Comprehensive Guide to Fiat 126 Repair Manual

For enthusiasts and owners of vintage automobiles, understanding the intricacies of their beloved machines is crucial. This section aims to equip you with valuable insights and practical knowledge necessary for the upkeep and restoration of your compact classic. Whether you’re tackling minor issues or planning a comprehensive overhaul, being well-informed will enhance both your experience and the vehicle’s longevity.

In the realm of automotive care, having a reliable source of guidance can make all the difference. From troubleshooting common problems to performing essential maintenance tasks, having structured information at your fingertips will empower you to take on challenges with confidence. This guide serves as a comprehensive resource, designed to illuminate the essential practices that every owner should know.

By delving into the specifics of the mechanics and systems that define your vehicle, you will gain not only proficiency in hands-on work but also a deeper appreciation for the craftsmanship behind these iconic machines. Armed with this knowledge, you will be prepared to preserve the unique character and charm of your compact classic for years to come.

Understanding the Fiat 126

This section aims to provide insights into a compact vehicle that has become an icon of its era. Known for its efficient design and practicality, this automobile has captivated enthusiasts and collectors alike. With a history rooted in innovative engineering, it represents a blend of functionality and style that appeals to a wide audience.

Key Features

- Compact dimensions for urban maneuverability

- Economical fuel consumption

- Distinctive design elements that stand out

- Accessible maintenance and parts availability

Historical Context

The vehicle emerged in a period marked by significant automotive advancements. It was designed to meet the demands of a rapidly changing world, where affordability and efficiency became paramount. As a result, it not only served as a reliable mode of transportation but also became a cultural symbol, reflecting the aspirations of its time.

Understanding this remarkable vehicle involves appreciating its heritage, engineering principles, and the role it has played in the automotive landscape. Its legacy continues to resonate with both fans and casual drivers, making it a timeless choice in the world of automobiles.

Common Issues and Troubleshooting

Understanding typical problems and their solutions is essential for maintaining a small vehicle. Many owners encounter similar challenges, and recognizing these can save time and effort in diagnostics. This section outlines frequent issues and offers guidance on how to address them effectively.

Engine Performance Problems

One of the most prevalent concerns relates to engine performance. Owners may notice symptoms such as stalling, reduced power, or difficulty starting. These issues can often be attributed to fuel delivery problems, ignition system failures, or air intake blockages. Regular checks of fuel lines, spark plugs, and air filters can prevent many of these issues from arising.

Electrical System Failures

Another common area of frustration involves the electrical system. Symptoms like dimming lights, malfunctioning indicators, or a dead battery can indicate underlying issues. Often, these problems arise from corroded connections or a failing alternator. Routine inspections of wiring and battery health can help maintain a reliable electrical system.

Tools Needed for Repairs

Having the right equipment is essential for performing maintenance and fixes effectively. Each task may require specific instruments, ensuring the job is done correctly and efficiently. This section outlines the essential tools that will aid in various procedures, from routine checks to more intricate overhauls.

Essential Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket wrenches, for loosening and tightening fasteners.

- Screwdrivers: Both flat-head and Phillips types are necessary for different screw configurations.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, and cutting.

- Hammers: A rubber mallet is ideal for delicate work, while a claw hammer serves for general use.

Specialized Equipment

- Torque wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Jack and jack stands: Necessary for lifting the vehicle safely to access the underside.

- Oil filter wrench: Helps in removing and installing the oil filter easily.

- Diagnostic scanner: Useful for reading error codes and diagnosing issues in modern vehicles.

Equipping yourself with these tools will significantly enhance your ability to carry out maintenance tasks, ensuring that your vehicle remains in optimal condition.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your vehicle in optimal condition. By following a systematic process, you can ensure that all critical components are regularly checked and serviced, enhancing performance and longevity. Routine care not only prevents unexpected issues but also maintains the vehicle’s value over time.

Routine Inspections

Fluid Checks and Changes

Regularly monitor essential fluids, including engine oil, coolant, and brake fluid. Top off or replace these fluids as necessary to prevent damage and maintain performance. Refer to the manufacturer’s recommendations for specific intervals and types of fluids suitable for your vehicle.

Engine Overhaul Procedures

Undertaking an engine refurbishment is a complex but rewarding process that can significantly enhance vehicle performance and longevity. This section outlines essential steps and considerations necessary for successfully reconditioning an engine, ensuring optimal functionality and reliability.

Preparation Steps

Before commencing the refurbishment, proper preparation is crucial. Follow these preliminary actions:

- Gather necessary tools and equipment, including wrenches, sockets, and measuring instruments.

- Secure a clean and organized workspace to facilitate efficient work.

- Consult technical documentation to familiarize yourself with engine specifications.

- Inspect components for wear and damage before disassembly.

Disassembly and Inspection

Disassembling the engine involves several detailed steps:

- Remove the engine from the vehicle, ensuring all connections are detached.

- Carefully take apart the engine, starting from external components and working inward.

- Label and organize parts to avoid confusion during reassembly.

- Inspect each component for signs of wear, such as cracks or excessive play.

Following these procedures will ensure a thorough and effective engine refurbishment, laying the groundwork for a successful reassembly and improved vehicle performance.

Electrical System Diagnosis

The electrical system of a vehicle plays a crucial role in its overall functionality and performance. Understanding how to effectively assess and troubleshoot this system is essential for any automotive enthusiast or technician. This section provides insights into common issues, diagnostic techniques, and essential components involved in the electrical framework.

Common Symptoms of Electrical Issues

Identifying signs of malfunction can often be the first step in resolving electrical problems. Symptoms may include flickering lights, difficulty starting the engine, or malfunctioning accessories. Noticing these indicators early can prevent further complications and ensure a more efficient diagnostic process.

Diagnostic Techniques

Utilizing systematic approaches is vital for accurate assessments. Start by checking the battery condition, as it is the primary power source. Use a multimeter to measure voltage and ensure connections are secure. Following this, inspect the wiring harness for any signs of wear, corrosion, or damage that could disrupt electrical flow.

Key Components to Inspect

Focusing on critical elements such as fuses, relays, and switches can provide valuable insights. A blown fuse may indicate an overload in the circuit, while faulty relays can lead to intermittent issues. Additionally, examining ground connections is essential, as poor grounding can lead to erratic behavior of electrical components.

In conclusion, a thorough understanding of the electrical system is imperative for effective diagnosis and repair. By recognizing symptoms, employing proper diagnostic methods, and inspecting essential components, one can significantly enhance the reliability and performance of the vehicle.

Bodywork Repairs and Techniques

Maintaining the exterior of a vehicle is essential for both aesthetics and functionality. This section will explore various methods and skills needed to address common issues related to the bodywork, ensuring that your automobile remains in optimal condition.

Common Issues

Several typical problems may arise with the outer surface of a vehicle, including:

- Dents and dings from minor collisions or hail.

- Rust and corrosion due to exposure to elements.

- Scratches that affect the paint finish.

- Misalignment of panels after accidents.

Repair Techniques

There are various techniques to restore the bodywork effectively:

- Dent Removal: Utilize tools such as a hair dryer and dry ice to remove minor dents. Heat the area, then apply the dry ice to contract the metal.

- Rust Treatment: Sand down rusted areas, apply a rust inhibitor, and repaint to prevent further damage.

- Scratch Repair: Use fine sandpaper to smooth the scratched surface, followed by touch-up paint for a seamless finish.

- Panel Alignment: Assess and adjust misaligned panels using appropriate tools to ensure proper fit and appearance.

By mastering these techniques, you can enhance the longevity and visual appeal of your vehicle’s bodywork, contributing to its overall value and enjoyment.

Suspension and Steering Adjustments

Maintaining optimal performance in a vehicle’s suspension and steering systems is crucial for ensuring a smooth and safe driving experience. Proper adjustments can significantly enhance handling, stability, and comfort. This section outlines the essential procedures and considerations for achieving the best results in these areas.

Key Suspension Adjustments

To achieve the desired ride quality and handling characteristics, several adjustments may be necessary:

- Spring Preload: Adjusting the tension in the springs can alter ride height and responsiveness.

- Damping Settings: Modifying shock absorber settings affects how the vehicle responds to bumps and road imperfections.

- Alignment: Ensuring the wheels are properly aligned contributes to even tire wear and improved handling.

- Ride Height: Adjusting the height can impact the center of gravity and overall vehicle stability.

Steering System Adjustments

Fine-tuning the steering system enhances control and feedback during driving:

- Toe Adjustment: Altering the angle of the wheels relative to the vehicle centerline can improve tracking and tire wear.

- Camber Settings: Adjusting the tilt of the wheels affects cornering performance and stability.

- Steering Play: Reducing excess play in the steering wheel can enhance responsiveness and driver confidence.

- Power Steering System: Ensuring proper fluid levels and functionality is essential for smooth operation.

By diligently addressing these factors, drivers can achieve a balanced and enjoyable driving experience, allowing for better handling and overall performance on the road.

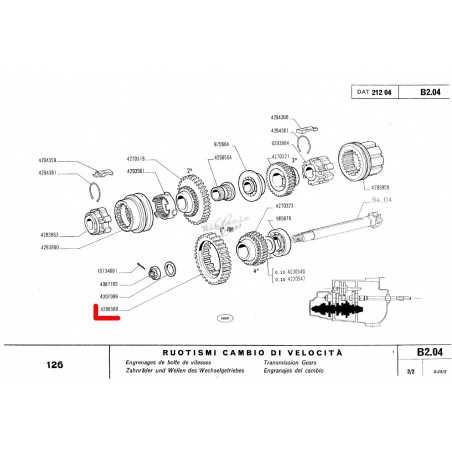

Transmission and Drivetrain Tips

Maintaining the transmission and drivetrain is essential for optimal vehicle performance. Understanding the components and their functions can significantly enhance driving experience and longevity. This section provides valuable insights to keep these systems in excellent condition.

Regular inspections and timely maintenance are key to preventing major issues. Ensure all connections are secure, fluids are at proper levels, and there are no signs of wear or damage. Here are some essential tips:

| Tip | Description |

|---|---|

| Check Fluid Levels | Monitor transmission fluid levels regularly; low fluid can lead to overheating and damage. |

| Inspect for Leaks | Look for fluid spots under the vehicle to catch leaks early. |

| Listen for Noises | Pay attention to unusual sounds while driving, which may indicate mechanical issues. |

| Clutch Adjustment | Ensure the clutch is properly adjusted for smooth engagement and disengagement. |

| Routine Servicing | Follow a schedule for servicing to keep components functioning optimally. |

Implementing these practices will not only extend the life of the transmission and drivetrain but also enhance overall performance. Regular attention to these systems is a wise investment for any vehicle owner.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is essential for both personal safety and the protection of the vehicle. By adhering to specific guidelines, one can minimize risks and enhance the overall effectiveness of the work being undertaken.

First and foremost, always wear appropriate protective gear. This includes gloves, goggles, and sturdy footwear. These items help shield against injuries caused by sharp objects, chemicals, or falling components.

Moreover, it is crucial to work in a well-ventilated area. Proper airflow reduces the buildup of harmful fumes and ensures a safer workspace, especially when dealing with fuels or solvents.

Additionally, make sure to have the necessary tools and equipment within reach before starting any task. This practice not only saves time but also limits the chances of accidents that may occur while searching for items mid-task.

Always disconnect the battery before beginning work on electrical systems. This simple step can prevent unexpected shocks and short circuits, safeguarding both the individual and the vehicle.

Finally, keep the workspace organized. A tidy area reduces the likelihood of accidents caused by tripping or misplacing tools. Regularly assessing and cleaning the environment contributes to a more efficient and secure maintenance experience.