Comprehensive Guide to Repairing Husqvarna 136 Chainsaw

In the world of outdoor equipment, understanding how to properly maintain and troubleshoot your machinery is crucial for optimal performance. This resource serves as a vital tool for enthusiasts and professionals alike, ensuring that their equipment runs smoothly and efficiently over time. Whether you are dealing with minor adjustments or significant issues, having a thorough understanding of the workings of your chainsaw can save both time and money.

Effective upkeep of your device not only enhances its longevity but also promotes safety during operation. Knowledge of the various components and their functions empowers users to identify potential problems before they escalate. This guide will delve into essential techniques and best practices, offering step-by-step instructions to help you navigate any challenges that may arise.

Additionally, this document will highlight common pitfalls and provide insights into troubleshooting methods. By familiarizing yourself with the intricacies of your machine, you will be better equipped to address concerns swiftly and confidently. Embrace the opportunity to enhance your skills and ensure that your equipment remains in peak condition, ready for any task at hand.

Understanding Husqvarna 136 Basics

Familiarity with outdoor power tools is essential for efficient maintenance and operation. This section provides foundational knowledge about a specific chainsaw model, highlighting its design, features, and optimal usage. Understanding these basics will enhance your experience and ensure safety while working with this equipment.

Key Features

The chainsaw in question boasts several notable characteristics that set it apart. It typically includes a robust engine, which delivers powerful performance, making it suitable for various tasks such as cutting firewood or managing yard debris. Additionally, ergonomic design elements enhance user comfort and control, allowing for extended usage without excessive fatigue.

Maintenance Essentials

Regular upkeep is vital to prolong the life of your equipment. Basic maintenance tasks include checking and replacing the air filter, ensuring the chain is properly lubricated, and inspecting the spark plug for wear. By following these simple guidelines, you can maintain optimal performance and prevent potential issues.

Common Issues with Husqvarna 136

When working with outdoor power equipment, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems is essential for effective troubleshooting and maintenance. This section highlights typical issues that can arise with this particular model and offers insights into potential solutions.

Starting Difficulties

One prevalent concern involves difficulties with starting the unit. This can be attributed to several factors, including fuel quality, air filter condition, and spark plug functionality. Ensuring that fresh fuel is used and that the air intake is clean can significantly enhance starting performance. Additionally, checking the spark plug for wear or damage is crucial for proper ignition.

Chain and Bar Problems

Another frequent issue pertains to the chain and guide bar. Users often report problems such as chain slipping or excessive wear. Proper tension adjustment is vital; an improperly tensioned chain can lead to inefficient cutting and increased wear. Regular lubrication of the bar and chain is also necessary to prevent overheating and damage during operation.

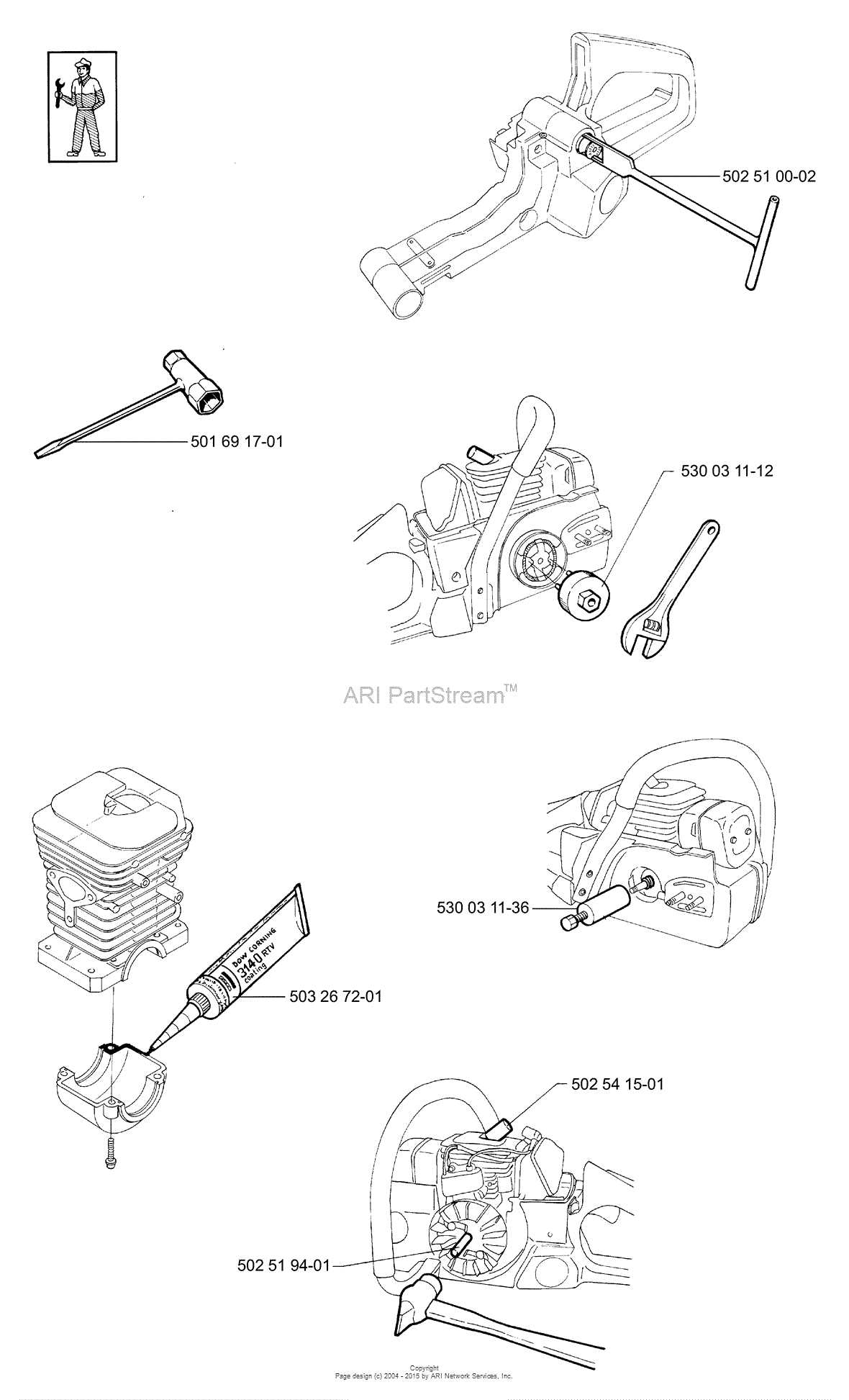

Tools Required for Repair

Having the right equipment is essential for performing maintenance and fixing issues effectively. This section outlines the necessary implements that will facilitate the process, ensuring efficiency and safety.

Essential Hand Tools

- Flathead screwdriver

- Phillips screwdriver

- Adjustable wrench

- Pliers

- Torque wrench

Specialized Equipment

- Chain sharpener

- Compression tester

- Fuel system cleaner

- Spark plug wrench

- Measuring tools

Equipping yourself with these tools will ensure that you can tackle any tasks that arise, maintaining optimal performance and longevity.

Step-by-Step Repair Instructions

This section provides a comprehensive guide for restoring functionality to your equipment. By following these detailed steps, you can efficiently troubleshoot and fix common issues, ensuring optimal performance.

-

Identify the Issue: Begin by observing the symptoms of malfunction. Common problems may include:

- Difficulty starting the engine

- Unusual noises during operation

- Poor cutting performance

-

Gather Necessary Tools: Ensure you have the following tools on hand:

- Screwdriver set

- Wrench set

- Clean cloths

- Replacement parts as needed

-

Safety Precautions: Before starting any work, remember to:

- Disconnect the spark plug to prevent accidental starts.

- Wear protective gloves and eyewear.

-

Disassemble the Unit: Carefully remove the casing or cover to access internal components. Keep track of screws and small parts.

-

Inspect Internal Components: Look for wear, damage, or blockages in the following areas:

- Fuel lines

- Air filter

- Ignition system

-

Clean or Replace Parts: Depending on your findings, either clean the affected areas or replace damaged components with new ones.

-

Reassemble the Unit: Once repairs are complete, carefully put the unit back together, ensuring all screws and fasteners are secure.

-

Test the Equipment: Reconnect the spark plug and start the engine to verify that the issues have been resolved.

By following these systematic steps, you can effectively address and resolve issues, prolonging the lifespan of your equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your outdoor power equipment. Regular care not only enhances performance but also minimizes the risk of unforeseen issues. Adopting a proactive maintenance routine can lead to reliable operation and greater satisfaction in your work.

Regular Cleaning

Keeping your equipment clean is vital for optimal performance. After each use, remove any debris, dirt, or residue from the exterior and components. Pay special attention to air filters and cooling fins, as these areas can accumulate grime that affects efficiency. Utilizing a soft brush or compressed air can effectively eliminate unwanted particles.

Routine Inspections

Conducting periodic inspections allows you to identify potential problems before they escalate. Check for wear and tear on essential parts, such as blades and belts. Lubricating moving components helps reduce friction and prolongs the lifespan of the equipment. Always refer to the guidelines for specific maintenance intervals and procedures to follow.

Replacing Essential Parts Safely

Ensuring the safe replacement of vital components in machinery is crucial for maintaining optimal performance and preventing accidents. This section emphasizes the importance of adhering to proper procedures and guidelines during the replacement process. Understanding the necessary precautions can help mitigate risks and extend the lifespan of your equipment.

Preparation and Tools

Before initiating any replacement task, it is essential to gather all required tools and parts. Ensure that you have the appropriate equipment for the specific components you are working on. Reviewing the manufacturer’s recommendations and having a clean workspace will enhance safety and efficiency. Always wear suitable protective gear to safeguard against potential hazards.

Step-by-Step Replacement Process

Follow a systematic approach when replacing parts. Begin by disconnecting power sources and carefully removing any coverings. Keep track of each component and fastener to ensure correct reassembly. When installing new parts, follow the guidelines closely, securing each element as specified. After the replacement is complete, conduct a thorough inspection to confirm everything is properly in place before reactivating the machine.

Troubleshooting Electrical Problems

Addressing issues related to electrical systems can often be daunting, but with a systematic approach, many common challenges can be identified and resolved. Understanding the potential sources of electrical failures is crucial for restoring functionality and ensuring safety. This section will guide you through key steps and considerations for diagnosing and fixing electrical malfunctions.

Identifying Common Symptoms

Before diving into repairs, it’s important to recognize typical indicators of electrical issues. These may include:

- Unresponsive controls

- Inconsistent power delivery

- Strange noises or smells

Paying attention to these signs can help pinpoint the problem more quickly.

Basic Troubleshooting Steps

Once symptoms are noted, follow these basic steps to troubleshoot:

- Inspect Connections: Check all wiring and connections for signs of damage or corrosion. Ensure that all plugs and sockets are secure.

- Test the Power Source: Use a multimeter to verify voltage at the power source. If no power is present, the source may need attention.

- Examine Components: Look at individual components like switches and fuses for failure. Replace any that appear faulty.

By methodically working through these steps, you can often isolate and remedy electrical issues effectively.

Importance of Regular Cleaning

Maintaining equipment in optimal condition is crucial for its longevity and performance. Regular cleaning plays a vital role in preventing wear and tear, ensuring smooth operation, and enhancing efficiency. This practice not only improves the lifespan of the machinery but also contributes to safety during use.

- Prevents Build-Up: Accumulation of debris and residue can hinder performance. Frequent cleaning helps to eliminate these blockages.

- Enhances Performance: Clean components operate more efficiently, leading to better results during operation.

- Increases Safety: Dirt and grime can obscure moving parts, posing risks. Keeping equipment clean reduces potential hazards.

- Reduces Maintenance Costs: Regular upkeep minimizes the likelihood of serious issues that could require expensive repairs.

In conclusion, establishing a routine cleaning schedule is an essential practice for anyone who uses machinery regularly. It ensures that the equipment remains in prime condition, allowing for consistent performance and safety.

When to Seek Professional Help

Understanding when to enlist the expertise of a professional can be crucial for ensuring optimal performance and longevity of your equipment. While some issues can be managed independently, certain complexities may require specialized knowledge and tools that only trained technicians possess.

Identifying Complex Issues

Some malfunctions may not be immediately apparent and can worsen if left unattended. Unusual noises, inconsistent performance, or failure to start are signs that the problem may be beyond basic troubleshooting. In such cases, consulting a professional can prevent further damage and save on costly repairs in the long run.

Safety Concerns

If you encounter problems that could pose safety risks, such as fuel leaks or electrical faults, it is essential to seek help from an expert. Prioritizing safety ensures not only your well-being but also the integrity of the equipment.

Upgrades and Modifications Overview

Enhancing the performance and functionality of your equipment can lead to significant improvements in efficiency and durability. This section outlines various options for upgrades and modifications that can be implemented to tailor the device to better meet your specific needs.

Performance Enhancements

One of the primary focuses of modifications is to boost the operational capabilities of the machine. This may involve upgrading the air filter for improved airflow or replacing the spark plug with a high-performance variant. These adjustments can lead to better fuel efficiency and increased power output, resulting in a smoother user experience.

Durability Improvements

Strengthening the construction and materials of key components is crucial for long-term reliability. Consider using upgraded materials for wear-prone parts, such as the chain or bar, to extend their lifespan. Additionally, implementing regular maintenance practices, including lubrication and proper storage, can greatly enhance the overall durability of the device.