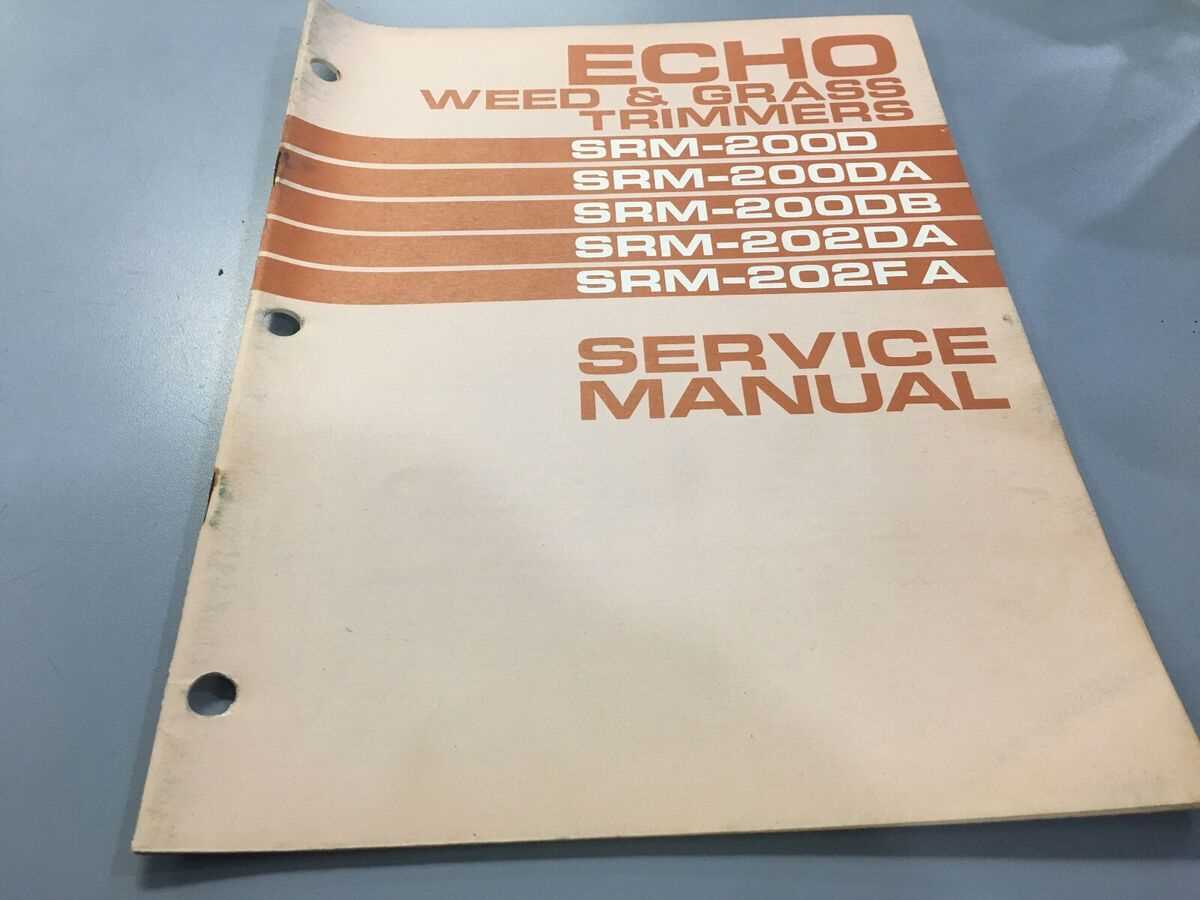

Comprehensive Guide to Repairing Your Echo String Trimmer

For enthusiasts of gardening and landscaping, maintaining equipment is crucial for optimal performance and longevity. Understanding how to troubleshoot and restore these devices can save time and money, ensuring that your tools remain in top shape throughout the seasons. This guide aims to provide essential insights into the upkeep of your gardening apparatus.

Each piece of equipment requires specific knowledge to address common issues effectively. Whether you encounter difficulty with the ignition system or notice diminished cutting efficiency, being equipped with the right techniques can make a significant difference. Proper maintenance not only enhances functionality but also prevents potential breakdowns, allowing for a seamless gardening experience.

Through careful examination and step-by-step procedures, this resource will empower you to take charge of your tools. With attention to detail and a systematic approach, you will be able to diagnose problems, replace worn parts, and keep your gardening gear running smoothly. Dive into the world of maintenance, and unlock the full potential of your outdoor tools.

Understanding Echo String Trimmers

When it comes to maintaining your outdoor space, having the right equipment is essential. This section will delve into the intricacies of a specific type of garden tool designed for precise cutting and edging. These devices are favored by homeowners and professionals alike for their efficiency and versatility.

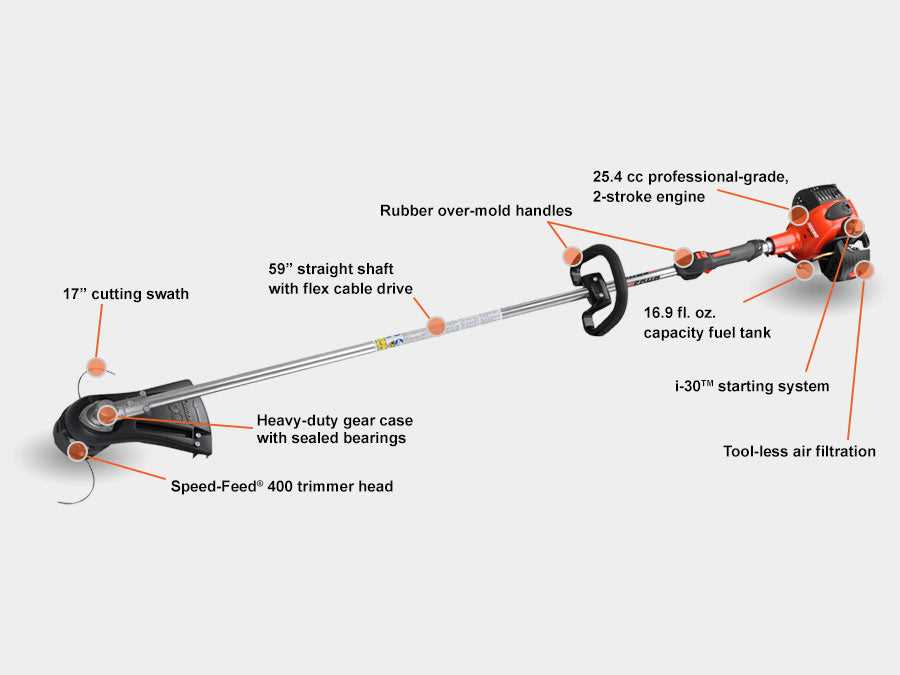

Key features that define this category of equipment include:

- Lightweight design for easy handling

- Adjustable cutting lengths to suit various tasks

- Powerful engines that provide consistent performance

- Interchangeable accessories for enhanced functionality

Understanding how to operate and maintain these tools is crucial for achieving optimal results. Here are some common components to be aware of:

- Power Source: Various options, including gas and electric, each with unique benefits.

- Cutting Mechanism: Different types of cutting heads can be used, depending on the desired finish.

- Handle and Shaft Design: Ergonomics play a significant role in user comfort and control.

In conclusion, familiarizing yourself with the features and components of this essential gardening tool will enhance your experience and effectiveness in maintaining a well-groomed yard.

Common Issues with Echo Trimmers

Various challenges can arise with outdoor maintenance tools, impacting their performance and efficiency. Understanding these issues is essential for maintaining optimal functionality and prolonging the life of the equipment. Below are some frequently encountered problems and their potential solutions.

Frequent Problems

- Difficulty Starting

- Inconsistent Cutting Performance

- Overheating of the Engine

- Excessive Vibration

- Fuel Leaks

Possible Causes and Solutions

- Difficulty Starting: This can result from stale fuel or a clogged air filter. Check the fuel quality and replace the filter if necessary.

- Inconsistent Cutting Performance: Often due to dull blades or incorrect line length. Sharpen the blades and ensure proper line installation.

- Overheating of the Engine: This may occur from prolonged use without breaks. Allow the machine to cool down and ensure proper ventilation.

- Excessive Vibration: Usually caused by unbalanced components. Inspect and tighten all parts to reduce vibrations.

- Fuel Leaks: Check for damaged hoses or seals. Replace any worn-out parts to prevent leaks.

Essential Tools for Repairing Trimmers

Maintaining outdoor cutting equipment requires a specific set of instruments to ensure efficiency and longevity. Having the right tools on hand not only simplifies the process but also enhances the quality of the work performed. This section highlights the indispensable implements needed for effective servicing and upkeep of these machines.

First and foremost, a reliable set of wrenches and screwdrivers is crucial. These allow for easy disassembly and reassembly of various components, ensuring that each part can be accessed without hassle. Additionally, a torque wrench is important for adhering to manufacturer specifications, preventing over-tightening that could lead to damage.

Another key item is a multi-tool, which can handle various tasks, from cutting to scraping, making it versatile for different repair scenarios. Safety equipment, such as gloves and goggles, should also be prioritized to protect oneself during maintenance procedures.

Moreover, specialized tools like fuel line pliers and carburetor adjustment tools can be particularly useful for dealing with engine-related issues. Keeping a comprehensive toolkit will ultimately streamline the process and enhance the overall functionality of the equipment.

Lastly, having a clean workspace equipped with a sturdy workbench will facilitate effective repairs, allowing for better organization of parts and tools. By ensuring that all essential instruments are available, one can maintain the equipment’s performance and extend its operational life.

Step-by-Step Guide to Maintenance

Regular upkeep of your gardening tool is essential for ensuring optimal performance and longevity. Following a systematic approach to care will help prevent issues and keep the equipment running smoothly throughout the season.

-

Inspection: Begin by examining the equipment for any visible damage or wear. Check components such as the cutting head, handle, and motor casing.

-

Cleaning: Remove any debris and grass clippings from the exterior. Use a soft brush or cloth to clean the surfaces, paying special attention to air vents and cooling fins.

-

Lubrication: Apply appropriate lubricants to moving parts to ensure smooth operation. Refer to your manufacturer’s recommendations for suitable products.

-

Line Replacement: If the cutting line is worn or damaged, replace it with new material. Follow the manufacturer’s instructions for the correct length and installation method.

-

Fuel Check: Inspect the fuel tank and ensure it is filled with the proper mixture. Empty and refill if necessary, following the specified ratios.

-

Electrical Components: For electric models, check the power cord and connections for fraying or damage. Ensure all electrical components are functioning correctly.

-

Final Test: Once maintenance is complete, conduct a test run to verify that everything operates correctly. Listen for unusual noises and observe performance.

By adhering to this maintenance guide, you can enhance the efficiency of your gardening tool and extend its lifespan, ensuring it remains a reliable companion for your outdoor tasks.

Replacing the String and Spool

Maintaining optimal performance of your gardening tool involves regular replacement of the line and spool. This process ensures that your equipment runs efficiently, allowing for effective cutting and trimming. Understanding how to carry out this task can significantly enhance your gardening experience.

Follow these steps to successfully replace the line and spool:

- Gather Required Tools:

- New line

- Replacement spool

- Scissors or cutting tool

- Protective gloves

- Power Down: Ensure the device is completely turned off and unplugged to avoid accidents.

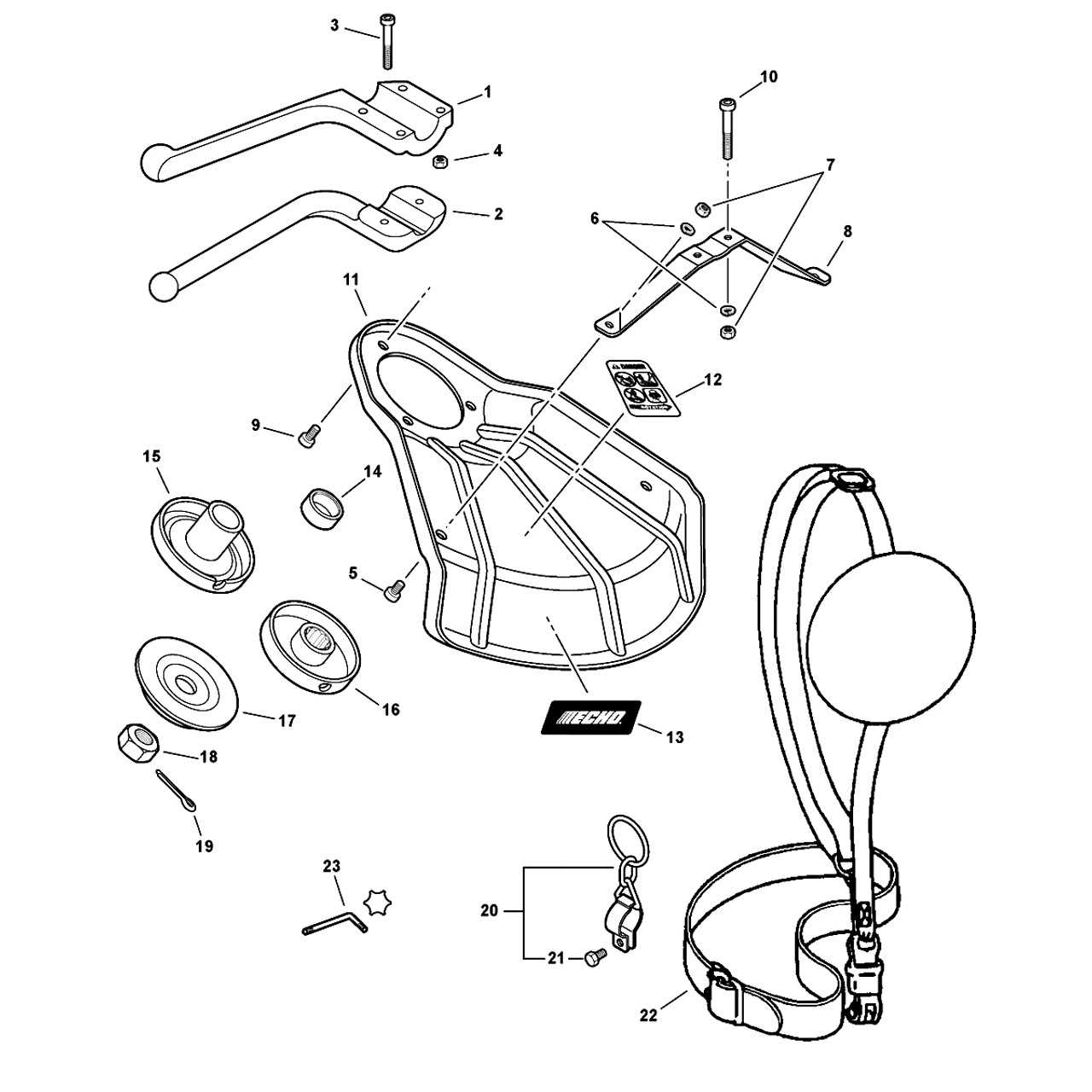

- Remove the Spool: Locate the release tabs on the spool casing. Press these tabs to detach the spool from the main body.

- Empty the Old Line: Take out any remaining line from the spool. If it is tangled, gently unwind it.

- Prepare the New Line: Cut a length of the new line according to the manufacturer’s specifications, typically around 10 to 15 feet.

- Wind the New Line: Insert one end of the line into the spool and begin to wind it in the designated direction, ensuring it is evenly distributed.

- Secure the Line: Once the line is wound, leave a few inches free to prevent it from slipping off during use.

- Reattach the Spool: Align the spool with the body of the tool and press it firmly until it clicks into place.

- Test the Setup: Power on the device briefly to ensure the line extends properly and functions as intended.

Regularly replacing the line and spool will help maintain the efficiency and longevity of your gardening equipment, allowing you to tackle your yard work with ease.

Diagnosing Engine Problems

Identifying issues with small engines can be a challenging yet crucial task for maintaining optimal performance. A systematic approach helps in pinpointing the root cause of malfunctioning. By observing specific symptoms and conducting a series of checks, you can effectively determine the underlying problems.

1. Check for Fuel Issues: Start by examining the fuel system. Stale or contaminated fuel can lead to poor engine performance. Ensure that the fuel is fresh and free from debris. Inspect the fuel lines for cracks or leaks, as these can hinder fuel delivery.

2. Examine the Air Filter: A clogged air filter restricts airflow, affecting combustion efficiency. Remove the filter and clean or replace it if necessary. Regular maintenance of the air filter is essential for ensuring adequate airflow.

3. Inspect the Spark Plug: The spark plug is vital for ignition. Check for wear, carbon buildup, or damage. A faulty spark plug can cause misfiring or starting difficulties. Replace it if you notice any issues.

4. Listen for Unusual Noises: Pay attention to the sounds the engine makes during operation. Unusual noises may indicate internal problems such as worn bearings or damaged components. Documenting these sounds can help in diagnosing the issue accurately.

5. Monitor Engine Performance: Take note of any changes in performance, such as loss of power or irregular idling. These symptoms can be indicative of deeper issues. Conducting a thorough evaluation will provide insights into necessary interventions.

By following these steps and maintaining an organized diagnostic approach, you can effectively address engine problems and restore functionality. Regular upkeep and timely interventions are key to prolonging the lifespan of your equipment.

Cleaning the Air Filter Effectively

Maintaining optimal airflow is crucial for the efficient performance of any outdoor power equipment. A clean air filter ensures that the engine receives the right amount of air, which can enhance fuel efficiency and prolong the lifespan of the machine. Regular cleaning is essential to prevent dirt and debris buildup, which can lead to performance issues.

Tools and Materials Needed

- Soft brush or cloth

- Warm, soapy water

- Clean water for rinsing

- Compressed air (optional)

- Protective gloves

Step-by-Step Cleaning Process

- Ensure the equipment is turned off and cool to the touch.

- Remove the air filter cover carefully to access the filter.

- Gently tap the filter to dislodge loose dirt. For stubborn particles, use a soft brush or cloth.

- Wash the filter in warm, soapy water. Rinse thoroughly to remove all soap residues.

- Allow the filter to air dry completely before reinstalling.

- If available, use compressed air to blow out any remaining debris from the filter.

Regular inspection and cleaning of the air filter can significantly improve performance and reliability. Follow these steps to keep your equipment running smoothly and efficiently.

Checking and Replacing Spark Plugs

Ensuring optimal performance of your outdoor equipment often involves examining and swapping out certain components. One critical part of this maintenance is the spark plug, which plays a vital role in the ignition process. Regular checks can prevent starting issues and promote efficiency, making it essential to understand how to evaluate and replace this component effectively.

Identifying Issues with Spark Plugs

Before replacing the spark plug, it’s important to recognize signs that indicate it may need attention. Common symptoms include difficulty starting the engine, irregular idling, and reduced power during operation. Inspecting the spark plug can reveal vital information about the engine’s condition.

Steps for Replacement

Follow these steps to ensure a proper replacement:

| Step | Description |

|---|---|

| 1 | Ensure the equipment is turned off and cool to avoid burns. |

| 2 | Remove the spark plug wire by grasping the boot and pulling it straight off. |

| 3 | Use a spark plug socket to unscrew the old plug from the engine. |

| 4 | Inspect the old spark plug for wear or damage, such as carbon buildup or cracks. |

| 5 | Install the new spark plug by threading it in by hand, then tightening it with the socket. |

| 6 | Reconnect the spark plug wire securely. |

Regular maintenance of the spark plug not only enhances performance but also extends the lifespan of your equipment. Following these guidelines can help ensure smooth operation and prevent unexpected issues during use.

Fuel System Troubleshooting Tips

Ensuring optimal performance of small engines often requires attention to their fuel systems. Issues within this area can lead to various operational problems, making it essential to identify and resolve them efficiently. Understanding common signs of fuel-related difficulties is crucial for maintaining equipment longevity.

Check Fuel Quality: Always start by inspecting the fuel itself. Stale or contaminated fuel can cause starting issues and poor engine performance. If the fuel has been sitting for an extended period, consider draining the tank and replacing it with fresh gasoline.

Inspect Fuel Lines: Look for any signs of wear, cracks, or blockages in the fuel lines. Damaged lines can restrict fuel flow, leading to inefficient operation. Ensure all connections are secure and replace any damaged components as necessary.

Examine the Filter: A clogged fuel filter can hinder performance by restricting fuel flow. Regularly check and replace the filter to ensure the engine receives a steady supply of fuel. This simple step can significantly improve efficiency.

Test the Fuel Pump: If the system has a pump, it should be checked for proper function. Listen for unusual noises or signs of leaks. A malfunctioning pump may need to be replaced to restore proper fuel delivery.

Verify Fuel Mixture: For two-stroke engines, an incorrect fuel-to-oil ratio can lead to performance issues. Double-check the mixing instructions and ensure the ratio is adhered to for optimal operation.

Inspect Carburetor: A dirty or malfunctioning carburetor can disrupt the fuel-air mixture. Cleaning or adjusting the carburetor may be necessary to achieve the right performance. Regular maintenance of this component can prevent many fuel system problems.

By following these troubleshooting tips, users can address common fuel system challenges effectively, ensuring smooth operation and extending the life of their equipment.

Adjusting the Carburetor Settings

Proper calibration of the fuel delivery system is essential for optimal performance of your gardening tool. This section outlines the necessary steps to fine-tune the air-fuel mixture, ensuring efficient operation and reduced emissions. Achieving the right balance can lead to smoother functioning and improved longevity of the engine.

Understanding the Adjustment Screws

The adjustment mechanism typically consists of three screws: low-speed, high-speed, and idle. Each screw serves a distinct purpose in regulating fuel flow at different engine speeds. Familiarizing yourself with these components is crucial before proceeding with adjustments.

Steps for Adjustment

To begin, ensure the engine is warm. Start with the low-speed screw, turning it clockwise to enrich the mixture or counterclockwise to lean it. After achieving a stable idle, move on to the high-speed screw. Adjust it similarly until you notice optimal acceleration and power output. Finally, fine-tune the idle screw for a steady idle speed without stalling.

Inspecting Electrical Components Safely

Ensuring the safety of electrical systems is crucial when performing any form of maintenance. A thorough examination of electrical components not only prevents accidents but also extends the lifespan of the equipment. This section will guide you through the essential safety protocols and methods to inspect these components effectively.

Essential Safety Precautions

Before beginning any inspection, it is vital to adhere to safety measures to protect yourself from potential hazards. Always disconnect the power supply to the device and use insulated tools. Wear appropriate personal protective equipment (PPE) such as gloves and safety goggles to shield against electrical shock and debris.

Steps for Inspecting Components

Follow these steps to ensure a thorough and safe inspection:

| Step | Action |

|---|---|

| 1 | Turn off and unplug the device from the power source. |

| 2 | Check for any visible signs of wear or damage on wires and connectors. |

| 3 | Test for continuity using a multimeter, ensuring that all connections are intact. |

| 4 | Inspect circuit boards for any burnt components or corrosion. |

| 5 | Reconnect power temporarily to check functionality, ensuring safety precautions are still observed. |

By following these steps and maintaining a safety-first mindset, you can effectively inspect electrical components while minimizing risks associated with electrical systems.

Safe Handling of Repair Tools

Proper management of tools during maintenance tasks is essential for ensuring safety and efficiency. Adhering to best practices not only protects the individual performing the work but also preserves the integrity of the equipment involved. Understanding how to handle tools safely minimizes the risk of accidents and enhances overall productivity.

Essential Safety Practices

Before initiating any task, it’s vital to familiarize yourself with the tools you will be using. Always inspect equipment for any signs of wear or damage. Use protective gear such as gloves and safety glasses to shield yourself from potential hazards. Additionally, ensure that your workspace is organized and free of clutter to avoid tripping hazards or misplacing tools.

Storing Tools Correctly

After use, tools should be cleaned and stored in designated areas to prevent damage and maintain organization. Keeping them in a dry, secure location reduces the risk of accidents and prolongs their lifespan. Regular maintenance checks on tools can further enhance safety, ensuring they remain in optimal working condition.

When to Seek Professional Help

Understanding when to call in an expert can save time, money, and frustration. While many issues can be addressed with basic knowledge and tools, certain complications require specialized skills and experience. Recognizing the limits of your capabilities is crucial for maintaining efficiency and safety.

If you encounter persistent malfunctions that do not resolve with standard troubleshooting methods, it may be a sign that professional intervention is necessary. Unusual noises, smoke, or inconsistent performance often indicate deeper underlying problems that can pose risks if not handled correctly.

Moreover, if you lack the appropriate tools or are uncertain about the repair process, attempting to fix complex issues on your own can lead to further damage. In such cases, seeking help from a qualified technician is advisable to ensure proper diagnostics and safe resolution.