Dixon Mower Repair Guide for Optimal Performance

Maintaining your outdoor machinery is crucial for ensuring its longevity and optimal performance. Understanding the intricacies of your equipment can significantly enhance its functionality and prevent common issues that may arise during operation. This guide aims to provide comprehensive insights into troubleshooting and enhancing the efficiency of your lawn care tools.

Whether you are a seasoned gardener or a novice, having access to detailed information on servicing and upkeep can empower you to tackle any challenges that may occur. Familiarizing yourself with the components and mechanisms involved in your equipment will not only save you time but also reduce costs associated with professional assistance.

In the following sections, we will delve into various aspects of maintaining your machinery, offering step-by-step instructions and practical tips. Emphasizing preventative measures and routine checks will help you cultivate a productive and enjoyable gardening experience.

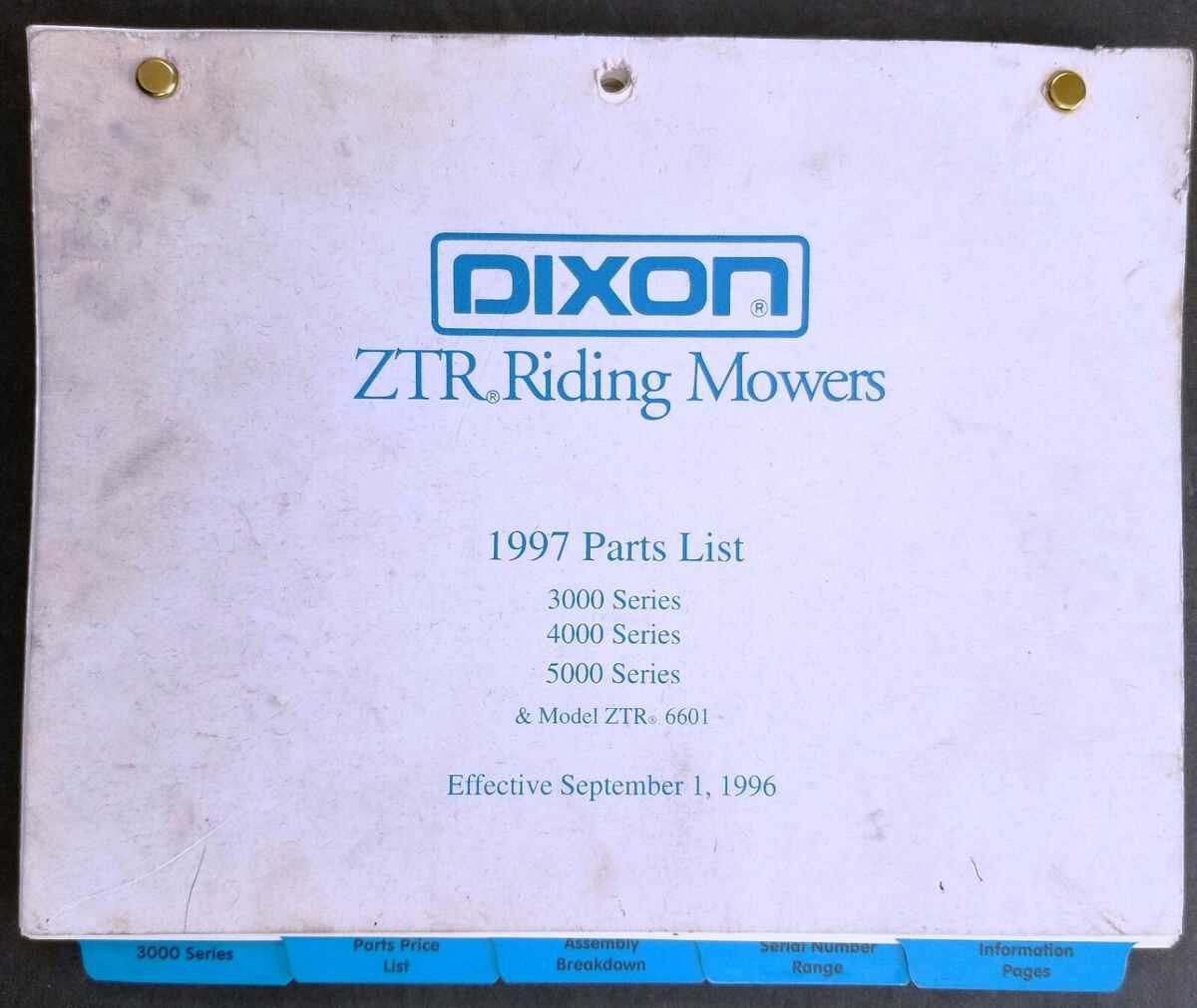

Dixon Mower Repair Manual Overview

This section provides an essential guide for maintaining and troubleshooting your lawn care equipment. Understanding the components and their functions is crucial for ensuring longevity and optimal performance. Here, you will find valuable insights into common issues, suggested solutions, and preventative measures to enhance the efficiency of your machinery.

Key Components and Their Functions

Every piece of landscaping equipment comprises various parts that work together harmoniously. Familiarizing yourself with these components, such as the engine, cutting deck, and transmission, can significantly ease the process of upkeep. Regular inspections and timely replacements are vital to avoid more significant complications down the line.

Troubleshooting Common Issues

Identifying problems early can save both time and resources. Common challenges include starting difficulties, uneven cuts, and noise during operation. This guide outlines straightforward diagnostic steps to help you pinpoint the root cause and implement effective solutions. Regular maintenance routines, such as oil changes and blade sharpening, are emphasized to prevent these issues from arising.

By staying informed and proactive, you can ensure that your equipment remains in peak condition, ultimately leading to a more enjoyable and efficient lawn care experience.

Common Dixon Mower Issues

When operating outdoor machinery, users may encounter various challenges that can hinder performance. Understanding these typical problems can lead to effective troubleshooting and maintenance, ensuring optimal functionality over time.

- Engine Difficulties:

- Starting issues can arise from a drained battery or faulty ignition components.

- Overheating may result from insufficient oil levels or clogged air filters.

- Cutting Problems:

- Uneven cutting might indicate dull blades or misaligned deck settings.

- Grass clumping can occur due to wet conditions or clogged discharge chutes.

- Transmission Trouble:

- Loss of power can be a sign of worn belts or damaged gears.

- Unusual noises during operation may signal issues with the drive system.

- Electrical Failures:

- Flickering lights or non-functioning components often point to wiring issues.

- Fuse problems can lead to complete electrical shutdowns.

Addressing these concerns promptly can enhance performance and prolong the lifespan of your equipment. Regular inspections and maintenance practices are key to preventing these common challenges.

Essential Tools for Repairs

To ensure effective maintenance and restoration of outdoor equipment, having the right instruments at hand is crucial. These tools not only facilitate the process but also enhance the overall efficiency and safety of tasks performed.

Wrenches are fundamental for loosening or tightening various components, while screwdrivers of different types allow for precise handling of screws in diverse settings. An adjustable pliers can also prove invaluable for gripping and manipulating parts that are difficult to reach.

For tasks requiring accuracy, a multimeter helps in diagnosing electrical issues, and a socket set is essential for dealing with nuts and bolts in tight spaces. Additionally, a toolbox is beneficial for organizing these items, ensuring everything is readily accessible when needed.

Step-by-Step Maintenance Guide

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. This guide will provide a clear and systematic approach to maintaining your device, helping you avoid common pitfalls and enhancing its efficiency. By following these steps, you can ensure that your equipment remains in peak condition throughout its lifespan.

Essential Tools Needed

| Tool | Purpose |

|---|---|

| Wrench Set | To tighten or loosen bolts and nuts. |

| Screwdriver | For adjusting screws and fasteners. |

| Oil Can | To lubricate moving parts. |

| Filter Replacement | To ensure clean air and fluid flow. |

| Cleaning Brush | To remove debris and buildup. |

Maintenance Steps

1. Begin with a thorough inspection of the device. Check for any visible signs of wear, damage, or loose components. Address any issues immediately to prevent further complications.

2. Clean the exterior and undercarriage to remove dirt and debris. This not only improves appearance but also prevents clogging and overheating.

3. Change the filters regularly. This is crucial for maintaining airflow and preventing engine strain.

4. Lubricate all moving parts as recommended in your specific guidelines. Proper lubrication minimizes friction and extends the lifespan of components.

5. Regularly check and adjust the tension of belts and cables. Ensuring they are in optimal condition is vital for effective operation.

6. Lastly, always consult your detailed guidelines for any specific maintenance needs tailored to your model. Adhering to these steps will keep your device functioning efficiently.

Understanding the Engine Components

Grasping the essential parts of an engine is crucial for anyone looking to enhance their knowledge of small machinery. Each component plays a vital role in the overall function, contributing to the efficient operation and longevity of the equipment. By familiarizing oneself with these elements, operators can make more informed decisions regarding maintenance and troubleshooting.

Core Elements of an Engine

The heart of any engine is its internal structure, which typically includes the cylinder, piston, and crankshaft. The cylinder houses the piston, which moves up and down to create the power needed for operation. The crankshaft converts this linear motion into rotational energy, ultimately driving the equipment. Understanding these core elements lays the foundation for recognizing how power is generated and transmitted.

Supporting Components

In addition to the primary parts, several supporting components enhance functionality. These include the ignition system, fuel delivery mechanism, and cooling system. The ignition system ignites the fuel-air mixture, while the fuel delivery mechanism ensures a consistent supply of fuel to the engine. Meanwhile, the cooling system prevents overheating, safeguarding against damage. Familiarity with these auxiliary components helps in comprehending the overall performance and efficiency of the engine.

Adjusting the Blade Height

Achieving the perfect cut requires attention to the height at which the cutting component operates. Proper adjustment not only enhances the aesthetic of the landscape but also promotes the health of the grass by preventing damage.

Before starting the adjustment process, consider the following factors:

- The type of grass and its growth conditions

- The desired length of the grass after cutting

- The season and weather conditions

Follow these steps to effectively modify the cutting height:

- Ensure the equipment is turned off and cool to avoid any accidents.

- Locate the adjustment mechanism, usually found near the wheel assembly or cutting unit.

- Determine the desired height using a measuring tool for accuracy.

- Loosen the adjustment knobs or levers to allow for height modification.

- Raise or lower the cutting component to the preferred setting.

- Tighten the knobs or levers securely to maintain the new height.

After adjusting, it’s beneficial to test the new height by performing a trial cut. This ensures the settings are correct and allows for any further tweaks if necessary.

Troubleshooting Electrical Problems

When dealing with mechanical equipment, electrical issues can arise unexpectedly, leading to performance difficulties. Identifying the root cause of these problems is essential for restoring functionality. This section provides guidance on how to systematically diagnose and resolve common electrical malfunctions.

1. Check the Power Supply: Ensure that the unit is receiving adequate power. Inspect the power cord for any visible damage and verify that the outlet is functioning properly by testing it with another device.

2. Inspect Fuses and Breakers: Often, a blown fuse or a tripped breaker can interrupt power. Locate the fuse box and check for any blown fuses or reset any tripped breakers to restore electrical flow.

3. Examine Connections: Loose or corroded connections can lead to erratic behavior. Carefully inspect all electrical terminals and connectors for signs of wear or oxidation, tightening or cleaning them as necessary.

4. Test the Battery: If the equipment uses a battery, ensure it is charged and functioning. Utilize a multimeter to check the voltage and look for any signs of swelling or leakage that may indicate failure.

5. Assess Electrical Components: Components such as switches, relays, and solenoids can fail over time. Use a multimeter to test these parts for continuity and proper operation, replacing any faulty components.

By following these steps, users can effectively troubleshoot and address electrical issues, ensuring that the equipment operates smoothly and efficiently.

Replacing Worn-Out Parts

Maintaining the efficiency and longevity of your equipment often requires the timely substitution of aged components. Over time, certain elements can wear down due to regular use, leading to decreased performance and potential failures. Understanding when and how to replace these parts is crucial for optimal functioning.

Identifying worn-out components can significantly enhance the lifespan of your machine. Common signs of wear may include:

- Unusual noises during operation

- Decreased power or efficiency

- Visible damage or deterioration

- Frequent breakdowns or malfunctions

When planning to replace these parts, follow these essential steps:

- Assess the Condition: Thoroughly inspect the machinery to determine which parts require replacement.

- Gather Necessary Tools: Ensure you have the appropriate tools on hand for a smooth replacement process.

- Obtain Quality Components: Purchase high-quality replacements from reputable suppliers to guarantee compatibility and performance.

- Follow Installation Guidelines: Adhere to the manufacturer’s instructions or standard procedures for proper installation.

- Test Functionality: Once the new parts are installed, conduct a thorough test to confirm that everything operates correctly.

Regularly replacing aged components not only enhances performance but also prevents more extensive issues in the future. Keeping track of the condition of various parts is key to ensuring reliable operation.

Seasonal Maintenance Tips

Regular upkeep is essential to ensure optimal performance and longevity of your equipment throughout the year. Adapting your care routine to the changing seasons can significantly enhance efficiency and prevent potential issues.

Spring: As the weather warms, it’s crucial to prepare your device for increased usage. Begin by checking and changing the oil, inspecting the air filter, and sharpening the cutting blades. Ensure that all moving parts are well-lubricated to minimize wear and tear during the busy months ahead.

Summer: High temperatures can strain your machine. Monitor fuel levels and consider using a fuel stabilizer to prevent degradation. Regularly clean the undercarriage to avoid debris build-up, which can lead to overheating. Additionally, keep an eye on tire pressure and adjust as necessary for optimal traction.

Fall: As activity slows, focus on preparation for the dormant season. Clean and store your equipment properly by removing any grass clippings or dirt. Check for any wear and replace parts if needed. It’s also wise to change the oil and fuel to protect internal components during the winter months.

Winter: While your device may not be in use, maintenance remains vital. Store it in a dry, sheltered location to prevent rust and damage from the elements. Regularly check for any signs of pests or corrosion, and consider running the engine occasionally to keep it in good working condition.

By implementing these seasonal tips, you can ensure that your equipment remains in excellent shape and ready for action when needed.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on outdoor equipment is essential for both the technician and the machine’s longevity. Adhering to basic guidelines minimizes risks and enhances efficiency throughout the process.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE). This includes gloves to safeguard your hands, goggles to protect your eyes from debris, and sturdy footwear to prevent injuries from heavy parts. Head protection is also advisable when working under or around machinery.

Work Environment Safety

Maintain a clean and organized workspace. Remove any obstacles that could lead to trips or falls. Ensure adequate lighting to enhance visibility, especially in tighter spaces. Disconnecting power sources before beginning any task is crucial to prevent accidental starts. Proper ventilation is also important when dealing with fumes or dust.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining optimal performance and longevity. Whether you are looking for specific elements or generic alternatives, understanding the best sources can save both time and money.

One of the most reliable places to begin your search is through authorized dealers. These vendors typically stock original parts and can provide expert advice tailored to your needs. Additionally, they often have access to the latest updates regarding availability and new products.

Online marketplaces are another excellent option, offering a wide range of parts from various manufacturers. Websites specializing in outdoor equipment can provide customer reviews, helping you make informed decisions based on others’ experiences. Make sure to check the seller’s ratings and return policies before making a purchase.

Local hardware stores may also carry essential components, especially common items. Building a rapport with staff can lead to valuable insights about special orders or upcoming sales. Furthermore, many community groups and forums focus on outdoor machinery, where members often share resources and recommendations for parts sourcing.

Lastly, consider salvage yards or recycling centers that specialize in equipment. These places can offer significant savings on used parts that are still in good condition, promoting sustainability while keeping your costs low.