Complete Repair Guide for Husqvarna Rider 155

Understanding the intricacies of lawn tractor upkeep is essential for ensuring optimal performance and longevity. These machines, designed for efficiency, require regular attention to various components to maintain their functionality. This guide aims to provide comprehensive insights into the maintenance and troubleshooting processes for these versatile garden tools.

From the engine to the cutting deck, each element plays a crucial role in the overall operation. By familiarizing oneself with the essential procedures, users can prevent common issues and enhance their mowing experience. Emphasizing a proactive approach not only saves time but also reduces potential repair costs.

Additionally, having access to detailed information about routine checks, adjustments, and repairs empowers users to take control of their equipment’s performance. With the right knowledge, maintaining a well-functioning lawn tractor becomes a manageable task, paving the way for a lush and beautifully landscaped yard.

Overview of Husqvarna Rider 155

This section provides a comprehensive look at a versatile and efficient gardening machine designed for optimal performance in various lawn care tasks. With its innovative design and user-friendly features, it stands out in the market, catering to both professional landscapers and enthusiastic homeowners.

Equipped with a powerful engine, this machine ensures reliable operation while maintaining a compact structure for easy maneuverability. The ergonomic controls enhance the user experience, allowing for seamless navigation across different terrains. Additionally, its cutting system is engineered to deliver precise results, ensuring a beautifully manicured lawn.

Maintenance is straightforward, with accessible components that simplify routine checks and servicing. The durability of materials used in construction guarantees longevity, making it a wise investment for anyone seeking to enhance their outdoor space. Overall, this machine embodies the perfect blend of functionality and innovation, making it a top choice for lawn care enthusiasts.

Common Issues with Rider 155

Every machine has its quirks, and this model is no exception. Users often encounter a variety of challenges that can affect performance and usability. Understanding these common problems can aid in identifying and addressing them promptly, ensuring smoother operation and longevity.

1. Engine Starting Difficulties: One prevalent issue is the difficulty in starting the engine. This can be caused by various factors such as stale fuel, a weak battery, or issues with the ignition system. Regular maintenance and timely checks can help mitigate this problem.

2. Uneven Cutting: Another frequent concern is uneven cutting. This may result from dull blades, improper deck height adjustment, or tire pressure inconsistencies. Keeping blades sharp and ensuring correct settings can improve cutting performance.

3. Overheating: Machines can overheat during prolonged use, leading to potential damage. Insufficient cooling due to blocked air vents or low coolant levels are common culprits. Regular cleaning and monitoring coolant levels are crucial to prevent this issue.

4. Steering Problems: Users may also experience difficulties with steering responsiveness. This could stem from worn-out components or misalignment. Regular inspection of the steering mechanism can help maintain control and safety.

5. Electrical Failures: Electrical issues, such as blown fuses or malfunctioning lights, can disrupt operation. Regular checks of the electrical system and prompt replacement of faulty parts can enhance reliability.

Addressing these common issues proactively can lead to a more efficient and enjoyable experience with the machine. Regular maintenance and timely repairs are essential to keep everything running smoothly.

Tools Required for Repairs

When undertaking maintenance tasks, having the right instruments at hand is crucial for ensuring efficiency and effectiveness. A well-equipped toolkit not only streamlines the process but also minimizes the risk of damage to the equipment. This section outlines the essential tools that will aid in performing various adjustments and troubleshooting procedures.

Essential Hand Tools

Start with a basic set of hand tools, which includes wrenches, screwdrivers, and pliers. These items are fundamental for loosening or tightening bolts and screws. A combination of both flat-head and Phillips screwdrivers will cover most fasteners. Additionally, a good pair of pliers is indispensable for gripping and manipulating small components.

Specialized Equipment

For more intricate tasks, consider adding specialized equipment to your arsenal. Tools such as spark plug wrenches and multimeters can provide significant assistance. A spark plug wrench is essential for inspecting and replacing spark plugs, while a multimeter aids in diagnosing electrical issues. Investing in these tools can save time and improve the overall quality of maintenance.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to the upkeep of your garden equipment, ensuring optimal performance and longevity. Regular maintenance is crucial to prevent issues and enhance the efficiency of your machine. Follow these systematic steps to keep your device in excellent working condition.

1. Routine Inspection

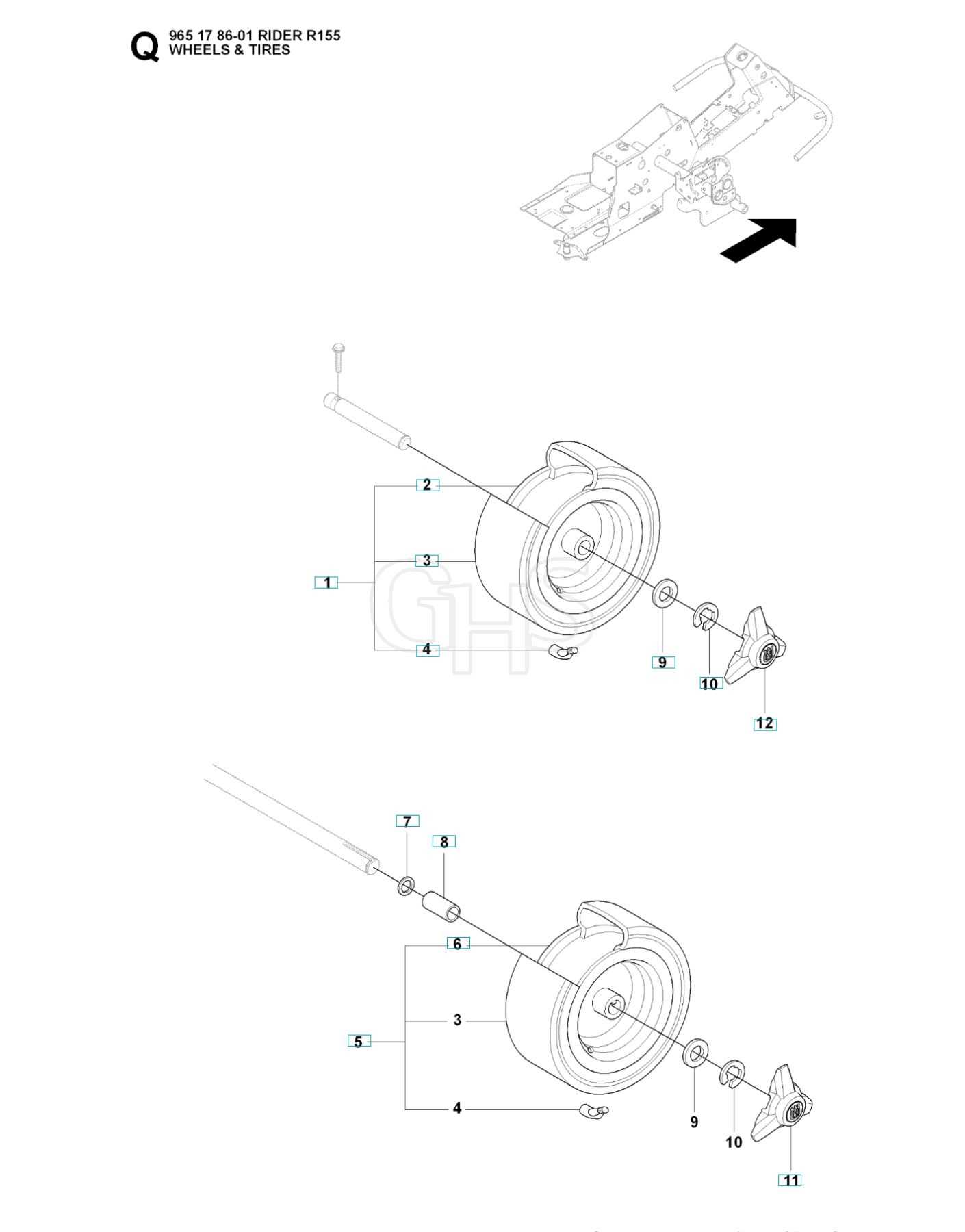

Begin with a thorough inspection of the equipment. Check for any visible signs of wear or damage, including the blades, belts, and tires. Ensure that all fasteners are tight and that there are no loose components. Addressing minor issues early can prevent more significant problems down the line.

2. Cleaning Procedures

Maintaining cleanliness is vital for the performance of your machinery. After each use, remove any grass clippings, dirt, or debris from the exterior and undercarriage. Use a brush or compressed air to reach difficult areas. Regular cleaning not only improves functionality but also extends the life of your equipment.

Follow these steps diligently to ensure your garden equipment remains reliable and efficient throughout its lifespan.

Engine Troubleshooting Tips

When facing issues with your machine’s power unit, systematic evaluation is essential for effective resolution. Understanding common symptoms and their underlying causes can significantly simplify the troubleshooting process.

Here are some helpful guidelines to consider:

- Check Fuel Supply:

- Ensure the tank has sufficient fuel.

- Inspect for any fuel leaks or clogs in the lines.

- Inspect the Spark Plug:

- Remove and examine the spark plug for wear or damage.

- Clean or replace it if necessary to ensure optimal ignition.

- Examine the Air Filter:

- Check for dirt or blockages that may hinder airflow.

- Clean or replace the filter to maintain engine efficiency.

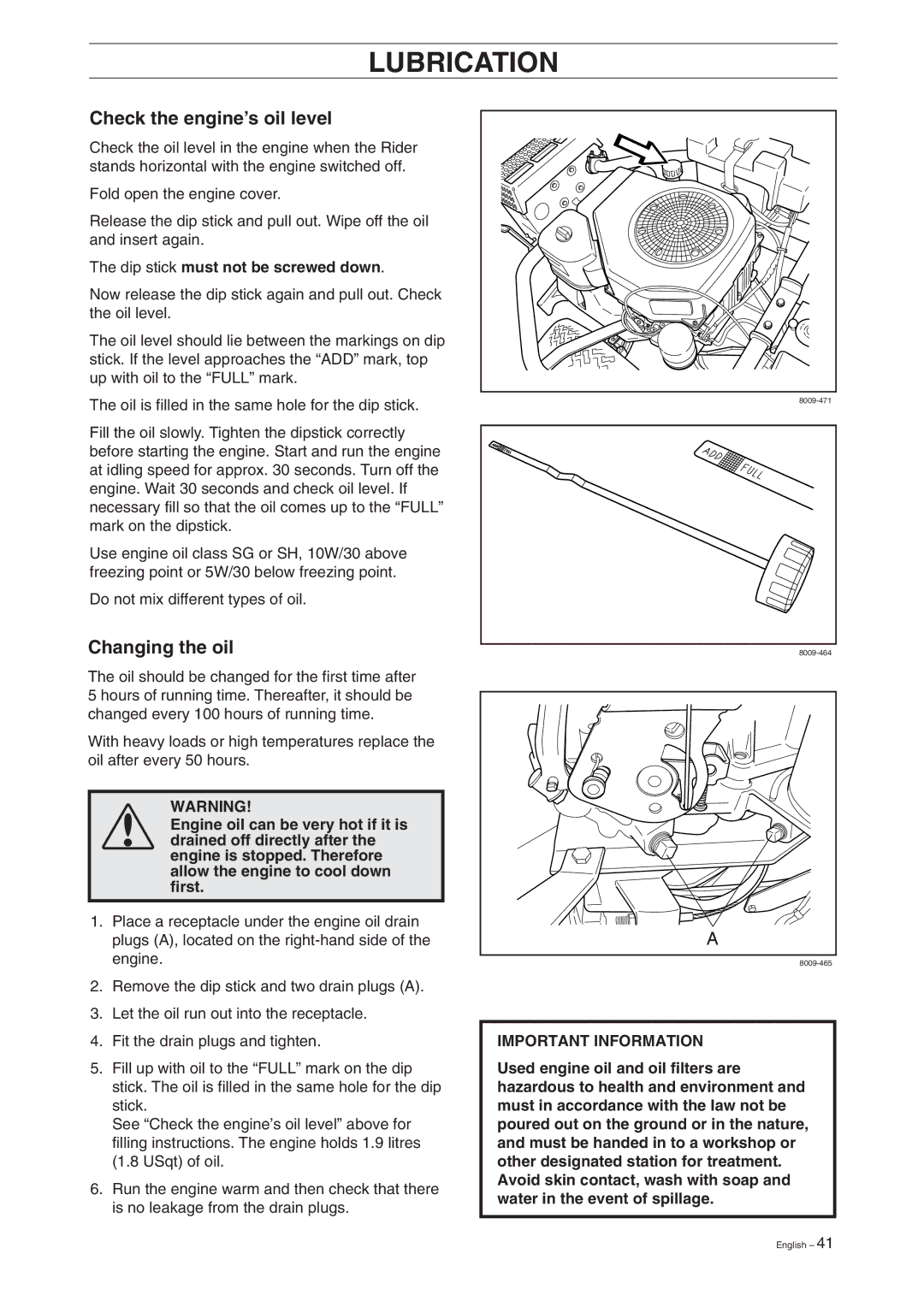

- Review Oil Levels:

- Ensure that oil levels are adequate for proper lubrication.

- Change the oil if it appears dirty or contaminated.

- Inspect Belts and Cables:

- Look for frayed or broken belts that may impact performance.

- Check cables for wear and ensure connections are secure.

By methodically addressing these areas, you can diagnose and resolve many common engine-related issues effectively.

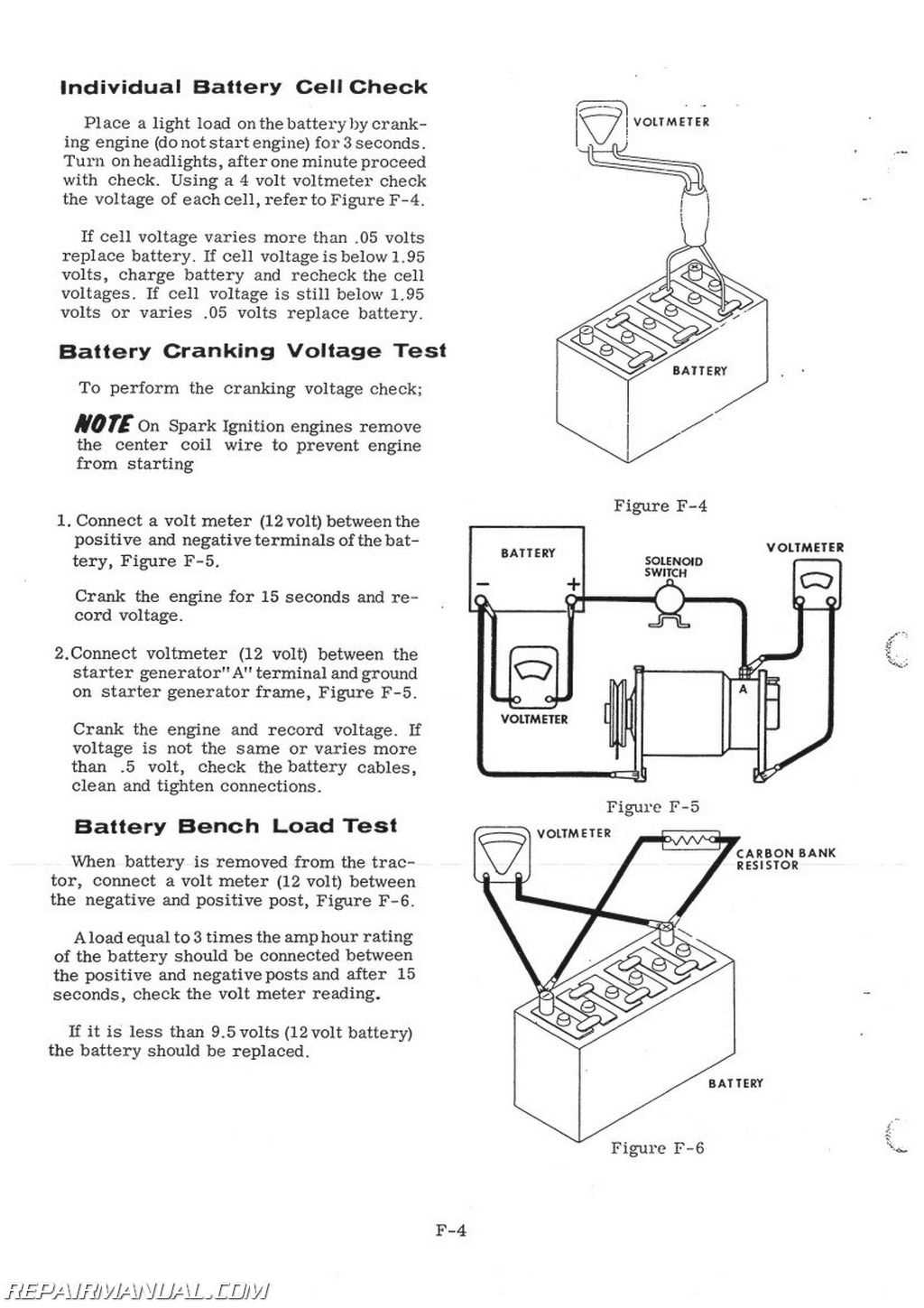

Electrical System Diagnostics

The electrical system of any machinery is crucial for its optimal performance. Proper diagnostics can help identify issues that may disrupt functionality, ensuring reliable operation. This section provides an overview of common diagnostic procedures and troubleshooting techniques for the electrical components.

Common Issues and Symptoms

Identifying electrical faults involves recognizing specific symptoms that may indicate underlying problems. Below are typical issues encountered:

| Symptom | Possible Cause |

|---|---|

| Starting problems | Weak battery or faulty starter |

| Dim lights | Insufficient voltage supply |

| Intermittent function | Loose connections or damaged wiring |

| Overheating components | Short circuits or overcurrent issues |

Diagnostic Procedures

To effectively diagnose electrical issues, follow these steps:

- Inspect all connections for signs of wear or corrosion.

- Utilize a multimeter to measure voltage at various points in the system.

- Test components individually to isolate the faulty part.

- Refer to wiring diagrams for correct troubleshooting paths.

By systematically addressing each symptom and following proper diagnostic protocols, one can ensure the longevity and reliability of the electrical system.

Blade Replacement Procedures

Replacing the cutting element of your machine is essential for maintaining optimal performance and ensuring a clean cut. This process not only improves efficiency but also prolongs the life of the equipment. Proper handling during the replacement is crucial for safety and effectiveness.

Step 1: Prepare the Equipment

Begin by ensuring the machine is turned off and disconnected from any power source. This reduces the risk of accidental activation during the replacement process. Use appropriate protective gear, including gloves and safety goggles.

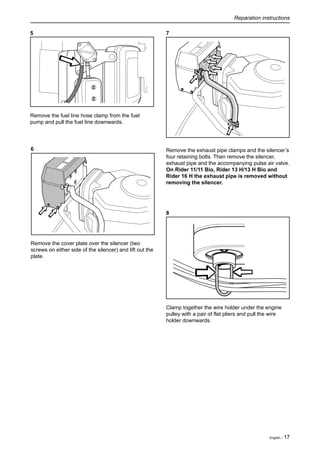

Step 2: Access the Blade

Locate the cover or housing that protects the cutting element. This may require the use of tools to unscrew or unclip the cover. Once removed, carefully inspect the area for any debris that may obstruct the blade removal.

Step 3: Remove the Old Blade

Identify the fastening mechanism holding the blade in place. This may involve loosening bolts or nuts. Use the correct tools to ensure a secure grip. Carefully detach the old blade, paying attention to its orientation for accurate installation of the new one.

Step 4: Install the New Blade

Position the new cutting element in the same orientation as the old one. Secure it using the fastening mechanism, making sure it is tightened adequately to prevent any movement during operation. Double-check the alignment to ensure proper functioning.

Step 5: Reassemble and Test

Replace the cover or housing, ensuring all fastenings are secure. Reconnect the power source and conduct a test run to verify that the new blade operates smoothly. Monitor for any unusual sounds or vibrations that may indicate improper installation.

Following these steps will help ensure that the cutting component is replaced efficiently and safely, allowing your equipment to perform at its best.

Transmission Adjustments Explained

Properly adjusting the transmission of a riding mower is crucial for optimal performance and longevity. These adjustments ensure that the power is efficiently transferred from the engine to the wheels, allowing for smooth operation and responsiveness. Understanding how to make these tweaks can greatly enhance the machine’s functionality.

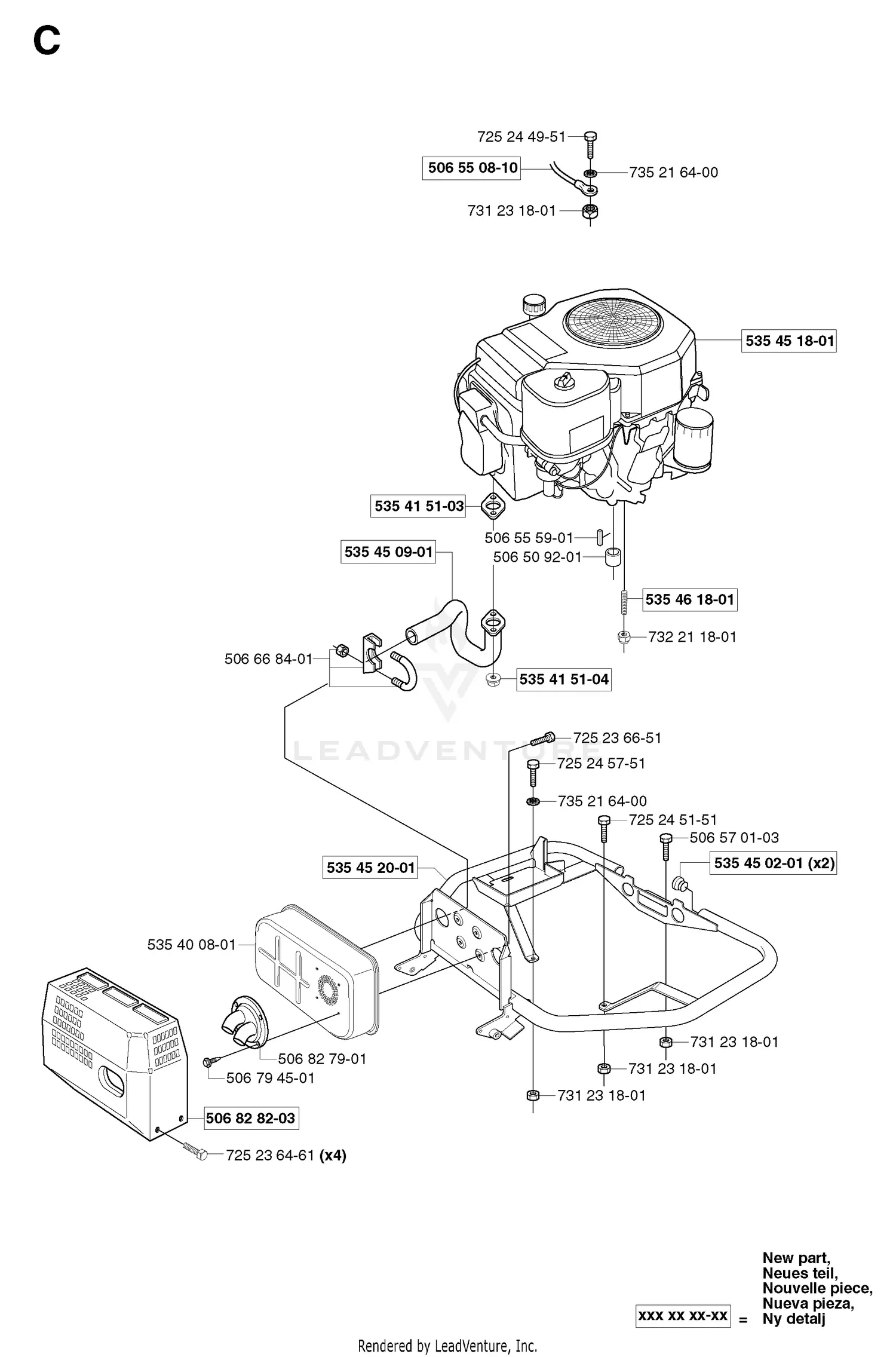

Key Components of Transmission Adjustment

The transmission system consists of several components that must work together seamlessly. Key elements include the drive belt, pulleys, and gear settings. Each of these parts plays a vital role in how the machine responds to user inputs. Regular inspection and adjustment can prevent premature wear and ensure consistent performance.

Adjustment Procedure Overview

When adjusting the transmission, it’s essential to follow a systematic approach. Below is a table outlining the general steps involved in the adjustment process:

| Step | Description |

|---|---|

| 1 | Inspect the drive belt for signs of wear or damage. |

| 2 | Check the tension of the drive belt; it should be snug but not overly tight. |

| 3 | Examine the pulleys for proper alignment and function. |

| 4 | Adjust gear settings as needed to ensure smooth shifting. |

| 5 | Test the transmission by running the machine and observing its responsiveness. |

Following these steps will help maintain the effectiveness of the transmission, ensuring that the equipment operates efficiently for years to come.

Deck Leveling Techniques

Achieving the proper leveling of the mowing deck is essential for optimal performance and a well-groomed lawn. Ensuring that the cutting blades are evenly positioned enhances the quality of the cut and prevents uneven wear on the machine. This section will explore effective methods to achieve precise leveling of the deck.

1. Preparation: Before starting the leveling process, it is crucial to prepare the equipment. Ensure the machine is parked on a flat, level surface. Engage the parking brake and switch off the engine to guarantee safety during adjustments.

2. Initial Measurements: Utilize a measuring tool to determine the current height of the cutting blades from the ground. Measure the distance from the blade tips to the ground at multiple points, typically the front and rear of the deck, to assess any discrepancies.

3. Adjusting the Deck: Based on the measurements taken, make the necessary adjustments to the deck height. Most models have adjustment points, which may involve turning knobs or bolts. Follow the manufacturer’s guidelines to achieve the desired height at the front and rear.

4. Final Checks: After making the adjustments, re-measure the blade heights to confirm that they are now level. It may require several iterations to achieve the perfect balance. Once satisfied, perform a test cut on grass to evaluate the effectiveness of the leveling.

Regular maintenance of the deck leveling not only ensures superior cutting performance but also prolongs the lifespan of the equipment.

Seasonal Maintenance Checklist

Regular upkeep is essential for ensuring optimal performance and longevity of your gardening equipment. A well-structured seasonal maintenance checklist can help identify key tasks that need attention, ultimately enhancing the efficiency and reliability of your machine throughout the year.

Spring Preparation

As the growing season begins, it’s crucial to prepare your equipment. Start by checking and replacing the air filter to ensure proper airflow. Inspect the blades for any signs of wear and sharpen or replace them as necessary. Additionally, change the oil and replace the spark plug to maintain a smooth operation. Finally, clean the fuel system to prevent any issues during startup.

Autumn Wrap-Up

Before winter sets in, it’s important to prepare your equipment for storage. Drain the fuel tank or add a fuel stabilizer to prevent degradation. Clean the exterior thoroughly to remove any debris and prevent rust. Check all belts and cables for wear, replacing them if needed. Finally, ensure that the machine is stored in a dry, sheltered location to protect it from harsh weather conditions.

Cleaning and Care Best Practices

Maintaining your outdoor equipment is essential for ensuring its longevity and optimal performance. Regular cleaning and proper care not only enhance the appearance of your machinery but also prevent potential issues that could arise from neglect. Adopting a routine that incorporates these practices can significantly improve the lifespan of your equipment.

1. Regular Inspection: Before each use, take a moment to inspect your machine for any debris, loose parts, or signs of wear. Addressing these issues early can prevent more significant problems down the line.

2. Cleaning After Use: After operating your equipment, it is crucial to remove any dirt, grass clippings, or other residues. Use a brush or a gentle wash to keep the surfaces clear. This practice helps prevent corrosion and buildup that can hinder performance.

3. Lubrication: Ensure that all moving parts are properly lubricated. Refer to your manufacturer’s guidelines for the recommended types of lubricants and frequencies. This will help reduce friction and wear.

4. Fuel Maintenance: If your machine uses fuel, consider using a fuel stabilizer to prevent degradation. Regularly check fuel lines and replace filters as needed to maintain efficient operation.

5. Seasonal Care: At the end of each season, perform a thorough maintenance check. This includes changing oils, inspecting belts, and replacing any worn components. Preparing your equipment for storage can prevent damage during the off-season.

By following these best practices, you can ensure that your outdoor equipment remains in peak condition, ready to tackle tasks whenever needed. Remember, a little effort in cleaning and maintenance goes a long way in preserving functionality and performance.

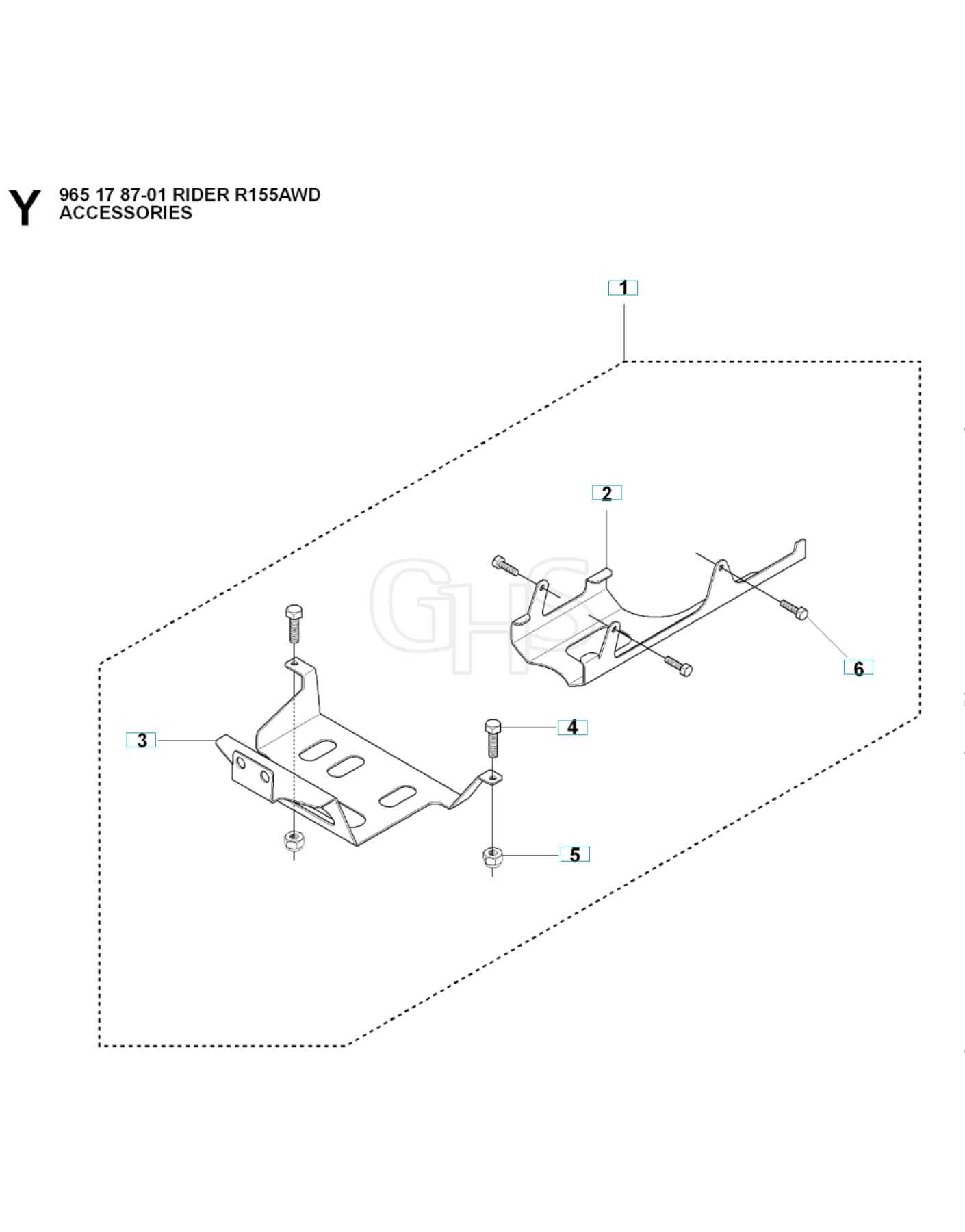

Where to Find Replacement Parts

Locating suitable components for your outdoor equipment is crucial for maintaining optimal performance. Various sources provide options for acquiring necessary items, ensuring that your machinery operates smoothly and efficiently. Understanding where to search can save time and money.

Here are some common avenues to explore when seeking parts:

| Source | Description | Advantages |

|---|---|---|

| Authorized Dealers | Local shops that specialize in brand-specific components. | Genuine parts, expert advice, and warranties. |

| Online Retailers | Websites that offer a wide range of products for various models. | Convenience, competitive pricing, and home delivery. |

| Second-Hand Markets | Platforms for buying used or refurbished items. | Cost savings and potential for rare finds. |

| Manufacturer’s Website | Official online store of the equipment maker. | Direct access to new components and specifications. |

| Local Repair Shops | Independent businesses that fix and service equipment. | Personalized service and often a selection of parts. |

By exploring these options, you can effectively source the necessary items to keep your equipment in peak condition.

Owner Experiences and Tips

This section aims to share valuable insights and practical advice from users who have firsthand experience with their compact mowing machines. Understanding the real-world performance and maintenance can significantly enhance your ownership experience.

- Regular Maintenance: Consistent upkeep is crucial for longevity. Users recommend creating a schedule for routine checks, including:

- Oil changes

- Blade sharpening

- Battery inspection

- Air filter cleaning

- Terrain Considerations: Adapting your approach based on the landscape can improve efficiency. Many owners find it helpful to:

- Adjust cutting height for varying grass types

- Use different mowing patterns to avoid wear

- Plan mowing routes to minimize obstacles

- Winter Storage: Proper off-season care ensures readiness for the next mowing season. Recommendations include:

- Draining fuel to prevent stale gas issues

- Storing in a dry, sheltered area

- Checking belts and cables for wear before storage

- Community Resources: Connecting with fellow owners can be beneficial. Joining local clubs or online forums allows for:

- Sharing tips and tricks

- Finding local service providers

- Exchanging experiences regarding upgrades and modifications

lessCopy code

By incorporating these shared experiences and practical tips, owners can maximize their enjoyment and efficiency while using their machines.