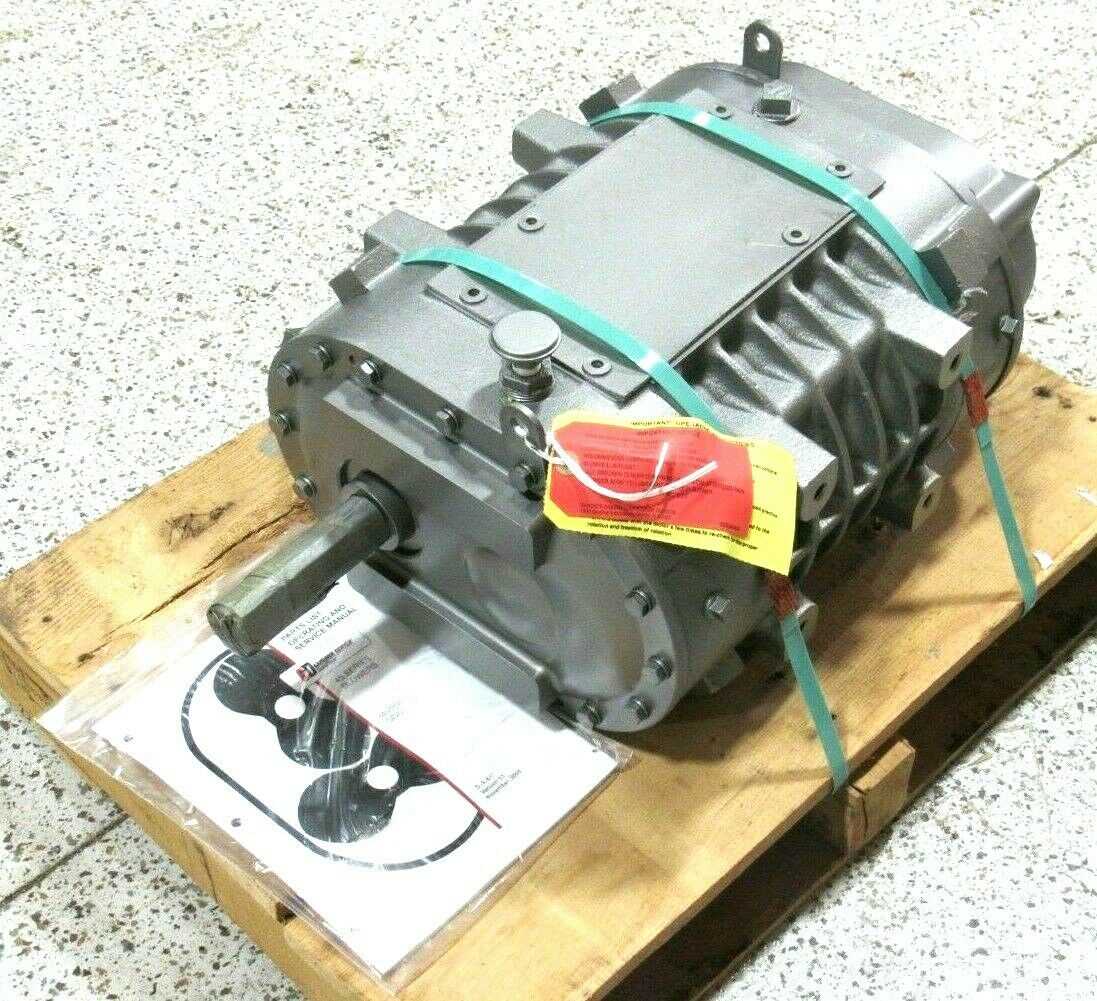

Gardner Denver Blower Repair Guide

When it comes to ensuring the efficiency and longevity of air circulation devices, understanding their intricacies is essential. This guide provides an in-depth look at the necessary steps to keep these machines running smoothly. From troubleshooting common issues to performing routine maintenance, the knowledge shared here empowers users to tackle potential problems confidently.

Having access to a thorough resource can significantly enhance your ability to address challenges that may arise with your machinery. This compilation of procedures and tips is designed to facilitate a hands-on approach, making it easier for operators to engage with their systems effectively. Whether you are a novice or an experienced technician, this information serves as a valuable reference to optimize performance.

By familiarizing yourself with the various components and their functions, you can proactively prevent malfunctions and improve the overall functionality of your equipment. The insights provided will guide you in conducting assessments and implementing solutions that enhance operational reliability. Prepare to delve into a world of maintenance techniques that ensure your air movement systems are always at their best.

Understanding Gardner Denver Blower Components

In any air-moving device, the individual parts play crucial roles in ensuring efficiency and reliability. A thorough comprehension of these elements allows for better maintenance and troubleshooting, ultimately enhancing performance and longevity.

The key components typically include:

- Housing: This outer shell provides protection and structural integrity to the internal mechanisms.

- Impellers: These rotating blades are essential for moving air, creating the necessary pressure differences.

- Motor: The driving force behind the system, responsible for powering the impellers.

- Inlet and Outlet Ports: These openings facilitate air entry and exit, impacting flow dynamics.

- Bearings: Critical for reducing friction, these components allow smooth rotation of moving parts.

Each part must function in harmony to achieve optimal operation. Understanding their specific functions can aid in identifying potential issues and implementing effective solutions.

Common Issues with Blower Operation

When dealing with industrial air-moving devices, users often encounter various operational challenges. Understanding these frequent complications can help in maintaining efficiency and ensuring longevity. Below are some of the typical concerns that operators may face.

| Issue | Description | Potential Solution |

|---|---|---|

| Noisy Operation | Unusual sounds may indicate mechanical wear or misalignment. | Inspect components for damage and align as necessary. |

| Insufficient Airflow | Reduced air movement can result from blockages or filter issues. | Check and clean filters; ensure no obstructions in ducts. |

| Vibrations | Excessive shaking can be a sign of imbalance or loose parts. | Tighten loose fittings and balance moving elements. |

| Overheating | Excessive temperatures may arise from prolonged use or lack of maintenance. | Ensure adequate cooling and perform regular maintenance checks. |

| Power Fluctuations | Inconsistent power supply can affect performance. | Examine electrical connections and rectify any issues. |

Step-by-Step Repair Procedures

This section provides a comprehensive guide to fixing common issues related to air-moving devices. By following these detailed instructions, you can effectively address various challenges that may arise during operation, ensuring optimal performance and longevity of the equipment.

Before commencing any maintenance tasks, it is crucial to prepare adequately. Gather all necessary tools and safety equipment, and ensure you have access to the device’s specifications for reference.

| Step | Description |

|---|---|

| 1 | Disconnect power source to prevent accidents. |

| 2 | Inspect the exterior for visible damage or wear. |

| 3 | Open the housing to access internal components. |

| 4 | Check all connections and wiring for secure attachments. |

| 5 | Clean internal parts to remove any buildup or debris. |

| 6 | Replace any damaged or worn-out components as necessary. |

| 7 | Reassemble the unit carefully, ensuring all parts are correctly fitted. |

| 8 | Reconnect the power source and conduct a functionality test. |

By adhering to these procedures, you can maintain the functionality and reliability of your air-moving equipment, thus enhancing its performance and extending its service life.

Essential Tools for Blower Maintenance

Proper upkeep of your air-moving equipment is crucial for optimal performance and longevity. Having the right instruments at your disposal can make routine check-ups and fixes more efficient. Here’s a guide to some key implements you should consider for effective maintenance.

- Wrenches: Adjustable and socket wrenches are essential for loosening and tightening various fasteners.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will help in accessing different components.

- Cleaning Supplies: Brushes, cloths, and specialized cleaners will assist in keeping surfaces free of debris.

- Multimeter: This tool is critical for checking electrical connections and ensuring everything functions correctly.

- Lubricants: High-quality oil or grease is necessary for maintaining moving parts and reducing friction.

By equipping yourself with these fundamental tools, you can ensure that your equipment remains in peak condition and operates smoothly for years to come.

Safety Precautions During Repair

Ensuring safety while handling mechanical systems is crucial for both efficiency and well-being. Proper precautions not only protect the technician but also enhance the lifespan of the equipment. Understanding the fundamental practices is essential for a successful maintenance process.

Essential Guidelines

Adhering to safety measures can significantly reduce risks. Here are key practices to follow:

| Guideline | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear, such as gloves, goggles, and steel-toed boots, to safeguard against potential hazards. |

| Disconnect Power Sources | Before starting any work, ensure all power supplies are disconnected to prevent accidental activation. |

| Work Environment | Keep the workspace clean and organized to avoid trips and falls, ensuring all tools are within easy reach. |

| Follow Manufacturer Guidelines | Refer to specific instructions provided by the equipment’s manufacturer to ensure compliance with safety standards. |

Emergency Preparedness

Being ready for unforeseen circumstances is vital. Have a first aid kit readily available and know the emergency contact numbers in case of an incident. Familiarize yourself with the location of emergency exits and fire extinguishers to ensure a swift response in critical situations.

Diagnosing Performance Problems

Identifying issues with operational efficiency is crucial for maintaining optimal functionality in any machinery. This section will guide you through common symptoms and methods to pinpoint the underlying causes of reduced effectiveness.

Common Symptoms of Inefficiency

Several indicators can suggest that your equipment is not performing as expected. Unusual noises, fluctuating pressure levels, or decreased output may all point to potential malfunctions. Observing these signs early can prevent more extensive damage and costly repairs.

Methods for Troubleshooting

Begin by inspecting all components for wear or damage. Ensure that connections are secure and free from obstructions. Utilizing diagnostic tools can help measure performance metrics accurately. Regular maintenance is key; adhering to a schedule can catch issues before they escalate. Thorough documentation of any anomalies will aid in the troubleshooting process and support future reference.

Replacement Parts and Compatibility

Ensuring optimal functionality of your equipment often hinges on selecting appropriate components. Understanding the various replacement elements available and their compatibility with existing systems is crucial for maintaining efficiency and prolonging the lifespan of your machinery.

Identifying Compatible Components

When considering substitutes, it’s essential to verify that new parts align with the specifications of your unit. Many manufacturers provide detailed information about compatible items, helping you avoid potential issues during installation. Always check the part numbers and specifications before making a purchase to ensure a proper fit.

Quality and Performance Considerations

Opting for high-quality alternatives can significantly impact the performance of your system. While generic parts may be tempting due to lower costs, they often lack the durability and reliability of original components. Investing in reputable replacements not only enhances functionality but also minimizes the risk of future malfunctions.

Preventive Maintenance Tips for Longevity

Regular upkeep is essential to extend the life of your equipment and ensure optimal performance. By implementing simple yet effective maintenance practices, you can avoid costly repairs and downtime. This section outlines key strategies to keep your machinery running smoothly.

Routine Checks

- Inspect components regularly for wear and tear.

- Clean air filters and vents to prevent blockages.

- Lubricate moving parts according to the manufacturer’s guidelines.

- Monitor operating temperatures to detect potential issues early.

Scheduled Servicing

- Establish a maintenance schedule based on usage and operating conditions.

- Replace worn-out parts promptly to avoid further damage.

- Keep a detailed log of all maintenance activities for reference.

Assembly and Disassembly Techniques

Understanding the methods for putting together and taking apart machinery is crucial for effective maintenance. Proper techniques not only ensure safety but also enhance the longevity and performance of the equipment. This section will explore best practices that facilitate smooth operations during these processes.

Preparation Steps

Before starting the assembly or disassembly process, gather all necessary tools and components. Ensure that the workspace is clean and organized to minimize the risk of losing parts. It’s also advisable to consult relevant documentation to familiarize yourself with specific requirements or configurations.

Executing the Process

When assembling, start by aligning parts carefully to avoid forcing them together, which could cause damage. Use appropriate fasteners and torque settings to secure components firmly without over-tightening. During disassembly, work systematically, keeping track of each piece and its orientation. Labeling parts can streamline reassembly, preventing confusion.

Safety should always be a priority. Utilize personal protective equipment and follow safety protocols to protect yourself from potential hazards. By adhering to these techniques, you can achieve efficient assembly and disassembly while maintaining the integrity of the machinery.

Consulting the Manufacturer’s Guidelines

When addressing maintenance and troubleshooting for industrial equipment, referring to the specifications provided by the original producer is essential. These documents contain vital information tailored to the specific model, ensuring optimal performance and longevity.

Key Benefits of Manufacturer Guidelines

- Ensures compliance with safety standards

- Provides detailed operational instructions

- Includes troubleshooting procedures for common issues

- Outlines recommended maintenance schedules

How to Access the Documentation

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Search for the specific model documentation.

- Download or view the guidelines in PDF format.