Comprehensive Guide to Echo SRM-210 Repairs

Ensuring the longevity and optimal performance of your gardening tools is essential for achieving the best results in your outdoor projects. This section focuses on the key aspects of maintaining a popular model used by many enthusiasts. From understanding the intricacies of its components to addressing common issues, the information provided will empower users to enhance their experience.

Proper upkeep not only prolongs the life of your equipment but also improves its efficiency during use. Familiarizing yourself with the intricacies of this particular device can prevent minor problems from escalating and becoming major setbacks. The insights shared here will guide you through effective strategies for care and troubleshooting, enabling you to keep your tool in peak condition.

By equipping yourself with the knowledge contained within, you’ll gain confidence in handling various maintenance tasks. Whether it’s routine inspections or resolving unexpected malfunctions, the guidance provided will serve as a valuable resource. This proactive approach to equipment care will ultimately lead to a more satisfying gardening experience.

Understanding the Echo SRM-210

This section delves into the intricacies of a specific outdoor power tool, focusing on its design, features, and functionality. Understanding the mechanisms and components that contribute to its performance is essential for both users and those interested in maintenance. This tool is known for its reliability and efficiency, making it a popular choice among landscapers and gardeners.

Key Features and Components

At the core of this equipment is its powerful engine, designed to handle various tasks with ease. The lightweight construction enhances maneuverability, while the ergonomic handle ensures comfort during extended use. The design includes several components that work together to optimize performance, including:

| Component | Function |

|---|---|

| Engine | Powers the tool and provides necessary torque |

| Fuel System | Ensures efficient fuel delivery for optimal performance |

| Cutting Head | Facilitates trimming and cutting various types of vegetation |

| Safety Features | Enhances user protection during operation |

Maintenance Considerations

Regular upkeep is crucial to maintain the tool’s efficiency and longevity. This involves checking components, cleaning filters, and ensuring the fuel system operates smoothly. Understanding these maintenance aspects will help users extend the life of their equipment and ensure reliable performance in the field.

Common Issues and Troubleshooting Tips

When operating a string trimmer, users may encounter various challenges that can hinder performance. Understanding these common problems and their solutions can significantly enhance the overall experience and efficiency of the equipment.

Frequent Problems

- Engine Not Starting: This is one of the most prevalent issues faced by users. It may stem from fuel problems, spark plug issues, or a clogged air filter.

- Inconsistent Power: Fluctuating power output can lead to inefficiency and frustration, often caused by fuel blockage or a dirty carburetor.

- Excessive Vibration: Unusual vibrations can indicate loose components or damage to the cutting head.

- Line Feed Problems: If the cutting line fails to advance properly, it may be due to a faulty spool or incorrect winding.

Troubleshooting Solutions

- For starting issues, ensure fresh fuel is used, check the spark plug for wear, and clean or replace the air filter.

- If experiencing inconsistent power, inspect the fuel system for clogs and clean the carburetor as needed.

- To address excessive vibration, tighten all screws and check the cutting head for damage or imbalance.

- For line feed issues, rewind the spool correctly and replace it if damaged.

Essential Tools for Repairs

When it comes to fixing outdoor power equipment, having the right tools is crucial for effective maintenance and troubleshooting. A well-equipped toolkit not only simplifies the process but also ensures that tasks are completed efficiently and safely. Understanding which instruments are necessary can greatly enhance the quality of your work.

Basic Hand Tools

Every technician should start with a selection of fundamental hand tools. Items such as screwdrivers, wrenches, and pliers are indispensable. Screwdrivers come in various types and sizes to accommodate different screws, while wrenches are essential for loosening or tightening bolts. Having a variety of pliers allows for greater versatility when handling components of various shapes and sizes.

Specialized Equipment

In addition to basic hand tools, certain specialized equipment can significantly aid in maintenance tasks. For example, a torque wrench is vital for ensuring that fasteners are tightened to the correct specifications. A multimeter can be invaluable for diagnosing electrical issues, allowing for accurate readings of voltage, current, and resistance. Investing in these specialized tools will enhance your ability to tackle a range of maintenance challenges effectively.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your garden equipment. Regular upkeep is essential to prevent malfunctions and extend the life of your device.

Follow these essential steps for effective maintenance:

- Clean the Exterior

- Use a soft brush or cloth to remove dirt and debris.

- Check for any signs of wear or damage on the casing.

cssCopy code

- Examine the blades for sharpness and integrity.

- Replace any damaged or dull blades to maintain efficiency.

- Ensure the fuel tank is filled with fresh fuel.

- Verify that the oil level is adequate and change it if necessary.

- Remove the air filter and clean it thoroughly.

- Replace it if it shows signs of damage or excessive dirt.

- Check the pull cord for any fraying or damage.

- Ensure the starter engages properly during operation.

By following these guidelines regularly, you can maintain your equipment in peak condition, ready for use whenever you need it.

Replacing the Cutting Head

Swapping out the cutting head is a straightforward process that can significantly enhance the performance of your equipment. Regular maintenance ensures optimal functionality, allowing for efficient trimming and edging tasks. This guide outlines the necessary steps for a smooth replacement.

Required Tools and Materials

- New cutting head

- Screwdriver

- Protective gloves

- Safety goggles

Step-by-Step Instructions

- Ensure the device is turned off and disconnected from any power source.

- Wear protective gear to safeguard against any debris.

- Locate the locking mechanism on the cutting head.

- Use the screwdriver to loosen the screws holding the head in place.

- Carefully remove the old cutting head from the shaft.

- Position the new cutting head onto the shaft, ensuring a secure fit.

- Tighten the screws firmly to secure the new head.

After replacing the cutting head, conduct a brief test run to confirm that everything is functioning correctly. Regularly check the head for wear and replace as needed to maintain top performance.

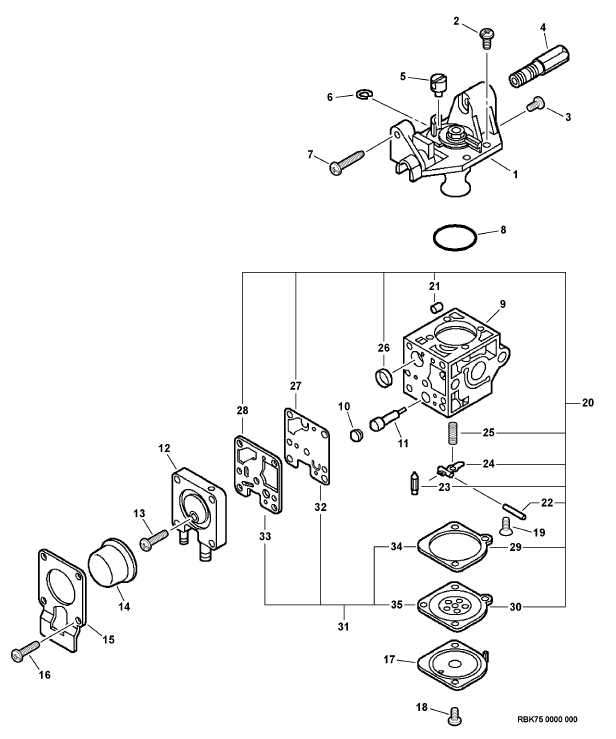

Fuel System Inspection and Fixes

Maintaining an optimal fuel system is essential for the efficient operation of any outdoor power equipment. Regular inspection and timely repairs can prevent performance issues and extend the lifespan of the machine. This section will guide you through essential steps for examining and resolving common fuel-related problems.

Start by checking the following components:

- Fuel Lines: Look for cracks, leaks, or blockages. Damaged lines can lead to fuel loss and performance issues.

- Fuel Filter: A clogged filter can restrict fuel flow. Replace it if it appears dirty or worn.

- Fuel Tank: Inspect the tank for any debris or contamination. Clean it if necessary to ensure a clear fuel supply.

- Carburetor: Check for clogs or improper adjustments. Cleaning and tuning may be needed to restore optimal function.

When diagnosing fuel issues, consider the following fixes:

- Replace any damaged fuel lines to ensure a proper flow.

- Change the fuel filter if it is dirty, as this will improve fuel delivery.

- Flush and clean the fuel tank to eliminate contaminants.

- Service the carburetor by cleaning jets and adjusting settings for optimal performance.

By following these inspection and repair steps, you can enhance the reliability of your equipment and ensure it operates at peak performance.

Electrical Components Overview

This section provides a comprehensive look at the vital electrical elements that play a crucial role in the functionality of outdoor power tools. Understanding these components is essential for proper maintenance and troubleshooting.

At the core of any electrical system are the essential parts that ensure efficient operation. Each component serves a specific function, contributing to the overall performance and reliability of the equipment.

| Component | Function |

|---|---|

| Motor | Converts electrical energy into mechanical energy, driving the tool. |

| Switch | Controls the flow of electricity, allowing the user to start and stop the device. |

| Battery | Stores electrical energy, providing power when the device is not plugged in. |

| Wiring | Conducts electricity between components, ensuring proper connections and functionality. |

| Fuse | Protects the circuit from overload by breaking the connection if excessive current flows. |

By familiarizing oneself with these components, users can enhance their understanding of the equipment, leading to better care and improved longevity.

Blade Sharpening Techniques Explained

Maintaining the effectiveness of cutting tools is essential for optimal performance. Proper sharpening methods not only enhance the tool’s efficiency but also prolong its lifespan. Understanding various techniques can help achieve a precise edge, making tasks easier and more effective.

Using a Sharpening Stone: One of the most traditional methods involves a sharpening stone. By selecting the right grit, you can gradually refine the blade’s edge. Begin by holding the tool at the correct angle, usually around 20 degrees, and move the blade across the stone in a sweeping motion. This technique allows for controlled sharpening and can produce a razor-sharp edge.

File Sharpening: Another effective method is using a file. This approach is particularly beneficial for tools that have developed nicks or are significantly dull. Choose a single-cut file for a finer finish. Position the file against the edge and push it away from you, applying consistent pressure. This method not only sharpens but can also reshape the blade as needed.

Electric Sharpeners: For those seeking efficiency, electric sharpeners provide a quick solution. These tools often come with preset angles and can rapidly restore a dull blade. However, it’s crucial to follow the manufacturer’s guidelines to avoid overheating or damaging the cutting edge during the process.

Honing: After sharpening, honing the blade ensures that the edge is aligned perfectly. Using a honing rod, maintain a consistent angle and glide the blade along the rod. This step removes any small burrs and refines the edge, resulting in a cleaner cut during use.

Safety Precautions During Repair

When undertaking maintenance on any equipment, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions can ensure a smooth and secure working environment, allowing for effective troubleshooting and resolution of issues.

Before beginning any task, always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles. These items help protect against debris and potential hazards that may arise during the process. Additionally, ensure the work area is well-lit and organized to minimize risks.

Always disconnect the power source before attempting any adjustments or inspections. This simple step can prevent electric shock or unintended operation of the device. Familiarize yourself with the specific components and their functions to avoid confusion while working.

Lastly, keep a first-aid kit nearby and know the emergency procedures in case of an accident. Being prepared can significantly reduce the severity of any mishaps that may occur during maintenance activities.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often be a straightforward process when you know where to look. With the right strategies, you can ensure a seamless experience in sourcing what you need to maintain your device’s functionality.

Online Retailers: One of the most efficient ways to find the necessary parts is through various online marketplaces. These platforms often provide a vast selection of items, making it easy to compare prices and availability. Look for reputable sellers with positive reviews to ensure quality.

Local Hardware Stores: Don’t overlook the value of local shops. Many hardware stores stock a range of parts and can order specific items if they’re not available on the shelves. Building a relationship with staff can also yield helpful advice and recommendations.

Specialized Websites: There are numerous websites dedicated to specific equipment types. These sites typically offer an extensive inventory and may feature forums where users share their experiences and tips on sourcing components. Engaging with these communities can provide insights into which parts work best.

Manufacturer Support: If you are having trouble finding what you need, reaching out to the manufacturer directly can be beneficial. They can guide you on where to purchase authentic components, ensuring compatibility and reliability.

By utilizing these resources, you can simplify the process of finding the parts essential for keeping your equipment in optimal condition.

Tips for Longevity and Performance

Maintaining optimal functionality and extending the lifespan of your outdoor equipment requires attention to detail and proactive care. By following a few simple practices, you can ensure that your tool operates at peak efficiency and remains in good condition for years to come.

Regular Maintenance Practices

Consistent upkeep is crucial. Clean the air filter regularly to prevent dirt buildup, which can hinder performance. Additionally, checking and replacing the spark plug when necessary can significantly enhance the engine’s efficiency. Keeping the cutting head sharp ensures clean cuts, reducing strain on the motor and enhancing overall effectiveness.

Proper Storage Techniques

When not in use, store the equipment in a dry and sheltered location. This protects it from moisture and harsh weather conditions that can cause corrosion or other damage. Emptying the fuel tank before long periods of inactivity can prevent fuel degradation, ensuring reliable starts when you need it again.