Essential Guide to Hobart M802 Repair Manual

Understanding the intricacies of your kitchen apparatus is essential for ensuring its longevity and optimal performance. This section delves into the critical aspects of maintaining and troubleshooting your device, providing essential insights for users at all levels. Knowledge of the functioning elements and potential issues can significantly enhance the overall efficiency of your culinary environment.

In this guide, you will find detailed procedures and practical advice aimed at empowering users to handle common challenges that may arise. By familiarizing yourself with the various components and their operations, you can confidently address concerns that might otherwise disrupt your workflow. Our focus will be on simplifying complex tasks and clarifying processes to make maintenance approachable.

Equipped with this information, you will be better prepared to ensure your appliance remains in peak condition. Whether you are a seasoned chef or a casual cook, this resource serves as a valuable companion in navigating the upkeep of your essential equipment. Embrace the opportunity to enhance your skills and keep your tools functioning flawlessly.

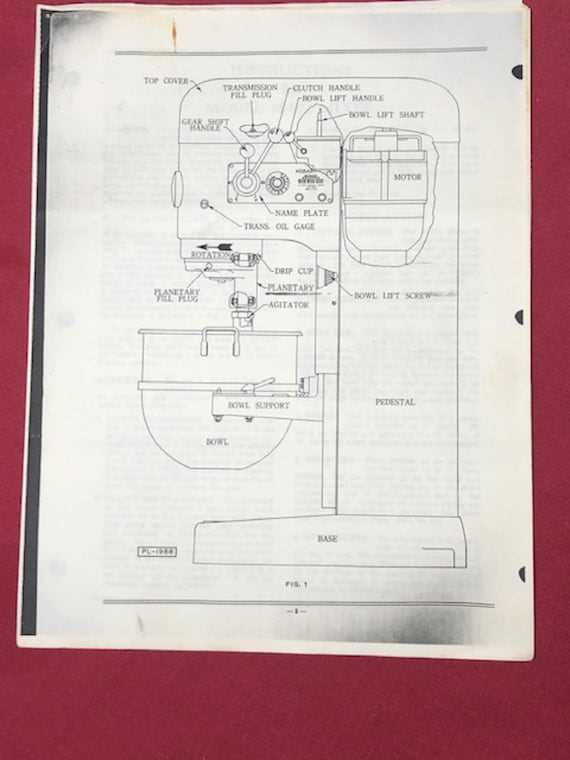

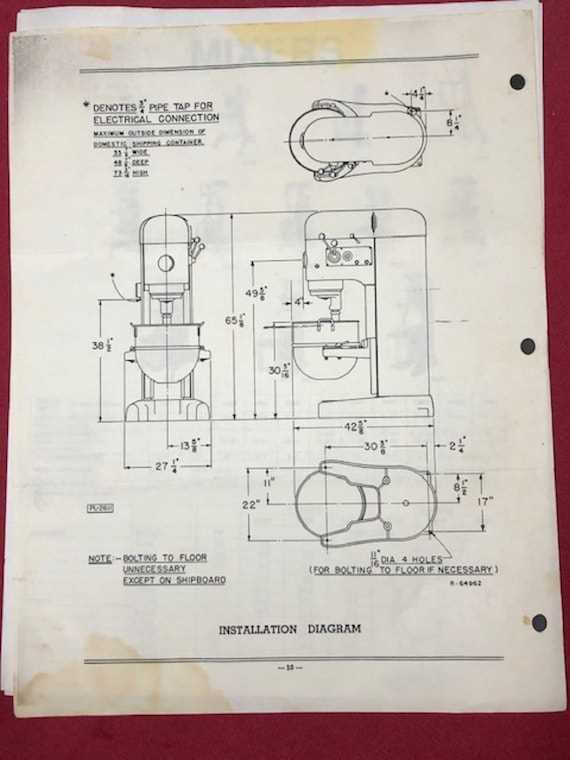

Overview of Hobart M802 Features

This section explores the key attributes of a renowned food processing machine designed for heavy-duty applications. Known for its robust construction and user-friendly interface, it serves as an essential tool in commercial kitchens, ensuring efficiency and reliability in food preparation tasks.

Durability and Design

The unit boasts a sturdy build that can withstand the rigors of constant use. Crafted from high-quality materials, it features a sleek design that not only enhances its aesthetic appeal but also ensures longevity. This combination of strength and style makes it an indispensable asset in any culinary environment.

Performance and Efficiency

Equipped with powerful motors and advanced technology, this machine offers superior performance, allowing for quick and efficient mixing. Its variable speed settings provide versatility, accommodating a variety of recipes and ingredients. Users can expect consistent results, making meal preparation faster and more efficient.

In summary, the standout characteristics of this appliance make it a vital component for any professional kitchen, balancing performance with durability and ease of use.

Common Issues with Hobart M802

This section highlights frequent challenges encountered with a well-known kitchen equipment model, focusing on its operational and mechanical aspects. Understanding these issues can help users troubleshoot effectively and maintain optimal performance.

Typical Problems

- Motor Overheating

- Inconsistent Mixing Speed

- Unusual Noises During Operation

- Electrical Failures

Symptoms and Solutions

- Motor Overheating: This can occur due to prolonged use or blockages. Ensure proper ventilation and allow the machine to cool down regularly.

- Inconsistent Mixing Speed: A common issue often linked to worn belts or improper settings. Check and adjust the speed settings or replace worn components.

- Unusual Noises: Grinding or squeaking sounds may indicate issues with gears or bearings. Inspect these parts and lubricate or replace as necessary.

- Electrical Failures: If the equipment fails to start, check the power source, cords, and fuses. Repair or replace any damaged electrical components.

Essential Tools for Repairing M802

When tackling maintenance tasks for this equipment, having the right instruments at your disposal is crucial for efficiency and effectiveness. The following tools will facilitate a smoother process and ensure that each component is addressed properly.

Basic Toolkit

A foundational set of tools is essential for any technician. These include a variety of wrenches, screwdrivers, and pliers, which are vital for disassembling and reassembling parts. Ensure that your toolkit is well-stocked with both standard and metric sizes to accommodate different fasteners.

Specialized Equipment

In addition to the basic toolkit, certain specialized items may be required for more intricate procedures. These tools are designed to handle specific tasks that standard tools may not effectively address. Below is a table outlining some of the key specialized tools and their functions:

| Tool | Function |

|---|---|

| Torque Wrench | Ensures proper fastening torque for bolts and screws. |

| Caliper | Measures precise dimensions of components for accurate fitting. |

| Multimeter | Tests electrical connections and identifies issues in circuits. |

| Wire Strippers | Facilitates clean stripping of insulation from wires. |

Step-by-Step Repair Process

This section outlines a systematic approach to fixing kitchen equipment, ensuring efficiency and safety throughout the procedure. By following these clear guidelines, technicians can address issues effectively and restore functionality.

- Preparation:

- Gather all necessary tools and replacement parts.

- Ensure the workspace is clean and organized.

- Review the specific issues reported with the equipment.

- Disassembly:

- Disconnect the unit from the power source.

- Carefully remove any covers or panels to access internal components.

- Keep track of screws and small parts for reassembly.

- Inspection:

- Examine all parts for signs of wear, damage, or malfunction.

- Test electrical connections with a multimeter.

- Identify any components that require replacement or adjustment.

- Replacement:

- Install new parts as needed, following manufacturer specifications.

- Ensure all connections are secure and properly aligned.

- Reassembly:

- Reattach panels and covers, making sure everything fits snugly.

- Double-check that no tools or parts are left inside the unit.

- Testing:

- Reconnect the unit to the power source.

- Run the equipment to confirm that it operates correctly.

- Monitor for any unusual sounds or issues during operation.

Following these steps will help ensure that the kitchen appliance is restored to optimal working condition, minimizing downtime and maximizing efficiency.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial to prevent accidents and injuries. Proper awareness and adherence to safety measures create a secure working environment, allowing for efficient troubleshooting and enhancement of equipment functionality.

Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots. This gear minimizes the risk of injuries from sharp edges, heavy objects, or hazardous substances.

Before commencing any work, disconnect power sources to prevent accidental energization. This step is essential for safeguarding both the technician and the equipment being serviced.

It is vital to keep the workspace organized. Clutter can lead to slips, trips, or falls, which may result in serious injuries. Ensure that all tools are accounted for and stored safely when not in use.

Follow manufacturer guidelines and use the correct tools for each task. Using improper tools can lead to equipment damage or personal injury. Regularly inspect tools for wear and tear to ensure they are in good condition.

Lastly, be aware of your surroundings. Make sure that others are aware of your work area and potential hazards. Communicating with colleagues helps maintain a safe and productive environment.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent care and attention. Regular maintenance not only prolongs the lifespan of your machinery but also enhances its performance. Here are essential practices to keep your unit in optimal condition.

- Regular Cleaning: Remove debris and residue from surfaces. Accumulated dirt can lead to overheating and malfunction.

- Inspect Components: Routinely check parts for wear and tear. Early detection of issues can prevent major breakdowns.

- Lubricate Moving Parts: Apply appropriate lubricants to reduce friction. This will help in maintaining smooth operations and minimizing wear.

- Monitor Operating Conditions: Keep an eye on temperature and pressure levels. Ensure that the equipment is used within its specified limits.

- Replace Filters: Change filters regularly to ensure optimal airflow and prevent contamination. Clogged filters can reduce efficiency.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and procedures outlined by the manufacturer.

By implementing these maintenance strategies, you can significantly extend the life of your machinery and ensure it operates efficiently for years to come.

Understanding M802 Electrical Components

The electrical system of industrial equipment is crucial for optimal performance and efficiency. A solid grasp of the various electrical parts and their functions enables operators and technicians to troubleshoot effectively and maintain equipment in peak condition.

Power Supply components provide the necessary energy to the system. These elements convert and regulate voltage levels, ensuring that all parts receive appropriate power for operation. Understanding their specifications is vital for diagnosing potential issues.

Circuitry serves as the network through which electrical signals travel. Familiarity with wiring diagrams and connections can help in identifying faults and ensuring correct assembly. Connector types and their placements play a significant role in maintaining a reliable flow of electricity.

Sensors monitor various operational parameters, relaying important data back to the control unit. Recognizing how these devices function aids in interpreting their readings and making necessary adjustments to enhance productivity.

Control Units, including relays and switches, act as the brains of the operation, managing power distribution and executing commands based on sensor input. A clear understanding of their operation is essential for efficient troubleshooting and repair.

By familiarizing oneself with these key electrical components, users can ensure longevity and reliability in their machinery, minimizing downtime and enhancing overall productivity.

Identifying Mechanical Failures

Recognizing issues in machinery is crucial for maintaining optimal performance and longevity. By systematically examining equipment, one can detect irregularities that indicate potential malfunctions. Understanding the common signs of mechanical breakdowns allows for timely intervention and can prevent costly repairs.

Common Indicators of Malfunctions

- Unusual Noises: Grinding, squeaking, or knocking sounds can suggest worn components or misalignments.

- Performance Drops: A noticeable decline in efficiency or output often signals underlying issues.

- Visible Wear: Inspecting parts for signs of wear, such as cracks or corrosion, can provide early warnings of failure.

- Excessive Heat: Overheating can indicate friction problems or inadequate lubrication.

- Leaks: Fluid leaks around joints and seals may point to seal failures or component wear.

Steps for Diagnosis

- Conduct a visual inspection to identify any obvious damage or wear.

- Listen for any unusual sounds during operation.

- Monitor the performance metrics regularly to detect any fluctuations.

- Check for temperature changes in components to catch overheating issues.

- Review maintenance logs to ensure timely servicing and identify recurring problems.

Where to Find Replacement Parts

Finding the right components for your equipment can be a challenge, but several resources can simplify the process. Understanding where to look is crucial to ensure that you obtain high-quality items that fit your specific needs.

Online Retailers: Numerous online platforms specialize in selling parts for various types of machinery. Websites like Amazon, eBay, and dedicated parts suppliers often have extensive inventories. Searching for your model and part number can yield quick results, allowing you to compare prices and availability.

Manufacturer’s Website: The official website of the brand often provides a catalog of components along with specifications. Many manufacturers also offer direct purchasing options, which can guarantee the authenticity of the parts.

Local Distributors: Visiting local distributors or suppliers can be beneficial. They often have knowledgeable staff who can assist in identifying the correct items. Establishing a relationship with these businesses can also lead to insights on new stock or exclusive deals.

Repair Shops: Authorized repair centers are another valuable resource. They not only sell parts but can also provide expert advice on installation and compatibility. Utilizing their expertise can save time and prevent errors.

Forums and Community Groups: Engaging with online forums and community groups dedicated to your equipment can lead to recommendations for reliable sources. Members often share their experiences and may point you to lesser-known suppliers.

By exploring these avenues, you can effectively source the necessary components to keep your machinery running smoothly.

Troubleshooting Techniques for Common Problems

When dealing with machinery, it’s crucial to identify and resolve issues efficiently to ensure optimal performance. This section focuses on effective methods to diagnose prevalent challenges encountered during operation. By applying systematic approaches, users can streamline the process of finding solutions, thus minimizing downtime and enhancing functionality.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| Electrical Failure | No power, flickering lights | Check the power source, inspect fuses, test connections. |

| Mechanical Jam | Unusual noises, inability to operate | Examine moving parts, remove debris, lubricate as needed. |

| Overheating | Excessive heat, automatic shut-off | Assess airflow, clean vents, check temperature settings. |

| Poor Performance | Inconsistent results, slow operation | Inspect components for wear, calibrate settings, replace filters. |

| Fluid Leaks | Puddles beneath the machine | Locate the source, tighten connections, replace seals if necessary. |

Utilizing these strategies allows operators to address issues proactively, ensuring that equipment remains in peak condition and continues to meet operational demands.

User Experiences and Repair Stories

This section focuses on shared experiences and anecdotes from individuals who have encountered issues with their equipment. Personal stories can provide valuable insights into common challenges and effective solutions. By examining these narratives, users can learn from one another and enhance their understanding of maintenance practices.

Many users have faced various malfunctions, prompting them to seek out community advice or explore do-it-yourself fixes. Here are some notable accounts that highlight different approaches and outcomes:

| User | Issue | Solution | Outcome |

|---|---|---|---|

| John D. | Heating element failure | Replaced the element with a compatible part | Restored functionality |

| Sarah K. | Noise during operation | Lubricated moving parts | Reduced noise significantly |

| Mike L. | Power issues | Checked and tightened connections | Resolved the problem |

| Emily T. | Inconsistent performance | Cleaned and calibrated settings | Improved efficiency |

These narratives illustrate the diverse experiences users have had and the innovative solutions they employed. Such stories not only foster a sense of community but also empower individuals to tackle their own challenges with confidence.