Comprehensive Guide to Generac Diagnostic Repairs

In the realm of machinery and equipment, having access to comprehensive support literature is essential for ensuring optimal performance and longevity. These documents serve as invaluable resources, offering step-by-step insights into troubleshooting and upkeep. By familiarizing oneself with these guidelines, users can effectively navigate common issues and enhance the overall functionality of their devices.

Whether dealing with minor adjustments or more complex challenges, understanding the principles outlined in these texts empowers individuals to address concerns proactively. The information provided not only clarifies standard operating procedures but also highlights safety measures essential for successful engagement. By investing time in learning from these resources, users are better equipped to maintain their systems efficiently.

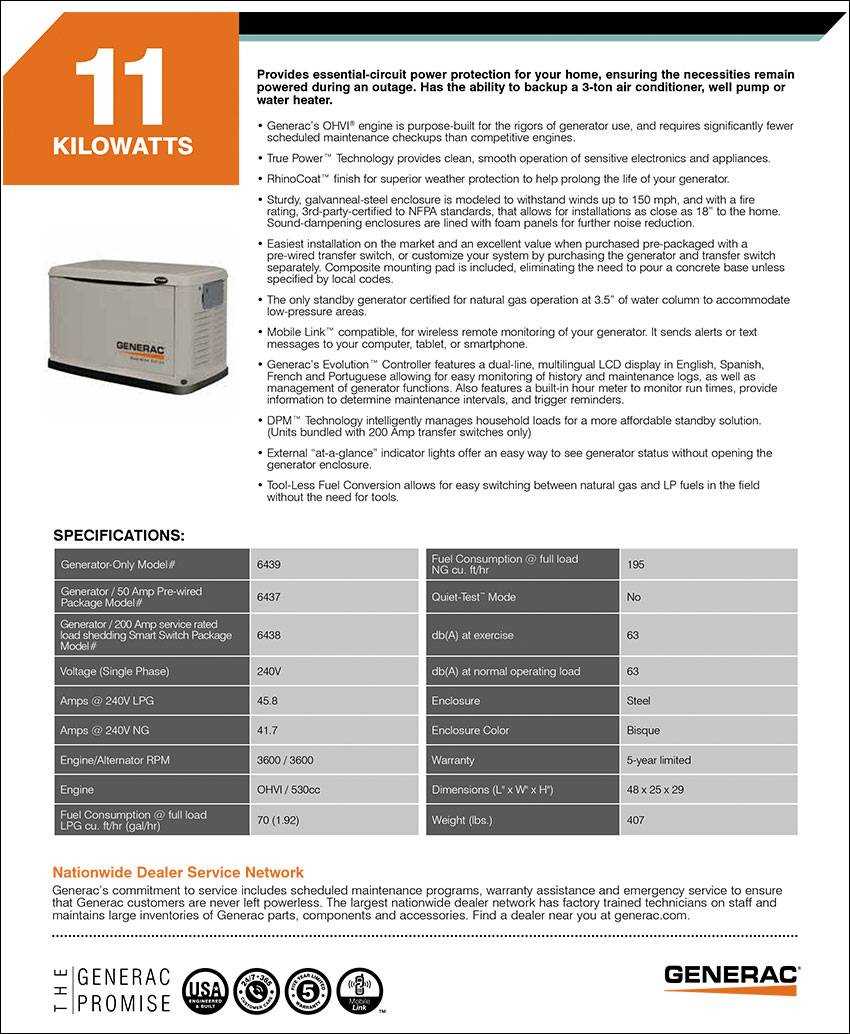

This section provides a comprehensive look at a range of products designed to deliver reliable power solutions for various needs. These items are essential for ensuring that users can effectively manage their energy requirements in both residential and commercial settings.

Types of Power Solutions

- Portable generators

- Standby power systems

- Inverter generators

Features and Benefits

- Enhanced fuel efficiency for prolonged usage.

- Automatic start capabilities for convenience.

- Quiet operation to minimize noise disruption.

Understanding Diagnostic Repair Procedures

This section delves into the essential methods employed to identify and resolve issues in machinery and equipment. A comprehensive approach ensures that all potential faults are considered, leading to effective solutions.

Key Steps in the Process

- Initial Assessment: Gathering information about the symptoms and operational history.

- Systematic Evaluation: Conducting tests to pinpoint the malfunctioning components.

- Implementation of Solutions: Applying the appropriate fixes based on the analysis.

- Verification: Ensuring that the implemented solutions effectively resolve the identified problems.

Importance of Methodical Analysis

A structured analysis is crucial for achieving accurate results. By following a systematic approach, technicians can minimize downtime and enhance the overall performance of the equipment.

Common Issues in Generac Systems

When dealing with backup power units, users may encounter various challenges that can hinder performance and efficiency. Understanding these frequent complications can help in troubleshooting and maintaining optimal operation.

Frequent Complications

- Insufficient power output

- Unusual noises during operation

- Failure to start

- Overheating issues

Recommended Solutions

- Check fuel levels and quality.

- Inspect the battery and connections.

- Examine air filters for clogs.

- Review user settings and configurations.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues that may arise with your equipment. By following these outlined steps, you can effectively diagnose problems and implement solutions.

-

Initial Assessment: Begin by checking the overall condition of the unit.

- Inspect for visible damage or wear.

- Ensure all connections are secure.

- Verify that the power source is functioning.

-

Operational Check: Attempt to start the unit.

- If it fails to start, listen for unusual sounds.

- Observe any warning lights or indicators.

- Take note of any error codes displayed.

-

Component Inspection: Focus on specific parts that may require attention.

- Check the battery and fuel levels.

- Inspect air filters and exhaust systems for blockages.

- Examine electrical connections and components for corrosion.

-

Documentation Review: Refer to any provided instructions or guidelines.

- Consult troubleshooting sections for specific issues.

- Follow suggested procedures for maintenance and repair.

-

Final Testing: After making adjustments, test the unit again.

- Monitor performance closely during operation.

- Check for any recurring problems or new symptoms.

- Document any changes for future reference.

Essential Tools for Repairs

Having the right equipment is crucial for effectively addressing issues and performing maintenance tasks. This section outlines the fundamental instruments that will facilitate the troubleshooting and restoration processes, ensuring that tasks are completed efficiently and safely.

Basic Hand Tools

Essential hand tools include items such as screwdrivers, wrenches, and pliers. These versatile instruments are necessary for loosening, tightening, and manipulating various components. A well-organized toolbox containing these basics can significantly expedite the repair process.

Specialized Instruments

In addition to hand tools, specialized devices such as multimeters and diagnostic testers play a vital role in identifying specific faults. These tools allow for precise measurements and assessments, enabling users to diagnose problems accurately before proceeding with repairs.

Safety Precautions During Repairs

Ensuring a safe environment during maintenance tasks is crucial for preventing accidents and injuries. Proper precautions must be taken to protect both the technician and the equipment involved.

Before starting any work, it’s essential to disconnect the power source to avoid electric shock. Always wear appropriate personal protective equipment, such as gloves and safety goggles, to shield against potential hazards.

Maintain a clutter-free workspace to minimize risks of trips and falls. Familiarize yourself with the specific components being handled, and consult relevant guidelines to ensure a comprehensive understanding of safety measures.

In addition, ensure proper ventilation when working with potentially harmful substances. Keeping a first aid kit accessible can also provide peace of mind in case of emergencies.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular attention and care. Implementing a few key practices can significantly extend its lifespan and enhance reliability.

Regular Inspections: Frequently examine all components for signs of wear and tear. Look for any loose connections, corrosion, or dirt accumulation that may hinder performance.

Cleanliness: Keeping the equipment clean is crucial. Remove dust and debris from surfaces and ensure that air vents are unobstructed to prevent overheating.

Fluid Checks: Regularly monitor and replace fluids as necessary. This includes oil, coolant, and fuel, as they play vital roles in maintaining efficient operation.

Scheduled Servicing: Adhering to a maintenance schedule can help identify potential issues before they escalate. Professional servicing should be performed according to the manufacturer’s recommendations.

Proper Usage: Always operate the equipment within its specified limits. Overloading or improper use can lead to premature failure and costly repairs.

By following these essential maintenance tips, you can ensure that your equipment remains in peak condition for years to come.

Understanding Error Codes and Messages

Error codes and messages play a crucial role in identifying issues within a system. They serve as indicators that help users and technicians diagnose problems effectively. By interpreting these signals, one can pinpoint malfunctions and take appropriate corrective actions.

Interpreting the Codes

Each error code is designed to convey specific information about the malfunction. Understanding the meaning behind these codes allows users to troubleshoot issues more efficiently. It is essential to refer to the relevant resources to decode these messages accurately.

Common Messages and Solutions

Many systems present users with common messages indicating operational faults. Recognizing these messages can lead to swift resolutions. For instance, a warning may suggest a need for maintenance, while another could indicate a power supply issue. Addressing these messages promptly can prevent further complications.

Replacement Parts and Accessories

Ensuring optimal performance of equipment often necessitates the use of specific components and supplementary items. These parts play a crucial role in maintaining functionality and extending the lifespan of the system. It is essential to select high-quality replacements that align with the original specifications to guarantee seamless integration.

Commonly required components include filters, batteries, and spark plugs, which help maintain efficiency and reliability. Additionally, various accessories, such as extension cords and protective covers, enhance the overall operation and safeguard the equipment from environmental factors. Regularly assessing the condition of these parts and replacing them as needed can prevent unexpected breakdowns and improve overall performance.

When sourcing replacement items, it is advisable to consult reputable suppliers who provide authentic products designed for compatibility. This ensures that the chosen parts not only fit perfectly but also uphold the expected standards of safety and durability.

When to Seek Professional Help

Knowing when to enlist the assistance of a specialist can save time and prevent further complications. It is essential to recognize specific situations where expert intervention is necessary to ensure optimal performance and safety of your equipment.

Here are key indicators that it’s time to reach out to a professional:

- The device fails to start despite troubleshooting attempts.

- Unusual noises or vibrations occur during operation.

- There are visible signs of damage or wear.

- Performance issues persist after basic maintenance.

- Electrical components show signs of malfunction.

Addressing these issues promptly with the help of a qualified technician can prevent further damage and ensure that your equipment operates effectively and safely.

Best Practices for Regular Checks

Performing routine inspections on equipment is essential for maintaining optimal performance and longevity. Regular assessments help identify potential issues before they escalate, ensuring smooth operation and minimizing downtime.

Scheduled Maintenance

Establishing a timetable for checks allows for systematic evaluation of functionality. Adhering to a regular maintenance schedule ensures that all critical components are thoroughly inspected, lubricated, and adjusted as necessary. This proactive approach can greatly enhance reliability.

Documentation and Tracking

Keeping detailed records of inspections and any maintenance performed is vital. This documentation serves as a reference point for future checks and can help pinpoint recurring issues. Tracking performance metrics can also aid in understanding equipment behavior over time, facilitating informed decisions for any necessary adjustments.

Customer Support and Resources

Accessing reliable assistance and comprehensive materials is essential for ensuring optimal performance of your equipment. Customers can benefit from various avenues to seek help and obtain information relevant to their needs.

- Online Knowledge Base: A dedicated online platform provides a wealth of articles, FAQs, and troubleshooting guides to help users resolve common issues independently.

- Customer Service Hotline: A direct line to knowledgeable representatives is available for those who prefer personalized assistance or have specific inquiries.

- Community Forums: Engaging with other users through forums allows individuals to share experiences, tips, and solutions to common challenges.

- Video Tutorials: Visual learning resources can enhance understanding by demonstrating processes and techniques step-by-step.

- Documentation Downloads: Essential documents, including setup guides and user instructions, can be easily accessed to support effective usage.

Utilizing these resources can empower customers to maintain their equipment efficiently and make informed decisions.