Ultimate Guide to Husqvarna Weed Eater Repair Manual

When it comes to keeping your garden tools in top shape, understanding their functionality and common issues is essential. Whether you are a seasoned gardener or a weekend hobbyist, having the right knowledge can save you time and money. This guide will provide insights into troubleshooting, maintenance techniques, and practical tips to ensure your equipment runs smoothly for years to come.

From minor adjustments to more extensive servicing, knowing how to address typical challenges can significantly enhance your experience with outdoor machinery. Emphasizing preventative measures and regular upkeep will not only extend the lifespan of your tools but also improve their performance. With the right approach, you can tackle any problem that arises with confidence.

As we delve into the specifics, this guide will highlight the most common components that may require attention and offer step-by-step instructions for resolving frequent malfunctions. By following these recommendations, you’ll be well-equipped to handle your outdoor equipment, ensuring it remains a reliable companion in your gardening endeavors.

Understanding Husqvarna Weed Eaters

In the realm of outdoor maintenance, efficient tools play a pivotal role in ensuring a well-kept landscape. This segment delves into the intricacies of a specific type of cutting equipment designed to tackle overgrown vegetation. By exploring their features, mechanisms, and maintenance practices, users can enhance their understanding and ensure optimal performance.

Key Features

These versatile tools come equipped with various characteristics that cater to different landscaping needs. Understanding these features can aid in selecting the right device for specific tasks.

| Feature | Description |

|---|---|

| Engine Type | Different models offer either gas or electric engines, each with unique benefits regarding power and convenience. |

| Cutting Width | The size of the cutting area varies, affecting how efficiently larger spaces can be managed. |

| Weight | Lightweight options allow for easier maneuverability, while heavier models may provide enhanced stability. |

| Handle Design | Ergonomic handles ensure comfort during prolonged use, reducing strain on the user. |

Maintenance Practices

To maintain peak performance, regular upkeep is essential. Users should familiarize themselves with basic servicing techniques to prolong the lifespan of their equipment.

Routine checks of the cutting apparatus, engine components, and fuel systems can prevent common issues and ensure that the tool operates effectively. By adhering to recommended maintenance schedules, users can achieve consistent results and avoid unnecessary complications.

Common Issues with Weed Eaters

Maintaining outdoor trimming equipment can sometimes lead to a variety of challenges. Users often encounter specific problems that affect performance and efficiency. Understanding these common difficulties can help in troubleshooting and ensuring smooth operation.

Fuel-Related Problems

One of the most frequent issues involves the fuel system. Old or contaminated fuel can lead to starting difficulties and erratic performance. Regularly changing fuel and using fresh gasoline can mitigate these concerns. Additionally, checking for air leaks in the fuel lines is crucial, as they can cause improper mixing and combustion.

Line and Cutting Mechanism Issues

Another prevalent challenge is related to the cutting line and mechanism. Users may experience problems such as line breakage or jamming. Ensuring that the line is correctly loaded and using the appropriate thickness can prevent these issues. Regularly inspecting the cutting head for debris can also enhance efficiency and longevity.

Essential Tools for Repair

When it comes to maintaining outdoor equipment, having the right instruments on hand is crucial for effective troubleshooting and maintenance. Proper tools not only facilitate the process but also ensure safety and efficiency during work. This section outlines the fundamental items that every enthusiast should consider for successful upkeep tasks.

Basic Tools

- Wrenches: Useful for loosening and tightening various nuts and bolts.

- Screwdrivers: Essential for removing and securing screws of different sizes.

- Pliers: Handy for gripping, twisting, and cutting wires or small components.

- Socket Set: Provides versatility for different fastener sizes.

- Utility Knife: Great for cutting through tough materials or components.

Specialized Tools

- Multimeter: Ideal for testing electrical components and connections.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Fuel Mixing Jug: Necessary for accurately measuring fuel and oil mixtures.

- Cleaning Brushes: Important for maintaining cleanliness of filters and air passages.

- Protective Gear: Safety glasses and gloves are vital for personal protection.

Step-by-Step Maintenance Guide

Regular upkeep of your outdoor equipment is essential for optimal performance and longevity. This guide provides a comprehensive approach to maintaining your tools, ensuring they function smoothly and efficiently throughout their lifespan.

Essential Tools and Materials

- Protective gloves

- Screwdriver set

- Wrench

- Lubricating oil

- Cleaning brush

- Fuel mixture

Maintenance Steps

- Preparation: Start by ensuring the equipment is turned off and cooled down. Wear protective gloves to avoid injuries.

- Cleaning: Remove any debris or grass clippings from the exterior. Use a cleaning brush to get into hard-to-reach areas.

- Inspecting Parts: Check the cutting mechanism and other components for wear and tear. Replace any damaged parts as necessary.

- Lubrication: Apply lubricating oil to moving parts to reduce friction and wear.

- Fuel Check: Examine the fuel mixture and refill if needed. Ensure you’re using the correct ratio for optimal performance.

- Final Inspection: Once maintenance is complete, perform a final check to ensure everything is reassembled correctly and securely.

Following this maintenance guide will help keep your outdoor equipment in top shape, allowing for effective use in your gardening tasks.

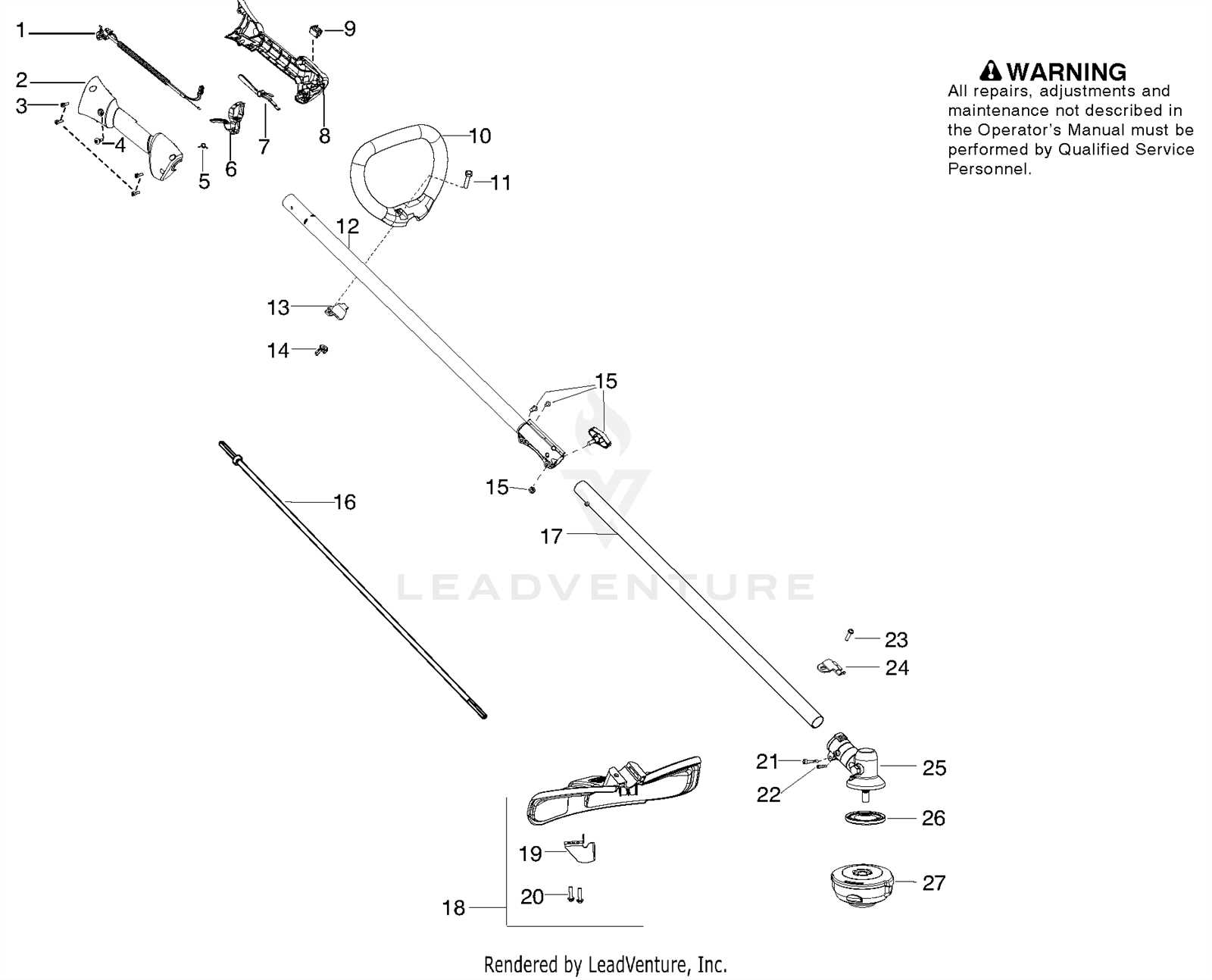

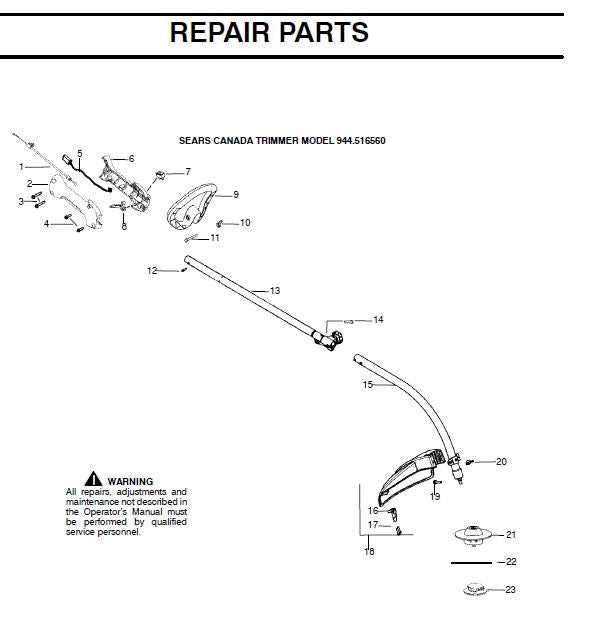

Replacing the String Line

Changing the cutting line is an essential maintenance task that ensures your trimming tool operates effectively. A worn or broken line can hinder performance and reduce efficiency. This section will guide you through the steps necessary to replace the line with ease, ensuring your equipment remains in optimal condition for yard work.

Tools and Materials Needed

Before starting the replacement process, gather the following tools and materials:

| Item | Description |

|---|---|

| Replacement Line | Choose the appropriate thickness and type for your model. |

| Scissors | For cutting the new line to the required length. |

| Screwdriver | To open the spool casing if necessary. |

Steps for Replacement

Follow these straightforward steps to successfully change the cutting line:

- Ensure the equipment is turned off and disconnected from the power source.

- Remove the spool from the trimmer head by unscrewing or pressing the release tabs.

- Take out the old line, if present, and discard it properly.

- Cut a length of new line according to the manufacturer’s specifications.

- Feed the new line through the spool, following the directional arrows if applicable.

- Reassemble the spool and secure it back into the trimmer head.

- Test the trimmer to ensure the line is advancing correctly.

Regularly checking and replacing the cutting line will help maintain the performance of your trimming tool, making yard maintenance easier and more efficient.

Diagnosing Engine Problems

Identifying issues with the engine is crucial for ensuring optimal performance and longevity of your outdoor power equipment. By systematically evaluating various symptoms, you can pinpoint the underlying problems and take appropriate action to restore functionality. This section outlines common signs of engine trouble and provides a structured approach to diagnosing them.

| Symptom | Possible Causes | Recommended Actions |

|---|---|---|

| Engine Won’t Start | Empty fuel tank, faulty spark plug, clogged air filter | Check and refill fuel, inspect and replace spark plug, clean or replace air filter |

| Engine Runs Rough | Dirty fuel, stale fuel, carburetor issues | Use fresh fuel, clean the carburetor, check for leaks |

| Excessive Smoke | Overfilled oil, oil leakage, faulty engine seals | Check and adjust oil level, inspect for leaks, replace seals if necessary |

| Loss of Power | Clogged exhaust, worn spark plug, fuel delivery problems | Inspect exhaust for blockages, replace spark plug, check fuel lines for obstructions |

| Unusual Noises | Loose parts, low oil level, damaged components | Tighten loose parts, check oil level, examine components for damage |

By following these guidelines, you can effectively troubleshoot and address engine issues, enhancing the reliability and efficiency of your equipment. Always consult specific documentation for detailed procedures and safety precautions.

Cleaning the Air Filter

The air filter plays a crucial role in maintaining optimal engine performance by ensuring a clean airflow. Regular maintenance of this component can significantly enhance efficiency and prolong the lifespan of your equipment.

To properly clean the air filter, follow these steps:

- Turn off the engine and disconnect the spark plug to ensure safety.

- Locate the air filter housing, which is usually situated near the carburetor.

- Remove the cover of the air filter housing, typically secured by screws or clips.

- Take out the air filter gently to avoid damaging it.

Once the air filter is removed, it’s time for cleaning:

- If the filter is foam, rinse it under warm water mixed with mild soap. Squeeze gently to remove dirt.

- For paper filters, gently tap it to dislodge dust, or use compressed air for a more thorough clean.

- Allow the filter to dry completely before reinserting it.

Finally, reinstall the air filter by reversing the removal steps and ensure that everything is secured properly. Regular cleaning of the air filter is essential to keep your engine running smoothly and efficiently.

Checking Fuel System Efficiency

Ensuring the proper functioning of the fuel delivery system is crucial for optimal performance. An efficient system guarantees that the engine receives the right mixture of fuel and air, leading to effective combustion and overall reliability. This section will guide you through the steps to evaluate the efficiency of your fuel system.

Symptoms of Fuel System Issues

Recognizing signs of inefficiency can help address problems early. Common symptoms include:

- Difficulty starting the engine

- Inefficient operation or reduced power

- Excessive smoke or unusual emissions

- Frequent stalling

- Increased fuel consumption

Steps to Check Efficiency

Follow these steps to assess the functionality of your fuel delivery system:

- Inspect Fuel Lines: Check for any cracks, leaks, or blockages in the fuel lines that could hinder flow.

- Examine the Filter: Ensure the fuel filter is clean and free from debris; replace it if it appears clogged.

- Test Fuel Quality: Use fresh fuel that meets the manufacturer’s specifications, as old or contaminated fuel can affect performance.

- Check the Fuel Pump: Listen for unusual sounds when the engine is running, which may indicate a failing pump.

- Evaluate Carburetor Function: Inspect the carburetor for blockages or malfunctions that could disrupt the fuel-air mixture.

By systematically checking these components, you can ensure your fuel system operates efficiently, ultimately enhancing performance and longevity.

Battery and Electrical Troubleshooting

Addressing issues related to power sources and electrical components is essential for maintaining optimal performance in outdoor tools. Understanding how to diagnose and rectify these problems can significantly enhance the lifespan and functionality of your equipment.

Begin by checking the battery charge. A depleted battery is often the primary culprit behind performance failures. Use a multimeter to assess voltage levels and determine if the battery needs recharging or replacement. If the battery appears to be in good condition, inspect the connections for any signs of corrosion or looseness, as these can disrupt the flow of electricity.

Next, examine the electrical components, including fuses and wiring. A blown fuse may prevent the device from operating altogether. Ensure that all connections are secure and free from damage, as frayed wires can cause shorts or erratic behavior. If any components show signs of wear, consider replacing them to restore functionality.

Lastly, if issues persist after checking the battery and wiring, it may be beneficial to review the user manual for any specific electrical troubleshooting guidelines related to your model. This can provide additional insights into resolving complex electrical problems effectively.

Upgrading Your Weed Eater Parts

Enhancing the components of your gardening tool can significantly improve its performance and longevity. Whether you’re looking to boost efficiency or increase durability, upgrading parts is a practical approach to maintaining your equipment. Here are some key upgrades to consider:

- String Trimmer Line: Choose a high-quality, thicker line to reduce breakage and improve cutting efficiency.

- Head Assembly: Upgrading to a more advanced head can facilitate easier line changes and provide better cutting capability.

- Motor Components: Consider replacing or upgrading the motor for enhanced power output and efficiency.

- Handles and Grips: Ergonomic handles can reduce fatigue during extended use, improving comfort and control.

- Shield and Guard: A sturdy shield can protect you from debris while improving the overall safety of your tool.

Before purchasing new parts, ensure compatibility with your existing equipment. Researching the best options available can lead to an efficient and effective upgrade process, ultimately enhancing your gardening experience.

Regularly maintaining and upgrading your components not only helps in achieving better results but also extends the lifespan of your gardening tool, ensuring that it remains a reliable companion in your outdoor tasks.

Safety Tips for DIY Repairs

Engaging in do-it-yourself maintenance can be a rewarding experience, but it is essential to prioritize safety throughout the process. By following specific precautions, you can minimize risks and ensure a successful outcome. This section outlines crucial safety guidelines to keep in mind when tackling equipment upkeep on your own.

Essential Safety Precautions

- Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear.

- Ensure you are working in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Disconnect power sources before beginning any work to prevent accidental starts.

- Keep your workspace organized and free from clutter to reduce the risk of accidents.

- Read all instructions and safety warnings in the product guidelines prior to commencing any task.

Proper Handling Techniques

- Use the right tools for the job to ensure efficiency and safety.

- Always handle sharp or moving parts with caution, maintaining a firm grip.

- Be aware of your surroundings and avoid distractions while working.

- If you encounter resistance or difficulty, stop and reassess rather than forcing the equipment.

- After completing maintenance, double-check that all components are securely reassembled.

By adhering to these safety measures, you can enhance your DIY experience and protect yourself from potential hazards while maintaining your equipment effectively.