiring or blown fuses, requiring careful inspection to identify the source of the problem.

5. Vibration and Noise: Excessive vibration or unusual noises during operation can indicate misalignment or worn parts. Addressing these concerns promptly can prevent further damage and maintain optimal performance.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to effectively address common issues that may arise with your equipment. By following these detailed steps, you can ensure that your tool remains in optimal condition and functions smoothly.

Identify the Problem

Begin by examining the tool to pinpoint the specific malfunction. Listen for unusual noises and check for visible wear or damage that could indicate the source of the issue.

Gather Necessary Tools

Before starting any work, collect all essential tools and replacement parts required for the task. Having everything on hand will streamline the process and minimize downtime.

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for achieving optimal results. A well-stocked toolbox not only enhances efficiency but also ensures safety during the process. Whether you are a novice or a seasoned professional, understanding the basic tools required for any undertaking is fundamental.

Key Hand Tools

Hand tools are the backbone of any maintenance kit. Items such as screwdrivers, wrenches, and pliers are essential for a variety of tasks. Each type serves a unique purpose, allowing for precise adjustments and assembly. Investing in high-quality hand tools can significantly improve the ease and effectiveness of your work.

Power Equipment

For more demanding projects, power tools provide the necessary strength and speed. Tools like drills and sanders can save considerable time while delivering superior results. It’s important to choose equipment that suits the specific job at hand, ensuring both performance and reliability.

Maintenance Tips for Longevity

Proper upkeep of your woodworking equipment is essential for ensuring its longevity and optimal performance. By following a few simple practices, you can extend the lifespan of your tools and enhance their efficiency, saving both time and money in the long run.

Regular Cleaning

Keeping your machinery clean is crucial. Dust and debris can accumulate, leading to overheating and wear. Make it a habit to wipe down surfaces and remove sawdust after each use. Pay special attention to air vents and blades, ensuring they remain free of obstructions.

Routine Inspections

Conducting regular inspections helps identify potential issues before they become serious problems. Check for loose screws, worn belts, and other signs of wear. Early detection allows for timely adjustments or replacements, maintaining the tool’s performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Cleaning | After each use | Focus on blades and air vents |

| Lubrication | Monthly | Use appropriate lubricants |

| Inspection | Every 3 months | Check for wear and tear |

| Blade Replacement | As needed | Monitor cutting efficiency |

By adhering to these maintenance tips, you can ensure your equipment remains in peak condition, allowing for precise and effective woodworking projects for years to come.

Identifying Parts and Components

Understanding the various elements and assemblies of your equipment is crucial for effective maintenance and troubleshooting. Each part plays a specific role, contributing to the overall functionality and efficiency. Familiarizing yourself with these components can simplify repairs and enhance performance.

| Component | Description | Function |

|---|---|---|

| Base | The sturdy foundation of the unit. | Supports the entire structure and absorbs vibrations. |

| Motor | The power source for operation. | Drives the cutting blades and other moving parts. |

| Cutter Head | Houses the cutting blades. | Engages with the material to create a smooth finish. |

| Feed Rollers | Located above the cutter head. | Guide and push the material through the machine. |

| Depth Adjustment Lever | Used to set the thickness of the cut. | Allows for precision in material processing. |

Recognizing these parts will aid in proper handling and care, ultimately leading to prolonged service life and optimal performance. Regular inspection and awareness of each component’s role can prevent common issues and facilitate effective operation.

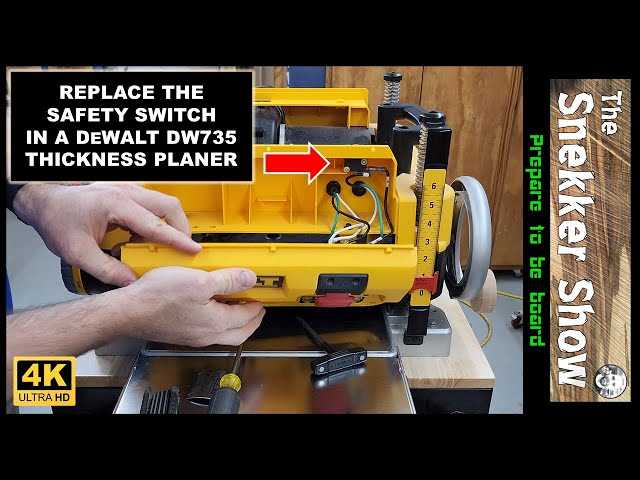

Troubleshooting Electrical Problems

Electrical issues can significantly hinder the performance of your equipment. Identifying and resolving these problems is essential for maintaining optimal functionality. This section will guide you through common electrical faults and provide effective solutions to restore your tool’s performance.

Identifying Common Symptoms

Start by observing any irregular behaviors. Symptoms such as flickering lights, inconsistent power, or strange noises can indicate underlying electrical malfunctions. Check for any tripped circuit breakers or blown fuses, as these can be primary indicators of a fault.

Steps to Diagnose and Resolve Issues

Begin your troubleshooting by ensuring all connections are secure. Loose wires can lead to intermittent power supply. Next, use a multimeter to measure voltage at various points; this will help identify where the power flow is disrupted. If the device still does not operate, inspect internal components such as capacitors and switches for signs of damage or wear.

If you discover faulty components, consider replacing them with appropriate parts to ensure safety and functionality. Always prioritize safety by disconnecting power before attempting any repairs.

Upgrading Your DW735 Model

Enhancing your woodworking tool can significantly improve performance and efficiency. By implementing specific upgrades, you can optimize functionality, extend lifespan, and adapt your equipment to meet your evolving needs. This section discusses several effective modifications to elevate your machine’s capabilities.

Key Upgrades to Consider

- Blades: Switching to high-quality, sharp blades can enhance cut precision and reduce strain on the motor.

- Table Extensions: Adding extensions can provide additional support for larger workpieces, improving stability during operation.

- Dust Collection System: Integrating an efficient dust extraction system helps maintain a clean workspace and promotes better visibility.

Installation Tips

- Before starting any upgrade, ensure the machine is powered off and unplugged.

- Carefully read the instructions for each component to ensure proper installation.

- Consider seeking assistance from a professional if you are unfamiliar with mechanical modifications.

With the right upgrades, you can significantly enhance the functionality and efficiency of your woodworking equipment, allowing you to tackle more complex projects with ease.

Safety Precautions During Repair

Ensuring a safe environment while performing maintenance or troubleshooting tasks is crucial for both personal safety and the proper functioning of the equipment. Adhering to specific guidelines can help mitigate risks and prevent accidents, allowing for a smoother and more efficient process.

Personal Protective Equipment

Wearing appropriate protective gear is essential. This includes safety glasses to shield your eyes from debris, gloves to protect your hands from sharp edges, and ear protection if you are working in a noisy environment. Additionally, using a dust mask can help avoid inhaling harmful particles that may be released during the work.

Work Area Organization

Keeping your workspace tidy is vital. Remove any unnecessary tools and materials that could cause tripping hazards. Ensure that all equipment is unplugged and properly secured before beginning any tasks. Good organization not only enhances safety but also increases efficiency during the job.

Where to Find Replacement Parts

When it comes to maintaining your tools, sourcing high-quality components is essential for ensuring optimal performance and longevity. Whether you need a blade, motor, or any other accessory, locating reliable suppliers is key to keeping your equipment in top condition.

One of the best places to start your search is through authorized dealers. These retailers often carry genuine components that are specifically designed for your equipment, ensuring compatibility and reliability. Additionally, visiting the manufacturer’s official website can provide valuable resources and links to trusted distributors.

Online marketplaces have also become popular for finding spare parts. Websites like Amazon and eBay feature a wide array of options, including both original and aftermarket parts. Always check seller ratings and reviews to ensure you’re purchasing from a reputable source.

Local hardware stores may stock some of the more common components, making it convenient for quick repairs. It’s worth calling ahead to confirm availability.

Lastly, consider joining online forums or communities dedicated to tool enthusiasts. These platforms can be invaluable for recommendations on where to find parts, as well as tips on installation and maintenance.