Comprehensive Guide to Greenlee 767 Repair Manual

When it comes to ensuring the longevity and optimal performance of essential tools, having access to detailed resources is crucial. This section provides valuable insights and step-by-step guidance tailored to assist users in navigating common issues and enhancing functionality.

In the realm of mechanical devices, understanding the intricacies of operation can greatly influence efficiency and safety. By exploring practical advice and troubleshooting techniques, individuals can develop a deeper connection with their machinery.

Ultimately, this guide aims to empower users with the knowledge necessary to tackle challenges head-on, fostering a proactive approach to upkeep. Dive into the nuances of maintaining your equipment and unlock its full potential.

Understanding Greenlee 767 Functionality

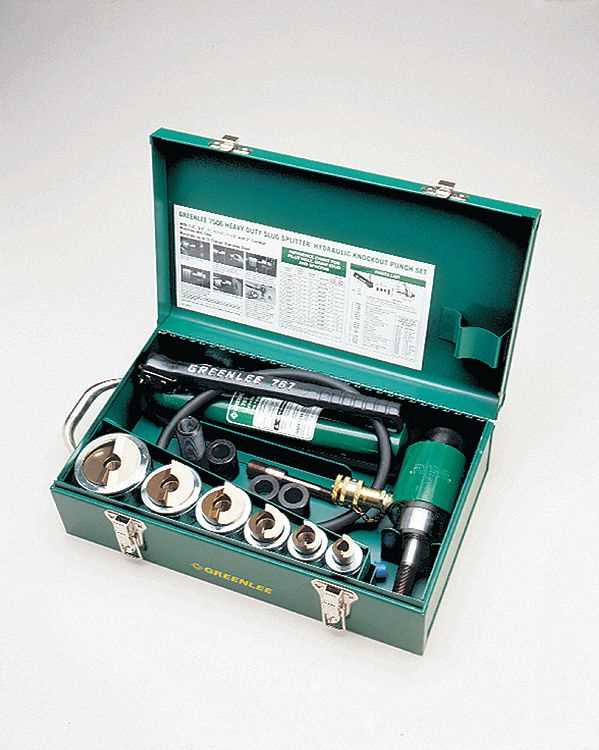

This section explores the operational principles of a versatile tool designed for various applications in electrical work and construction. Its primary functions enable users to efficiently handle tasks such as cable preparation, conduit bending, and hole cutting. By understanding the mechanics and features of this equipment, users can maximize productivity and ensure safety while achieving precise results.

Key Features and Capabilities

The device incorporates advanced mechanisms that allow for seamless operation across different tasks. With a focus on user-friendliness, it boasts intuitive controls and ergonomic design, making it suitable for both professionals and DIY enthusiasts. Features such as adjustable settings and durable construction enhance its reliability and longevity, ensuring it can withstand the demands of regular use.

Application Scenarios

This tool is ideal for various scenarios, from simple home projects to complex industrial tasks. Its ability to adapt to different materials and environments makes it a valuable asset for electricians and contractors alike. By leveraging its functionalities, users can tackle projects efficiently, reducing time spent on manual labor while maintaining high-quality outcomes.

Common Issues with Greenlee 767

In the world of specialized tools, certain models may encounter recurring problems that can hinder performance and efficiency. Understanding these common challenges can assist users in identifying issues early and taking appropriate measures to ensure optimal operation.

Frequent Challenges

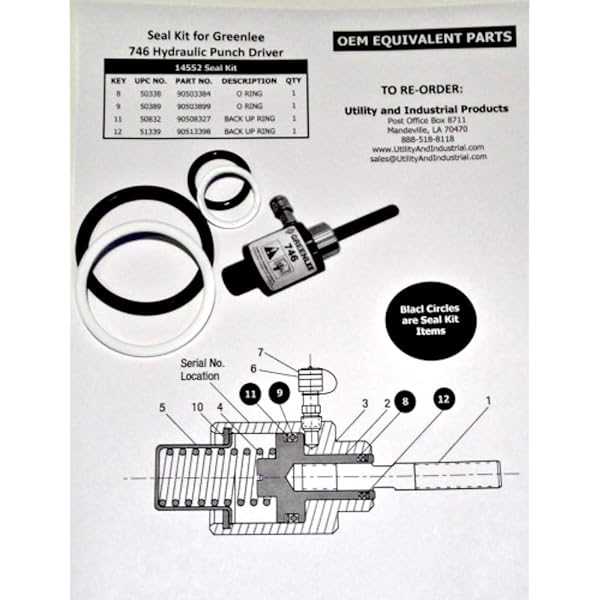

- Hydraulic Leaks: One of the most prevalent issues involves hydraulic fluid escaping from seals or hoses, which can lead to a significant drop in pressure.

- Electrical Malfunctions: Components such as switches and connectors may fail, causing disruptions in power delivery.

- Worn Components: Over time, various parts may experience wear and tear, resulting in decreased functionality and efficiency.

- Operational Inconsistencies: Users may notice irregular performance, often attributed to blockages or obstructions within the system.

Troubleshooting Steps

- Check for visible signs of leaks and inspect hoses and fittings.

- Test electrical connections and replace any faulty components.

- Examine moving parts for wear; replace as necessary.

- Clear any blockages in the system to restore smooth operation.

By proactively addressing these common challenges, users can prolong the lifespan of their tools and maintain high standards of performance in their projects.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance task. Whether you are dealing with electrical components, plumbing, or mechanical systems, specific instruments can significantly enhance efficiency and accuracy. Understanding which tools are necessary can save time and ensure a job well done.

1. Multimeter: A versatile device for measuring voltage, current, and resistance. This tool is indispensable for diagnosing electrical issues and ensuring proper functioning of circuits.

2. Wire Strippers: Essential for safely removing insulation from electrical wires without damaging the conductors. A good pair of strippers can make wiring tasks much smoother.

3. Pliers: Various types, including needle-nose and slip-joint pliers, are vital for gripping, twisting, and cutting wires or small components. Their ergonomic design allows for better leverage in tight spaces.

4. Screwdrivers: A complete set, including flathead and Phillips, is necessary for loosening and tightening screws. Magnetic tips can add convenience, preventing screws from falling during work.

5. Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening and ensuring safety.

6. Safety Gear: Protective eyewear, gloves, and ear protection are crucial for ensuring personal safety while working on any project. Prioritizing safety can prevent accidents and injuries.

Having these fundamental instruments on hand will enable you to approach tasks with confidence and skill, leading to successful outcomes in your projects.

Step-by-Step Repair Procedures

This section outlines the essential processes involved in fixing equipment effectively. By following a systematic approach, you can ensure that all necessary tasks are performed accurately, leading to a successful restoration of functionality. Each stage is broken down to facilitate understanding and execution, making it accessible even for those with minimal experience.

Preparation Steps

Before diving into the actual work, it’s crucial to gather all necessary tools and materials. A well-organized workspace enhances efficiency and minimizes distractions. The following table lists essential items you may need:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and secure screws |

| Wrench | To tighten or loosen bolts |

| Multimeter | To check electrical connections |

| Replacement Parts | To replace worn or damaged components |

Execution of Repairs

Once preparations are complete, follow these key steps to address issues effectively:

- Disconnect the power source to ensure safety.

- Inspect the equipment for visible damage or wear.

- Remove any faulty components carefully.

- Install the new or repaired parts as needed.

- Reassemble the unit, ensuring all connections are secure.

- Test the equipment to confirm successful restoration.

By adhering to these outlined procedures, you can tackle maintenance tasks with confidence and skill, ultimately extending the lifespan of your tools.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both the individual and the equipment involved. Proper precautions help to minimize risks and prevent accidents, creating a secure environment for effective troubleshooting and adjustments. Adopting a proactive approach to safety can significantly enhance the overall repair experience.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. This may include safety goggles, gloves, and ear protection, depending on the nature of the work. Ensuring that all gear is in good condition and fits properly can prevent injuries from flying debris or exposure to harmful substances.

Work Area Organization

Maintaining a clean and organized workspace is vital for safety. Clutter can lead to accidents, such as slips or falls. Additionally, ensuring that tools and materials are stored correctly can reduce the risk of mishaps during the maintenance process. Regularly checking the work area for potential hazards helps to create a safer environment for all tasks.

Parts and Components Overview

This section provides a comprehensive look at the various elements and assemblies that contribute to the functionality of the device. Understanding these components is crucial for effective maintenance and troubleshooting.

The following key parts play a significant role in the operation:

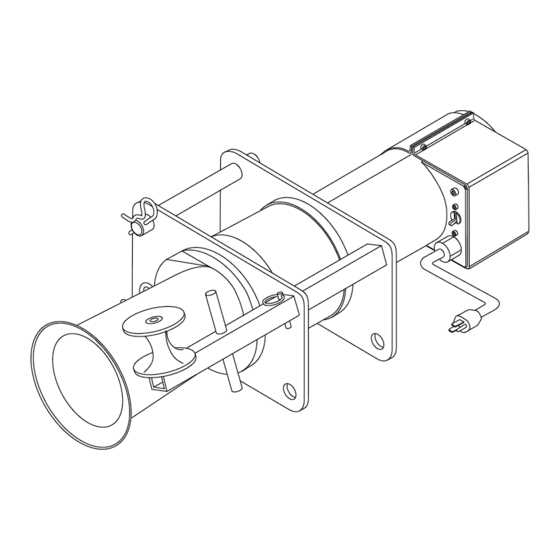

- Main Frame: The sturdy structure that houses and supports all internal mechanisms.

- Power Supply: Converts electrical energy to power the machine’s operations.

- Control Panel: Interface for the user, allowing adjustments and monitoring of the device’s status.

- Hydraulic System: Facilitates movement and operation through fluid pressure.

- Cutting Tools: Specialized attachments that perform specific tasks, often interchangeable based on the requirements.

Each component is designed to work in harmony with the others, ensuring optimal performance and reliability. Regular inspection and understanding of these parts can lead to enhanced efficiency and longevity of the equipment.

Below is a detailed list of essential components and their functions:

- Actuator: Translates electrical signals into mechanical movement.

- Pressure Gauge: Monitors the fluid pressure within the hydraulic system.

- Safety Switch: Prevents accidental operation by requiring specific conditions to be met.

- Hoses and Fittings: Facilitate the flow of hydraulic fluid throughout the system.

- Electrical Wiring: Connects various components, enabling communication and power distribution.

Familiarity with these parts not only aids in the correct operation of the equipment but also empowers users to address minor issues independently.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for maintaining the efficiency and safety of any equipment. By systematically examining potential faults, users can prevent further damage and ensure optimal performance. This section will provide guidance on common electrical malfunctions and practical steps for diagnosing them.

Common Symptoms and Causes

When dealing with electrical difficulties, recognizing the symptoms can lead to quicker resolutions. Below is a table outlining prevalent signs, their potential causes, and suggested actions to take:

| Symptoms | Possible Causes | Recommended Actions |

|---|---|---|

| No Power | Blown fuse or tripped circuit breaker | Check fuses and reset breakers |

| Intermittent Function | Loose connections | Tighten all connections |

| Strange Noises | Worn components | Inspect and replace damaged parts |

| Overheating | Overloaded circuits | Reduce load and assess wiring |

Step-by-Step Diagnostic Approach

To effectively troubleshoot, follow these steps: First, ensure safety by disconnecting power sources. Next, visually inspect for obvious issues like frayed wires or burnt components. Use a multimeter to measure voltage and continuity, confirming that all parts are functioning correctly. Document findings and address any discrepancies methodically. This structured approach will facilitate the identification of underlying issues and aid in restoring normal operation.

Maintaining Your Greenlee Equipment

Proper upkeep of your tools is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances the efficiency of your equipment but also helps prevent costly repairs and downtime. Here are some key practices to consider for effective care.

- Inspect regularly for wear and tear.

- Clean equipment after each use to prevent buildup of debris.

- Lubricate moving parts as recommended to reduce friction.

- Check electrical components for signs of damage or corrosion.

- Store tools in a dry, safe environment to avoid rust and deterioration.

In addition to these practices, following the manufacturer’s guidelines can provide further insights into specific maintenance needs. Regularly scheduled service can also help identify potential issues before they escalate.

- Perform a thorough inspection at least once a month.

- Replace any worn-out components immediately.

- Calibrate tools as necessary to ensure accuracy.

- Keep an inventory of spare parts for quick access.

By dedicating time to maintain your equipment, you not only enhance its performance but also extend its useful life, ensuring reliability in all your projects.

Finding Replacement Parts Easily

Locating suitable components for your tools can be a straightforward process when you know where to look. Understanding the best resources and strategies can save time and effort, ensuring that your equipment remains in top working condition.

Here are several effective ways to find the parts you need:

- Online Retailers: Many websites specialize in selling tool components. Look for reputable vendors that offer a wide selection of items.

- Manufacturer’s Website: Often, the official site provides a catalog of available parts, complete with diagrams and descriptions.

- Local Hardware Stores: Visit stores in your area; they may carry common replacement items or can order them for you.

- Forums and Communities: Engage with online forums where enthusiasts and professionals discuss tools. Members often share links to suppliers or even sell parts directly.

- Distributors: Authorized distributors may offer a broader range of options and have the expertise to help you find the right component.

By utilizing these resources, you can ensure that your tools are always equipped with the necessary parts, enhancing their longevity and performance.

Frequently Asked Questions About Repairs

This section addresses common inquiries regarding maintenance and troubleshooting procedures. Understanding these elements can help users effectively manage their equipment and ensure optimal performance.

-

What are the most common issues encountered?

Users often face problems such as:

- Electrical malfunctions

- Mechanical wear and tear

- Inadequate power supply

- Component misalignment

-

How can I identify a problem early?

Signs to watch for include:

- Unusual noises during operation

- Inconsistent performance

- Visual damage to components

- Unexpected power fluctuations

-

What tools are needed for basic maintenance?

Essential tools may include:

- Screwdrivers (various sizes)

- Wrenches and pliers

- Multimeter for electrical testing

- Lubricants and cleaning supplies

-

Is it advisable to perform repairs myself?

This depends on your expertise. If you have sufficient knowledge, DIY fixes can save time and money. However, for complex issues, consulting a professional is recommended.

-

Where can I find replacement parts?

Replacement components can typically be sourced from:

- Authorized dealers

- Online marketplaces

- Local hardware stores

- Manufacturer’s websites