Comprehensive Guide to Repairing Your Husqvarna Riding Mower

The proper upkeep of outdoor machinery is essential for ensuring longevity and optimal performance. This section provides valuable insights into maintaining and troubleshooting various types of lawn care equipment. Understanding the intricacies of these machines can significantly enhance their functionality and efficiency.

Regular attention to the essential components not only extends the life of the equipment but also improves its reliability during use. This guide offers practical steps and tips for identifying common issues, performing necessary adjustments, and executing routine tasks that help keep your machinery in excellent condition.

Whether you are a seasoned professional or a casual user, having a thorough understanding of your equipment will empower you to address any concerns proactively. By following the outlined procedures, you can achieve a smooth operation and enjoy a well-kept lawn.

When it comes to maintaining and fixing outdoor machinery, having the right equipment is crucial for efficient and effective work. The proper tools not only ensure safety but also enhance the overall quality of the job. Here’s a guide to some fundamental instruments that every technician should consider having in their toolkit.

- Wrenches: A set of adjustable and fixed wrenches is essential for loosening and tightening various fasteners.

- Screwdrivers: Both flathead and Phillips head screwdrivers are necessary for accessing different types of screws throughout the device.

- Socket Set: A comprehensive socket set allows for easier removal of nuts and bolts, especially in tight spaces.

- Plier Set: Needle-nose and standard pliers are helpful for gripping and manipulating small components.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specified torque, preventing damage.

- Blade Sharpener: Keeping blades sharp is essential for optimal performance; a good sharpener will make this task straightforward.

- Fuel Container: A designated container for fuel is necessary for safe storage and transportation of fuel, minimizing spills.

- Gloves and Safety Gear: Protective gear is vital to ensure the safety of the user while handling machinery and tools.

Having these basic tools at your disposal can significantly streamline the maintenance process, allowing for quick troubleshooting and efficient problem-solving. Regular inspections and timely interventions will lead to a longer lifespan for your equipment.

Step-by-Step Troubleshooting Guide

This section aims to assist users in identifying and resolving common issues that may arise during the operation of their gardening equipment. By following a structured approach, one can systematically diagnose problems and implement effective solutions to ensure optimal performance.

Begin by observing the symptoms displayed by the equipment. Note any unusual sounds, vibrations, or performance inconsistencies. These initial observations will guide the troubleshooting process. Next, check the fuel supply, ensuring that it is adequate and fresh, as stale fuel can cause starting and operational issues.

Examine the ignition system, including the spark plug. Remove the spark plug and inspect it for wear or fouling. A clean, functioning spark plug is crucial for effective engine performance. If necessary, replace it with a new one.

Inspect the air filter to ensure it is clean and unobstructed. A clogged filter can restrict airflow, leading to poor engine performance. If the filter appears dirty, clean or replace it as required.

Lastly, review the blade assembly for any signs of damage or dullness. A sharp, well-maintained blade is essential for effective cutting. Sharpen or replace blades that show signs of wear.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. Implementing simple maintenance practices can significantly extend the lifespan of your machine, keeping it in optimal condition for years to come. Below are essential tips to help you achieve this goal.

Regular Inspections

- Check the oil levels and replace it according to the manufacturer’s recommendations.

- Inspect the air filter frequently and clean or replace it as needed.

- Examine the blades for sharpness and any signs of damage; sharpen or replace as necessary.

Seasonal Care

- Before the winter season, clean the equipment thoroughly to remove debris and dirt.

- Store in a dry, sheltered area to prevent rust and deterioration.

- At the start of each season, perform a complete checkup to ensure all components are functioning correctly.

Parts Replacement and Upgrades

Maintaining the optimal performance of your equipment often requires replacing specific components or enhancing its capabilities. This section outlines essential procedures and considerations for part modifications and upgrades to ensure longevity and efficiency. By carefully selecting and installing high-quality replacements, users can significantly improve functionality and extend the life of their machinery.

Identifying Necessary Replacements

Before initiating any replacement process, it is crucial to identify components that show signs of wear or diminished performance. Common areas that may require attention include the cutting blades, belts, and filters. Regular inspections can help pinpoint these issues early, preventing further damage and ensuring smooth operation.

Upgrading Components for Enhanced Performance

Upgrading certain elements can lead to improved efficiency and enhanced user experience. Consider investing in advanced cutting systems or high-performance engines. These upgrades not only optimize functionality but can also lead to better fuel efficiency and reduced operational costs. Always consult with a knowledgeable professional or reliable source to choose compatible and high-quality components for your enhancement projects.

Engine Care and Performance Enhancements

Maintaining optimal performance in your power equipment involves diligent attention to its engine. Proper care not only extends the lifespan of the engine but also ensures efficient operation. This section will explore essential practices and enhancements that can significantly improve engine functionality.

Regular Maintenance Practices

- Oil Changes: Regularly changing the oil is crucial for keeping the engine lubricated and reducing wear. Follow the manufacturer’s recommendations for frequency.

- Air Filter Cleaning: A clean air filter ensures that the engine receives adequate airflow. Inspect and clean or replace the filter as necessary to maintain performance.

- Spark Plug Inspection: Check the spark plugs for signs of wear or buildup. Replacing old spark plugs can lead to improved starting and efficiency.

- Fuel Quality: Always use fresh, high-quality fuel. Stale or contaminated fuel can cause performance issues and damage the engine.

Performance Enhancement Tips

- Upgrade Fuel System: Consider installing a performance carburetor or fuel injector to improve fuel delivery and overall efficiency.

- Optimize Exhaust Flow: Upgrading the exhaust system can enhance engine breathing, leading to better performance and power output.

- Engine Tuning: Regular tuning, including adjustments to the air-fuel mixture and ignition timing, can lead to noticeable improvements in responsiveness and efficiency.

Electrical System Diagnostics

This section covers the essential aspects of evaluating the electrical framework of your equipment. Understanding the intricacies of the electrical components is crucial for effective troubleshooting and ensuring optimal performance. By systematically analyzing various elements of the electrical system, one can identify potential issues and rectify them efficiently.

Common Electrical Issues

Several prevalent electrical problems may arise, affecting the functionality of the machinery. Recognizing these issues early can save time and prevent further damage. Below are some of the typical electrical concerns encountered:

| Issue | Description | Possible Causes |

|---|---|---|

| Weak Start | Difficulty in initiating the engine. | Weak battery, corroded terminals, faulty ignition. |

| Flickering Lights | Inconsistent lighting during operation. | Loose connections, failing alternator, wiring issues. |

| Battery Drain | Battery depletes rapidly. | Parasitic draw, damaged battery, charging system failure. |

Diagnostic Steps

To effectively diagnose electrical issues, follow these systematic steps:

- Begin by checking the battery condition and connections.

- Inspect wiring harnesses for signs of wear or damage.

- Utilize a multimeter to measure voltage and continuity.

- Test switches and relays to ensure proper operation.

- Consult the equipment’s specifications for component ratings and tolerances.

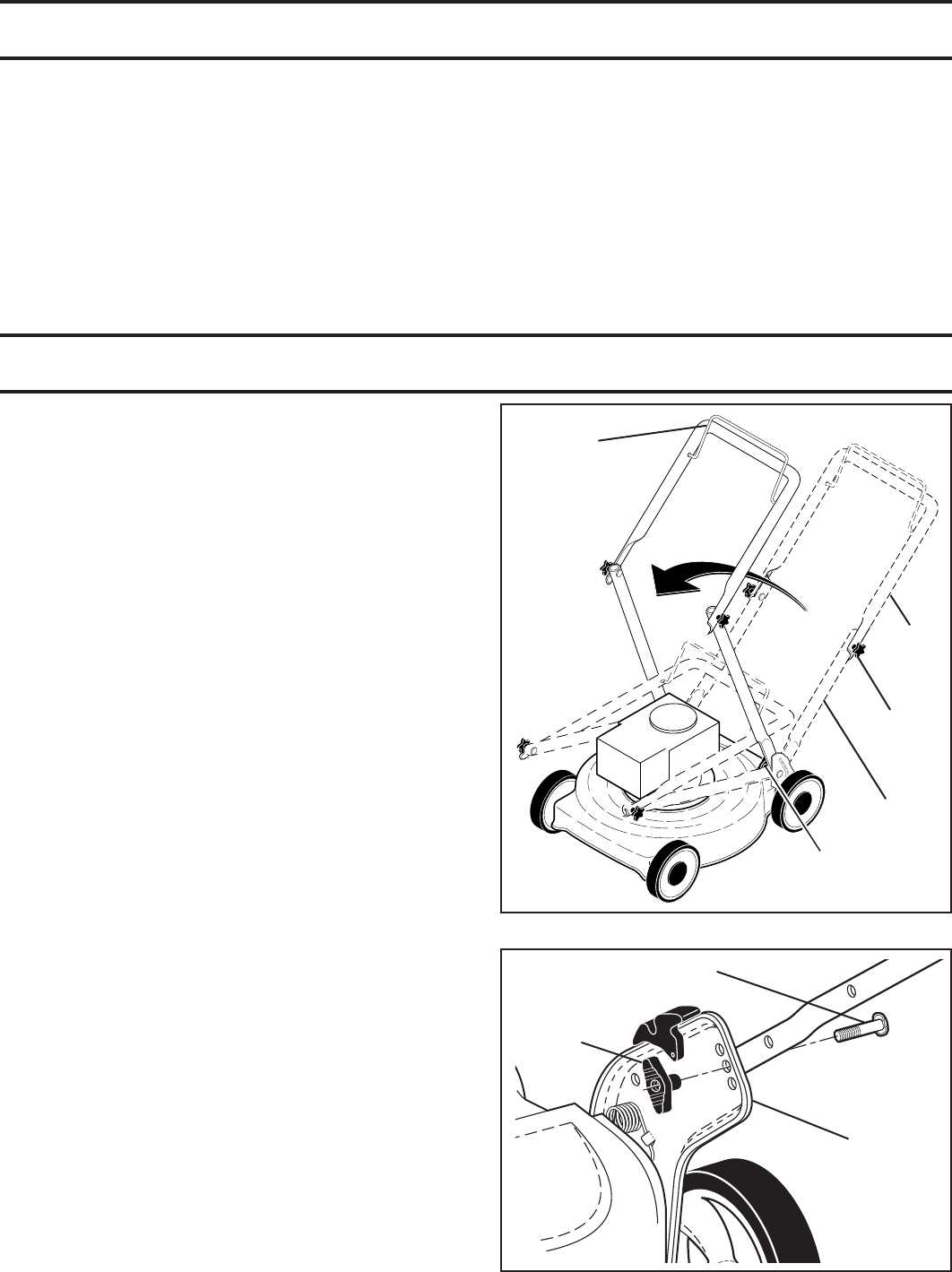

Safety Procedures During Repairs

Ensuring a safe environment while conducting maintenance on machinery is crucial for both the individual performing the task and the equipment itself. Adhering to specific guidelines helps prevent accidents and promotes a secure working atmosphere.

1. Personal Protective Equipment (PPE): Always wear appropriate safety gear, including gloves, goggles, and sturdy footwear. This equipment is essential for protecting against potential hazards such as sharp objects or chemicals.

2. Work Area Organization: Keep your workspace tidy and free from clutter. A well-organized area reduces the risk of tripping and allows for easier access to tools and parts.

3. Disengage Power Sources: Before starting any maintenance tasks, ensure that all power sources are disconnected. This step is vital in preventing accidental starts and ensuring safety during inspections.

4. Proper Tool Usage: Utilize the correct tools for each task, as specified by the manufacturer’s guidelines. Using inappropriate tools can lead to injuries or damage to components.

5. Follow Instructions Carefully: Always adhere to detailed procedures provided for any work undertaken. Understanding each step minimizes mistakes and enhances safety.

6. Seek Assistance When Necessary: If unsure about any aspect of the maintenance process, do not hesitate to seek help from a knowledgeable individual. Collaborating with someone experienced can significantly enhance safety and efficiency.

Cleaning and Maintenance Procedures

Regular upkeep and proper cleaning are essential for ensuring optimal performance and longevity of your equipment. By adhering to recommended practices, you can prevent premature wear and maintain the efficiency of the machine. This section outlines key procedures for keeping your device in excellent working condition.

General Cleaning Steps

To maintain the exterior and functionality of your machine, follow these general cleaning steps:

| Step | Description |

|---|---|

| 1 | Remove debris such as grass clippings and dirt after each use to prevent buildup. |

| 2 | Use a soft brush or cloth to clean all surfaces, ensuring that no dust or grime remains. |

| 3 | Inspect and clean air filters periodically to ensure proper airflow and performance. |

Maintenance Recommendations

In addition to cleaning, implementing routine maintenance practices will enhance the reliability of your machine. Consider the following recommendations:

| Task | Frequency |

|---|---|

| Check oil levels | Every 5 hours of operation |

| Sharpen blades | After every 25 hours of use |

| Inspect belts and cables | Monthly |

Seasonal Preparation for Mowers

Proper seasonal preparation is crucial for ensuring optimal performance and longevity of your gardening equipment. Taking the time to perform essential maintenance tasks at the start of each season can prevent breakdowns and enhance efficiency throughout the year. This guide outlines key steps to prepare your machinery for varying weather conditions and usage demands.

Here are the primary tasks to consider for effective seasonal readiness:

- Inspect and Clean:

- Remove any debris from the chassis and cutting deck.

- Check for signs of wear or damage on blades and belts.

- Clean air filters and fuel systems to ensure proper airflow and fuel flow.

- Check Fluids:

- Examine oil levels and replace oil if it appears dirty or aged.

- Inspect the coolant levels and top off as needed.

- Verify that the fuel system is clean and filled with fresh fuel.

- Test Electrical Components:

- Check the battery charge and clean terminals.

- Inspect wiring for any signs of damage or corrosion.

- Test lights and other electronic systems for functionality.

- Sharpen Blades:

- Ensure that the cutting edges are sharp for clean cuts.

- Replace any blades that are severely worn or damaged.

- Adjust Settings:

- Calibrate the height settings for cutting grass according to seasonal growth patterns.

- Adjust throttle and speed settings for different terrains.

Following these steps will help maintain the efficiency and reliability of your gardening equipment. Regular maintenance not only prolongs the lifespan of your tools but also ensures a well-kept outdoor space.

Frequently Asked Repair Questions

This section addresses common inquiries related to maintenance and troubleshooting for various lawn care equipment. Understanding these frequently posed questions can help users identify issues and find appropriate solutions efficiently.

Common Issues and Solutions

Many individuals encounter challenges with their gardening machinery. A prevalent concern is when the equipment fails to start. This can often be attributed to fuel supply issues or a drained battery. Ensuring that the fuel is fresh and the battery is fully charged can often resolve these problems.

Maintenance Tips

Regular upkeep is essential for prolonging the lifespan of your equipment. It’s advisable to inspect the blades frequently for wear and replace them as necessary. Additionally, checking air filters and oil levels can prevent many operational difficulties, ensuring optimal performance.