Floor Jack Repair Guide

Ensuring the longevity and efficiency of your lifting equipment is crucial for safe and effective operation. Proper care not only enhances performance but also minimizes the risk of accidents. Understanding the fundamentals of upkeep is essential for any user.

In this section, we will explore various techniques and practices to keep your lifting apparatus in optimal condition. Whether you are a professional mechanic or a DIY enthusiast, having a comprehensive approach to maintenance will empower you to tackle potential issues proactively.

Regular inspection and troubleshooting play a significant role in identifying wear and tear before it escalates into major problems. By familiarizing yourself with common challenges and solutions, you can ensure that your equipment operates smoothly and safely.

There are various types of lifting devices available, each designed for specific purposes and applications. Understanding the differences can help users select the right tool for their needs.

- Hydraulic Lifters: These use fluid pressure to lift heavy loads, making them efficient and powerful.

- Pneumatic Lifters: Utilizing air pressure, these devices are ideal for quick lifting and lowering tasks.

- Mechanical Lifters: Relying on mechanical advantage, these are simple but effective for lighter loads.

- Electric Lifters: These provide the convenience of powered operation, suitable for frequent use.

Choosing the right lifting device depends on factors such as load capacity, frequency of use, and specific application requirements.

Essential Safety Precautions

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Following proper guidelines not only protects the individual performing the task but also safeguards those nearby. Awareness of potential hazards and adherence to safety measures creates a secure working environment.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes safety goggles to protect the eyes, gloves to prevent cuts and abrasions, and sturdy footwear to guard against falling objects. Proper attire minimizes the risk of injury and enhances overall safety.

Stability and Support

Before beginning any maintenance work, ensure that the equipment is stable and securely supported. This involves checking for level ground and using appropriate support structures to prevent any unexpected movements. A solid foundation is vital for safe operations.

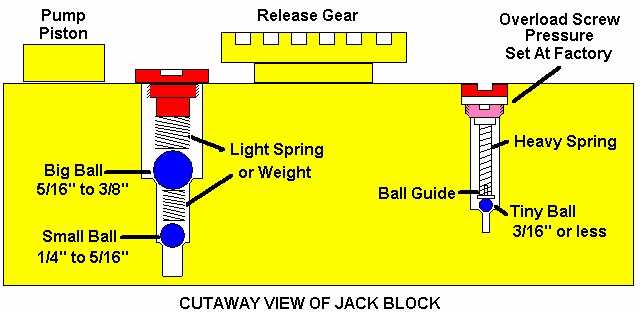

Basic Components of a Floor Jack

Understanding the essential parts of this lifting tool is crucial for effective maintenance and optimal performance. Each component plays a vital role in the overall functionality and safety of the equipment.

- Frame: The main structure that supports all other parts and provides stability.

- Piston: A cylindrical part that moves up and down, creating hydraulic pressure.

- Hydraulic Fluid Reservoir: Holds the hydraulic fluid necessary for operation.

- Release Valve: Controls the lowering mechanism of the tool.

- Handle: Used to operate and maneuver the device.

- Wheels: Provide mobility, allowing the tool to be easily positioned under vehicles.

Each of these elements is designed to work together, ensuring efficient lifting and lowering actions, contributing to the tool’s overall effectiveness in various tasks.

Identifying Common Issues

Recognizing typical problems is essential for maintaining optimal performance and ensuring safety. By being aware of the signs of malfunction, users can take prompt action to prevent further complications.

One prevalent issue is leakage. This can manifest as fluid pooling beneath the unit, indicating a compromised seal or a damaged hose. Regular checks for leaks can help in early detection.

Another common concern is difficulty in operation. If the mechanism does not lift or lower smoothly, it may suggest wear in the internal components. Listening for unusual noises during use can also provide insight into potential mechanical failures.

Lastly, instability during use is a critical problem. If the unit wobbles or tilts, it could lead to unsafe situations. Ensuring that the base is level and free from obstructions is vital for safe operation.

Tools Needed for Repairs

Proper tools are essential for maintaining and restoring equipment effectively. Having the right instruments at hand not only simplifies the process but also enhances safety and efficiency. Below are key items that can assist you in this task.

- Wrenches: Various sizes are needed to loosen or tighten components.

- Sockets: A socket set will provide versatility for different fasteners.

- Ratchets: Useful for quick adjustments without needing to reposition the tool frequently.

- Screwdrivers: Both flathead and Phillips types will be necessary for accessing screws.

- Pliers: Helpful for gripping and twisting parts securely.

In addition to these basic tools, consider having the following items for a more comprehensive toolkit:

- Torque wrench: Ensures fasteners are tightened to the correct specifications.

- Safety goggles: Protects your eyes from debris during maintenance.

- Gloves: Provides hand protection while working with sharp or hot components.

- Lubricants: Helps reduce friction and wear on moving parts.

- Cleaning supplies: Keeps the work area and tools free from dirt and grime.

Having these tools will prepare you for various tasks, making the overall process smoother and more effective.

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing common issues with lifting devices. By following these detailed steps, users can effectively address problems and ensure optimal functionality.

Tools and Materials Needed

- Wrench set

- Screwdrivers

- Pliers

- Lubricating oil

- Replacement parts

Repair Steps

- Begin by assessing the device for any visible damage or wear.

- Disassemble the components carefully, keeping track of all parts.

- Inspect each part for defects, noting any that need replacement.

- Clean all parts to remove dirt and debris, ensuring smooth operation.

- Apply lubricant to moving parts to enhance performance.

- Reassemble the components in reverse order, ensuring tight connections.

- Test the device to confirm that it operates correctly.

Maintenance Tips for Longevity

Ensuring the durability of your lifting equipment requires consistent care and attention. Proper maintenance not only extends the life of your device but also enhances its performance and safety. Below are essential practices to keep your lifting tools in optimal condition.

Regular Inspections

- Check for any signs of wear or damage before each use.

- Inspect all moving parts for smooth operation.

- Look for leaks in hydraulic systems and address them immediately.

Cleaning Procedures

- Clean the exterior regularly to prevent dirt buildup.

- Use appropriate cleaning agents to avoid corrosion.

- Lubricate moving components to ensure effortless movement.

By following these maintenance tips, you can significantly increase the lifespan and reliability of your lifting apparatus.

Troubleshooting Hydraulic Problems

Identifying issues in hydraulic systems is essential for maintaining optimal performance. Various factors can lead to malfunctioning, from fluid leaks to pressure inconsistencies. Understanding these potential problems helps in effective diagnosis and resolution.

Common Signs of Trouble: A noticeable decrease in lifting capability often indicates an underlying issue. Additionally, unusual noises or vibrations during operation may suggest internal faults or low fluid levels. These symptoms require immediate attention to prevent further damage.

Fluid Leaks: One of the most frequent problems arises from leaks in hoses or fittings. Inspecting connections for wear or damage can reveal the source. Replacing compromised components is crucial to restore functionality.

Pressure Issues: Insufficient pressure can hinder operation. Checking the pressure gauge can help identify if the system is performing below standard. If low pressure is detected, it may be necessary to inspect the pump or adjust the relief valve.

Contamination: Contaminated fluid can cause serious issues within the system. Regularly changing the hydraulic fluid and using a filtration system can prevent such problems. Clean fluid is vital for the longevity of the equipment.

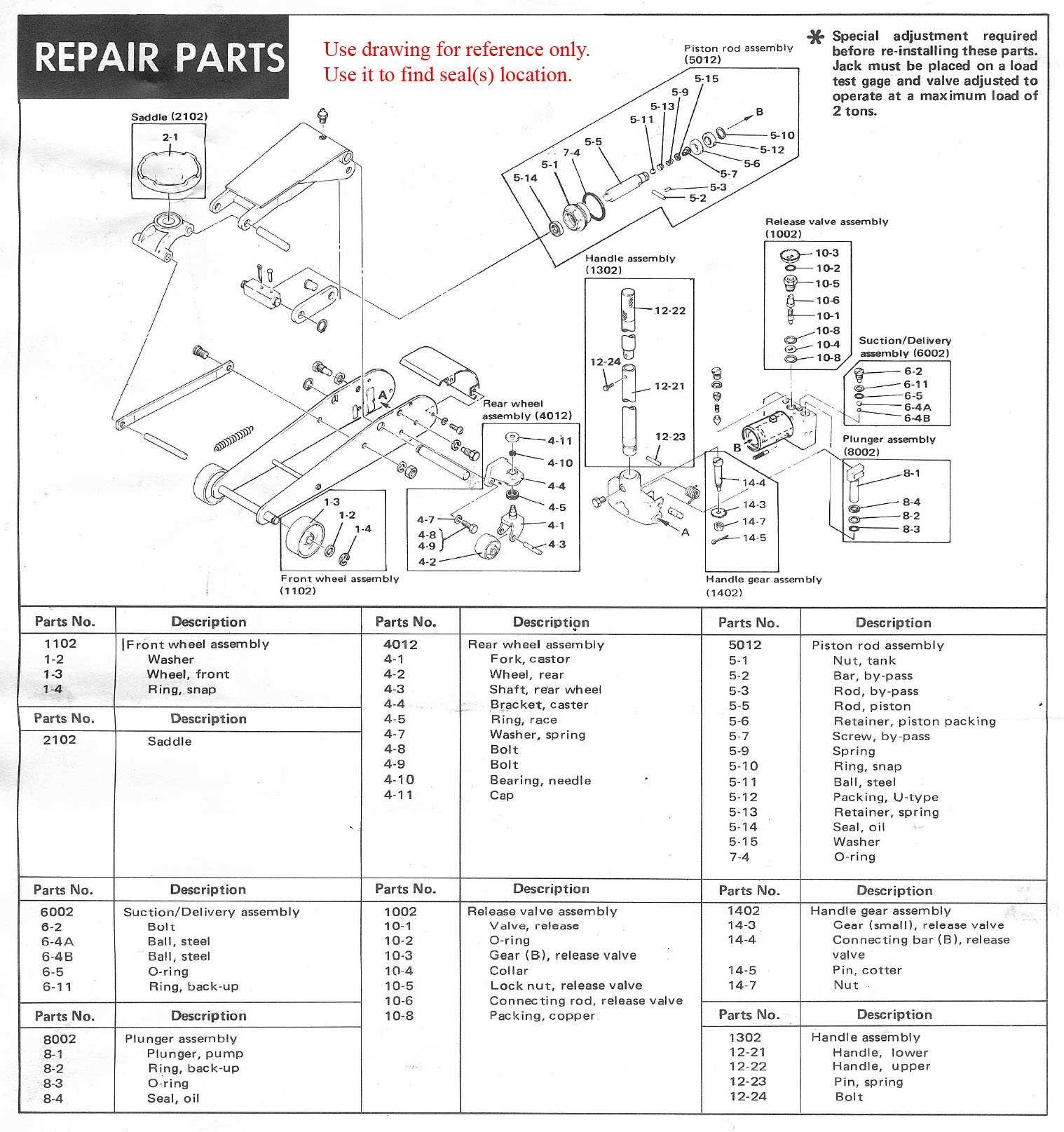

Replacing Worn-Out Parts

Over time, certain components of your lifting device may become less effective due to wear and tear. Timely replacement of these elements is crucial for maintaining optimal functionality and safety. This section outlines key steps and considerations when swapping out aging parts.

To ensure a successful replacement process, follow these guidelines:

- Identify Worn Components: Regularly inspect the equipment to determine which parts show signs of damage or deterioration.

- Gather Necessary Tools: Before starting, collect all required tools and replacement parts to streamline the process.

- Follow Manufacturer Instructions: Refer to the provided documentation for specific guidelines on removing and installing new components.

- Test the Device: After replacement, conduct thorough testing to confirm that the equipment operates smoothly and safely.

By addressing worn components promptly, you can extend the lifespan of your device and enhance its performance.

Testing Your Floor Jack After Repair

After completing maintenance on your lifting device, it is crucial to ensure its functionality and safety. This section will guide you through the necessary steps to verify that everything operates smoothly.

Start with the following checklist:

- Inspect the hydraulic fluid level and ensure it is adequate.

- Examine the seals and hoses for any signs of leakage.

- Test the handle for smooth operation.

Once you have completed the visual checks, proceed to conduct a functional test:

- Position the device on a flat, stable surface.

- Gradually pump the handle to raise the lifting mechanism.

- Observe for any unusual sounds or resistance during the lifting process.

- Once raised, check if it holds the weight without dropping.

By following these steps, you can confirm that your lifting tool is in good working order and ready for use.

When to Seek Professional Help

In certain situations, it is crucial to recognize when expert assistance is necessary. While many issues can be handled independently, some problems may require specialized knowledge or tools to ensure safety and effectiveness. Understanding the signs that indicate the need for professional intervention can prevent further complications.

Signs of Major Malfunction

If you encounter significant operational failures or unusual noises during usage, it is advisable to consult a professional. These symptoms may suggest deeper mechanical issues that could lead to hazardous situations if not addressed promptly.

Inadequate Tools and Knowledge

When lacking the proper tools or experience to perform necessary tasks, seeking help from a skilled technician is wise. Attempting repairs without the right equipment or understanding can result in additional damage or personal injury.