Ducati 1098 Comprehensive Repair Guide

Maintaining a high-performance two-wheeler is crucial for ensuring its longevity and optimal functionality. This guide offers essential insights into the upkeep and troubleshooting processes, empowering riders to handle various challenges with confidence. A well-maintained machine not only enhances the riding experience but also contributes to safety on the road.

Understanding the intricacies of motorcycle systems can seem daunting. However, by breaking down complex procedures into manageable steps, enthusiasts can become adept at performing routine checks and repairs. The goal is to provide a practical resource that caters to both novices and experienced riders, enabling them to tackle maintenance tasks effectively.

From engine adjustments to electrical system diagnostics, this guide encompasses a wide range of topics relevant to motorcycle care. Each section is designed to be straightforward, offering valuable tips and detailed instructions to aid in resolving common issues. By following the outlined procedures, riders can ensure their machines remain in peak condition for countless journeys ahead.

Ducati 1098 Repair Manual Overview

This section provides an insightful summary of essential documentation for maintaining and servicing a high-performance motorcycle. Understanding the key elements of these resources can enhance the ownership experience and ensure optimal functionality.

Key Features of the Documentation

- Detailed instructions for routine maintenance tasks

- Specifications for various components

- Diagnostic troubleshooting guides for common issues

- Safety precautions to consider during servicing

Importance of Comprehensive Guides

Access to well-structured documentation is crucial for both novice and experienced enthusiasts. Such resources not only facilitate efficient repairs but also promote a deeper understanding of the vehicle’s mechanics.

- Improved reliability through regular maintenance.

- Enhanced performance by following manufacturer guidelines.

- Increased safety by identifying potential issues early.

Essential Tools for Maintenance

Proper upkeep of a high-performance machine requires a selection of indispensable instruments. Utilizing the right tools not only ensures effective servicing but also enhances the longevity of the vehicle. Below is a comprehensive list of essential implements for maintaining optimal performance.

- Socket Set: A diverse range of sockets is crucial for loosening and tightening various fasteners.

- Torque Wrench: Ensures that components are tightened to the manufacturer’s specifications, preventing damage.

- Multi-Tool: A versatile option for various tasks, including cutting and screwing.

- Chain Tool: Necessary for adjusting or replacing the drive chain.

- Oil Filter Wrench: Simplifies the removal and installation of the oil filter.

Each of these tools plays a vital role in the routine servicing and adjustment of the machine, making them essential for any enthusiast or professional mechanic.

Common Issues and Fixes

This section addresses frequent problems encountered in high-performance motorcycles and provides practical solutions to enhance reliability and performance. Understanding these common concerns can help owners maintain their machines more effectively.

- Electrical Issues:

- Weak battery: Ensure terminals are clean and connections are tight. Replace the battery if necessary.

- Faulty wiring: Inspect for frayed wires or loose connections that can cause intermittent failures.

- Cooling System Problems:

- Overheating: Check coolant levels and inspect the radiator for blockages.

- Leaking hoses: Examine hoses for cracks and replace them if leaks are detected.

- Transmission Difficulties:

- Difficulty shifting gears: Inspect the clutch cable for proper tension and adjust as needed.

- Strange noises: Listen for unusual sounds and check for proper lubrication in the transmission components.

- Brake Issues:

- Squeaking brakes: Clean brake pads and rotors; consider replacing pads if wear is excessive.

- Soft brake lever: Check fluid levels and bleed the brake lines if necessary.

By addressing these issues promptly, owners can ensure a safer and more enjoyable riding experience. Regular maintenance checks can help identify potential problems before they become serious.

Engine Disassembly Procedures

This section outlines the systematic approach to disassembling the power unit of a high-performance motorcycle. Proper techniques are essential to ensure that all components are carefully handled, maintaining their integrity for reassembly or inspection. Each step must be executed with precision to avoid damage to critical parts.

Preparation Steps

Before initiating the disassembly process, ensure that the workspace is clean and organized. Gather the necessary tools, such as wrenches, screwdrivers, and torque specifications, to facilitate a smooth operation. It is advisable to document the sequence of disassembly for accurate reassembly later.

Disassembly Steps

Follow these steps to effectively disassemble the engine:

| Step | Description |

|---|---|

| 1 | Remove external components, such as the air intake and exhaust systems, to access the engine casing. |

| 2 | Detach the engine from the frame, ensuring to label all connections for reference. |

| 3 | Unscrew the engine casing bolts, carefully lifting the casing to avoid damage to seals. |

| 4 | Remove the cylinder head and carefully document the positioning of all hardware. |

| 5 | Disassemble the piston assembly, taking care to avoid scratching the cylinder walls. |

| 6 | Inspect each component for wear or damage, ensuring they are ready for potential refurbishment. |

Following these procedures will facilitate an efficient disassembly process, laying the groundwork for effective maintenance and rebuilding efforts.

Transmission Troubleshooting Steps

This section provides a structured approach to diagnosing issues related to the gear shifting mechanism. Understanding the fundamental principles and potential problems can facilitate effective resolution and enhance performance.

Identifying Symptoms

Begin by observing any irregularities in gear engagement or shifting patterns. Common indicators include grinding noises, difficulty in changing gears, or unexpected slipping. Document these observations, as they will aid in pinpointing the root cause during further analysis.

Inspection and Testing

Once symptoms are noted, proceed with a thorough inspection of the transmission components. Check for signs of wear, damaged seals, or insufficient lubrication. Testing the clutch operation can also reveal issues affecting gear engagement. Utilizing appropriate diagnostic tools will provide additional insights into the system’s functionality.

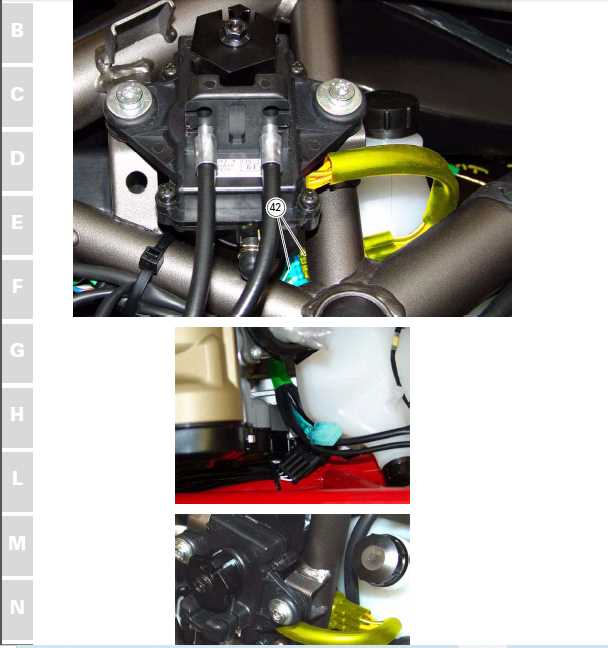

Electrical System Diagnostics

The examination of the electrical system is crucial for ensuring optimal performance and safety in high-performance machines. This process involves a systematic approach to identifying faults, verifying component functionality, and ensuring proper connections throughout the network.

Initial Steps: Begin with a visual inspection of all wiring and connectors. Look for signs of wear, corrosion, or loose connections that may affect the overall system integrity. It’s essential to address any visible issues before proceeding with more in-depth testing.

Diagnostic Tools: Utilize specialized equipment such as multimeters and oscilloscopes to assess voltage levels and signal integrity. These tools allow for precise measurement and analysis, enabling the identification of potential problems within the circuitry.

Common Issues: Electrical failures often stem from faulty sensors, relays, or wiring harnesses. Each component should be tested methodically to isolate the source of the malfunction. Pay close attention to components that exhibit irregular behavior during operation.

Conclusion: Regular diagnostics of the electrical system not only enhances reliability but also contributes to the overall longevity of the vehicle. Maintaining a proactive approach in troubleshooting can prevent minor issues from escalating into significant failures.

Suspension Adjustment Guidelines

Proper tuning of the suspension system is essential for enhancing the handling characteristics and overall performance of a motorcycle. Achieving the right balance ensures that the ride is both comfortable and responsive, allowing for better control in various conditions. This section outlines key considerations and methods for adjusting suspension components effectively.

Compression and Rebound Settings

Adjusting the compression and rebound settings is vital for optimizing the suspension’s response to different terrains. Compression damping affects how quickly the suspension compresses under load, while rebound damping controls the speed at which it returns to its original position. Start by setting both adjustments to the manufacturer’s baseline recommendations, then fine-tune based on personal preference and riding style.

Preload Adjustments

Preload adjustment plays a crucial role in determining the ride height and weight distribution of the motorcycle. By altering the preload, riders can influence how much the suspension compresses under their weight. To achieve a balanced setup, adjust the preload until the motorcycle sits at a suitable height, ensuring that both front and rear suspension are evenly loaded during operation.

Brake System Maintenance Tips

Proper upkeep of the braking mechanism is essential for ensuring optimal performance and safety. Regular checks and timely interventions can prevent issues that may compromise the efficiency of the stopping system. This section outlines key strategies for maintaining brake functionality effectively.

Regular Inspection

Conducting frequent inspections is crucial. Look for signs of wear and tear on the brake pads and rotors. Replacing worn components promptly will enhance braking efficiency and prevent further damage to the system.

Fluid Quality and Levels

Maintaining the correct fluid level and quality is vital for effective braking. Ensure that the brake fluid is free from contaminants and has not absorbed moisture. Flush the system and replace the fluid as recommended to maintain optimal performance.

Replacing Tires and Wheels

Maintaining optimal performance and safety on two wheels involves the regular replacement of rubber and rims. This process not only enhances the vehicle’s handling but also ensures that riders can navigate various terrains with confidence. Understanding the essential steps and tools required for this task is crucial for any enthusiast.

Preparation and Tools Needed

Before embarking on the task of changing rubber and rims, gather the necessary tools to streamline the process. The following items are recommended:

| Tool | Purpose |

|---|---|

| Jack | Lifts the vehicle for easy access to wheels |

| Torque Wrench | Ensures proper tightness of bolts |

| Tire Levers | Facilitates removal of old rubber |

| Air Compressor | Inflates new rubber |

| Spanner Wrench | Removes wheel bolts |

Steps for Changing Rubber and Rims

Follow these steps to effectively replace rubber and rims:

- Secure the vehicle on a flat surface and engage the parking brake.

- Use the jack to lift the vehicle, ensuring stability.

- Loosen the bolts with the spanner wrench and remove the wheel.

- Utilize tire levers to detach the old rubber from the rim.

- Position the new rubber onto the rim, ensuring proper alignment.

- Inflate the new rubber using the air compressor to the recommended pressure.

- Reattach the wheel to the vehicle, tightening bolts with the torque wrench.

- Lower the vehicle and perform a final check to ensure everything is secure.

Regularly monitoring and replacing rubber and rims not only extends the life of the vehicle but also enhances the overall riding experience.

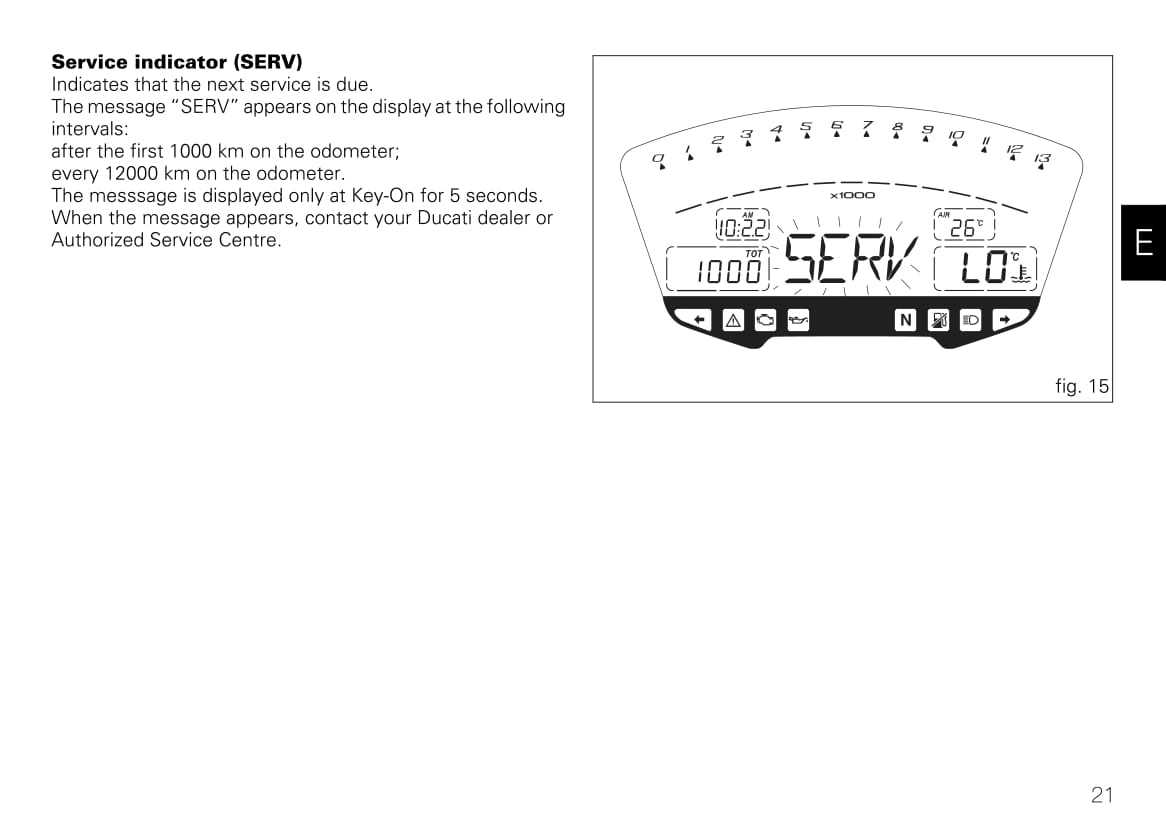

Regular Service Intervals Explained

Maintaining optimal performance and reliability of a high-performance motorcycle involves adhering to specific service timelines. Regular checks and maintenance tasks are crucial for ensuring the longevity of components and preventing unforeseen issues. Understanding the recommended intervals for these procedures helps riders keep their machines in peak condition.

Importance of Scheduled Maintenance

Scheduled upkeep not only enhances the lifespan of various parts but also improves safety and overall riding experience. By following these timelines, owners can address wear and tear before it escalates into significant problems. This proactive approach saves time and resources in the long run.

Typical Service Intervals

Service intervals often vary based on usage and environmental factors, but common recommendations include oil changes every 3,000 to 5,000 miles, brake fluid replacement annually, and inspections of tires, brakes, and chain frequently. Additionally, it is advisable to check electrical systems and coolant levels during routine maintenance. Adhering to these guidelines ensures that the motorcycle remains reliable and performs at its best.

Cleaning and Lubrication Techniques

Maintaining the performance and longevity of a high-performance motorcycle involves implementing effective cleaning and lubrication methods. Proper care not only enhances the aesthetic appeal but also ensures that all mechanical components function smoothly and efficiently.

Regular cleaning helps to remove dirt, grime, and debris that can accumulate over time, potentially affecting the performance of various parts. Additionally, appropriate lubrication is crucial for minimizing friction and wear on moving components, thereby prolonging their lifespan.

| Task | Recommended Frequency | Suggested Products |

|---|---|---|

| Chain Cleaning | Every 500 km | Chain cleaner spray |

| Chain Lubrication | After cleaning | High-quality chain lube |

| Bodywork Cleaning | As needed | Motorcycle wash solution |

| Brake Component Inspection | Every 1,000 km | Brake cleaner |

By adhering to a regular schedule for these essential maintenance tasks, riders can ensure optimal performance and reliability, making each journey more enjoyable.

Upgrading Performance Components

Enhancing the efficiency and power of your motorcycle can significantly improve your riding experience. By focusing on key components, you can elevate performance levels, responsiveness, and overall handling. This section outlines essential upgrades that can lead to a more thrilling ride.

Key Areas for Enhancement

- Exhaust System: Upgrading to a high-performance exhaust can reduce weight and improve airflow, resulting in better power output.

- Fuel Management: Optimizing the fuel delivery system ensures that the engine receives the right mix of air and fuel for maximum performance.

- Suspension: Enhanced suspension components improve handling and stability, allowing for better control during aggressive riding.

- Braking System: Upgrading brakes with high-quality calipers and rotors enhances stopping power and safety.

Considerations for Upgrades

- Compatibility: Ensure that any components you choose are compatible with your motorcycle’s model.

- Installation: Professional installation may be necessary for certain upgrades to ensure proper function and safety.

- Budget: Set a budget for your enhancements, as costs can vary widely based on the components selected.

By strategically upgrading performance components, you can create a more exhilarating and responsive riding machine, tailored to your personal preferences and style.

Safety Precautions During Repairs

Ensuring a secure environment is crucial when undertaking maintenance tasks. Adhering to safety measures not only protects the individual performing the work but also preserves the integrity of the machinery involved. By following specific guidelines, one can minimize risks and enhance the overall efficiency of the process.

General Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the workspace is clean and organized to avoid accidents and distractions.

- Disconnect the power source before beginning any disassembly or maintenance tasks.

Handling Tools and Equipment

- Use the right tools for the job to prevent damage and ensure safety.

- Regularly inspect tools for wear or damage and replace them as needed.

- Store tools safely when not in use to prevent injuries.