Comprehensive Guide to International Truck Repair Manuals

The realm of large vehicle upkeep encompasses a vast array of knowledge and resources designed to ensure optimal performance and longevity. For those engaged in the maintenance and troubleshooting of these robust machines, having access to detailed documentation is crucial. This information serves as a foundation for understanding the intricate systems and components that contribute to their functionality.

In this section, we delve into comprehensive resources that provide invaluable insights into the care and management of substantial vehicles. These guides cover everything from routine maintenance procedures to advanced diagnostics, enabling mechanics and enthusiasts alike to enhance their expertise and address challenges effectively.

Whether you are a professional technician or a dedicated hobbyist, familiarizing yourself with these essential texts will empower you to tackle repairs with confidence. The structured approach found in these resources ensures that you can quickly find the information needed to resolve issues and implement best practices in vehicle care.

Understanding Truck Repair Manuals

Grasping the intricacies of vehicle maintenance documentation is essential for ensuring optimal performance and longevity of heavy vehicles. These resources serve as comprehensive guides, offering detailed instructions and insights for addressing various mechanical issues. Familiarity with these materials can significantly enhance the troubleshooting process, ultimately leading to more efficient repairs.

Such documentation typically encompasses various sections, each designed to provide specific information. Below is a table summarizing common components found in these guides:

| Section | Description |

|---|---|

| Introduction | An overview of the vehicle, including specifications and features. |

| Troubleshooting | Step-by-step procedures for diagnosing common problems. |

| Maintenance Procedures | Guidelines for regular upkeep to prevent issues. |

| Parts Catalog | A list of components, including part numbers and descriptions. |

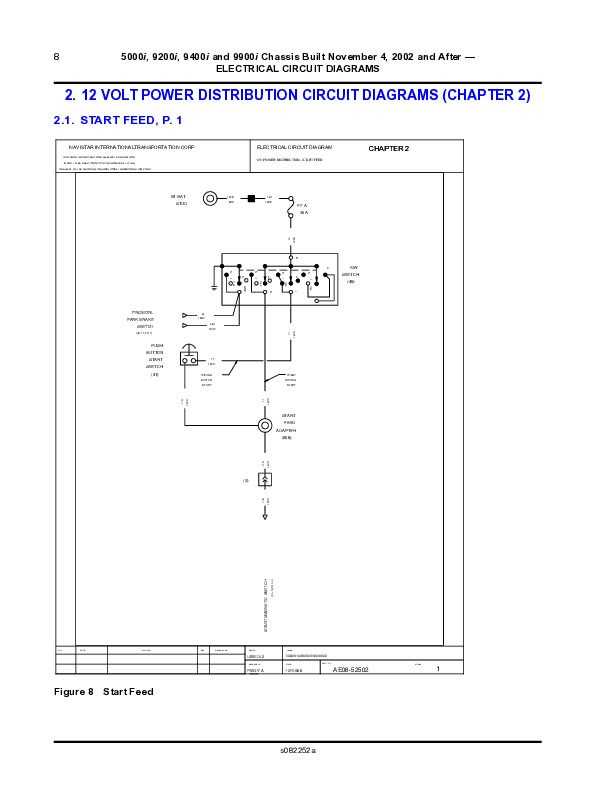

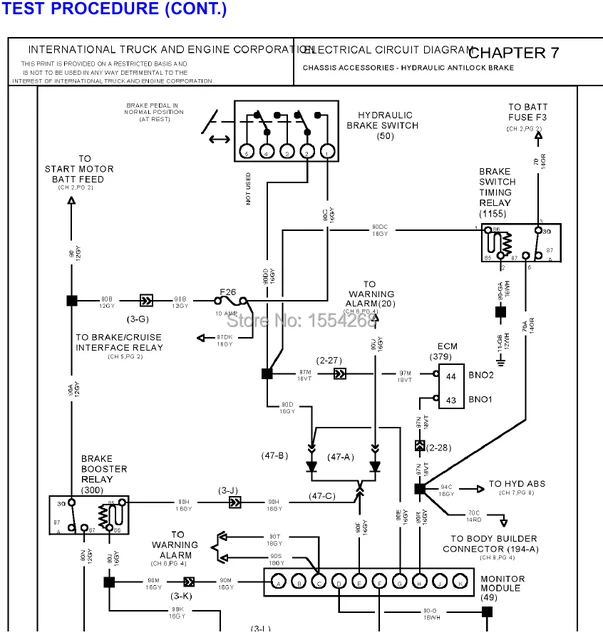

| Wiring Diagrams | Visual representations of electrical systems for easier navigation. |

By utilizing these structured elements, users can navigate complex tasks with greater ease and confidence, ensuring that their vehicles remain in peak condition.

Importance of International Standards

Establishing uniform guidelines plays a crucial role in enhancing efficiency and safety across various industries. These benchmarks ensure consistency, enabling professionals to operate with a shared understanding, regardless of geographic boundaries. By adhering to these principles, organizations can improve their practices and outcomes, fostering a collaborative environment.

Such frameworks also facilitate trade and commerce, simplifying transactions and reducing barriers between entities. When businesses follow agreed-upon protocols, they can better communicate and understand each other’s products and services, leading to smoother operations and increased trust.

Furthermore, these standards contribute to quality assurance, helping to minimize errors and inconsistencies in processes. Organizations that implement these guidelines can enhance their reputation and reliability, ultimately benefiting their customers and stakeholders.

In a rapidly evolving world, embracing universally accepted practices is vital for innovation and progress. It encourages the development of new technologies and methodologies that align with the needs of diverse markets, promoting sustainable growth and competitiveness.

Key Components of Repair Manuals

A comprehensive guide serves as an essential resource for maintenance and troubleshooting. It typically encompasses vital information that aids technicians in understanding complex machinery, ensuring effective performance and longevity.

Essential Elements

- Detailed Specifications: Provides technical data, including dimensions, capacities, and performance parameters.

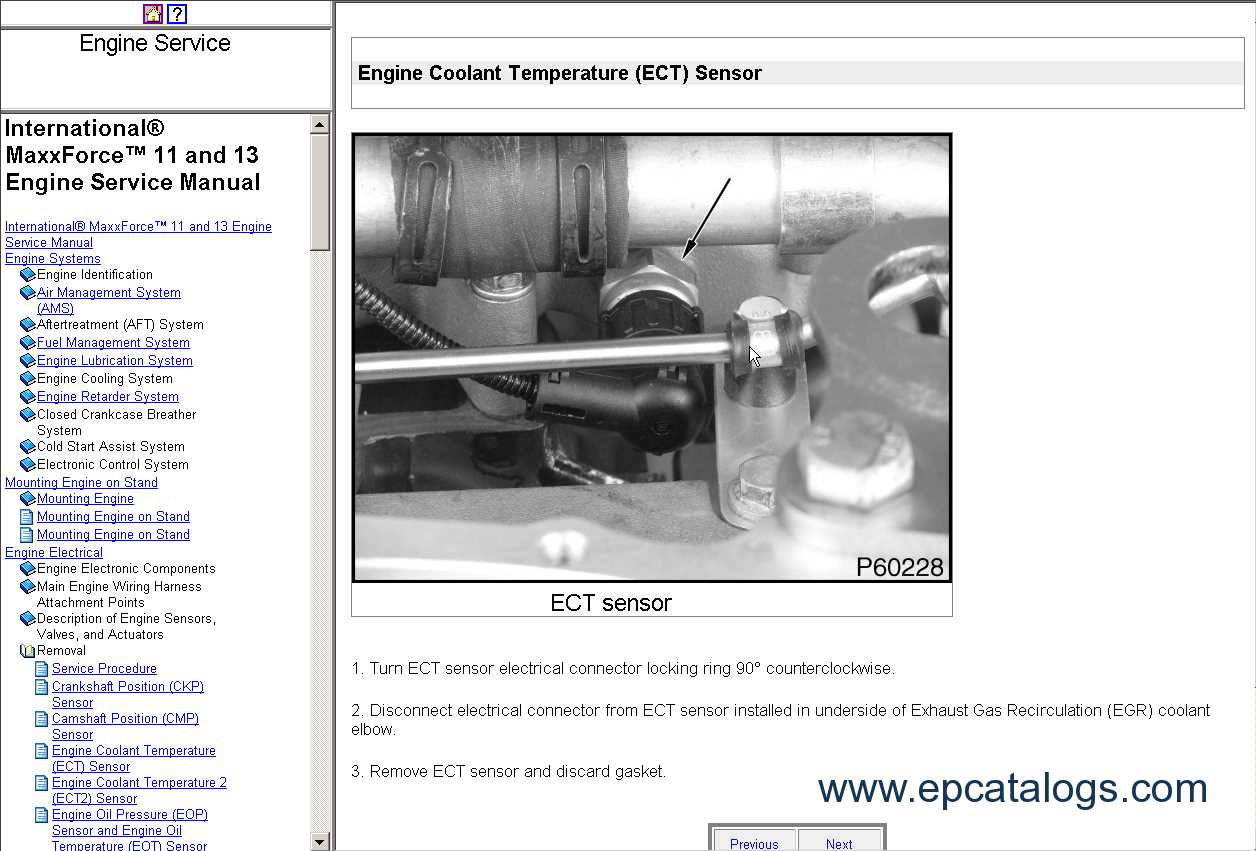

- Diagrams and Illustrations: Visual aids that clarify assembly, disassembly, and component locations.

- Step-by-Step Procedures: Instructions outlining systematic approaches to various tasks.

- Diagnostic Tips: Guidance on identifying and resolving common issues that may arise during operation.

- Safety Precautions: Important information regarding handling and operational safety to prevent accidents.

Supportive Information

- Maintenance Schedules: Timelines indicating when specific services should be performed.

- Parts Lists: Inventory of components with part numbers for easy identification and ordering.

- Wiring Diagrams: Electrical schematics that illustrate circuitry and connections for troubleshooting electrical issues.

- Common Troubleshooting Scenarios: Examples of frequent problems along with suggested solutions.

Benefits of Using Digital Formats

The transition to electronic documentation offers numerous advantages that enhance accessibility and efficiency. By utilizing digital resources, users can experience a streamlined approach to obtaining information, leading to improved workflows and productivity.

| Advantage | Description |

|---|---|

| Accessibility | Digital formats allow users to access information from anywhere at any time, eliminating the need for physical copies. |

| Searchability | Users can quickly find specific topics or details using search functions, saving time and effort. |

| Updatability | Electronic documents can be easily updated, ensuring that users always have the most current information at their fingertips. |

| Cost-effectiveness | Reducing the need for paper and printing contributes to lower operational costs and supports environmental sustainability. |

| Storage Efficiency | Digital files require significantly less physical space, making storage and organization much simpler. |

How to Choose the Right Manual

Selecting the appropriate guide for maintenance and servicing is crucial for effective vehicle upkeep. With a variety of resources available, understanding your specific needs and requirements will help streamline the selection process. This ensures you receive the most accurate and relevant information for your machinery.

Assess Your Vehicle’s Specifications

Before diving into the available resources, it’s essential to understand the unique features and specifications of your vehicle. Consider aspects such as the make, model, and year of manufacture. A thorough grasp of these details will enable you to filter out irrelevant materials and focus on those that cater specifically to your vehicle’s needs.

Evaluate the Source and Content Quality

Not all resources are created equal. Look for guides that are well-reviewed and recommended by professionals in the industry. Check for updates and revisions to ensure the information is current and applicable. Additionally, consider the comprehensiveness of the content, including troubleshooting tips, diagrams, and step-by-step instructions, to enhance your understanding and execution of maintenance tasks.

Common Repair Procedures Explained

This section delves into frequently encountered maintenance tasks that are essential for keeping vehicles in optimal condition. Understanding these processes can enhance efficiency and prolong the lifespan of the machinery. Below, we outline some of the most prevalent actions performed by technicians.

Routine Maintenance Tasks

Regular upkeep is crucial for ensuring reliability and performance. Here are some common activities:

- Oil Change: Essential for lubricating engine components and preventing wear.

- Filter Replacement: Keeping air and fuel filters clean is vital for optimal function.

- Tire Inspection: Regularly checking tire pressure and tread depth prevents accidents and improves fuel efficiency.

Advanced Diagnostics and Repairs

When issues arise, advanced troubleshooting methods are employed to diagnose and resolve problems effectively. Key procedures include:

- Electrical System Testing: Ensuring all electronic components are functioning properly.

- Engine Performance Analysis: Utilizing specialized tools to assess and enhance engine efficiency.

- Transmission Service: Addressing issues related to gear shifting and fluid quality.

Mastering these essential tasks can greatly benefit vehicle owners and technicians alike, contributing to smoother operations and reduced downtime.

Maintenance Tips for Truck Owners

Proper care and upkeep are essential for ensuring the longevity and reliability of your heavy vehicle. Regular attention to various components can prevent breakdowns and costly repairs, allowing for smoother operations and enhanced safety on the road.

Start with routine inspections to identify any wear and tear. Check fluid levels, including oil, coolant, and transmission fluid, as maintaining the right levels is crucial for optimal performance. Regularly replacing filters can also enhance engine efficiency and prolong its lifespan.

Tire maintenance is vital; ensure that they are properly inflated and rotated as needed. This not only improves fuel efficiency but also enhances handling and safety. Keep an eye on tread wear and replace tires that show significant signs of aging or damage.

Don’t overlook the importance of brake system checks. Regularly inspect brake pads, rotors, and fluid levels. Addressing any issues promptly can prevent more severe problems down the line and ensure safe stopping power.

Lastly, keeping the vehicle clean, both inside and out, can help prevent rust and corrosion. Regular washing, especially after exposure to salt or grime, is a good practice. Additionally, detailing the interior can maintain a comfortable driving environment.

Accessing Online Resources and Communities

In today’s digital age, a wealth of information is readily available for those seeking guidance in the field of heavy vehicle maintenance. Online platforms provide valuable resources and connect enthusiasts, professionals, and learners, fostering a vibrant community for sharing knowledge and troubleshooting techniques. These platforms often host a variety of content, including guides, forums, and video tutorials, making it easier to access the help needed for effective vehicle care.

Finding Valuable Information

When searching for specific knowledge, consider exploring the following types of online resources:

- Dedicated Websites: Many sites focus on various aspects of vehicle maintenance, offering detailed articles and user-friendly navigation.

- Forums and Discussion Boards: Engage with fellow enthusiasts and professionals to ask questions, share experiences, and learn from real-world scenarios.

- YouTube Channels: Visual learners can benefit from video demonstrations that walk through repair processes step by step.

Joining Online Communities

Becoming part of a community can significantly enhance your knowledge and skills. Consider these options:

- Social Media Groups: Platforms like Facebook and Reddit host groups dedicated to various vehicle topics, where members actively discuss tips and solutions.

- Local and Global Networks: Many organizations offer online membership, connecting you with local meet-ups or global forums for broader insights.

- Webinars and Virtual Workshops: Participate in online learning events that provide expert knowledge and interactive Q&A sessions.

By utilizing these online resources and engaging with communities, individuals can enhance their understanding and efficiency in vehicle upkeep, benefiting from the collective expertise available in the digital realm.

Comparing OEM vs. Aftermarket Manuals

When it comes to choosing documentation for maintenance and service, two main categories often emerge: original equipment manufacturer (OEM) materials and aftermarket options. Each type has its own merits and potential drawbacks, making it essential for users to understand their differences before making a decision.

Advantages of OEM Materials

- Accuracy: OEM documents are typically crafted by the manufacturers themselves, ensuring precise specifications and details.

- Comprehensive Coverage: These resources often cover every aspect of the equipment, from routine tasks to complex diagnostics.

- Manufacturer Support: Access to support and updates directly from the manufacturer can be invaluable for troubleshooting.

Benefits of Aftermarket Options

- Cost-Effectiveness: Aftermarket publications are usually more affordable than their OEM counterparts.

- Variety: Users can find a wide range of resources tailored to different needs and preferences.

- Practical Insights: Some aftermarket materials include tips and tricks from experienced technicians, enhancing practical knowledge.

In conclusion, the choice between OEM and aftermarket resources depends largely on individual requirements, budget constraints, and the level of detail needed for effective maintenance and servicing.

Interpreting Technical Diagrams and Codes

Understanding complex visual representations and symbolic notations is crucial for effective problem-solving in mechanical contexts. This section aims to provide insights into how to decode these intricate designs and references, facilitating a clearer comprehension of machinery and components.

Technical diagrams often include various elements that require interpretation. Familiarity with these components enhances one’s ability to diagnose issues and implement solutions. Here are key aspects to consider:

- Symbols: Each diagram features unique symbols that represent different parts or functions. Knowing these is essential for accurate analysis.

- Lines and Arrows: Lines often indicate connections, while arrows can denote movement or flow. Understanding their directionality is vital.

- Labels and Codes: Diagrams typically contain numerical or alphanumeric codes that correspond to specific components. Familiarizing oneself with these references streamlines the identification process.

To enhance proficiency in interpreting these resources, consider the following strategies:

- Study Reference Guides: Utilize supplementary materials that explain common symbols and notations.

- Practice with Examples: Engage with various diagrams to improve familiarity and speed in interpretation.

- Collaborate with Peers: Discussing interpretations with others can provide new insights and clarify misunderstandings.

By mastering the art of reading technical illustrations and codes, individuals can significantly improve their efficiency in troubleshooting and maintaining complex machinery.

Tools Needed for Effective Repairs

Having the right equipment is crucial for successfully addressing mechanical issues. A well-equipped workspace allows for efficient diagnostics and ensures that any adjustments can be made swiftly and accurately. Understanding the essential implements can significantly enhance the quality of work performed.

| Tool | Purpose |

|---|---|

| Socket Set | Used for fastening and loosening bolts and nuts. |

| Wrenches | Essential for gripping and turning fasteners. |

| Diagnostic Scanner | Identifies electronic issues and retrieves fault codes. |

| Torque Wrench | Ensures proper tightening of bolts to specified settings. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

| Screwdrivers | Essential for driving screws in various applications. |

| Multimeter | Measures electrical parameters like voltage and current. |

| Jack and Stands | Provides support for lifting vehicles safely. |

Equipping yourself with these essential tools not only streamlines the process but also boosts confidence in handling various tasks effectively.

Frequently Asked Questions on Repairs

This section addresses common inquiries related to maintenance and restoration processes for heavy vehicles. It aims to provide clarity and guidance for individuals seeking to enhance their understanding and efficiency in handling various issues.

What should I do if my vehicle displays warning lights?

Warning lights indicate potential problems. It is essential to consult the specific documentation for your model to understand the meaning of each light and take appropriate action.

How can I identify unusual noises from the engine?

Listening for irregular sounds can help diagnose issues. Refer to the reference guide to pinpoint possible causes and recommended solutions for specific noise patterns.

What maintenance tasks should be performed regularly?

Routine tasks, such as checking fluid levels, inspecting belts, and monitoring tire pressure, are crucial. Follow the suggested schedule outlined in the reference literature to ensure optimal performance.

Where can I find parts for my vehicle?

Parts can be sourced from authorized dealers or reputable aftermarket suppliers. It’s advisable to cross-reference part numbers in the documentation to ensure compatibility.

How do I know if a repair is necessary or if I can postpone it?

Assessing the severity of the issue is key. Consult the troubleshooting section of your reference materials to evaluate symptoms and determine urgency based on the guidelines provided.

Future Trends in Truck Maintenance Manuals

The evolution of maintenance documentation is set to revolutionize how operators engage with their vehicles. As technology advances, the methods by which technicians access, understand, and utilize these essential resources will transform, leading to enhanced efficiency and improved operational safety.

Digital Integration

One significant trend is the shift towards digital formats. This change promises a more interactive and accessible experience for users. Key benefits include:

- Real-time updates that ensure accuracy.

- Searchable databases that allow quick information retrieval.

- Multimedia elements, such as videos and interactive diagrams, enhancing comprehension.

Augmented Reality and Artificial Intelligence

The integration of augmented reality (AR) and artificial intelligence (AI) is poised to further reshape the landscape. These technologies offer numerous advantages:

- AR can overlay information directly onto the machinery, guiding technicians through complex procedures.

- AI can analyze data trends to predict maintenance needs, reducing downtime.

- Smart assistance tools can provide instant answers to queries, streamlining the troubleshooting process.