Essential Guide to Jet Ski Repairs

Owning a personal watercraft can be an exhilarating experience, providing countless hours of enjoyment on the water. However, to ensure optimal performance and longevity, understanding the various aspects of upkeep is essential. This section delves into key practices and considerations for maintaining these high-speed machines, ensuring they remain in peak condition.

Regular attention to specific components not only enhances performance but also contributes to safety. Familiarizing oneself with the operational mechanics and routine maintenance tasks can prevent minor issues from escalating into significant problems. Adopting a proactive approach to care will help owners fully enjoy their aquatic adventures.

In the following segments, we will explore common troubleshooting techniques, essential tools, and best practices for effective maintenance. Whether you are a novice or an experienced enthusiast, this information will be invaluable in keeping your craft running smoothly and efficiently.

Ensuring that your watercraft operates at its best involves regular upkeep and careful attention to detail. By following a few essential practices, you can enhance the longevity and efficiency of your vessel. This section provides crucial insights to help maintain peak functionality.

Regular Inspection

Frequent evaluations can prevent minor issues from escalating into significant problems. Pay attention to the following components:

- Hull for signs of damage or wear

- Engine components for leaks or irregularities

- Fuel system for cleanliness and efficiency

Proper Cleaning

Cleaning your craft after each use is vital for preserving its appearance and performance. Follow these cleaning tips:

- Rinse off saltwater and debris to prevent corrosion.

- Use a soft cloth to wipe down surfaces, avoiding scratches.

- Inspect and clean the air intake and exhaust areas.

Tools Required for Jet Ski Repairs

Having the right equipment is essential for maintaining and fixing watercraft. Proper tools not only facilitate the process but also ensure that each task is completed efficiently and safely. Below is a list of necessary implements that every enthusiast should have on hand.

- Wrenches: Various sizes to fit different bolts and nuts.

- Screwdrivers: Both flathead and Phillips for different screw types.

- Pliers: Needle-nose and standard for gripping and twisting.

- Socket Set: A complete set for quick and easy access to various sizes.

- Torque Wrench: For ensuring proper tightness on critical components.

- Multimeter: To test electrical systems and diagnose issues.

- Oil Change Kit: Necessary for maintaining engine performance.

- Cleaning Supplies: Brushes and cloths for maintaining cleanliness.

- Safety Gear: Gloves and goggles to protect against injury.

These items are fundamental for anyone looking to undertake maintenance tasks. Investing in high-quality tools can significantly enhance the overall experience and effectiveness of the work being performed.

Step-by-Step Engine Troubleshooting

This section provides a comprehensive approach to diagnosing issues related to the propulsion system of your watercraft. Following a systematic procedure can help identify problems effectively and restore optimal performance.

Begin the troubleshooting process by examining key components that may affect engine functionality. Use the table below to guide your assessment:

| Component | Symptoms of Failure | Potential Solutions |

|---|---|---|

| Fuel System | Engine sputters, loss of power | Check for clogged filters, replace fuel lines |

| Ignition System | Engine won’t start, misfires | Inspect spark plugs, check ignition coil |

| Cooling System | Overheating, strange noises | Clean water intake, check for blockages |

| Exhaust System | Excessive smoke, unusual odors | Inspect for leaks, clean muffler |

By following this structured approach, you can systematically diagnose and address issues, ensuring your vessel operates smoothly and efficiently.

How to Change Jet Ski Oil

Regular maintenance of your watercraft is essential for optimal performance and longevity. One of the crucial aspects of upkeep is the replacement of the lubrication fluid. This process ensures that the engine operates smoothly, reducing wear and tear and enhancing overall efficiency.

Necessary Tools and Materials

- New lubrication fluid

- Oil filter

- Oil pump or siphon

- Wrench set

- Drain pan

- Rags or paper towels

- Funnel

Steps to Follow

- Prepare the workspace by gathering all necessary tools and materials.

- Ensure the vessel is on a stable surface and the engine is cool.

- Locate the drainage plug beneath the engine and place the drain pan underneath it.

- Unscrew the drainage plug to allow the used fluid to drain completely.

- Once drained, replace the drainage plug securely.

- Remove the old filter using the wrench and install the new one.

- Using the oil pump or siphon, pour the new lubrication fluid into the designated fill opening, using a funnel to prevent spills.

- Check the oil level with the dipstick and add more fluid if necessary.

- Start the engine for a few minutes to circulate the new fluid, then check for leaks around the filter and drain plug.

- Dispose of the old lubrication fluid and filter according to local regulations.

Inspecting and Replacing Spark Plugs

Ensuring optimal performance of your watercraft involves regular checks and maintenance of its internal components. Among these, the condition of ignition elements plays a crucial role in engine efficiency and reliability. This section will guide you through the process of examining and substituting these essential parts, ensuring your vessel operates smoothly.

Inspection Process

Before replacing any components, it’s important to conduct a thorough inspection. Follow these steps:

- Remove the ignition cover carefully to access the spark plugs.

- Examine the plugs for any signs of wear, such as cracks or heavy carbon buildup.

- Check the electrode gap using a feeler gauge; it should meet the manufacturer’s specifications.

- Look for corrosion or damage on the plug threads and ceramic insulator.

Replacement Steps

If the inspection indicates that replacement is necessary, adhere to the following guidelines:

- Gather the required tools: a socket wrench, torque wrench, and new spark plugs.

- Remove the old plugs using the socket wrench, turning counterclockwise.

- Clean the threads in the engine to remove debris or old sealant.

- Install the new plugs by hand to avoid cross-threading, then tighten with the wrench.

- Ensure each plug is torqued to the specifications indicated in the manufacturer’s documentation.

Following these steps will help maintain the performance and longevity of your watercraft, allowing for enjoyable and trouble-free outings on the water.

Cleaning the Fuel System Effectively

Maintaining a clean fuel system is essential for optimal performance and longevity of your watercraft. Regular cleaning prevents the buildup of contaminants that can disrupt the fuel flow and affect engine efficiency. Here, we outline a step-by-step approach to effectively clean the fuel system.

Step-by-Step Guide

- Gather Necessary Tools and Materials:

- Fuel system cleaner

- Wrench set

- Fuel filter replacement

- Container for old fuel

- Safety goggles and gloves

- Safety Precautions:

- Ensure the watercraft is in a well-ventilated area.

- Wear protective gear to avoid contact with fuel and cleaning agents.

- Drain Old Fuel:

Begin by draining the old fuel from the tank into a suitable container. This helps eliminate impurities that may have settled over time.

- Clean Fuel Lines:

Disconnect the fuel lines and use the cleaner to flush out any deposits. Inspect the lines for wear or damage and replace them if necessary.

- Replace the Fuel Filter:

Remove the old fuel filter and install a new one. This step ensures that any remaining contaminants are filtered out before the fuel reaches the engine.

- Reassemble and Test:

Reconnect all components and fill the tank with fresh fuel. Start the engine to ensure everything is functioning correctly.

Regular maintenance of the fuel system not only enhances performance but also extends the lifespan of your watercraft. Following these steps will ensure a clean and efficient fuel delivery system.

Handling Electrical Problems in Jet Skis

Addressing electrical issues in watercraft requires a systematic approach to diagnose and resolve problems effectively. Understanding common symptoms and their causes is essential for restoring functionality and ensuring safe operation on the water.

Begin by inspecting the battery and connections, as they are often the source of power-related difficulties. Ensure that terminals are clean and tightly secured. A multimeter can be employed to check voltage levels, helping to identify whether the battery is holding a charge or if it needs replacement.

| Common Electrical Issues | Possible Causes | Recommended Solutions |

|---|---|---|

| No power | Dead battery or faulty connections | Check battery charge and clean terminals |

| Intermittent electrical failure | Worn wiring or loose connections | Inspect and repair wiring harnesses |

| Malfunctioning gauges | Defective sensors or poor wiring | Test sensors and replace if necessary |

By following these steps and utilizing appropriate diagnostic tools, operators can effectively troubleshoot and resolve electrical issues, ensuring optimal performance of their watercraft.

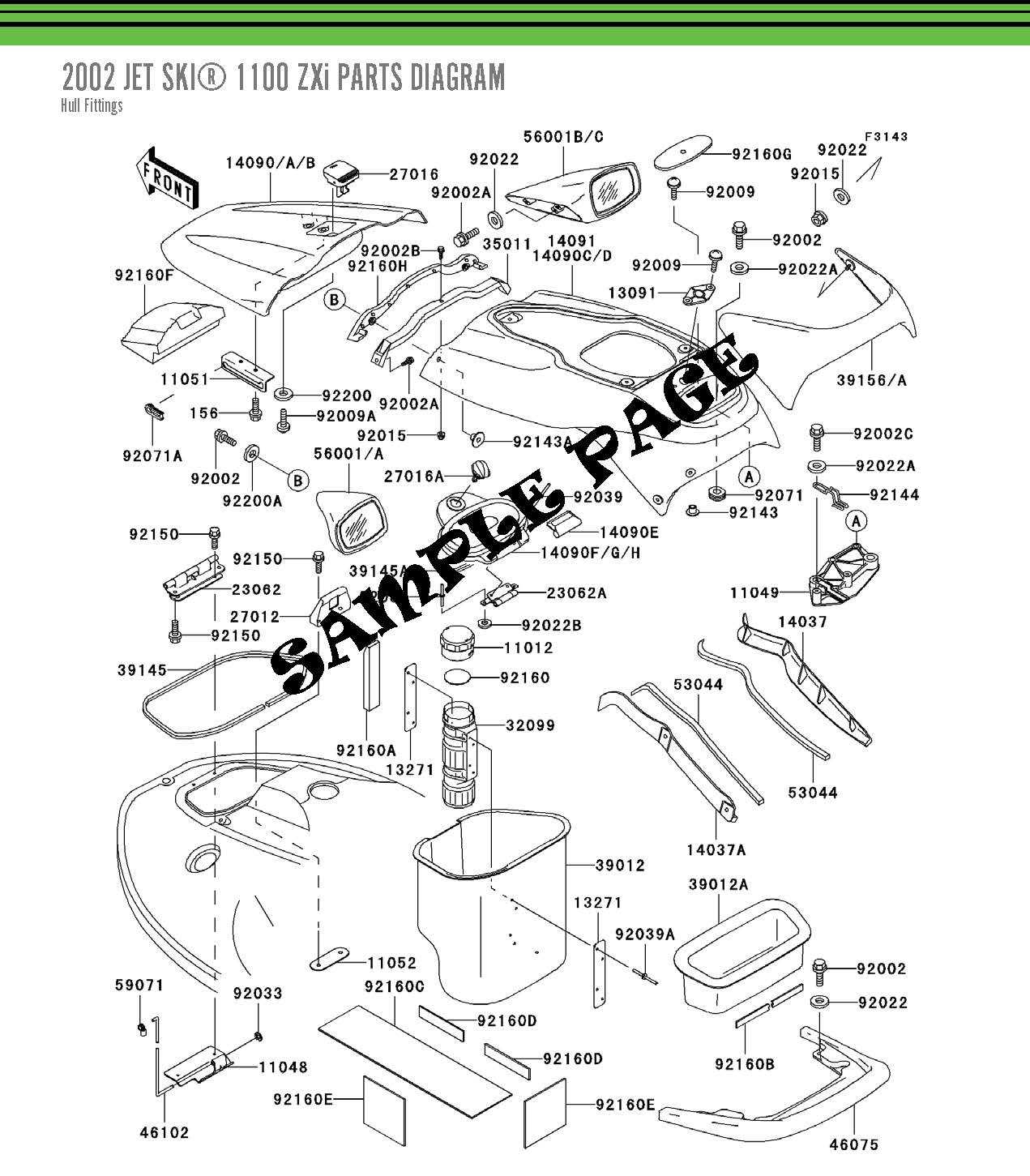

Replacing Impellers and Wear Rings

Maintaining the efficiency of your watercraft is essential for optimal performance. One crucial aspect of this upkeep involves the periodic replacement of specific components that experience significant wear over time. This section will guide you through the process of replacing essential parts that ensure smooth operation and enhance your vessel’s longevity.

Tools and Materials Needed

- Replacement impeller

- New wear rings

- Socket set

- Screwdriver

- Torque wrench

- Grease

Replacement Procedure

- Begin by removing the protective cover to access the internal components.

- Carefully detach the old impeller by unscrewing any bolts that secure it in place.

- Remove the wear rings, taking care to clean the surrounding area to prevent debris contamination.

- Install the new wear rings and ensure they are seated properly.

- Attach the new impeller, ensuring that all bolts are tightened to the manufacturer’s specified torque settings.

- Replace the cover and test the operation to ensure everything is functioning correctly.

Winterization Procedures for Jet Skis

Preparing personal watercraft for the cold season is essential to ensure optimal performance when the warmer months return. Properly safeguarding these vehicles during winter helps prevent damage caused by freezing temperatures and inactivity. This section outlines effective strategies to winterize your watercraft and maintain its longevity.

Draining and Flushing the System

Begin by draining all water from the cooling system. This step is critical to avoid freezing and potential damage to the engine. Flush the system with fresh water to eliminate any debris or salt deposits that could lead to corrosion. Afterward, ensure that the system is thoroughly drained, and consider running antifreeze through the system to provide added protection against freezing.

Storage and Maintenance Tips

When storing your vehicle, choose a dry, temperature-controlled environment if possible. Elevate the unit to keep it off the ground and prevent moisture accumulation. Regularly inspect and clean components to prevent buildup that could lead to deterioration. Additionally, covering the craft with a breathable cover can shield it from dust and debris while allowing moisture to escape.

Best Practices for Storing Jet Skis

Proper storage of watercraft is essential to ensure longevity and optimal performance. Implementing effective methods can protect your investment from environmental damage, deterioration, and potential mechanical issues. This section outlines key strategies for maintaining your vessel during off-season months or extended periods of inactivity.

Choosing the Right Location

Selecting an appropriate storage location is crucial. Ideally, it should be dry, well-ventilated, and protected from harsh weather conditions. Avoid areas prone to flooding or extreme temperature fluctuations. Here are some recommended locations:

| Location Type | Advantages | Disadvantages |

|---|---|---|

| Indoor Garage | Temperature control, protection from elements | Space constraints |

| Storage Facility | Security, specialized services | Cost |

| Outdoor Cover | Accessibility, low cost | Exposure to weather, less protection |

Preparation Before Storage

Before placing your watercraft in storage, thorough preparation is necessary. This includes cleaning the exterior, draining fuel and water, and conducting essential maintenance checks. Such actions will help prevent damage and ensure readiness for the next use. Here are key steps to follow:

| Preparation Step | Description |

|---|---|

| Clean Thoroughly | Remove dirt, debris, and salt to prevent corrosion |

| Drain Fluids | Empty fuel and water systems to avoid contamination |

| Check Battery | Remove or maintain battery to extend lifespan |

Finding Replacement Parts and Accessories

Locating suitable components and add-ons is crucial for maintaining optimal performance and extending the lifespan of your watercraft. Whether you’re upgrading or fixing issues, understanding where to source quality items can make a significant difference.

Here are several effective methods to find the parts you need:

- Authorized Dealers: These retailers offer genuine products and expert advice, ensuring compatibility and reliability.

- Online Marketplaces: Websites like eBay or Amazon provide a wide range of options, often at competitive prices. Check reviews and ratings before purchasing.

- Specialty Shops: Local stores focusing on marine supplies often stock specific components and accessories suited for various models.

- Forums and Community Groups: Engaging with enthusiasts online can lead to recommendations for parts and sources. Members often share their experiences and can point you toward reputable sellers.

- Manufacturer’s Website: Directly visiting the manufacturer’s site can yield a list of approved vendors and available items.

By exploring these avenues, you can ensure that you acquire the right components to keep your craft in top condition.

Understanding Warranty and Service Policies

The significance of understanding warranty and service policies cannot be overstated. These guidelines serve as a crucial framework for users, ensuring that they are aware of their rights and obligations regarding maintenance and support. Proper knowledge of these terms can greatly enhance the ownership experience and provide peace of mind.

Typically, warranty agreements cover specific defects in materials and workmanship for a defined period. It’s essential for owners to familiarize themselves with what is included in the warranty, as well as any exclusions that may apply. Additionally, knowing the procedures for claiming service under warranty can streamline the process should any issues arise.

Furthermore, service policies often dictate the frequency of recommended maintenance and inspections. Adhering to these guidelines not only prolongs the lifespan of the equipment but also ensures optimal performance. Users should take the time to understand these recommendations and consider them an integral part of responsible ownership.

Ultimately, being well-informed about warranty and service policies empowers users to make better decisions regarding their investments. It promotes proactive maintenance and helps avoid potential pitfalls associated with neglecting these important aspects.