Ultimate Guide to Echo Chainsaw Repair

Maintaining outdoor power tools is essential for ensuring their longevity and performance. This section delves into the intricacies of caring for these devices, providing valuable insights and techniques that every user should know. A well-maintained tool not only operates more efficiently but also enhances the safety of its use.

Users often encounter various challenges that can affect functionality. Understanding the common issues and their solutions can significantly improve your experience. This guide offers step-by-step instructions and helpful tips, empowering you to address problems with confidence.

Regular upkeep is crucial in preventing future malfunctions. By following the recommended practices, you can keep your equipment in optimal condition. This knowledge not only saves time and money but also ensures that your tools remain reliable for all your outdoor tasks.

This section provides a detailed approach to addressing common issues that may arise with your equipment. By following these organized steps, you can effectively diagnose and fix problems, ensuring optimal performance and longevity.

Initial Assessment

Before diving into the fixing process, it’s important to evaluate the situation thoroughly. Here are some key points to consider:

- Check for any visible damage or wear.

- Ensure that all components are securely attached.

- Examine the power source for any irregularities.

Step-by-Step Process

Follow these steps to address the identified issues:

- Disconnect the power supply to ensure safety.

- Carefully remove any obstructing parts.

- Inspect the internal mechanisms for dirt or debris.

- Clean the components using appropriate tools.

- Replace any worn-out parts with new ones.

- Reassemble the unit carefully, ensuring all parts are in place.

- Reconnect the power and conduct a test to verify functionality.

Tools Needed for Repairs

Proper maintenance of equipment requires a selection of essential instruments to ensure efficient and effective work. Having the right tools at hand not only simplifies the process but also enhances the quality of the repairs. Below is a list of commonly needed items that can aid in restoring functionality to your equipment.

Basic Hand Tools

Start with fundamental hand tools such as screwdrivers, pliers, and wrenches. These items are crucial for disassembling parts and making necessary adjustments. A set of various sizes will allow you to tackle different components with ease.

Specialized Equipment

In addition to basic tools, consider investing in specialized equipment. A torque wrench, for example, helps in applying the correct amount of force when tightening bolts, preventing damage. Cleaning brushes and lubricants are also important for maintaining optimal performance.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent accidents and injuries. Adopting proper precautions helps create a secure environment, allowing for effective troubleshooting and servicing of equipment. It is crucial to remain vigilant and prepared for any potential hazards during the process.

Essential Gear and Equipment

Before starting any maintenance work, make sure to equip yourself with appropriate protective gear. This includes gloves, goggles, and sturdy footwear. Protective clothing acts as a barrier against potential injuries from sharp components or debris. Additionally, having a well-lit workspace enhances visibility, reducing the risk of mishaps.

Work Area Organization

Maintaining an organized workspace is vital for safety. Clear away any clutter and ensure that tools and materials are within easy reach. An orderly environment minimizes distractions and the likelihood of accidents. Always double-check that the equipment is powered off and disconnected from any power source before beginning your tasks.

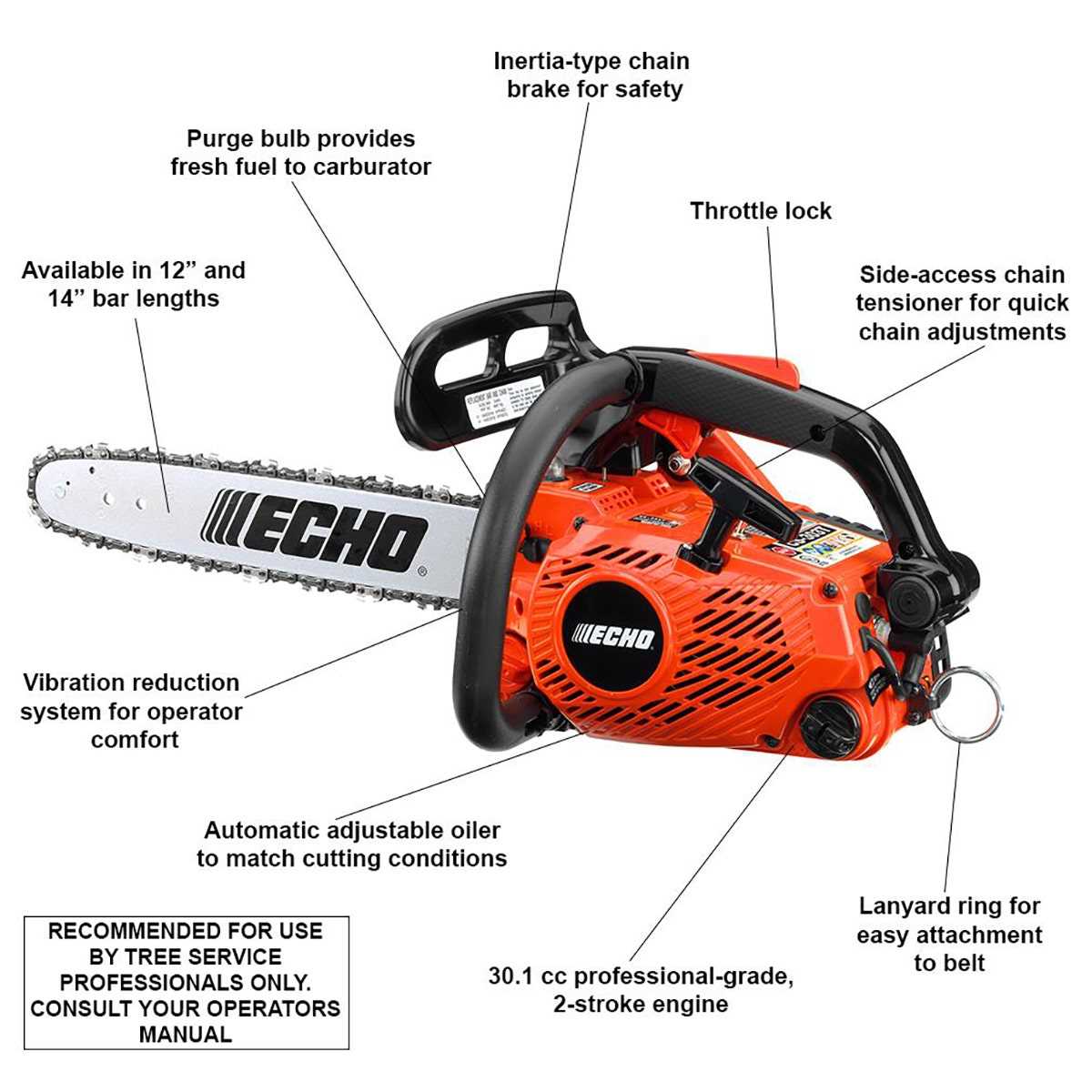

Replacing Chains and Bars

Maintaining optimal performance of cutting tools often involves replacing essential components such as the cutting element and guide. This process ensures efficiency and safety during operation, allowing users to achieve the best results.

To successfully change these parts, follow these straightforward steps:

| Step | Action |

|---|---|

| 1 | Disconnect the power source to ensure safety. |

| 2 | Remove the existing cutting element by loosening the tensioning mechanism. |

| 3 | Carefully detach the guide from its mount. |

| 4 | Install the new guide and secure it firmly. |

| 5 | Attach the new cutting element, ensuring proper alignment. |

| 6 | Tighten the tension to the manufacturer’s specifications. |

| 7 | Reconnect the power source and test the assembly. |

Regularly replacing these components will not only prolong the life of the equipment but also enhance performance during use. Always refer to specific guidelines for best practices related to your tool.

Fuel System Troubleshooting

Addressing issues within the fuel delivery system is essential for optimal performance. Common problems can lead to poor starting, irregular operation, or stalling. Identifying the source of these issues involves examining various components such as the fuel lines, filters, and carburetors.

Common Symptoms

Symptoms of fuel-related problems may include difficulty starting, inconsistent power during operation, or excessive smoke. Observing these signs can help pinpoint the underlying issue.

Diagnostic Steps

To troubleshoot effectively, start by inspecting fuel lines for cracks or blockages. Next, check the fuel filter for clogs, and ensure the carburetor is clean and properly adjusted. Replacing old fuel with fresh, high-quality gasoline can also resolve many issues.

Electrical Components Inspection

Regular examination of electrical parts is crucial for maintaining optimal performance and safety in your equipment. By identifying issues early, you can prevent more significant problems and ensure reliable operation.

Key Components to Check

- Batteries

- Wiring connections

- Switches

- Fuses

- Motor terminals

Inspection Steps

- Disconnect the power source to ensure safety.

- Visually inspect all wiring for signs of wear or damage.

- Check connections for tightness and corrosion.

- Test switches for functionality using a multimeter.

- Examine fuses for continuity and replace if necessary.

- Assess the condition of the battery and replace if performance is weak.

By following these steps, you can maintain the electrical integrity of your equipment, ensuring longevity and efficient performance.

Adjusting Chain Tension

Proper tension of the cutting component is crucial for optimal performance and safety. If the tension is too loose, it can cause the element to derail, while excessive tightness may lead to unnecessary wear or damage.

To achieve the correct tension, first, ensure the device is turned off and the power source is disconnected. Locate the adjustment mechanism, which typically consists of a tensioning screw. Using the appropriate tool, gradually turn the screw to increase or decrease the tension. It is essential to check the tightness regularly, ensuring that the component moves freely without excessive slack.

Note: Always refer to the manufacturer’s guidelines for specific recommendations regarding tension settings to maintain equipment longevity.

Cleaning Air Filters

Regular maintenance of air filtration systems is essential for optimal performance of outdoor power tools. Keeping these components clean ensures efficient airflow and prolongs the lifespan of the equipment.

Importance of Clean Filters

Dirty filters can restrict airflow, leading to poor engine performance and increased fuel consumption. By maintaining clean filters, you enhance the overall functionality and reliability of your equipment.

Steps to Clean Air Filters

- Remove the filter from the housing.

- Inspect the filter for any visible damage or excessive dirt.

- If the filter is washable, rinse it with warm water and a mild detergent.

- Allow the filter to air dry completely before reinstallation.

- If the filter is non-washable, consider replacing it with a new one.

Regularly checking and cleaning air filters can lead to significant improvements in performance and efficiency. Make this part of your routine maintenance to ensure your equipment operates smoothly.

Seasonal Maintenance Checklist

Regular upkeep of your outdoor cutting tool is essential for optimal performance and longevity. A well-maintained unit ensures safety and efficiency, allowing you to tackle your tasks with confidence. Below is a comprehensive checklist to guide you through seasonal maintenance.

| Task | Frequency | Description |

|---|---|---|

| Inspect the blade | Every use | Check for dullness or damage, and sharpen or replace as needed. |

| Clean air filter | Monthly | Remove and clean the filter to ensure proper airflow and engine efficiency. |

| Check fuel system | Every season | Inspect fuel lines for cracks and replace old fuel to prevent engine issues. |

| Lubricate moving parts | Every season | Apply appropriate lubricant to all moving components to reduce friction. |

| Inspect safety features | Every use | Ensure that all safety guards and switches are functional and intact. |

When to Seek Professional Help

Sometimes, tackling issues on your own can lead to frustration or further complications. Recognizing when to call in an expert can save time and ensure safety.

Signs That Indicate Professional Assistance is Needed

- Unusual noises during operation

- Persistent malfunctions despite troubleshooting

- Inability to resolve safety concerns

- Severe wear or damage to components

- Unfamiliarity with advanced techniques

Benefits of Hiring a Professional

- Expertise in diagnosing complex problems

- Access to specialized tools and equipment

- Ensured compliance with safety standards

- Potential for a longer lifespan of the equipment