Comprehensive Guide to Jabsco Marine Toilet Repairs

Ensuring the functionality of your onboard sanitation apparatus is crucial for a pleasant and hygienic experience while at sea. This guide provides essential insights into maintaining and troubleshooting these vital systems, allowing you to address common issues effectively and efficiently. By understanding the components and mechanisms involved, you can extend the lifespan of your equipment and prevent inconvenient malfunctions.

From the intricacies of plumbing connections to the mechanisms that facilitate waste management, knowledge is key. With the right techniques and tools at your disposal, even complex problems can be tackled with confidence. Whether you’re dealing with clogs, leaks, or mechanical failures, our comprehensive approach will empower you to take control of your vessel’s sanitation needs.

Engaging with this guide not only enhances your technical skills but also ensures that your sailing adventures remain enjoyable and hassle-free. By familiarizing yourself with maintenance practices, you will cultivate a safer environment onboard, making each journey more comfortable for everyone involved.

Understanding Jabsco Marine Toilets

Familiarizing yourself with onboard sanitation systems is essential for ensuring comfort and hygiene during voyages. These fixtures, designed for use in aquatic environments, operate differently than their land-based counterparts, requiring a solid grasp of their mechanics and maintenance. This section provides insight into the functionality and care of these vital installations.

Components and Functionality

These systems typically consist of several key elements that work together to facilitate effective waste management. Understanding how each part operates can significantly ease troubleshooting and maintenance tasks. Below is an overview of the main components:

| Component | Description |

|---|---|

| Flush Mechanism | Responsible for moving waste through the system, often utilizing either manual or electric operation. |

| Holding Tank | A reservoir designed to temporarily store waste until it can be properly disposed of. |

| Seals and Gaskets | Prevent leaks and ensure airtight operation, crucial for odor control. |

| Pumps | Assist in the movement of waste and water, with various designs suited for different setups. |

Maintenance Tips

Regular upkeep is crucial for the longevity of these systems. Common practices include checking for wear on seals, ensuring the flush mechanism operates smoothly, and cleaning components to prevent build-up. By adhering to these guidelines, users can maintain optimal performance and extend the lifespan of their fixtures.

Common Issues with Marine Toilets

Maintaining a functional sanitation system aboard can be challenging due to various complications that may arise. Understanding these frequent problems is essential for effective troubleshooting and ensuring comfort on the water.

Clogs and Blockages

One of the most prevalent issues involves clogs, often caused by the accumulation of debris or inappropriate materials. Regular maintenance and proper usage can significantly reduce the likelihood of such blockages. It is advisable to avoid flushing non-biodegradable items to keep the system clear.

Seals and Leaks

Another common concern is the deterioration of seals, which can lead to leaks. Over time, gaskets and O-rings may wear out, compromising their effectiveness. Routine inspections and timely replacements of these components can help prevent unpleasant odors and water damage.

Identifying and addressing these issues promptly can enhance the overall functionality and longevity of your sanitation system, ensuring a more enjoyable experience while navigating the waters.

Tools Needed for Repair

Proper maintenance requires a selection of essential instruments to ensure effective and efficient servicing of your equipment. Having the right tools at hand not only simplifies the process but also enhances the quality of the work performed.

| Tool | Purpose |

|---|---|

| Adjustable Wrench | For loosening and tightening various fittings and connections. |

| Screwdriver Set | For removing and securing screws in different sizes. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components. |

| Utility Knife | For cutting seals, gaskets, and other materials with precision. |

| Multimeter | To check electrical connections and troubleshoot issues. |

| Sealant | To ensure watertight seals and prevent leaks. |

| Bucket | For catching any spills or excess fluids during the process. |

Equipping yourself with these fundamental instruments will facilitate a smoother workflow and help achieve optimal results in your servicing tasks.

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to diagnosing and resolving common issues associated with sanitation systems. By following these steps, you can effectively identify the root causes of malfunction and implement the necessary solutions.

Identifying Common Issues

Begin by observing the system for any noticeable problems. Here are some frequent concerns:

- No water flow

- Unpleasant odors

- Strange noises during operation

- Blockages

Step-by-Step Diagnosis

Follow these steps to troubleshoot the identified issues:

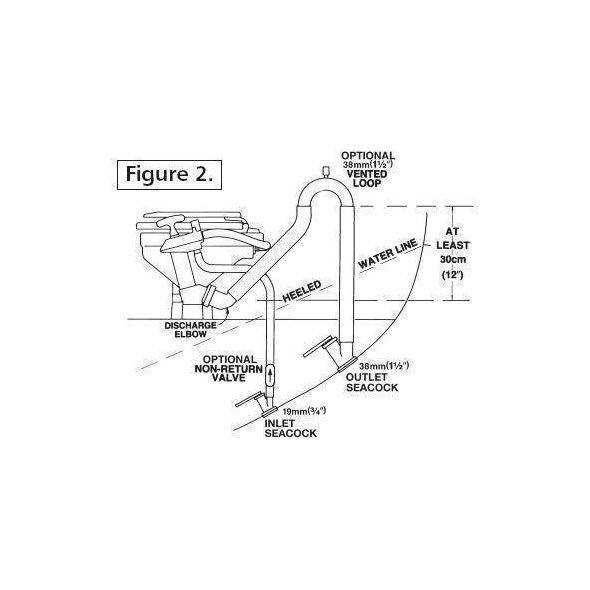

- Check Water Supply: Ensure that the water source is turned on and functioning properly.

- Inspect Hoses: Look for kinks or blockages in the hoses that could impede flow.

- Examine Seals: Check all seals and connections for signs of wear or leaks.

- Clear Blockages: Use appropriate tools to remove any debris obstructing the system.

- Test Components: Verify the functionality of all mechanical parts, including pumps and switches.

By methodically following these steps, you can efficiently address and rectify the common issues that may arise in your sanitation system.

Replacing Seals and Gaskets

Maintaining proper functionality of various components is essential for optimal performance. One key aspect of this maintenance involves the timely replacement of certain elements that can degrade over time. Ensuring a watertight seal and preventing leaks are crucial to preserving the integrity of the system.

Identifying Worn Components

Before proceeding with the replacement process, it’s important to inspect the current seals and gaskets for signs of wear or damage. Look for cracks, tears, or any signs of degradation that could lead to malfunction. Regular checks can help in identifying these issues early, preventing more extensive damage down the line.

Replacement Procedure

To begin the replacement, first, gather the necessary tools and new seals or gaskets. Carefully remove the old components, ensuring not to damage surrounding areas. Clean the surfaces thoroughly to promote a strong bond with the new parts. When installing the new seals, apply an appropriate lubricant if recommended, and ensure they are seated properly. Double-check alignment before reassembling to avoid future complications.

Cleaning the Toilet System

Maintaining cleanliness in the sanitation system is essential for optimal performance and hygiene. Regular upkeep prevents blockages, unpleasant odors, and ensures longevity. This section outlines the necessary steps to effectively clean the entire system, ensuring a smooth operation.

| Step | Description |

|---|---|

| 1 | Disconnect the system from the water source and power supply for safety. |

| 2 | Use a suitable cleaning agent to scrub the interior components, focusing on hard-to-reach areas. |

| 3 | Flush the system multiple times with fresh water to remove any residues. |

| 4 | Inspect and clean all hoses and connections to prevent buildup and ensure proper flow. |

| 5 | Reconnect everything and run the system to verify functionality. |

Replacing the Pump Mechanism

Replacing the pump unit is an essential task to ensure proper functioning of the waste disposal system on your vessel. Over time, wear and tear can lead to inefficiencies or complete failure of the mechanism, making it crucial to address any issues promptly. This guide will outline the steps necessary for a successful replacement, helping you maintain optimal performance.

Gathering the Necessary Tools

Before you begin, ensure you have all the required tools at hand. Typically, you will need a screwdriver, a wrench set, and a replacement pump unit. It is also advisable to have a bucket or towel ready to catch any residual fluids during the process. Preparing your workspace will facilitate a smooth replacement procedure.

Step-by-Step Replacement Process

Start by disconnecting the power supply and any hoses attached to the existing pump. Carefully remove the old unit by unscrewing it from its mounting. Once it’s free, install the new mechanism by reversing the disassembly steps. Secure all connections tightly to prevent leaks. Finally, reconnect the power and test the new pump to ensure everything operates correctly.

Electrical Components Overview

This section provides a detailed examination of the various electrical elements that play a crucial role in ensuring efficient operation. Understanding these components is essential for effective troubleshooting and maintenance, enabling optimal performance of the system.

Key Components

The electrical system consists of several key parts, each serving a specific function. Familiarity with these components allows for better diagnosis of issues and improved upkeep.

| Component | Function |

|---|---|

| Power Supply | Delivers electrical energy to the system. |

| Switches | Control the flow of electricity by opening or closing circuits. |

| Fuses | Protect the circuit by breaking the connection in case of overload. |

| Wiring | Connects different components, allowing electricity to flow between them. |

| Motors | Convert electrical energy into mechanical motion. |

Maintenance Tips

Regular inspection of these elements is vital for preventing failures. Ensuring that connections are secure, and replacing damaged parts promptly can significantly enhance the longevity and reliability of the entire system.

Maintenance Tips for Longevity

Ensuring the durability of your onboard sanitation system requires regular care and attention. By implementing simple maintenance practices, you can enhance performance, prevent issues, and extend the life of the equipment. Here are some essential tips to keep in mind.

Regular Cleaning

Maintaining cleanliness is crucial for the optimal functioning of your system. Follow these steps:

- Use appropriate cleaning agents to avoid damage.

- Rinse with fresh water after each use to minimize buildup.

- Inspect and clean all accessible parts periodically.

Routine Inspections

Conducting frequent checks can help identify potential problems before they escalate. Consider the following:

- Examine hoses for cracks or leaks.

- Check seals and fittings for wear and tear.

- Monitor performance for any unusual noises or functions.

By following these maintenance tips, you can ensure a reliable and efficient sanitation system for your vessel.

Identifying Leaks in the System

Detecting leaks within the plumbing framework is essential for maintaining functionality and preventing damage. Such issues can manifest in various ways, requiring careful observation and systematic troubleshooting to identify their sources accurately.

To start, visual inspections are crucial. Look for signs of moisture around joints, fittings, and hoses. Discoloration or water stains can indicate persistent leaks. Listen for unusual sounds, such as dripping or gurgling, which may signal an underlying problem.

Additionally, monitoring the system’s performance can help pinpoint irregularities. A decrease in efficiency or unexpected changes in pressure often suggests a leak. If water levels fluctuate without any apparent cause, this may warrant a closer examination of the entire setup.

Lastly, conducting a pressure test can be beneficial. By isolating sections of the system and checking for pressure drops, you can locate the exact area that requires attention. This method is especially useful for identifying leaks that are not immediately visible.

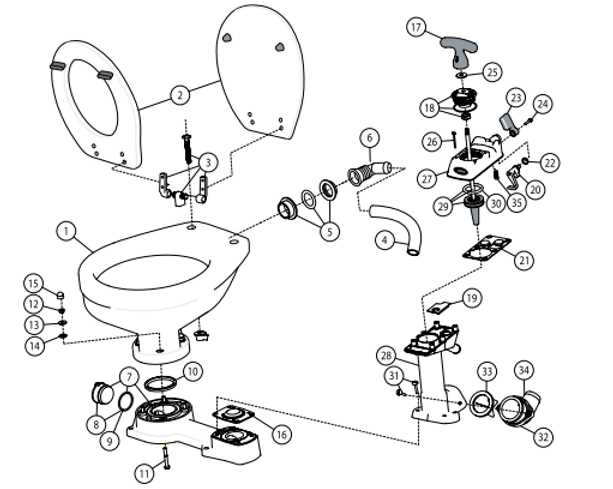

How to Disassemble the Toilet

Understanding the process of taking apart your sanitation fixture can greatly enhance your ability to troubleshoot and maintain it effectively. This guide will outline the necessary steps to carefully disassemble the unit, ensuring that each component is handled properly to prevent damage.

Preparation Steps

Before starting the disassembly, gather the required tools such as a screwdriver, pliers, and a container for small parts. Make sure the area is well-lit and free from clutter. It’s also advisable to familiarize yourself with the layout of the device to make the process smoother.

Disassembly Process

Follow these steps to successfully take apart the unit:

| Step | Action |

|---|---|

| 1 | Turn off the water supply and disconnect any hoses. |

| 2 | Remove the lid by unscrewing the securing bolts. |

| 3 | Take out the internal components, being mindful of any seals or gaskets. |

| 4 | Inspect each part for wear and replace as necessary. |

| 5 | Carefully reassemble the unit by reversing the steps. |

By following these steps, you can efficiently take apart your fixture for maintenance or inspection, ensuring optimal performance and longevity.

When to Call a Professional

Understanding the limits of your own skills is crucial when dealing with intricate systems on your vessel. While many issues can be resolved with a bit of research and effort, there are specific circumstances where seeking expert assistance is not only wise but necessary.

Here are some scenarios when you should consider bringing in a specialist:

- Persistent Issues: If problems continue despite your best efforts to fix them, it may indicate a deeper underlying issue.

- Complex Repairs: Tasks that involve extensive knowledge of plumbing or electrical systems often require professional insight.

- Safety Concerns: If there’s a risk of leaks or hazardous situations, it’s best to let an expert handle the job.

- Time Constraints: When you’re short on time or preparing for an upcoming trip, professional help can save valuable hours.

- Warranty Issues: Some repairs may void warranties if not performed by licensed technicians, making it crucial to follow guidelines.

Recognizing when to call in a professional can save you time, money, and frustration in the long run. Always prioritize safety and functionality over attempting a fix that may be beyond your expertise.

Upgrading Your Marine Toilet

Enhancing the efficiency and functionality of your sanitation system can greatly improve your on-board experience. Whether you’re looking for increased reliability, better performance, or more environmentally friendly options, upgrading can provide a range of benefits. This guide outlines key considerations and steps to elevate your current setup.

Benefits of Upgrading

Investing in an advanced system can lead to improved comfort, easier maintenance, and enhanced performance. Newer models often feature innovative designs that minimize odors and reduce water usage, making them more sustainable. Additionally, upgrades can enhance durability, ensuring a longer lifespan for your equipment.

Key Considerations

When selecting a new unit, consider factors such as size, installation ease, and compatibility with existing plumbing. Researching customer reviews and comparing features can help you make an informed decision. It’s also vital to assess the power requirements and waste disposal methods to ensure they align with your preferences.

| Feature | Old Model | Upgraded Model |

|---|---|---|

| Water Consumption | 1.5 Gallons per Flush | 0.5 Gallons per Flush |

| Odor Control | Basic Seal | Advanced Vacuum System |

| Durability | Standard Materials | Corrosion-Resistant Components |

| Ease of Maintenance | Manual Cleaning Required | Self-Cleaning Features |

Upgrading your system not only enhances functionality but also contributes to a more pleasant and efficient experience on the water. Careful consideration and informed choices will ensure your investment pays off in the long run.