Huskee Lawn Mower Repair Guide for Easy Maintenance

Maintaining outdoor equipment in optimal condition ensures smooth operation and extends the life of your tools. This guide provides an overview of essential techniques for assessing the state of various machinery, focusing on efficient ways to identify and address common issues. The aim is to support you in keeping your devices running smoothly with minimal downtime.

With regular upkeep, any outdoor tool can remain reliable and efficient over time. Here, you’ll find detailed steps and practical tips to manage everything from routine checks to more involved inspections. Following these guidelines will empower you to perform necessary tasks, ensuring that your equipment is always ready to meet your needs.

In this guide, we cover essential techniques that help address unexpected complications. Equipped with this knowledge, you’ll be prepared to tackle challenges independently, enhancing your skills and maintaining a high standard for all your outdoor devices.

Guide to Huskee Lawn Mower Repair

Maintaining and troubleshooting outdoor equipment can extend its functionality and ensure safe operation over time. A clear understanding of common issues, along with routine check-ups, allows users to address potential concerns and keep the machine in peak condition.

Understanding Common Issues

Frequent usage, seasonal wear, and environmental factors can impact machine performance. Knowing how to identify signs of wear, such as unusual sounds or reduced efficiency, can help in spotting areas that may need attention before issues become critical.

Basic Maintenance Tips

Regularly inspecting and cleaning essential parts not only prevents breakdowns but also promotes optimal function. This includes checking for debris build-up, examining fuel levels, and ensuring all moving parts are properly lubricated and secure. Consistent upkeep supports efficiency and prolongs the lifespan of outdoor equipment.

Troubleshooting Common Huskee Mower Issues

Regular maintenance and quick issue identification can ensure smooth operation and longevity of outdoor equipment. This guide highlights common performance setbacks, helping users pinpoint the source of problems and restore functionality efficiently.

Engine Starting Problems

If the engine fails to start, check for potential causes like fuel and oil levels, as well as spark plug health. Low fuel or dirty filters can lead to starting troubles, while a worn spark plug may need replacement to regain proper ignition. Ensuring these components are clean and functional can resolve startup issues quickly.

Uneven Cutting or Vibration

Unexpected vibrations or uneven trimming often result from debris buildup or blade imbalances. Inspect the blades for any visible damage, as well as grass or soil stuck underneath. Cleaning the blades and ensuring they’re well-aligned minimizes vibration and improves cut consistency. For severe imbalances, consider blade sharpening or replacement.

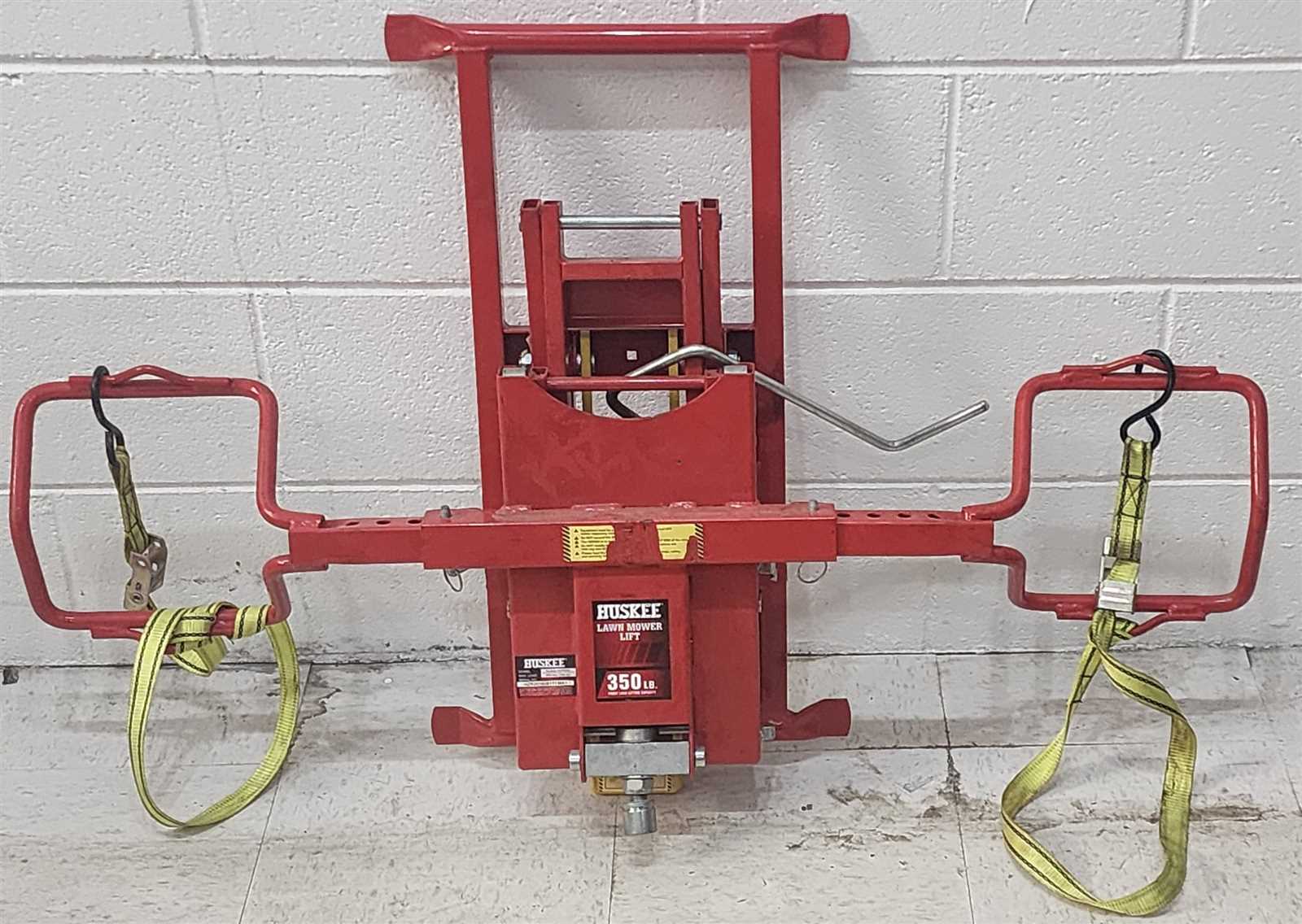

Steps to Replace the Mower Blade

Replacing the blade ensures efficient and safe operation, improving the quality of each cut and extending the equipment’s lifespan. The process is straightforward with the right tools and a few essential safety steps.

- Prepare the Equipment

- Disconnect the power source to prevent accidental startup.

- Position the machine on a flat surface and use a block to secure it in place.

- Access the Blade

- Gently tilt the machine to expose the blade assembly.

- Use a wrench to carefully loosen the bolt securing the blade.

- Remove the Old Blade

- Once the bolt is loose, take out the blade carefully.

- Inspect the blade mount for any damage or wear.

- Install

How to Adjust the Wheels for Optimal Cutting Height

Properly setting the wheels allows for a smooth and even trim, essential for maintaining a neat appearance on any grassy area. Adjusting the height is straightforward but requires attention to ensure the equipment remains level and stable during use.

Steps for Adjusting Wheel Height

To begin, locate the adjustment levers near each wheel. Most models feature a lever that moves in preset notches, allowing for various height settings. Carefully lift or lower the lever until the desired height is achieved, making sure to set each wheel to the same level.

Important Tips for Safe Adjustment

Before starting, always ensure the machine is off and cooled down. Use firm grip when moving levers, and check that all wheels are securely positioned in the same slot. This consistency prevents uneven cuts and enhances maneuverability.

Engine Maintenance Tips for Longevity

Maintaining the engine is essential to ensure that your equipment operates efficiently and remains in optimal condition for years to come. A well-cared-for engine reduces the likelihood of breakdowns and helps avoid costly repairs. Following a few key maintenance practices can significantly extend the lifespan of the engine.

Regular Oil Changes

Consistent oil changes are one of the most important steps in engine upkeep. Old oil loses its effectiveness in lubricating and protecting engine components, leading to increased wear. Always use the correct oil type as recommended, and aim to change it after every 25-50 hours of operation or as specified in the user guidelines.

Air Filter Cleaning and Replacement

The air filter prevents dirt and debris from entering the engine. A clean filter ensures optimal airflow, which is crucial for fuel combustion. Inspect the air filter regularly and clean or replace it as necessary, typically after every 25 hours of use or if it appears clogged. This simple step can significantly improve the engine’s efficiency and longevity.

Maintenance Task Fr Replacing a Huskee Mower Spark Plug

Changing the ignition component is a crucial aspect of maintaining optimal engine performance. Regularly replacing this part ensures efficient combustion and can lead to improved power output and fuel efficiency.

To begin the process, first, ensure that the engine is completely cool. Disconnect the spark plug wire to prevent accidental starts. Using a suitable socket wrench, carefully remove the old component. Examine it for signs of wear, such as excessive carbon buildup or corrosion, which can indicate the need for replacement.

Once the old piece is removed, take the new spark plug and verify its gap specifications according to the manufacturer’s guidelines. Carefully insert it into the engine, hand-tightening initially to avoid cross-threading. After securing it snugly, reconnect the ignition wire, ensuring a secure fit.

Finally, test the engine by starting it up. Listen for smooth operation, as any irregular sounds may suggest further adjustments are necessary. Regular maintenance, including this simple replacement, is essential for keeping the engine running efficiently.

Cleaning the Air Filter for Better Performance

Maintaining the cleanliness of the air filtration component is essential for optimal functionality and efficiency of the machinery. A clean filter allows for adequate airflow, ensuring that the engine operates smoothly and effectively. Neglecting this part can lead to decreased performance and potential damage over time.

To ensure your equipment remains in top condition, follow these steps to clean the air filter:

Step Action Details 1 Remove the Filter Carefully detach the filter from its housing, ensuring not to damage any components. 2 Inspect for Damage Check the filter for any signs of wear or damage. Replace if necessary. 3 Clean the Filter Use compressed air or a soft brush to remove dust and debris, ensuring thorough cleaning. 4 Reinstall the Filter Once cleaned, place the filter back in its original position securely. Regular attention to the air filtration system not only enhances performance but also extends the lifespan of the equipment, making it a crucial aspect of maintenance.

Checking and Changing the Oil Correctly

Maintaining the lubrication system of your machine is essential for optimal performance and longevity. Regularly monitoring and replacing the oil helps ensure that the engine operates smoothly and efficiently, preventing unnecessary wear and tear.

To begin the process, make sure the equipment is turned off and placed on a level surface. Allow the engine to cool down if it has been running. This step is crucial for accurate measurement and safe handling of the oil.

Next, locate the oil dipstick or filler cap, which is usually marked for easy identification. Remove it carefully and wipe it clean with a lint-free cloth. This ensures that any previous readings are eliminated, providing a clear view of the oil level.

Check the oil level by reinserting the dipstick without screwing it back in and then removing it again. The oil should be within the recommended range marked on the dipstick. If it is below the minimum level, you will need to add oil.

When it’s time to change the oil, place a suitable container beneath the drainage point. Remove the drain plug and allow the old oil to completely flow out. Once drained, replace the drain plug securely.

Finally, refill the engine with fresh oil through the dipstick tube, using a funnel to avoid spills. Refer to your device’s specifications for the correct type and amount of oil needed. After filling, check the level again with the dipstick to ensure it is within the optimal range.

By following these steps regularly, you can enhance the performance and durability of your equipment, keeping it in excellent working condition.

Fixing a Stuck or Loose Handle

Having difficulty with a handle that doesn’t function properly can be frustrating, but it’s a common issue that can usually be resolved with some simple steps. Whether the handle is stuck due to dirt buildup or has become loose over time, understanding how to address these problems can enhance your overall experience. This section provides guidance on how to effectively tackle these handle-related challenges.

Identifying the Problem

Before attempting any fixes, it’s essential to determine whether the handle is stuck or simply loose. A stuck handle may resist movement, while a loose handle will wobble or feel insecure. Inspect the attachment points and ensure that there are no visible obstructions or damage. Here’s a quick checklist to help you identify the issue:

Issue Symptoms Stuck Handle Handle does not move at all Loose Handle Handle wobbles or feels unstable Steps to Resolve the Issue

Once you have identified the problem, you can proceed with the appropriate steps to fix it. For a stuck handle, try cleaning the mechanism thoroughly and applying a lubricant to free any stuck components. If the handle is loose, check the fasteners and tighten them if necessary. Here are the steps to follow:

Step Action 1 Inspect the handle for any visible obstructions. 2 Clean the area around the handle to remove dirt or debris. 3 For stuck handles, apply a suitable lubricant and gently wiggle the handle. 4 For loose handles, locate the screws or bolts and tighten them appropriately. Sharpening the Mower Blade Efficiently

Maintaining the sharpness of cutting instruments is essential for achieving optimal performance and ensuring a clean cut. Properly honed edges reduce the effort needed during operation and promote healthy growth of the surrounding vegetation. This section will guide you through the efficient methods to achieve razor-sharp blades.

Choosing the Right Tools

Before beginning the sharpening process, select the appropriate tools for the task. A sharpening stone or file is often sufficient for minor touch-ups, while a bench grinder can be used for more significant blade restoration. Ensure that your tools are in good condition to avoid compromising the effectiveness of the sharpening process.

Step-by-Step Sharpening Process

Begin by safely detaching the cutting element from the machine. Clean the blade thoroughly to remove debris and rust, as this will improve the sharpening process. Position the blade securely and apply consistent pressure while moving the sharpening tool along the edge. Aim for a uniform angle to ensure an even cut. After sharpening, it is important to balance the blade to prevent vibrations during operation. Regular maintenance will prolong the life of the cutting instrument and enhance its efficiency.

Aligning the Cutting Deck Safely

Ensuring that the cutting platform is correctly positioned is crucial for achieving optimal performance and maintaining a well-groomed area. A properly aligned apparatus allows for even trimming and reduces the risk of uneven wear, leading to longer equipment life.

Before starting the alignment process, it is important to prepare the equipment and workspace. Ensure that the apparatus is on a flat, stable surface to facilitate accurate adjustments. Engage the safety features to prevent accidental operation during the procedure. It is advisable to have the necessary tools on hand, including wrenches and measuring devices, to assist in the alignment process.

Begin by checking the height settings on each side of the cutting platform. Adjust them to ensure they match the manufacturer’s specifications. Use a measuring tool to verify that the distance from the ground to the cutting edge is consistent across the width. If discrepancies are found, make the necessary adjustments to achieve balance.

After height adjustments, examine the angle of the cutting platform. Leveling the deck can help prevent scalping and promote efficient grass clipping. Adjust the tilt by loosening the mounting bolts and repositioning the deck as required. Tighten the bolts securely once the desired angle is achieved.

Lastly, perform a final inspection to confirm that all adjustments are secure and that the cutting platform is aligned correctly. Regular maintenance of the alignment can enhance performance and ensure that the equipment operates safely and efficiently.

Inspecting and Adjusting the Drive Belt

The drive belt is a crucial component in the operation of any equipment that relies on a mechanical connection for power transmission. Regular inspection and adjustment ensure that this element functions efficiently, preventing potential damage and maintaining optimal performance. Understanding how to properly evaluate and modify the tension and condition of the belt is essential for smooth operation.

Visual Inspection

Start by examining the drive belt for signs of wear, such as fraying, cracking, or excessive stretching. Ensure that it is properly aligned with the pulleys, as misalignment can lead to premature wear and ineffective performance. Take note of any unusual noises during operation, as these may indicate a problem with the belt or related components.

Adjustment Procedures

If the drive belt appears loose, adjust the tension according to the manufacturer’s specifications. This may involve repositioning the tensioner or adjusting the pulleys. Ensure that the belt is snug but not overly tight, as excessive tension can cause additional strain on the system. After adjustments are made, perform a final inspection to confirm that everything is aligned correctly and functioning as intended.

Battery Care for Electric Huskee Mowers

Maintaining the power source of your electric gardening equipment is crucial for optimal performance and longevity. Proper care and handling of batteries can significantly enhance their efficiency and lifespan. This section outlines essential practices to ensure your energy cells remain in top condition.

Regularly checking the battery’s charge level is essential. Ensure that it is adequately charged before use to prevent interruptions during operation. Additionally, it is advisable to avoid completely draining the battery, as this can lead to reduced capacity over time. Instead, recharge it after each use or when it reaches about 20% of its power.

Storing batteries correctly also plays a vital role in their maintenance. Keep them in a cool, dry place, away from direct sunlight and extreme temperatures. This environment helps to preserve their chemical composition and ensures they remain ready for use when needed.

Lastly, periodic cleaning of the battery terminals is necessary to prevent corrosion. Use a soft cloth to wipe away any dirt or grime, ensuring a secure connection. Following these guidelines will help maintain the efficiency and lifespan of your power source.